1398

Linoleum coverings are one of the popular floor coverings, although they have a warm structure, they do not always provide a comfortable temperature on the surface. In such situations, the use of insulation underneath is considered, while others say it is unnecessary. So is insulation needed for linoleum, and what material can be used for this?

The thin structure of the flooring material does not always provide comfortable conditions.

Types of linoleum

Linoleum can have a base or be baseless. Baseless linoleum is very thin and requires special preparation before installation, since it quickly tears and wears out on an uneven surface. This coating will last up to five years, but it must be borne in mind that it has absolutely no sound or heat insulation properties.

If there is a basis, the following are distinguished:

- Foam base . It has a small thickness of about 1.5–3 mm. The foam backing retains heat to some extent and absorbs sound. It is very soft and elastic, easy to stick to corners. The base can be supplemented with fiberglass, which will protect the coating from deformation and dents. The top decorative layer is covered with a protective film, which will extend the service life of the linoleum.

- Warm base . It consists of natural or artificial jute or felt, protected by a polymer layer. A soft and elastic coating up to 5 mm thick is perfect for bedrooms and will retain enough heat. The disadvantages include the insufficient strength of the top layer. It requires special care and is not suitable for rooms with high air humidity.

Linoleum with a base will protect your feet from the cold to some extent, however, if the floor is too cold, it will still need to be insulated.

Plywood insulated floor

High-quality insulation of the base can be achieved by installing an insulated plywood floor along the joists. Logs can be used regular or adjustable. Adjustable joists are convenient to use if there are uneven floors. If the unevenness is small and regular joists are installed, the differences can be leveled by using wedges.

You can lay plywood without joists on a flat concrete surface, however, if the room is located above an unheated one, this option will not save you in the cold in winter.

Installation of plywood floor:

- Logs are installed on the screed at a distance of 300–600 mm from each other.

- If the insulation does not tolerate moisture, waterproofing is installed.

- Then thermal insulation is installed between the joists.

- The plywood is sawn into squares and laid with small gaps between the sheets, both between each other and against the walls.

- The sheets are fixed with self-tapping screws, recessing them into the thickness of the plywood.

- Gaps and screw heads are filled with elastic putty.

Video: installation of plywood floor with penoplex insulation

Advantages:

- Environmentally friendly.

- Low price.

- Strength.

- High degree of thermal insulation.

Flaws:

- Instability to moisture.

- Not installed in rooms with low ceilings.

Preparing flooring for linoleum

Before laying linoleum over a concrete floor, it is extremely important to properly prepare the surface. The durability and quality of the coating service will depend on this stage

You should not lay linoleum on concrete without preparation - this will lead to rapid destruction of the layer. There are several methods of preparation; each master chooses the one that suits him best.

Wet screed

Before laying linoleum on concrete, a number of works are performed to level the floor, eliminate defects, and create a high-quality base for finishing.

Stages of work:

- Dismantling all previously laid coverings to bare concrete, removing debris and dirt, removing dust with a vacuum cleaner.

- Sealing all joints between ceilings and walls, sealing cracks with concrete mixture, filling potholes with foam.

- Surface waterproofing - the easiest way is to lay polyethylene film in strips of the required size with a large overlap, going onto the walls (slightly above the level of the future floor). To compensate for the thermal expansion of the finished screed, compensation/damping tape can be laid along the edges of the room.

- Marking the top level of the screed using a laser level, which will show a clear horizontal line on the wall. It is repeated with a pencil or by stretching the threads. The thickness of the screed is a maximum of 3 centimeters - this is the top level line.

- Installation of beacons on the floor - small sections of perforated profile. The height of the profiles is regulated by plastic wedges, which are tapped towards each other under the profile.

- Preparation of the solution: pour the dry mixture into water, mix thoroughly with a mixer attachment for a drill, and let the mixture settle.

- Pouring mortar in areas between two beacons installed in parallel. They begin pouring the mortar from the far wall, the excess is moved to the empty areas with a metal rule, the edges of which rest on the tops of the beacon profiles. So, in stripes, the surface is filled and becomes smooth.

- Next, wait until the solution hardens, following all care instructions.

Self-leveling mixture

Preparing a concrete floor for linoleum involves eliminating any unevenness and perfectly leveling the surface. Often, after pouring the screed, small defects appear that need to be corrected. If we lay linoleum thick and soft, with a springy backing, this can be avoided.

When you plan to lay thin linoleum without a base, it is imperative to level the floor to perfect condition. For this purpose, you can use ready-made dry mixtures of the water-soluble type.

Their difference from other materials used for rougher leveling is that they are able to independently distribute (spread) over the surface under the influence of gravity and do not require any mechanical processing.

After the mixture is poured, it is advisable to carefully treat the surface with a spiked roller. They do this starting from the far corners, walking towards them in special spiked shoes. After the mixture has hardened, you need to apply two layers of primer to the floor, and then lay the linoleum.

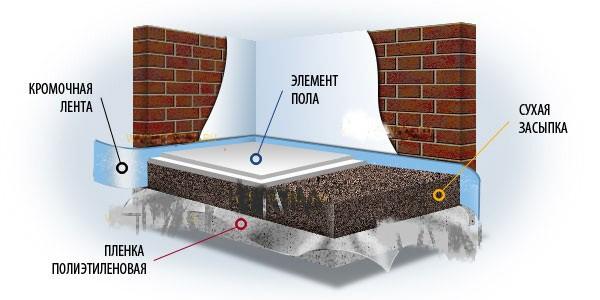

Dry screed

This technology is also used quite often and allows you to quickly and efficiently level the floor before starting to lay linoleum.

How to level a concrete floor:

- Careful dismantling of old flooring.

- Sealing all seams between the slab and the walls using polyurethane foam or cement-sand mortar.

- Cover the surface of the slab with a layer of waterproofing, choosing the most suitable material for this purpose.

- Placing beacons on the floor follows the same principle as in the case of using a wet screed.

- Filling all the spaces between the beacons with dry bulk insulation (expanded clay, for example, is good for this purpose). Carefully leveling the insulation using a metal rule.

- Laying floor slabs on top of beacons - you can use thick dense sheet plywood or gypsum fiber board sheets. The slabs are laid in two rows so that the joints of the slabs of the first row are not located under the joints of the second. You can also use ready-made materials to create the floor - the Superpol system, for example, which is already equipped with locks and guarantees a gapless connection.

Regardless of the chosen method of leveling the surface, all work should be performed very carefully and carefully, avoiding any inaccuracies and unevenness. Then it will be easier to lay linoleum, and the quality of installation of the finishing coating will increase significantly.

Floor insulation with cork

Cork consists of the bark of the cork tree and is considered an environmentally friendly product. Installation is carried out in two ways:

- Floating way. The rolled material is rolled out over the surface, joint to joint. The sheets are connected with construction tape.

- Using glue. When laying cork slabs. Cork flooring can also be used as a finishing surface.

Video: installation of cork backing

Pros:

- Naturalness of the material.

- High sound and heat insulation.

- Wear resistance.

- Resistance to moisture.

- Can also be used for laminate and carpet.

Minuses:

- High price.

Kinds

When building a room from scratch, the choice of flooring is made in advance. In a private house, the floor is usually warm, smooth and reliable, so any linoleum is chosen, and no underlay is needed here. It is also not necessary if they want to lay linoleum on top of an existing one, if the latter is in good condition. But when the floor is subject to repair or the task of sound and heat insulation is set, the underlay will help solve these problems. As a rule, this is required in post-war houses with wooden floors, barrack-type houses, Khrushchev-era buildings and private buildings.

For soundproofing

For sound insulation, you can choose a cork backing. This is perhaps the most versatile option, although expensive. The environmentally friendly backing, pressed from tree bark, gives softness, but when exposed to mechanical loads it deforms, leaving dents. Therefore it should be more dense. You can place it in a room where bulky and heavy furniture is not used. The option with a combined substrate will also reduce the amount of transmitted noise. It consists of wool, flax and jute. It is dense and rigid enough for a coating such as linoleum, and therefore fits very well under it.

The foam version can also be used; it is less environmentally friendly, but much cheaper than the others. It is produced from porous polymers, the basis of which is isolon, or penoizol. In addition, a thicker version of the backing for soft linoleum will not work, it will tear. With frequent walking, its pores stick together and over time, “paths” are formed in those places where linoleum is most often stepped on. To get rid of these troubles, a thin layer of plywood or fiberboard is nailed or screwed on top of the substrate.

For insulation

In addition to sound insulation, floor insulation is often required. It should be noted that the wooden floor itself is warm. But there are objects located above the arch of the building, on the ground floor, with a damp basement, or simply in the joints of external slabs or brickwork there are fistulas.

In these cases, there is always a draft under the floor. In addition to cork and combined substrates, which are also heat insulators, they use material made from flax fibers, which is rolled on special machines under high temperatures. This option protects the surface from drafts and also provides ventilation between the base of the floor and the linoleum, which prevents the accumulation of moisture inside.

The jute backing does not get wet, but absorbs moisture into itself, gradually getting rid of it. These options are impregnated with a fire retardant, which prevents the wood from rotting and protects against fungus. The foam material insulates the floor well and protects the space from drafts. But you need to take into account that over time it wears out. In addition, it does not allow moisture to pass through. In combination with waterproof linoleum, accidental water ingress into the joint does not bode well.

Expanded polystyrene for linoleum

Expanded polystyrene has a porous structure, which is a great advantage.

Method of installing polystyrene foam under the screed:

- Expanded polystyrene can be laid on concrete or soil. When laying on the ground, the surface is covered with crushed stone and sand in layers of 10–15 cm.

- Expanded polystyrene slabs are laid out.

- Beacons are being installed.

- A screed 5–8 cm thick is poured.

Advantages:

- High thermal insulation.

- Durability;

- High heat and sound insulation.

- Safety.

Flaws:

- Highly flammable material.

- Poor air permeability.

- Housing for rodents.

Video: floor insulation with polystyrene foam

Types of insulation

You can use the following types of insulation to insulate the floor under linoleum:

Penoplex insulation

stands out for its durability and long service life. This material is often used to insulate various surfaces. The thickness of these slabs is small, so the floor level rises to an insignificant height (for more details: “How to insulate a floor with penoplex - proven methods”).

This insulation for linoleum on a concrete floor has a significant advantage - it is easy to install; if necessary, it can be cut with an ordinary knife. It is the most popular among insulation materials; floor insulation in a private house is most often done with this material.

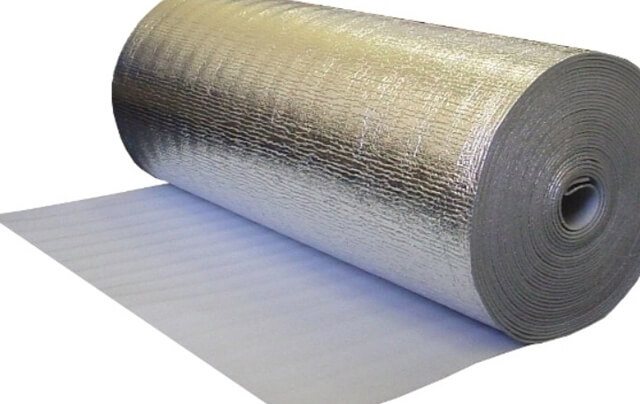

Izolon

– This is polyethylene foam with a closed cell structure. Has excellent characteristics:

- high thermal insulation rates;

- vapor barrier qualities;

- waterproof;

- safe;

- durable.

In addition, the cost of isolon is low.

There are two types: non-foil and foil insulation under linoleum.

Foamed polyethylene: insulation under linoleum

Foamed polyethylene has a closed-porous, light and elastic structure. Dense and fairly thick types of polyethylene foam can provide some degree of insulation. If you purchase an inexpensive thin substrate with large cells, it will not cope with the tasks assigned to it.

Pros:

- Non-toxic.

- Moisture resistant.

- Easy to install.

Minuses:

- May wrinkle under load.

- Only dense and thick types of substrate can be used as insulation.

Foil insulation consists of a foam base and a reflective foil surface.

The installation technology is very simple. The material is rolled out over the surface. The joints are sealed with aluminum tape.

Advantages of the material:

- Reflectivity.

- Resistant to temperature changes.

- Easy to install.

Flaws:

- Cannot be used for finishing with building mixtures.

- Additional insulation is required.

Linoleum. History of appearance and production technology

Linoleum is a flexible, water-repellent material made from polymers. The officially registered date of the appearance of linoleum is December 19, 1863. On that day, Englishman Frederick Walton , inventor and founder of the Linoleum Manufacturing Company, received a patent for the production of this floor covering.

Already at the beginning of the 20th century, Russia was the largest producer in Europe . In the 50s of the last century, due to a shortage of raw materials in the former Soviet Union, linoleum gave way to PVC covering, which had nothing in common with the original material, but still retained the old name of the floor covering.

Linoleum is produced on the basis of linseed oil that has undergone oxidation, which is how it got its name (from Latin, literally translated, linoleum sounds like linum - linen, linen + oleum - oil). The resulting mixture in the oxide process is called linoleum cement and when mixed with wood chips and the addition of resins, sheets of the well-known floor covering are obtained.

How to choose linoleum for the kitchen? You will find the answer in this article. And in this article you will learn how to properly glue linoleum joints.

Thermal insulation paint for insulation

The components of the paint are: water, acrylic dispersion, fiberglass additives, perlite, foam glass or ceramic microspheres.

Paint is applied to the surface with a thickness of 2–4 mm using a spray gun or a paint brush. The thickness of the paint layer affects the effectiveness of thermal insulation.

Pros:

- Resistance to high temperatures and atmospheric influences.

- Low heat transfer.

- Ability to last up to 50 years.

- Does not require special equipment for application.

- Thermal insulation.

- Corrosion protection.

- Fire resistance.

Minuses:

- Cannot be used as the main thermal insulator.

- High price for paint.

Video: technology for using heat-insulating paint

Warm floor

In addition to the above options, heated floor systems are widely used to insulate cold bases under linoleum. They can be water or electric. Thanks to this system, you can ensure a comfortable temperature regime.

Advantages of water systems:

- Creating a comfortable temperature.

- Possibility of temperature control.

- Economical.

- Safety.

Flaws:

- Possibility of bursting coolant pipes.

- Labor-intensive installation.

Video: installation instructions for a heated water floor

Advantages of electrical systems:

- Does not dry out the air.

- Warms up quickly.

- Durable.

Flaws:

- Increased energy consumption.

You can use any of the insulation methods you like. Each of the insulation options can be installed independently. If you have any questions, you can ask them on the website.

Video: installation of cable electric floor

What should be the thickness

In order for the heat insulator to perform its thermal insulation functions, it is necessary to ensure that the thickness of its layer is sufficient. When insulating a concrete base, it is necessary to lay insulation under the linoleum, the thickness of which is at least 4 mm. If the selected material has a smaller thickness, then you can get out of this situation if you lay it in several layers.

In the video - insulation under linoleum on a concrete floor:

But what is the consumption of linoleum glue per 1m2 is described in great detail in this article.

For those who want to find out what is better than linoleum or laminate in an apartment and how to make the right choice, you should follow this link and read the article.

Insulated

It is affordable and convenient. The product is made in two layers - the base itself and the working surface. The base is felt or jute.

Polyvinyl chloride is a working surface. If you foam it, you get a durable product. Its distinctive features are softness, elasticity, and lightness. It can be quickly installed in two different ways: with or without glue. The building material also has excellent thermal insulation and sound insulation qualities.

Despite these advantages, felt products have many disadvantages:

- The working surface has a fairly low level of strength. It can be damaged without any problems. Operation must be careful.

- Due to jute or felt, building materials may lose their performance characteristics after a certain period of time. Particularly those areas with the greatest traffic are beginning to deteriorate. The base begins to become thin, even if it is Tarquette linoleum on a felt base.

- Felt-based linoleum should not be used in rooms with a high content of water vapor, because it does not have waterproofing characteristics. The base is made from products that are of natural origin and “afraid” of moisture. After a certain period of time, you may notice the appearance of fungus or mold under the work surface.

These are the disadvantages of felt.

Now it is difficult to find on the construction market something that has a base made of jute or felt. It is rapidly being replaced by a warm-based product.

Insulation technology

Before laying insulation under linoleum on a wooden floor, you should prepare all the required materials and tools.

To work you need:

- insulation isolon or penoplex;

- backing for linoleum made from natural materials;

- sheets of plywood or fiberboard;

- polyethylene film;

- scotch;

- materials for fastening (screws, glue);

- screwdriver;

- knife;

- scissors;

- jigsaw

After this, you can proceed directly to the insulation process:

- First you need to inspect the surface under the top layer of flooring. To do this, you need to remove it. If the boards are good, then insulation can be done from this level.

- The substrate is laid. It is better to make a choice in favor of natural materials, as they are safer. However, there are also disadvantages here: such substrates may quickly wear out and insects may appear. Also, when choosing a substrate, you need to take into account its thickness, so that it does not work out, so that because of it the floor level will rise so much that it will be impossible to open the door.

- To avoid problems in the future, Izolon or penoplex is laid on top. All existing sheet joints must be glued together with construction tape.

- The next layer is laid plywood sheets or fiberboard. Next, everything needs to be secured using self-tapping screws.

- If fiberboard is selected, waterproofing should be done to prevent it from swelling. To do this, first a plastic film is laid down, then fiberboard is laid on top, which needs to be primed, and the film is laid on top again (for more details: “How to lay fiberboard on the floor under linoleum correctly”).

To prevent water from getting onto the lower layers of the floor, you should choose rectangular-shaped plinths for linoleum.

On a warm basis

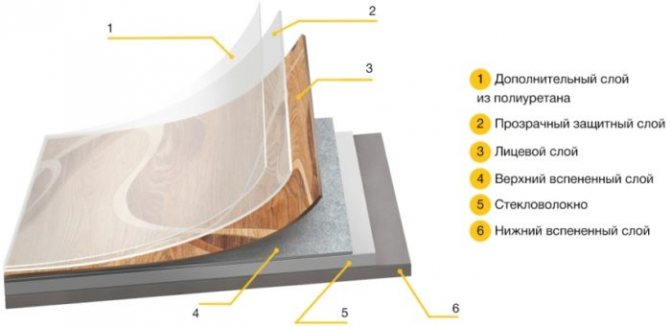

Thanks to modern technologies, today it is possible to create building materials consisting of many layers. Warm-based linoleum is one such building material. The product is made of five or six layers, each layer has a special function.

Unlike the previous version, inside this product there is foamed foam or foamed vinyl combined with polyester. This is an excellent insulator. Thanks to this foundation, the building material acquires elasticity and resistance to enormous loads.

It has a high level of stretch and does not rip or shrink. Thanks to its excellent waterproofing characteristics, this material perfectly tolerates high levels of humidity.

Fiberglass is the second layer.

With this layer of fiberglass it remains intact and durable. On the top of this layer there is foamed PVC, as well as a layer with a decorative pattern. And the drawing is protected by a working layer, which has distinctive wear resistance.

So, thanks to a structure consisting of many layers, this material acquires not only thermal insulation, but also noise insulation characteristics. Moisture and mechanical stress are also not a problem for this floor product.

Problems

What kind of insulation can be put under linoleum

The market is replete with materials for floor insulation - natural, polymer. There are special heating systems that operate from the network. When choosing a substrate, you should study its characteristics, and also take into account the characteristics of the room.

Which one is better to choose for a concrete floor?

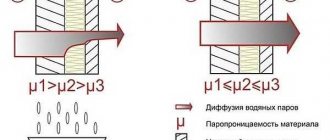

If there is concrete under the linoleum, it is better to give preference to a hard material. This is especially important if it is also planned to lay concrete mortar on the insulation. In this case, the insulation should not absorb water and be vapor permeable.

Insulation and concrete solution

For wooden floor

If you plan to lay linoleum on wood, soft, loose materials that do not hold their shape are suitable. It is important that the insulator can “breathe” and allow water vapor to pass through. The wooden floor covering is made precisely so that the structure “breathes”.

Is it possible to put insulation under linoleum?

There are types of linoleum already equipped with a thermal insulation layer. This material does not require additional insulation, but it is not cheap. It can be advantageous to purchase a conventional coating, to which an additional substrate is taken.

How to lay insulation with foil

The metallized coating reflects infrared radiation. Therefore, the insulation is laid so that the foil faces the inside of the room. The material is fixed on a flat concrete base with a special glue containing rubber.

The cost of an electric heating system ranges from 1,900 to 23,340 rubles. The price of a device is determined by its power, safety, and additional functions. The cost of the insulating substrate depends on the thickness of the material, technical characteristics, and manufacturer:

Before you start choosing materials that can be used to insulate concrete floors under linoleum , it will be useful to dwell on the advantages of this coating. Main characteristics of linoleum:

- Fairly low price;

- Aesthetics and the widest selection of colors and patterns on the coating;

- Durability and abrasion resistance;

- Easy installation.

What choice should I make?

Before choosing, be sure to familiarize yourself with some nuances:

- If you need a product for rooms that have a high content of water vapor, then it is best to choose a material that has a foam core because it has excellent thermal insulation properties.

- Building materials with jute or felt inside do not need to be glued, otherwise the thermal insulation can be damaged.

- If you use an “electric floor” heating system, then you should use ordinary insulated material as a flooring product, because it is the most natural. Foamed linoleum is not needed.

Compliance with these nuances is mandatory. Linoleum with insulation can be selected according to these criteria.

Popular types of substrates with thermal insulation properties

When starting to select insulation, it is necessary to take into account that the main selection criterion should be the material of the floor to be insulated. It can be either concrete or wood. You need to study the list of suitable materials that are best combined with the main floor material, find out the nuances of installing the substrate, and familiarize yourself with the list of advantages and disadvantages.

Fiberboard and plywood

The use of fiberboard or plywood sheets for floor insulation is one of the most cost-effective ways to insulate a floor. In addition, installing this type of coating will allow you to make the surface more even. Sheets of the selected material must be laid on the floor, marked according to the required dimensions and cut by sawing.

To attach to the concrete surface, you will need to use dowels, to wood - the same, plus self-tapping screws.

Multilayer linoleum

This type of linoleum is called warm. This coating is distinguished by the presence of a heat-insulating substrate consisting of jute fibers or felt. By choosing such linoleum, you will get rid of the need to install an additional insulating layer and reduce the amount of costs. The insulated surface must be smooth and free of noticeable flaws and level differences. The material is convenient and recommended for use in dwellings located on the upper floors of apartment buildings.

Advantages: The material has several layers and can simultaneously serve as a heat insulator and finishing coating. It is easy to install and can be laid without the use of glue. The coating is warm, soft, and comfortable to walk on.

The disadvantages are : high level of hydroscopicity - felt or jute substrate absorbs moisture well. The material must not be laid where there is a high level of humidity. Multilayer coating is not resistant to mechanical damage and stress. It can quickly become deformed and lose its original properties and visual appeal.

Cork floor insulation

Cork insulation is deservedly considered the best type of insulation for both concrete and wood floors. It has high thermal insulation qualities. The material can be found on sale both in the form of rolls and in panel form, with different sheet thicknesses.

ATTENTION! Before laying the cork, you will definitely need to level the floor surface. You can use plywood, fiberboard sheets or arrange a screed. Between the insulation itself and the base of the floor you will need to lay a waterproofing layer of polyethylene. The sheets should be tightly laid end to end, so the coating will be solid and there will be no heat leaks.

Advantages : The material is fireproof and resistant to high humidity. Produced from natural raw materials, which ensures high environmental friendliness. A long service life is guaranteed, if the installation is carried out correctly and the operating conditions meet the standards, the insulation will work effectively for 20 years or more.

Jute backing for linoleum

For the production of insulation, exclusively natural materials such as flax and wool are used. The principle of installing jute covering is similar to installing cork. It is imperative to provide a layer of waterproofing. The most commonly used film is polyethylene film. For concrete bases, you can apply waterproofing, available in liquid form. A brush is used for this.

Advantages of jute insulation: It weighs little and is easy to install. The material is environmentally friendly and resistant to aggressive substances.

Disadvantages: It is characterized by a high level of cost. It is easily deformed in high-traffic areas or from furniture standing on it, becomes uneven and loses its appearance.

Extruded polystyrene foam

This material makes it possible to insulate any type of floor, both in apartments and in private houses. EPPS has a porous structure, which determines its insulating properties. Produced in sheet form.

Installation is carried out either on the surface itself, or logs are installed, between which sheets of insulation are tightly laid. Sheets of plywood laid on top will provide the necessary level of rigidity for further laying of linoleum.

Advantages: Foamed extruded polystyrene is universal. It can be laid on both concrete and wooden floors. It is resistant to possible deformations, is not afraid of moisture, and does not support the development of mold fungi. It has a long service life and is inexpensive.

Disadvantages : Requires the installation of a layer of screed or installation of logs, which reduces the usable area. With a standard ceiling height in an apartment of 2 meters 70 centimeters, installing such a covering is not very practical.

Glass wool

The material also has an affordable price and is sold in slab and roll versions. If a concrete floor is insulated, you need to install joists and lay the raw materials in the space between them. Plywood or fiberboard sheets are laid on top, and a decorative coating is mounted on the leveled surface. It can be either linoleum or laminate. Such a substrate not only insulates well, but is also a sound insulator.

Advantages: Resistance to moisture, lack of toxicity, high level of fire safety. The insulation is lightweight, which simplifies the installation process and eliminates additional load on the floors.

Disadvantages: Service life is less than 10 years. Working with glass wool requires the use of protective equipment - a respirator, gloves and special clothing. Otherwise, microparticles of the material may damage the surface of the mucous membranes. When laying indoors, the insulation must be reliably insulated.

Liquid insulation – paint with thermal insulation effect

This option is ideal for rooms where it is not possible to raise the floor height due to a low ceiling. The floor under the linoleum covering can be insulated with paint, which forms a layer with many pores. It is very easy to apply such a substrate yourself, since all you need is a brush.

A concrete base requires preliminary preparation - cleaning, leveling, eliminating cracks and priming. Then the insulating layer is applied with a brush. After it dries, hardboard or plywood sheets are laid on top, which are covered with linoleum. When applying paint in a layer of 1 millimeter, its consumption corresponds to approximately 500 g/1m2. Thermal insulation characteristics correspond to a 5 mm layer of mineral wool.

Advantages: High-quality adhesion to any type of surface. It is not affected by humidity, fungus and mold do not develop on the insulation. Easy and simple to apply in any place, including hard-to-reach places.

Disadvantages : The insulated surface must be perfectly leveled. A single application does not create a layer sufficient for effective thermal insulation; combination with other types of insulation is required.

Penofol in rolls

It is polyethylene foam with a foil layer, characterized by high porosity and practicality. There are self-adhesive options that make the process of insulating a concrete surface for laying linoleum as easy as possible.

The thermal conductivity of the material is low due to the closed type of pores, and the foil layer is able to effectively reflect heat. Penofol is sold in the form of rolls. There are varieties of insulator with double foil, they retain heat even better.