What is used oil?

Refining is an oil-based product that is obtained during long-term operation of a car engine. Under the influence of external factors, the oil loses its normal characteristics and becomes unsuitable for further use. The mass of the product contains a whole complex of various particles formed during the operation of metal parts of mechanisms.

The used oil must be drained and replaced with new oil. When replacing, it is recommended to dispose of the waste at special collection points, where it finds its useful use in the form of fuel for heating the room.

Production of a boiler for development

Almost anyone can make a working boiler. There are many designs and methods, all of them have been tested in practice and are widely used. There are two main designs, let's look at them.

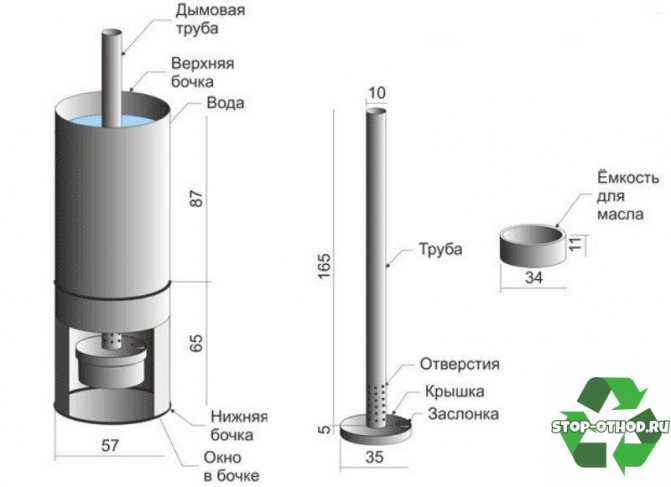

Drawings of heating units

In the first case, the boiler consists of two chambers connected to each other by a pipe with holes. The evaporation compartment is located in the lower chamber, where open combustion of the waste occurs. Afterburning occurs in a pipe with holes into which air is supplied naturally. After the pipe there is a second chamber, in which the speed of movement of fuel vapors decreases.

The partition in the upper compartment also serves for complete oxidation and connection with nitrogen. A chimney is installed higher, it serves to remove combustion products and additional draft. Light the boiler using a rag soaked in gasoline or kerosene. In the lower compartment there is a special damper that regulates the air supply to the first combustion chamber. For hot water supply and heating systems, a water jacket is installed in the second compartment. It is important to leave a gap between the pipe and the tank of at least 70 mm.

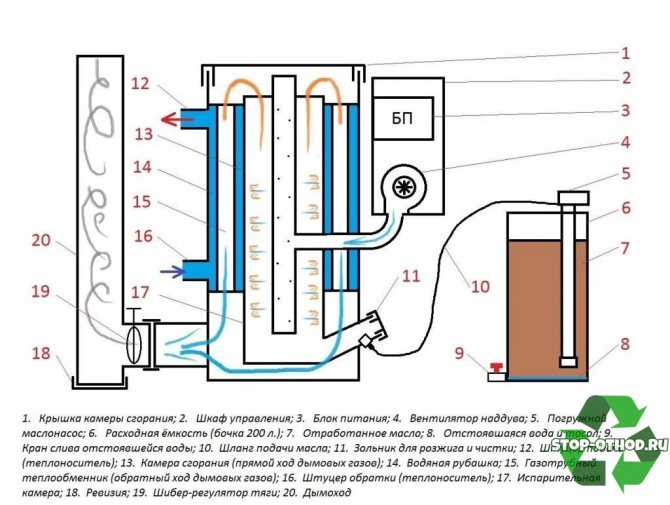

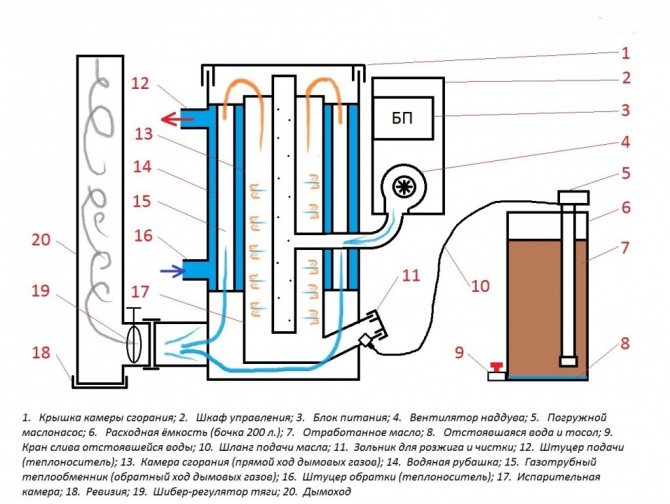

The second manufacturing method involves more economical use of fuel.

The power of the device can reach 15 kW.

The design contains a turbine for forced air supply. Increased boost burns the fuel mixture more efficiently. The waste tank is taken out separately and a valve is installed on it to regulate the oil supply to the boiler or stop it completely. As in the first case, the central pipe is equipped with slots or holes for efficient combustion of fuel vapors. The waste combustion products are also removed through the chimney; when installing it, sharp corners and sharp turns should not be allowed. Recommended length is at least 4 m.

This design allows you to comply with all safety requirements, and also makes it possible to easily install water elements of the heating system. The most economical.

Necessary materials

When making a waste oil boiler, the following materials may be needed:

- Gas cylinder with a volume of at least 50 l

- Metal pipes with diameters of 100 mm, thickness of 3 mm and 6 mm

- Metal sheets from 3 mm to 5 mm thick

- Car brake disc

- Steel pipe with a diameter of 15 mm

- Fireproof Fuel Supply Hose

- Ball valve

- Oil tank

- Steel cover, at least 5 mm thick

- Steel sheet no thinner than 3 mm, for water jacket

- Set of pipes for connections

It is recommended to use special products to protect against rust; this will extend the life of the boiler. In places where pipes are connected, paste and tow are used to increase sealing.

Tools used for manufacturing

During work you may need a variety of tools:

- For welding connections, transformer machines or inverters are used, since such connections are subject to increased requirements.

- Drill kit and hand electric drill to make holes for mounting and torch.

- Set of pipe thread dies.

- Grinding machine, two wheels for it: cutting and cleaning.

- Tape measure, metal ruler, gas wrench and device for marking on metal.

Before starting work, it is recommended to secure the welding site, and also use coolant when drilling.

Instructions for making a boiler for testing yourself

In order to make a waste oil boiler with your own hands, you must follow the following instructions:

- The gas cylinder must first be emptied. The valve is turned off from above, the container is turned over and all the contents are drained. The cylinder is washed with water, only then can welding and cutting work be carried out.

- Two openings are cut out in the container, leaving a strip of at least 50 mm between them. The upper compartment is made larger so that firewood can be loaded into it. The cut parts are not thrown away; these will be hatches for loading fuel.

- Hinges are welded to openings and hatches.

- A ring equal to the inner diameter of the cylinder is cut out of a sheet of steel 4 mm thick, and a hole is made in it slightly larger than the diameter of the burner (100 mm). Serves as a partition between the combustion compartment and the heat exchanger.

- Cut a piece 200 mm long from the steel pipe, make holes on the entire surface for a length of 95 mm.

- The burner blank is inserted into the previously made ring up to the holes and welded.

- The partition is installed at the level of the upper combustion compartment.

- A brake disc from a passenger car can serve as a blank for the evaporator. It is first necessary to close all the technological holes from the bottom and top; for this, two rings are cut out of a sheet of steel, one will be the bottom, and the other will be the lid. Then they are welded, a hole is made in the cover for subsequent installation of the coupling.

- A 150 mm long section is cut from the pipe, then you need to cut it lengthwise and slightly move the walls apart to 3-4 mm. Afterwards, the workpiece is welded to the combustion bowl and attached to the burner.

- A water jacket is formed from a steel sheet around the boiler, and everything should be scalded with a continuous seam.

- Pipes for draining and supplying water are installed at the bottom and top.

- Mount the chimney in the lid and install it on the boiler.

- A hole is made in the wall of the gas cylinder, a tube is inserted into it at an angle, its end is placed above the fuel supply window. After adjusting the extension length, the tube is scalded.

- A thread is cut on the mining supply pipe and a tap connected to the barrel is installed.

The principle of operation of the system and operating rules

The design operates thanks to a pump that supplies waste to the chamber where the oil evaporates. The walls of the chamber are made strong enough to withstand the temperature load. At the bottom of the boiler, the fuel turns into steam, it mixes with air and heats the water circuit. The entire mixture passes into the combustion chamber. In this location, combustion is carried out without residue, and the by-products of the combustion process exit through the chimney.

Despite the simple principle of operation, the system requires careful handling and compliance with operating rules. Safety measures when working with the boiler include:

- Monitor the operation of the structure and do not leave the active boiler unattended.

- Do not burn any materials other than fuel in the unit.

- Do not allow liquid to enter the inside of the boiler. Contact of water with a hot surface often leads to an accident and damages the heating device.

- Do not add waste to the boiler while it is active.

- Do not turn off the burner.

- As an additional measure, it is not recommended to continuously operate the unit at full power. Continuous operation in this mode will quickly render the boiler unusable.

With the right approach, the installation will work for a long time, and the operation process will not cause problems.

Advantages of heating boilers during testing

Heating boilers using waste oil have many advantages.

Economical

The boiler operates on primary waste oil. A properly configured device burns it completely .

More often, such devices are purchased by people who have access to fuel in unlimited quantities.

For example, workers at depots or engineering plants. But even if you have to buy used liquid, you will still be in the black.

The cost of oil is minimal, and it is consumed economically. The oil burns out completely, which means every penny spent on it will be spent.

Autonomy

Such a boiler operates autonomously, without connection to a stationary heating system . The buyer independently, regardless of the centralized supply of heat, decides where the device will be installed. This is relevant in private homes, where autonomous heating is extremely necessary in the cold season.

Simplicity of the device

The device is so easy to assemble and operate that some craftsmen are attempting to assemble it themselves. The operating principle of a homemade and purchased unit is similar, and the resources spent on manufacturing or purchasing are almost the same.

Affordability

It is no coincidence that such heating devices are extremely popular. Despite the fact that there are few manufacturers of such devices on the market, they do not inflate the cost, since they understand perfectly well that such a device can be assembled at home. Combined with the low price of fuel, the consumer can recoup their purchase within the first heating season.

Photo 1. Two boilers (yellow and red) running on waste oil. Manufacturer: Thermobile.

Wide range of applications

Waste oil boilers are used not only for heating residential premises. They can often be found in offices, institutions, and even industrial and warehouse areas. It is these factors that have influenced the fact that such devices have received a wide range of applications.

Environmental friendliness

The fuel burns completely. At the same time, no toxic waste or harmful substances are released into the surrounding atmosphere. The operation of the device is absolutely harmless to people and the environment. Many manufacturers' models are marked with environmental safety marks from various environmental organizations.

Efficiency of use

The device quickly heats the air and the room around it and maintains the set temperature. Warmth is felt almost immediately after turning on the device.

It not only remains in the room and does not disappear over time, but also spreads to other rooms.

Features of oil heating boilers

An oil heating boiler has a number of advantages and individual features that distinguish this equipment from other types of heating and heating systems.

Advantages:

- quick payback;

- versatility;

- compliance with environmental standards;

- autonomy;

- ease of installation and operation;

- comfort;

- safety.

The use of waste waste as raw material for boilers allows you to quickly recoup the costs of its purchase.

This is especially important for heating large industrial facilities. Payback in this case occurs in record time. Waste oil boilers are used for heating various places: service stations, garages, industrial premises. Such equipment will be simply indispensable for those organizations whose activities require the availability of used fuel and lubricants. Oil heating boiler contributes to environmental safety issues. It solves the problem of fuel and lubricant waste disposal. There is no need to throw waste oil into the environment; it is better to use it for space heating and water heating.

Waste heat boilers have the following operating principle: they generate energy in the form of heated water, steam or air flow.

You can find out more about gas recovery boilers here.

This type of heating equipment is autonomous and can be used in any conditions. It is very easy to install and use in the future. Installation is carried out in a short time in compliance with safety requirements. Ease of operation is ensured by the automation of the boiler operation and the simplicity of its design. There is no unpleasant odor or harmful emissions, and the operation of such equipment does not cause inconvenience or problems.

Heater design and drawings

Craftsmen engaged in the manufacture of waste oil boilers use in practice 3 methods of burning waste:

- surface combustion with pyrolysis afterburning in a perforated pipe and secondary chamber;

- the use of Babington burners and other homemade structures;

- combustion in a flame bowl, fuel supply is organized by the drip method, air is forced.

The first option is implemented in the famous garage stove, consisting of 2 chambers connected by a vertical perforated pipe. We described the second method in detail in the corresponding publication - a Babington burner is made and built inside the body of a steel boiler that previously operated on wood.

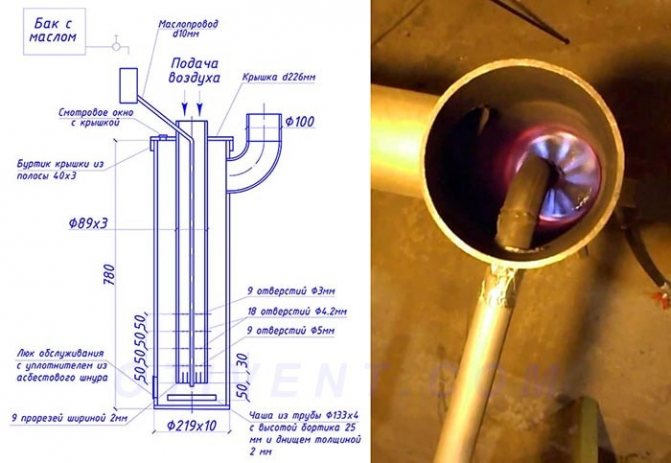

We propose to focus on the third option - a dropper stove, converting it into a double-turn (the correct name is two-pass) water boiler. The drawing below shows the basic version of this stove, made from a Ø219 mm pipe. Why it is recommended for beginners to take the drip principle of operation of the heating unit as a basis:

- The design of oil burners is quite complex. Assembly requires some experience and financial investment (for example, for Babington you will have to buy a compressor).

- Surface combustion heaters are fire hazardous (they shoot out flames when water gets into the fuel). Equipping a miracle stove with a water jacket is not an easy task.

- Fuel consumption during surface combustion is prohibitively high - up to 2 liters of waste per hour.

- According to reviews on the forums, the drippers are reliable and can work without automation (however, the owner will have to devote some time to the boiler to get used to manual control). The unit is relatively simple to manufacture.

Dripper stove - a prototype of a two-pass hot water boiler for burning liquid fuels

Note. We discussed in detail how to make a drip stove using waste oil yourself in a separate step-by-step instruction. If you are interested in other types of homemade liquid fuel heaters, go to the authoritative thematic forum termoportal.ru.

Liquid fuel boiler diagram

The dropper diagram shown in the drawing needs to be redone, since together with the fire tube heat exchanger the structure will not fit inside the gas cylinder - you will have to look for a large pipe with a diameter of 400 mm. The dimensions of the heat generator can be reduced without loss of power (15-20 kW) as follows:

- make an afterburner from a DN40 pipe, changing the number and diameter of the holes (more precisely indicated in the drawing);

- for the combustion chamber, take a DN150 pipe;

- weld a water jacket from two propane gas cylinders;

- heat exchanger – at least 8 flame tubes Ø32 mm;

- bowl size - according to the combustion chamber (DN150);

- height from the edge of the afterburner to the bottom of the bowl is 6.5-7 cm.

Installation and installation of a boiler during development?

Since boilers operate on liquid fuel, it is necessary to place the boiler in a specially designated area, at some distance from flammable and volatile liquids.

- You can build a special concrete platform for the boiler, with a small side. Such a side will provide passive safety in case of fuel overflow. We recommend making a concrete pedestal (platform) 20-30 cm high from the floor and pouring it level. Having installed a boiler on it, it will be convenient for you to maintain, light and clean it in the future.

- The boiler must be located in such a way that it can be easily serviced.

- Containers with flammable liquids (gasoline, solvents, varnishes, paints, etc.) must not be placed near the boiler.

- It is recommended to place the automation unit on the wall. It is strictly forbidden to install the automation unit on the boiler lid; this will lead to overheating and damage to the electronics.

- Oil hoses and wires leading to the motors should not touch the surface of the boiler.

- The temperature sensor is installed in a tube located on the side of the boiler.

- The waste oil container can be located within 0.7-1.5 meters from the boiler. The oil in the container cannot ignite on its own.

- The oil pump on the rod is immersed in the container. The oil pump is adapted to the neck of the barrel (60 - 200 liters). There is no additional need to cut a hole for the oil pump. When installing the oil pump, the oil pump motor and gearbox must be at the top, above the fuel surface.

Rating of the best models

When traditional heaters are not available, waste boilers become the most profitable and simple way out of a difficult situation. Considering that the equipment can operate on all types of liquid flammable materials, including animal fat and diesel fuel, it can be called ideal for emergency situations. By the way, to switch from one type of fuel to another, you just need to adjust the speed and volume of air required for combustion, which takes about 5 seconds.

| Category | Name | price, rub. |

| The best waste oil boilers made in Russia | GeKKON 50 | 108000 |

| Teplamos NT-100 | 268000 | |

| EcoBoil-30/36 | 460000 | |

| The best waste oil boilers made in Europe | Ecoheat 60 S | 280000 |

| Danvex B-60 | 290000 |

The best waste oil boilers made in Russia

Russian waste oil boilers are produced mainly in Voronezh. Today there are 10 more small enterprises engaged in the development and production of equipment according to their own engineering designs. However, not everyone has a state certificate for the production of heating equipment. When purchasing, it is imperative to read the documents, which guarantees safe operation.

GeKKON 50

A domestically produced pyrolysis boiler that can operate on crude oil, all grades of fuel oil, oils, fats, diesel fuel, kerosene, etc.

GeKKON 50

Specifications:

- Operating voltage – 220 V.

- Maximum temperature in the boiler – 95°C

- Dimensions – 460x660x950 mm

- Weight – 160 kg

- Fuel consumption - 2-5 l/hour

- Power consumption – 100 W.

The main advantage of this model is that almost all types of liquid hydrocarbons can be used as fuel. In addition, the unit is not critical to the viscosity and quality of the fuel; it does not require pre-filtration and heating.

In addition, there are several more advantages of the model - high efficiency, small dimensions, ease of maintenance and repair, reliability of all components and assemblies.

The average cost of the unit is 108,000 rubles.

Teplamos NT-100

A domestically produced boiler, which is designed for heating various industrial premises. The model is fully equipped and ready for launch. Double-circuit - used not only for heating, but also to provide hot water supply in the house.

Teplamos NT-100

Specifications:

- Dimensions – 1140x750x1180 mm

- Weight – 257 kg

- Maximum heating temperature of the coolant – 95°C

- Maximum thermal power - 99 kW

- Fuel consumption – 6 liters per hour

- Compressed air pressure – 0.8 – 1.0 bar

- Chimney diameter – 200 mm

The presence of a control panel allows you to control the equipment automatically. It includes a switch, thermostat, thermohydrometer, emergency thermostat.

A big plus of this model is the excellent thermal insulation of the boiler body made of high-density glass wool. All external elements of the case are powder coated to protect against corrosion.

The boiler has a door for maintenance of the combustion chamber, without the need to dismantle the burner.

The average cost of the device is 268,000 rubles.

Operating instructions Teplamos NT-100

EcoBoil-30/36

Single-circuit boiler designed to heat a room up to 300 square meters. meters for any purpose - residential buildings, industrial facilities.

EcoBoil-30/36

Specifications:

- Dimensions – 580x600x1100 mm

- Chimney diameter – 108 mm

- Water circuit volume – 38 l

- Boiler power – 28 kW

- Fuel consumption - 0.9-1.6 l/hour

The boiler can operate on waste oil, various vegetable oils, kerosene and automatic transmission oils.

The average price for this unit is 460,000 rubles.

Operating instructions "EcoBoil-30/36"

Review of popular models

If you still decide to buy a waste oil boiler, then below you can view the most popular models.

| Model | Characteristic | Price (average), rub. |

| Teplotherm GMB 5-9 kW | — Double-turn for exhaust, fuel oil, heating oil 5-9 kW with continuously adjustable coolant temperature and increased heat transfer area (efficiency 90%) — Has an oil pump power supply and a built-in boost fan. — Remote oil pump on a rod for a canister, barrel, etc. — Heating by manual ignition has two operating modes: minimum for maintaining combustion and maximum - operating mode. — Automation is implemented on the basis of a multifunctional microprocessor. — Automatic switching between modes. — Blocking from restarting after a power failure. — In case of attenuation, protection against oil overflow is provided. - The boiler is not afraid of boiling. — Oil consumption 0.6 — 1.1 l/hour. — Electrical power consumption — no more than 200 W. — The capacity of the water jacket is 12 liters. — Overall dimensions (LxWxH) 700 x 300 x 800 mm. — The diameter and height of the boiler without protruding parts are 320 x 650 mm. — Complete set: boiler, control cabinet, fuel hose, remote oil pump. — Chimney diameter 110 mm. — Weight 61 kg. | 52 000 |

| Teploterm GMB 10-15 kW | - 10-15 kW. — Blocking from restarting after a power failure. — Oil consumption 0.9 — 1.7 l/hour. — Electrical power consumption—no more than 200 W. — Water jacket capacity — 19 liters. — Overall dimensions (LxWxH) — 700 x 300 x 800 mm. — Diameter and height of the boiler without protruding parts. — 320 x 650 mm. — Chimney diameter 110 mm. — Weight 81 kg. | 58 000 |

| Teploterm GMB 10-20 kW | — Oil consumption 0.9 — 2.1 l/hour. — Water jacket capacity — 30 liters. — Power consumption — no more than 200 W. — Overall dimensions (LxWxH) — 850 x 370 x 900 mm. — The diameter and height of the boiler without protruding parts is 430 x 800 mm. — The kit includes a boiler, control cabinet, remote oil pump, fuel hose. — Chimney diameter 110 mm. — Weight 110 kg. | 68 000 |

| Teplotherm GMB 10-30 kW | — Fuel consumption 1.6 — 3 l/hour. — Electrical power consumption—no more than 200 W. — Minimum and maximum modes are adjustable. — Water jacket capacity — 44 liters. — Overall dimensions (LxWxH) — 780x370x1200 mm. — The diameter and height of the boiler without protruding parts is 430 x 1000 mm. — Chimney diameter — 159 mm. — Weight — 37 kg. | 78 000 |

| Teploterm GMB 30-50 kW | — Fuel consumption 3 — 5.5 l/hour. — Electrical power consumption—no more than 200 W. — Water jacket capacity — 57 liters. — The diameter and height of the boiler without protruding parts is 530 x 1100 mm. — Chimney diameter — 159 mm. — Weight — 271 kg. | 97 000 |

| Teplotherm GMB 30-70 kW | — Fuel consumption 3 — 7.5 l/hour. — Electrical power consumption—no more than 200 W. — Water jacket capacity — 77 liters. — The diameter and height of the boiler without protruding parts are 530 x 1400 mm. — Material — St3. — Chimney diameter — 159 mm. — Weight — 350 kg. | 117 000 |

| GeKKON 15 | — The rated power of the unit is 15000 W. — Conditional heated area — 150 m². — Working pressure (max) — 3 kg/cm². — Operating voltage — 220V. — Power consumption — 100 W. — Water temperature in the boiler (max) — 95 С. — Operating time without maintenance: 10-12 hours. — The outer diameter of the chimney is 110 mm. — Fuel consumption — 0.5-1.5 l/hour. — Weight — 100 kg. — Overall dimensions (LxWxH) - 850x560x360 mm. | 69 500 |

| GeKKON 30 | — The rated power of the unit is 30,000 W. — Conditional heated area 300 m². — Working pressure (max) - 3 kg/cm². — Operating voltage: 220V. — Power consumption - 100 W. — Water temperature in the boiler (max) - 95 C°. — Operating time without maintenance is 10-12 hours. — The outer diameter of the chimney is 115 mm. — Fuel consumption -1-3 l/hour. — Weight — 125 kg. — Overall dimensions (LxWxH) — 900x600x400 mm. | 80 200 |

| GeKKON 50 | — The rated power of the unit is 50,000 W. — Conditional heated area — 500 m². — Working pressure (max) - 3 kg/cm². — Operating voltage: 220V. — Power consumption - 100 W. — Water temperature in the boiler (max) - 95 C°. - Operating time without maintenance - 10-12 hours. — External diameter of the chimney: 135 mm. — Fuel consumption: 2-5 l/hour. — Weight — 160 kg. — Overall dimensions (LxWxH) — 950x660x460 mm. | 101 000 |

| GeKKON 100 | — Weight 250 kg. — Overall dimensions (LxWxH) — 11160x850x540 mm. — The rated power of the unit is 100,000 W. — Conditional heated area — 1000 m². — Heated area - up to 1000 m2. — Working pressure (max) - 3 kg/cm². - Operating voltage - 220 V. - Power consumption - 250 W. — Water temperature in the boiler (max) - 95 C°. — Operating time without maintenance is 10-12 hours. — The outer diameter of the chimney is 160 mm. — Fuel consumption - 3-10 l/hour. | 163 000 |

| EcoBoil-18/30 | — Types of oils that can be used for heating: used motor oils, transmission oils, hydraulic oils, kerosene. — Boiler power — 15 kW. — Oil consumption — 0.5-1 l/hour. — Weight — 57 kg. — Overall dimensions (L × W × H) — 500×500×1000 mm. — Chimney diameter — 108 mm. — Water circuit volume — 18 l. — The boiler package (single-circuit boiler) consists of a pressurization fan into the combustion chamber of the “scroll” type, a gear oil pump, a hose for connecting the oil pump with the supply to the boiler, an automatic control unit, an instruction manual, and a product data sheet. | 36 800 |

| EcoBoil-50/46 | — Boiler power — 46 kW. — Oil consumption — 2.5-3.2 l/hour. — Weight — 96 kg. — Overall dimensions (L × W × H) — 720 × 5720 × 1100 mm. — Chimney diameter — 133 mm. — Water circuit volume — 56 l. — Suitable for heating premises with a total area of up to 460 m². — Used oils of various origins are used as fuel: waste motor oils, gearbox and automatic transmission oils, oils from hydraulic equipment, diesel fuel and kerosene, various vegetable oils. — The boiler automation is connected to a 220 V network with a reduction to 12 V at the output (power supply to the oil pump motors and the inflatable furnace fan). — The boiler configuration (single-circuit boiler) is the same as the previous model. | 71 000 |

| EnergyLogic EL 340h | — Productivity — 4740 m³/hour. — Thermal power — 99.6 kW. — Fuel consumption — 8.5 l/h. — Power consumption — 2.2 kW. — Power supply — 220 V. — Chimney diameter — 285 mm. — Overall dimensions (WxDxH) — 1120x2520x560 mm. — Weight — 248 kg. — Standard equipment includes a fuel pump system, a fan, a fuel heater, a burner with a spray nozzle, a built-in air compressor, a horizontal steel heat exchanger, shutters for hot air outlet, a chimney elbow with a draft regulator, a thermostat, an hour meter, a heat exchanger, a draft meter, an hour meter , draft regulator, fuel filter. | 516 000 |

| DanVex B 30 | — DanVex boilers with high efficiency are designed for heating water in space heating systems, as well as for producing hot sanitary water (when equipped with a boiler). — This model has spark ignition. — Fuel/heat of combustion - waste oil, diesel, heating oil / 9000-10300 Kcal/kg. — Firebox type — reversible, two-pass. — Total thermal power — 35.6 kW/hour. — Useful thermal power — 31.3 kW/hour. — Electrical power consumption, max. - 1.4 kW/hour. — Mains voltage/frequency — 220/50 V/Hz. — Fuel consumption — 0.0033 m³/hour, 3.3 l/hour. — Combustion products are discharged into the chimney. — The diameter of the chimney pipe is 200 mm. — Overall dimensions (L*H*W) (without burner) — 795x625x585 mm. — The weight of the boiler without coolant is 157 kg. | 345 000 |

| Gnome 10-50 | — Thermal power 30-59 kW/h. - Min. firebox length 430 mm. — Engine power 110 W. — Engine speed 2800 rpm. — Designed for highly efficient combustion of various types of liquid fuel (any waste oils, vegetable oils, animal fats, diesel fuel, etc.). | 65 000 |

| De Dietrich 307/ii | — Power range — 180-230 kW. — Pressure drop — 0.03 (with a temperature difference of 15 degrees C) bar. — Excessive pressure in the furnace — + 1.6 mbar. — Coolant volume — 156 l. — The volume of the smoke circuit (firebox + channels) is 0.292 m3. — Fuel consumption — 379 kg/h. — Natural gas consumption — 410 m³/h. - Number of boiler sections - 7. - Firebox depth - 1101 mm. — Firebox volume — 0.174 m³. — Overall dimensions (WxDxH) — 796 x 1318 x 1297 mm. — Weight — 791 kg. | 216 000 |

You can read about the features of double-circuit boilers during testing here.

Waste oil is a good source of energy. In particular, when other heat carriers are not available or are not affordable. If everything is made with high quality, then a boiler using waste oil with your own hands will work no worse than one purchased at the factory.

The best waste oil boilers made in Europe

Waste oil boilers are produced both in Russia and abroad. Oddly enough, the most popular are domestically produced boilers and those from Finland. Domestic boilers are the most reliable, and those from Finland are the most economical

Ecoheat 60 S

This boiler model, operating on waste oil, can be used to heat various premises - warehouses, hangars, car service centers and other production areas.

Ecoheat 60 S

The unit is equipped with a burner, delivered fully assembled, ready for use. It can be connected to a separate boiler to obtain water.

Specifications:

- Dimensions – 1020x670x790 mm

- Weight – 243 kg

- Tank volume – 100 l

- Fuel consumption – 5.4 l. at one o'clock

- Thermal power – 60 kW

- Availability of fuel tank

- Compressed air pressure – 0.5-1.5 bar

Double-turn boiler

One of the most popular household waste oil boilers is a double-turn boiler. It heats water quickly and maintains a constant room temperature. The automation in a double-turn waste oil boiler is based on a multifunctional processor.

Characteristics of water heating equipment:

- power from 10 to 40 kW;

- smooth control of coolant temperature;

- efficiency up to 90%;

- fuel consumption rate per hour 1.0 - 2.7 l;

- oil savings up to 18%;

- Double-turn heating modes: maintaining combustion, working;

- built-in thermostat;

- water jacket up to 30 l;

- remote oil pump;

- manual ignition;

- blocking from secondary activation.

A double-turn waste oil boiler is suitable for use in any area where there is no centralized heating. For uninterrupted operation of a hot water heating system, a container with a supply of fuel for the entire heating season is required. Water can be supplied from a well.

Using a double-turn waste oil boiler with a power of 15 kW, it is quite possible to warm up a room of 150 square meters. m up to 200 heat for half an hour. In this case, the external air temperature can be down to -200C.

Rice. 3 Household double-turn waste oil boiler

A double-turn waste oil boiler is reliable, easy to operate and economical due to the double rotation of burning vapors in the heat exchanger.

Additional protection units against fuel overflow in case of extinguishing and against overheating of the coolant will make the operation of a double-turn water-heating boiler using waste oil autonomous. Fuel consumption will be controlled automatically.

Organization of drip oil supply

To do this, perform the following actions:

- Cut a piece 30-40 cm long from a pipe with a diameter of 8 cm.

- Make two holes in the pipe: one 2 cm from the bottom, the other 4 cm from the top. The diameter of the holes is 1 cm .

- Fittings are welded to the holes.

- A circle with a hole in the center is welded to the lower end of the pipe. Hole diameter - 1 cm.

- A fitting is welded to this hole.

- Similar actions are done at the other end. However, the hole should have a diameter of 3-4 cm and instead of a fitting, a nut with the appropriate dimensions is welded. You need to screw a long bolt into this nut, which will serve as an adjustment rod. You need to make several small holes in the plug for air movement .

- Flexible hoses are attached to the fittings. Two side flexible tubes are lowered into a container with oil. Before this, a pump is placed at the end of the hose attached to the lower side fitting, and another piece of tube with an oil filter is attached at the end.

- A drip clamp or some equivalent is placed on a short hose connected to the fitting at the lower end of the pipe . This element will allow you to control the supply of used oil.

- The structure with hoses is suspended in a vertical position.

- A funnel is placed under the end of the hose with a clamp, from which a flexible tube extends. It is connected to a pipe that is located inside the air duct.

After this, the homemade boiler for heating the house is ready. It is worth saying that its use is not easy, because after each oil change you need to adjust the fuel supply, or rather the drop frequency.

If the water jacket does not have time to absorb all the heat, then you can build a special chimney shown in various videos with an additional heat exchanger.

Advantages and disadvantages of a homemade boiler for mining

Such heating systems are often used for heating garages and other utility rooms, as well as summer cottages. They are rarely used for heating homes. However, this option of using oil boilers is also possible.

Oil consumption for servicing such a boiler ranges from half a liter to a liter per hour. Therefore, processing boilers are considered very economical.

To help you understand why oil boilers are so popular, we suggest looking at their advantages. This will help you decide if creating this design is worth your time.

The advantages of a homemade oil boiler:

- Inexpensive maintenance and assembly. The materials needed for a boiler for recycling are the simplest; if you make it yourself, it will cost you little. The oil on which it works is also not very expensive.

- You can use any recycled oil. It can be a natural or chemical product.

- By the way, this heating method also helps solve the problem of environmentally friendly oil processing. After all, if this product is simply poured into the trash, the atmosphere suffers greatly.

- This boiler is quite compact in size and does not take up much space.

Despite the undeniable advantages of such a system, such heating also has its disadvantages. The first thing is that it needs to be cleaned frequently. Also among the disadvantages of a boiler for processing, it is necessary to highlight the fact that the oxygen in the room quickly burns out. To minimize this side effect, you need to provide the room with good ventilation.

Installation Tips

Installing a boiler that uses waste oil is practically no different from installing other types of heaters. There is one advantage: thanks to the presence of turbocharging and smokeless combustion of liquid fuel, the chimney does not have to be raised by 6-7 meters. It is enough to remove the chimney head from the wind pressure zone and raise it to a height of 4 m.

Regarding proper installation, we will give the following recommendations:

- The boiler and steel chimneys not protected by insulation are located at a distance of 0.5 m from combustible walls and other elements of a wooden house. The minimum distance from fireproof structures is 100 mm.

- Pass through the outer wall and the entire outer section of the flue with an insulated pipe - a sandwich, otherwise there will be a lot of condensation and soot. The chimney installation technology is described in detail in a separate material.

- Be sure to install a safety group on the heating supply line.

- Organize a good exhaust hood in the furnace to remove odors. Combustion air intake can be provided from the street.

- Equip the supercharger with a speed regulator and the oil line with a valve. This will allow you to control the power of the heat generator manually. Do not confuse the control valve with a regular tap; shut-off valves are installed on pipelines in any case.

- Make a primitive automatic emergency stop - install a thermostat on the supply, turn off the fan and the oil pump in case of overheating of the coolant.

If the waste is fed by gravity, then for safety reasons it is advisable to install an electric shut-off valve on the fuel line. One subtlety: after an emergency shutdown, the boiler will not start on its own; you will have to light the oil manually or set up automatic ignition.

It is very advisable to insure the operation of the boiler in case of a power outage. A car fan, designed for a voltage of 12 volts, can be powered from a conventional battery, the rest of the equipment - pumps, thermostats - through an uninterruptible power supply unit.

The easiest way to supply used oil to the combustion chamber of the boiler is by gravity - from a container suspended from the wall. But such a system must be constantly monitored, plus as it is emptied, the interval between drops increases and the combustion intensity decreases.

Hence the recommendation: after the initial test of a double-turn boiler during testing, purchase a pump from a Ural motorcycle (or similar) and install it in a barrel of fuel. How to do this, see the latest video.

How to make a boiler for mining with your own hands

If you have the necessary materials on hand, you can even make a boiler yourself. The first thing you need for this is a pump to supply oil from the fuel tank to the combustion chamber.

In addition, you will need:

- a tank where the fuel will be stored;

- burner;

- appropriate pump for circulating water in the heating system.

In general, this is all, although in most cases the boiler works more efficiently with a compressor that supplies air; you can do without it, but with it combustion will occur faster.

If all the elements of the future boiler are at hand, then you can begin assembly. Experts believe that assembly is the most labor-intensive process in this matter. The most important thing is the scheme, which must be correctly calculated. You can entrust the development of the scheme to a trusted specialist, and take on the actual work according to the plan yourself.