Steam or hydro?

Vapor barrier and waterproofing are two groups of different films. Each group has its own varieties, which today are marked with letter designations.

- Waterproofing is films and membranes that are installed outside the thermal insulation, that is, outside the room. They protect the insulation from external moisture, that is, from precipitation. They are usually vapor permeable, so they also remove condensation from the insulation.

- Vapor barriers are films and membranes that are installed on the inside of the room, as if before thermal insulation. They protect the insulation from the penetration of water vapor from inside the house.

Now let’s figure out which side to lay the hydro- and vapor barrier.

Types of vapor barrier

Single layer polyethylene films

Made from low-density polyethylene, which provides an increased degree of steam penetration. This material often has defects due to the ingress of foreign particles during manufacturing. The cheapest type of insulating material .

Polyethylene films with reinforcement

Compared to single-layer polyethylene, reinforced vapor barrier has a slightly greater thickness , as it includes a reinforcing frame. It consists of polymer twisted threads located in mutually perpendicular directions. The mesh is attached to the polyethylene base by warm pressing.

This technique does not affect the waterproofing and mechanical properties of the material, but can reduce the degree of vapor barrier .

Anti-condensation film

It is made of two layers: smooth and fleecy . The smooth layer is attached to the insulated surface. The fleecy layer is created from cellulose fibers. When steam hits such a surface, it clings to the fibrous structure, thereby preventing moisture from flowing onto the underlying structures of pitched roofs. Excess water is removed along with the air through the ventilated space.

Polymers with foil layer

They are made of penofol or foamed polypropylene, coated with a thin layer of metal. Due to the reflective properties of metal surfaces, such vapor barrier provides an additional function of protection against heat loss .

Membranes (film for roof vapor barrier)

Membrane vapor barrier materials are divided into five main classes :

- Type A. Has increased resistance to moisture and wind. It is laid between the roofing covering and the heat-insulating layer. Manufacturing technology: spunbond. This vapor barrier does not allow moisture to flow through the cracks of the roofing material, as well as from the condensation that forms. The absence of a laminating layer allows the use of such membranes in roofing structures with a slope of more than 35 degrees . To remove excess moisture, it is necessary to install ventilation holes from a double sheathing located between the membrane and the insulation.

- Type AM . Unlike Type A, it has a multilayer structure . It is placed between the insulation and the roof to provide adequate protection from negative atmospheric influences. The most common is a three-layer construction, consisting of two layers of spunbond with a diffuse film located between them. It acts as a waterproofing agent, as it allows steam to pass through but retains water. Laying is done directly on the heat-insulating layer, which reduces labor costs for creating a ventilation gap.

- Type B. Double layer material. Consists of a layer of vapor barrier film and spunbond. It is used to protect insulation from internal building vapors. For use only in insulated roof structures .

- Type C. It is manufactured similarly to type B membranes. It has a stronger and thicker layer of spunbond, which provides better protection of the insulation from moisture. Used in insulated and non-insulated, pitched and flat roofs .

- Type D. Consists of polypropylene fabric, protected on one side with a laminating polymer coating. The structure of the material allows it to withstand significant mechanical stress . This dictates its installation between the insulation and the attic floor screed, as well as in non-insulated roof structures.

Laying waterproofing

Places of application: insulated roofs, structures with external insulation, suspended ventilated facades, attic floors.

How to lay: in the middle between the insulation and the outer cladding, the rough side towards the thermal insulation, the smooth side out. Often there is a manufacturer’s logo on the waterproofing; such a film should be attached with the logo facing out.

Characteristics: water resistance - from 300 to 1000 mm water column, vapor permeability - from 800 to 2000 g/m2 per day, tensile load - from 160 to 190 N/50 mm.

Types of vapor barrier materials

The classic vapor barrier material is polyethylene. This material requires careful handling, since if the film is stretched too much, it can tear when climatic conditions change. But there is one very important condition. Polyethylene must be perforated, otherwise it will not allow air to pass through, in addition to steam. It will not be possible to obtain a comfortable microclimate in the building with such a film. If this polyethylene is used as a membrane, it will interfere with the flow of air mass; it cannot be used for vapor barrier.

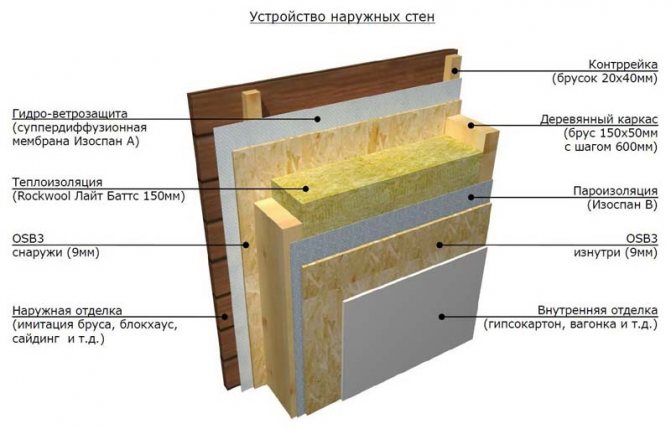

Scheme of vapor barrier of walls from the inside.

You can perforate polyethylene film with a special device. Take a roller with nails driven in. Such a “modernization” of polyethylene film will not be able to provide reliable vapor barrier for internal walls. Of course, membrane materials are very similar to polyethylene film, but they are very different from it in their multilayer structure.

Builders often use special mastics as vapor barrier materials. After application, such mastic is capable of allowing air to pass through while retaining moisture. Surface treatment with such mastic begins before finishing begins.

Membrane films have become a modern material that is used today when laying vapor barriers.

This material is able to prevent moisture from entering, while at the same time allowing air flow to pass through. Such membranes have a certain vapor permeability, which ensures normal operation of the insulation. When such a vapor barrier is installed, the cotton insulation does not get wet, the walls “breathe”, and there is no freezing.

Laying a vapor barrier

We figured out how to lay waterproofing, now we move on to vapor barrier.

Places of application: insulated and “cold” roofs, internal and external walls, frame walls, floors with a concrete base, interfloor, basement and attic floors.

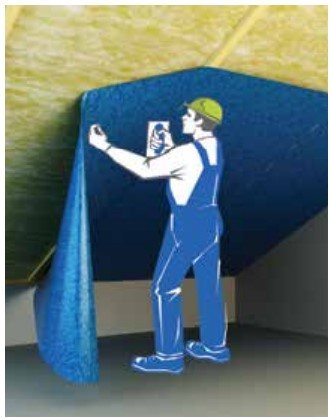

How to lay: exclusively on the inside of the insulation. The smooth side is towards the insulation, the rough side is towards the inside of the room. Professional builders recommend leaving a ventilated gap between the insulation and the film.

Characteristics: tensile load - from 135 to 1070 N/50 mm, resistance to steam - about 7.0 m² hour Pa/mg (or vapor-proof), water resistance - at least 1000 mm water column (or waterproof).

Cases in which isolation is necessary

There is a list of cases when the use of insulating material is simply necessary. When it is necessary to lay mineral wool as internal insulation, a vapor barrier is extremely necessary. The fact is that the material absorbs water extremely strongly, after which it settles. A layer of protective film avoids this problem.

The walls of frame houses should also be protected with a layer of film. The reason is similar to the first case. Inside sandwich models there is an insulating material that is resistant to exposure to water.

For ventilated facades, and in addition, external walls, it is worth attaching a layer of insulating material to protect against wind. The film provides protection from air currents, preventing the material from collapsing under the influence of the elements. As a result, the material breathes well and lasts a long time. Most often, such insulation is used for brick walls covered with cotton insulation.

The vapor barrier device ensures the maintenance of a constant indoor microclimate. This has a beneficial effect not only on the integrity of the building, but also on the health of the residents of the house. In addition, the material does not emit harmful substances when exposed to high temperatures, which is also a very pleasant quality.

Return to contents

What to do with the rest of the films?

Let's assume you bought non-specialized material. How to lay such hydro- and vapor barrier? Professional builders give general advice:

Which side should the hydro vapor barrier be laid on?

According to all the canons of physics, when the temperature decreases, vapor from the air always condenses, turning into liquid. In construction, this rule is always taken into account when arranging structures operating at the junction of the temperature difference between the room, insulation and the street, the ground. These include the roof, walls, base, and floor. Without high-quality insulation, a large amount of moisture accumulates on surfaces and in the structure of materials. This inevitably leads to deterioration of the properties of the foundations and their gradual destruction.

To avoid the negative consequences of the condensation process, when constructing critical structures, a specialized film is used - hydro-vapor barrier. Which side to put it on correctly is an important question.

Installation of water vapor barrier: which side?

There are several types of films. According to their structure they are divided into:

- Single-layer and double-layer (multi-layer);

- Diffusion;

- Anti-condensation.

The main task of builders is not to make a mistake on which side to lay a particular type of water vapor barrier, depending on the installation location. Incorrect application will lead to the opposite process: subsequent condensation of moisture on the surface of the membrane, as evidenced by the photo of improper arrangement of water vapor barrier.

Which side to lay a single-layer hydro-vapor barrier?

Simple single-layer films are made from polyethylene. Sometimes it is additionally reinforced with a polymer mesh to add strength. This material retains water, but allows steam in, in both directions. Therefore, the choice of installation side does not play a special role here .

It is only worth noting that such products have lost their relevance due to low efficiency and the emergence of membrane films.

Which side should the diffusion hydro-vapor barrier be laid on?

Modern film water vapor barrier for roofing is produced using a woven method from pure, 100% polypropylene. Its structure, if you look closely under a microscope, is a network of thin threads. Their interweaving forms microscopic cells. Their size is not sufficient for the unimpeded passage of water molecules in a vapor state.

High-quality diffusion hydro-vapor barrier for floors or roofs is made in two layers. Its specificity lies in its operation on the principle of a valve: passing steam from the air in only one direction (from an area of high pressure to an area of low). When there is oversaturation of moisture in the air in the room and under the influence of steam pressure (diffusion), water molecules literally seep through the film and excess moisture is removed outside.

Such material is laid when organizing a system of ventilated facades, on top of mineral insulation with the obligatory arrangement of a ventilated gap. This water vapor barrier is suitable for floors and walls.

Diffusion films usually have markings for installation, which are different for each manufacturer. Before installation, you must carefully study the instructions. Often such material is made dark and rough on the back side, lighter and smoother on the outside.

Installation is carried out with the light (water-repellent) smooth side facing away from the room in the following cases :

- for insulation when arranging the under-roof space;

- under insulation when laying the floor on concrete or soil;

- external thermal insulation when installing ventilation facades.

When installing a floor under a screed, protecting walls and ceilings in wet rooms (for example, baths, saunas), the water-repellent side should face the inside of the room:

Which side should the anti-condensation hydro-vapor barrier be laid on?

To give the material improved vapor barrier properties, one side of the diffusion film is coated with a special moisture-absorbing hydrophobic coating, polyester fabric, or an aluminum reflective layer is applied. Such membranes are called anti-condensation and superdiffusion. Due to the absorption of condensate, this hydro-vapor barrier is best suited for cold roofs: pitched type with metal decking. The absorbed moisture prevents the formation of metal corrosion. The additional layer provides better thermal protection.

Installing a vapor barrier in a garage in Moscow

Choose reliable craftsmen without intermediaries and save up to 40%!

- Fill out the application

- Receive offers with prices from masters

- Select performers by price and reviews

Order installation of vapor barrier in garage

Our website will help you quickly find a private craftsman or team to perform any repair work. Just place your request, and within a few minutes you will receive offers with prices from available craftsmen ready to fulfill your order.

Feedback on the task

Super master, did everything well and quickly!

Feedback on the task

Thanks to Alexander and Ivan for installing the partitions!

Feedback on the task

Alexey did everything in the best possible way, you can immediately see that he is a pro! God bless you!

Feedback on the task

We leveled the floor in the garage on a turnkey basis. I'm pleased with the result.

Feedback on the task

Oleg made the garage floor efficiently and on time

Roof vapor barrier device

There are two types of attics - cold and insulated. Vapor barrier is required for each of them, but in the first case it is installed directly on the attic floor, and in the second it is part of the roofing pie.

In the process of life activity in the house, moist air (steam) is formed, which rises to the ceiling and penetrates higher - through the attic into the roof. An insulated roof gradually begins to absorb moisture, which leads to a change in the structure and properties of the thermal insulation layer. Modern materials are not subject to rotting, they are not destroyed by humid air, so from this side they are not afraid of moisture. But in any case, the materials become damp and mold may appear inside, which negatively affects the microclimate of the room and the service life of the roof.

Read the series of articles on roofing: Vapor barrier for the roof Lathing for corrugated sheets How to choose the right slate How and with what to paint flat slate How to cover a roof with tiles

The steam rising upward contains small particles of water. In this case, only membrane films or other materials created specifically for vapor barrier can protect against diffusion. The membranes allow air to pass through perfectly, but do not allow moisture particles to penetrate the roof. Thus, even if the dew point is inside the roofing pie, condensation will not form there, and the insulation will remain safe and sound. And thanks to the gaps that are always left when installing the roof, air calmly circulates inside.