To install sewerage in a private house, special pipes and fittings must be used.

Without them, it is impossible to connect pipes. These shaped parts are made from a variety of materials, which affect their service life and sales value. Modern polymers are considered the most popular material for the production of pipes, adapters and fittings. Such products are much more convenient to use than installing their cast iron counterparts. Moreover, all the main parameters of such parts are exactly the same as those of steel elements.

Polymer pipes, as well as additional fittings, are made from several materials:

- Polypropylene - PP,

- Polyvinyl chloride - PVC.

To make a pipe connection, special adapters are used. They are very easy to maintain and install.

Why do you need an adapter?

Such parts belong to pipeline fittings, without which it is impossible to connect parts of different diameters. Moreover, such adapters are capable of connecting parts made of different materials.

Note that adapters are used when installing any type of sewer system; they remain the most indispensable part.

Today, a variety of materials are used to make them. They may differ in shape and size. Basically, the following popular materials are used for manufacturing:

- PVC;

- Polypropylene;

- Cast iron;

- Steel.

The design of adapters has several types:

- Concentric. Used only when installing a vertical line;

- Eccentric. Parts are used only when the pipes are horizontal.

Calculation of a pipeline made of polypropylene pipe

Home > Articles > Communications > Heating

Centralized heating systems belong to the main engineering communications of any settlement or individual facility, including several structures. Their pipelines are designed according to specific requirements and made from specific materials. In recent years, the effectiveness of using HP TREND PPR PN 20 and HP TREND STABI polypropylene pipes on such utility networks has been confirmed. However, there are certain sections of communications where metal still remains indispensable.

Required initial data

The calculation of a pipeline made of polypropylene pipe is carried out using the same method as was previously used for a metal pipe. But it will not be reliable and durable if operating conditions are not taken into account. Pipes based on polypropylene do not require open installation. The only exceptions are technical and installation rooms. Therefore, when designing heating networks, they often resort to more economical and safe solutions.

The development of such projects begins with drawing up schematic diagrams of the proposed piping. There they also choose the optimal engineering system (one-pipe, two-pipe, collector, combined, etc.), as well as ways to minimize mechanical and other damage. Therefore, the correct calculation of the cost of a pipeline made of polypropylene pipe should take into account the costs of insulating individual sections, the ability to compensate for linear expansion in the system, etc.

In order for the designed network to be of high quality, aesthetically pleasing, reliable and durable, you need to know its operational characteristics:

- maximum possible temperature, 0C;

- maximum permissible pressure (P, MPa);

- average value of the safety factor in heating systems (k=2.5);

- number of days of system operation per year;

- wall thickness of the pipes used (s, mm);

- the value of their outer diameter (D, mm).

Minimum operating time of heating systems

The service life of the designed heating system pipes can be determined by the calculated stress in their walls (QY).

QY = P(Ds)k/2s

The resulting value is transferred to the vertical axis of the graph. We find where the temperature isotherm of the transported liquid intersects this horizontal line (usually 80 0C). Next, from the resulting point we descend to the horizontal time axis (t, hour) or (t, years). This number is valid for continuous use of the system. Having drawn up the proportion for our case, we will obtain the operational duration of the pipeline with the given parameters. The deadline will be realistic if all installation and operational standards are observed.

Methods for adjusting service life for polypropylene pipes

If the calculated results differ from the required service life, in order to be able to use PPR pipes in heating networks, established standards allow the following adjustments:

- Reduced operating pressure. It is allowed to reduce the original value to the designed value and update the calculations performed. This will lead to an increase in service life.

- Reducing the operating temperature of the fluid. It is possible to reduce the calculated value to the minimum required and rebuild the schedule. This will make it possible to increase the service life.

Changes are allowed when installing communications in closed installation conditions (warm floors, heated structures, etc.).

Underfloor heating and its features

Water underfloor heating is used in both residential and industrial construction. It is installed in residential buildings, gyms, playgrounds, stadiums, industrial enterprises, and warehouses. It is used to warm bridges, underpasses, driveways, open staircases, parking lots, runways, etc.

When installing such water communications, it is important to comply with the temperature of the heated material established by the project:

- in residential premises 26-29 0C;

- in bathrooms 30-33 0C;

- along the contour of the pools 33-35 0С;

- for steps and parapets - depending on their location.

Reducing the flow speed moving through the pipeline to 0.3 m/s helps to transfer heat from water pipes to the heated mass (base) as much as possible. The calculation of pipeline pressure from a polypropylene pipe in such cases is carried out based on the designed temperature value for a given object. Usually it is not higher than 45 0C, which implies a pressure value in the pipes of up to 0.3 MPa.

Such heating circuits are equipped with HP TREND PPR PN 10 (PN 16) pipes. Their design - coils or skeins, also most satisfies the laying conditions, allowing you to avoid unnecessary nodes and connections. Installation is carried out in a spiral, in the form of loops or in combination. Calculations can be made to select the required pipe diameter and laying pitch.

When implementing underfloor heating, the required heat transfer of the material and the minimum permissible temperature of the base are taken into account. They can also be adjusted by the pitch and length of the contours used. If the heating coil exceeds 100 m, two independent circuits are made, and the arrays with them are separated by expansion joints, for filling which elastic materials are selected. The seams will prevent the structure from collapsing during thermal expansion of the arrays.

The distribution and receiving manifolds of the heating circuits are located close to each other, in cabinets or niches. Pipes in arrays are mounted on a metal mesh or on special insulating mats. When performing work, care must be taken to avoid damage to the pipeline.

Having calculated the pipeline from a polypropylene pipe and laid it, the system is filled with water to take the given shape. Next, the remaining layers of the floor are laid. For comfortable operation, underfloor heating must meet the requirements of the heating system of the entire room and complement it.

Basic properties of adapters

When laying sewer pipes yourself, PVC adapters are always installed. They make it possible to create any, even the most complex, pipeline configuration, as well as connect the necessary plumbing devices to it.

Thanks to sewer adapters, several technological operations can be carried out:

- Change the direction of the pipeline;

- Change to another size;

- Dispose of sewage when its temperature does not exceed 60 degrees;

- Remove chemical waste.

What types of adapters are there?

As mentioned above, various materials are used to make adapters. Details are divided into several groups:

- Transitional couplings. They are used to connect pipes of the same diameter. They are made in the form of a barrel. With such a coupling, the internal diameter is equal to the external size of the pipe used;

- Corners. Their bend is in the range of 45–90 degrees. The industry produces corners with threads on one side so that it is possible to connect a mixer;

- Crosses, as well as their analogues, tees. The parts are used in areas where several pipes are connected at the same time. Each side of the tee can have a specific diameter. There are metal tees equipped with an external thread at one end. The other end has an internal thread.

- Contours. These special devices make it possible to reduce the number of pipeline connections. Thanks to a certain bend, they can be used to bypass the pipe;

- Compensators. A device for smoothing temperature changes. The parts take on powerful shocks occurring in the system;

Properties of adapters installed on cast iron pipes

Many houses still have cast iron items. Therefore, when installing a sewer system, situations quite often arise in which it is necessary to connect pipes made of completely different materials. Most often you have to join plastic with cast iron.

To perform such a technological operation with high quality, it is simply impossible to do without a special adapter for cast iron. He will help you do this work quickly with minimal cost.

To ensure tightness, a rubber cuff is used. It is installed during any transition.

The inner cuff is inserted into the cast iron socket. This makes it possible to insert a plastic pipe of a certain diameter.

The outer diameter of the cuff is equal to the diameter of the socket. Therefore, the connection does not require additional treatment with sealant.

If there is no socket, a special external adapter is used to make the connection.

When the cast iron connection is completed, you can continue installing the plastic sewer system.

Sealing pipe joints

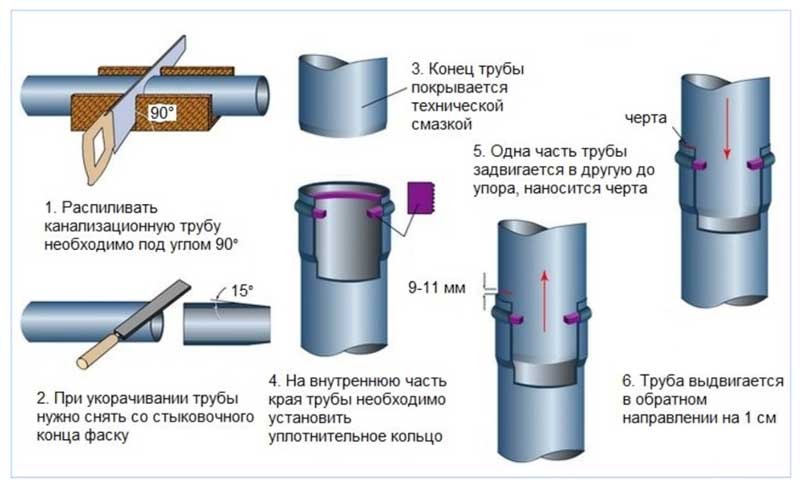

Rice. 11 Joining PVC pipes in the sewer

When installing a sewer line from plastic pipes, special sealing of the joints is not required - the sealing is carried out using built-in rubber rings. To increase the reliability of connections, you can use neutral or acidic silicone sealants for pipes - they additionally cover the cracks in socket joints. You can also use various adhesive insulating tapes for pipes (bitumen-based, foil tape, isolon) - they are wound from the outside in a spiral overlapping the butt joint.

Plastic bends play an important role in sewer line installation, allowing the line to be redirected at a wide range of different angles, sometimes using two bends in a group for a smooth transition. They are easily mounted by installing them into pipe sockets after simple preparation - removing the outer chamfer and lubricating the surface with soapy water or oil.

Types of compression adapters for HDPE

Please note that any compression fittings are complete products. Such adapters are divided into several types:

- Couplings. Manufactured in different sizes. The industry produces compression fittings equipped with metal threads. The design of the couplings provides for external thread cutting. Internal threads can also be cut;

- Corner outlet. This part helps change the direction of the highway. Manufactured with different threads;

- Tee. Helps to move the pipeline away from its original position, maintaining 90 degrees. The tee design is equipped with couplings on each side. The required thread is cut on one of them;

- Saddle. The part has two parts that crimp the pipe. It is used only when it is necessary to insert into a pipeline;

- Flanges. With their help, it is easy to connect metal products and HDPE pipes;

- Stub. It is installed on the end of the pipe and seals the pipe hermetically.

Types of adapters

Depending on the connection method, adapters are divided into certain groups:

- Welded;

- Glued;

- Threaded;

- Rubber.

In principle, the design for joining plastic and metal can have a variety of types:

- Coupling. Used in pipelines where there is no socket;

- Reduction. A part that makes it possible to connect parts of different diameters;

- Revision. The device is equipped with a lid. Through this hole you can get into the pipeline to clear the blockage. In the case of external sewerage, a well is installed;

- Retraction. The part makes it possible to direct the line at the desired angle, in the range of 30 – 90 degrees.

Size range

Ability to withstand pressure

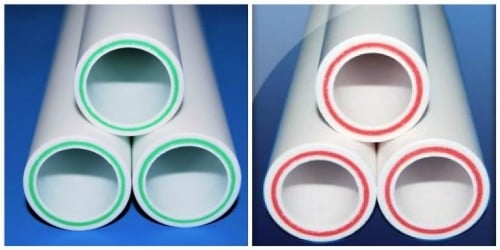

In general, products made from this material are divided into four main groups according to their ability to withstand a certain pressure:

- PN-10. The usual operating pressure is 1 MPa (a slight excess is allowed, just like other groups). Used to create water pipes with low temperatures.

- PN-16. Typical operating pressure is 1.6 MPa. They can be used for laying a system intended for cold water (up to 20 ° C), as well as one intended for hot water (up to 60 ° C).

- PN-20. Typical operating pressure is 2 MPa. Designed for hot (up to 95° C) water supply.

- PN-25. Typical operating pressure is 2.5 MPa. They are most often used for installation of heating systems, less often - for hot water supply.

The elements of this group are additionally reinforced. It is better to choose those options that use fiberglass as an additional layer. Know that the colors of this layer in different models do not indicate their quality, strength and other indicators. It’s just that each manufacturer chooses it at his own discretion.

The dimensions of polypropylene pipes and fittings are determined by three main parameters: diameter, length (for pipes) and wall thickness. Length is a secondary indicator. The most important parameters include the diameter (depending on their method of use: wiring, supply to the washing machine, etc.) and wall thickness (it is affected by the diameter of the product and its maximum permissible pressure ratings).

By wall thickness

Depending on their diameter they can be divided into groups:

- Ø-20 PN-10 — 1.9mm; PN-20 - 3.4mm; PN-25 - 3.4mm.

- Ø-25 PN-10 — 2.3mm; PN-20 - 4.2mm; PN-25 - 4.2mm.

- Ø-32 PN-10 — 3.0mm; PN-20 - 5.4mm; PN-25 - 5.4mm.

- Ø-40 PN-10 — 3.7mm; PN-20 - 6.7mm; PN-25 - 6.7mm.

- Ø-50 PN-10 — 4.6mm; PN-20 - 8.4mm; PN-25 - 8.4mm.

- Ø-63 PN-10 — 5.8mm; PN-20 - 10.5mm; PN-25 - 10.5mm.

Special adapters for steel pipes

The connection of metal pipelines is carried out using special adapter designs. These include:

Straight fittings. They are used when there is a thread on the internal cone, for a threaded connection along the internal cone. The part helps to join pipes and go from 4 mm to 11 mm, from 20 mm to 29 mm.

Straight fittings where the thread is cut on the outer cone. M8 is connected to the transition M10, M39 with the transition to M45.

They can also connect the threads of the outer cone and the sealing rubber. Thus, a connection is made between M12 and M16 threads and more.

Straight fittings in which the ends of the part are made to allow the use of a threaded connection. In this way, the copper parts are connected. The device is installed in domestic and technical water supply systems. 1/8 - 4 inch pipes are joined. Threaded connections can be made using external threads. It is possible to install a coupling with an internal thread.

Transitions. This special part is designed for welding joints of parts with a diameter of 20 - 1000 mm.

The definition of an adapter intended for pipelines of various diameters also applies to bends and tees that connect pipes of different sizes.

The fittings discussed are made from a variety of materials. Moreover, all of the above fittings are made from various structural materials and non-ferrous alloys. The main ones are:

- Low carbon steels;

- Copper;

- Alloys based on copper.

Some adapters have their own “natural look”. Most parts are produced with a special, additional coating. For example, nickel adapters. The main material is steel coated with a nickel alloy. As a result, the corrosion resistance of the part is greatly increased.

Pressure classification

Markings used for polypropylene structures often contain the designation N25, N10, etc. Based on this indicator, it is possible to determine the ability of the material to withstand the pressure of the liquid that circulates along the line.

All polypropylene pipe products offered on the market can be classified into the following types:

РN10

The main performance characteristics of these products are a pressure on the wall of 1 MPa, as well as a thickness of the order of 1.9–10 mm. On their basis, heated floors are often installed, as well as cold water supply systems at an operating temperature not exceeding 45 degrees. The following can be said about the geometry of these structures: the outer diameter is 20–110 mm, the inner diameter is 16–90 mm.

PN16

Products of this type often find application in major areas. The working pressure for it is 1.6 MPa. These products can be used in the installation of cold and hot water supply systems , for which the heating limit of the coolant is not 60 degrees.

PN20

During operation, polypropylene structures of this category can withstand a pressure on the wall of 2 MPa, the wall thickness is 16–18.4 mm. hot and cold water supply systems are created based on this material , in which the temperature of the transported liquid does not exceed 80 degrees. Products are manufactured with an outer diameter of 16–110 mm and an inner diameter of 10.6–73.2 mm.

РN25

These polypropylene products are designed for a pressure of 2.5 MPa and are distinguished by the presence of a reinforcing layer based on aluminum foil. Most often they are used in the construction of heating systems, as well as the installation of hot water supply systems, which are used to deliver liquids with temperatures up to + 95 degrees . A special feature of these structures is their multilayer structure, which allows them to withstand thermal and impact loads well. Finished products have a diameter of 13.2–50 mm, the outer diameter is 21.2–77.9 mm.

Adapters for different materials

You have to deal with mismatches of materials quite often. For example, plastic pipe and cast iron. Dealing with such a problem is very difficult.

There may be several reasons for the mismatch of pipeline materials:

- I would like to save money on a certain section of the highway;

- Application of new technologies;

- It is impossible to buy a part from the required material.

For example, a working water supply system was installed many years ago. The pipeline was made of steel.

To modernize the structure and replace steel pipes with polypropylene pipes, you will need adapters. With their help it will be possible to connect various materials. They connect any materials to each other. For example, a threaded adapter makes it possible to connect polypropylene to steel parts. One part is equipped with a brass thread, and the other with a plastic thread. Sometimes, instead of such a thread, the adapter is equipped with a special end for welding.