How to understand that the water in the heating system does not meet standards

Water from reservoirs, wells and city water pipelines is guaranteed to have high hardness so that it can be used directly in the boiler, only with different indicators. Any of them is dangerous for the boiler and water heating equipment.

You can verify this yourself by performing express tests using test strips to determine water hardness. They can be purchased at hardware stores or pet stores.

Paper indicators are treated with reagents; when they get into water, they acquire a certain color, which is compared with a standard scale.

Water hardness is determined in degrees (°F). According to GOST No. 31865 of 2012, the following hardness indicators are established by which natural water is classified:

- not higher than 2°F - soft;

- not higher than 10°F - average;

- above 10°F - extremely hard.

For use in boilers, water with a hardness of 2-5°F is already dangerous because it promotes scale formation, so it will need to be purified with water softening.

How to determine whether it is time to change the coolant?

The decision to replace glycol is made based on a chemical analysis of the working fluid. At D-Service, such research is performed free of charge and does not oblige the client to anything.

Based on the analysis, specialists can not only issue a conclusion about the need to replace the working fluid, but also make recommendations for changing its properties. We evaluate how the operating conditions of the system compare with the composition of the existing antifreeze.

Often, by selecting a different grade of ethylene glycol or propylene glycol, greater efficiency can be obtained from refrigeration and air conditioning units. In this regard, replacing glycol-based coolant can lead to improved equipment performance. On average, the service life of propylene glycol and ethylene glycol is 5 years.

Types of water softening filters

The domestic market is overflowing with offers for water purification filters, both domestic and Western-made. The user needs to understand which softener is best suited for the boiler and autonomous heating system. Next, you will need to select the most appropriate purification method for the initial composition of the water.

Polyphosphate filter

The most affordable and cheapest water softening filter for a boiler, and at the same time a very effective cleaning option. The ion exchange polyphosphate filter module consists of the following basic elements:

- Plastic container in the form of a flask, transparent;

- protective cover for cartridge replacement;

- drainage;

- softening chemical reagent—polyphosphate salt.

Raw or tap water enters the filter container, circulates through a chemical reagent in the form of polyphosphate salt crystals and is impregnated with sodium polyphosphates, forming a phosphate film. It envelops hardness salts, thereby neutralizing their scale-forming properties and protecting boiler heating surfaces from salt deposition.

Polyphosphate is a toxic substance, so after contact with it, water becomes undrinkable. These softeners must be used carefully in hot water supply systems, since due to possible leaks in the structure, water may enter the hot water supply or hot water supply line.

The service life of polyphosphate filters, or rather dissolving polyphosphate salt, is short. The standard consumption of the reagent is 5 grams per 1 ton of water. The reagent is replaced when its volume in the flask is halved. This happens after about six months of filter operation. The cost of polyphosphate ion exchange filters ranges from 500-1400 rubles, and replacing polyphosphates will cost the owner up to 350 rubles.

Magnetic filter

This is the most expensive and effective cleaning method. If you install a compact permanent magnetic filter in front of the boiler, you will not need to constantly regenerate it or change the filter material. It cannot soften water, that is, remove hardness salts from it.

The principle of its operation is different and is based on the transformative effect of a magnetic field on water, as a result of which its structure changes briefly.

Passing through the magnetic filter element, boiler water changes its own physical qualities, while the crystallization process when heating the liquid occurs more intensely, but not on the surface of the heated boiler walls, but in the water column. In connection with this, sludge is formed, which is easily removed by blowing or in a mud pan in front of the boiler.

A characteristic feature of this method of softening boiler water is the temporary nature of magnetization of water, therefore such a filter is installed as close as possible to the boiler unit.

The advantage of this treatment is that when water passes through a magnetic filter, it does not become technical and harmful to humans, therefore it is applicable in double-circuit boilers with hot water heating.

The service life of such softeners is practically unlimited, since the device has no moving or rubbing parts. The cost of installation ranges from 1,500 to 25,000 rubles, depending on the brand, design and hourly productivity of purified water.

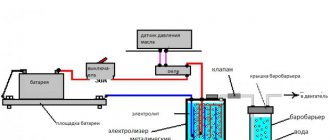

Electromagnetic

At a high temperature of hot water in the boiler circuit and a high circulation speed, complete separation of hardness salts from water only with the help of magnetic treatment often does not occur, especially for natural waters with high hardness. To enhance the magnetic effect, electrical treatment of the water is added by placing a specialized electrical treatment on the magnet.

Such a device also functions by treating the source with a magnetic force field, the strength of which is regulated by an effective electrical processor. This pair makes it possible to get a longer lasting effect.

The operation of such a device does not depend on pressure changes and temperature conditions. Transforming hardness salts not only do not harm the boiler, but also act as softening agents for previously deposited scale. Installation cost: from 5,000 to 30,000 rubles.

How does hard water affect boiler performance?

It is incorrect to consider the impact of low-quality water on a gas boiler without understanding the operating features of the boiler itself. There are all kinds of boilers, and each has its own operating nuances. Likewise, a gas boiler determines some features when supplying water, etc. There are three types of boilers:

- Gas;

- Hot water;

- Steam.

Gas ones naturally run on gas. This makes adjustments to equipment maintenance. Unlike steam and water heating devices, gas heating boilers have their own additional costs and work:

| Type of boiler equipment | Additional Maintenance and Costs |

| Gas | Gas prices (change) Constant work to remove carbon deposits Fighting soot Burner maintenance - cleaning |

For gas systems, the main concern, in addition to water softening, is working with gas. The burner and burner are open and heating comes directly from the fire. The gas supplied to enterprises often contains impurities and the burners smoke very heavily. Maintaining fire surfaces and burners in a clean condition also plays a big role in maintenance. These are additional costs. A gas boiler requires softened water no less than others. Only other filters have costs for heating water, as payment for electricity and payment for purifying steam, which is also obtained by boiling. What are the features of water operation in a gas boiler? Here the water is heated by direct fire. And scale will accumulate precisely in places where fire is concentrated. And you will have to remove both plaque and soot. That is, work from both sides.

What is the negative effect of hard water from a well on a boiler? The worst thing is scale deposits. It is this that has the properties of blocking the transfer of heat to water. Scale deposits have very good dielectric properties. When the surface covered with plaque becomes hot, the heat practically does not seep into the water, and the boiler begins to heat the water poorly. Everything remains to cook in the metal surface. That's why terrible accidents happen.

The surface begins to crumble and melt. The loads are very heavy; even hardened materials cannot withstand constant overheating. It turns out that using hard water is a direct path to a boiler explosion. Unless the maintenance staff strives to prevent all this. You can avoid this in several simple ways - using soft water and constant care of the boiler surfaces. But regular cleaning and rinsing will negatively affect the surfaces of boilers. They become overgrown with plaque faster and suddenly break faster. And all because of the raid. There is one way to protect the boiler from this - by softening the water for the boiler .

The best filters for the boiler

Before making a choice, you need to refer to the factory instructions and familiarize yourself with what the manufacturer offers as water treatment for the boiler. Then, in any SES laboratory or even from a water supply company, you need to take complete results of an analysis of the water that will be used to feed the boiler and heating networks. Before you begin selecting possible modifications, choose from a line of boiler or water heater filters.

In addition, when choosing, experts also advise paying attention to the following parameters:

- Productivity - determines the hourly volume of purified water, m3/hour.

- Dimensions and installation area so that the purifier can be integrated into the existing free space in the boiler room.

- Thread diameter - it must correspond to the diameter of the heating systems.

- Brand - it is safer to purchase a filter from a popular manufacturer and in branded stores. Unfortunately, there are many counterfeits in the retail chain, and in addition, in branded stores you can issue a reliable guarantee and consult on the procedure for using the filter.

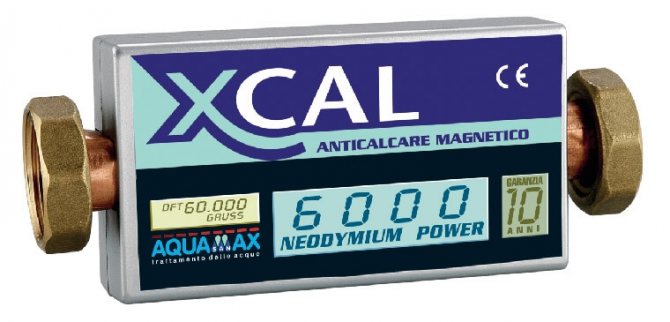

Magnetic filter Aquamax XCAL MEGAMAX

Aquamax XCAL MEGAMAX 1/2″ is an Italian highly efficient magnetic anti-scale filter for boilers and boilers. It cleans the heating surfaces of boilers from limestone formations. Designed for heat supply systems with high circulation rates.

The MEGAMAX magnetic softener is made of first-class non-corrosive steel and is considered not dangerous to people. The device does not require changing filter materials. Suitable for boilers with 1/2" piping and can purify water 0.8 m3/hour. Price: 1860 rub.

Phosphate filter Ecosoft SCALEX 200

The filter for the heating boiler Ecosoft SCALEX 200 prevents the formation of scale in heating systems and contains an ecological filter media that does not have polyphosphate, which allows its use not only in heating boilers, but also in hot water supply systems.

The SCALEX 200 filter has the function of chemical water purification and performs mechanical purification of suspended solids and rust products up to 100 microns in size.

Ecosoft SCALEX 200 does not remove hardness salts from make-up water, but has a comprehensive effect on them thanks to the simultaneous use of 3 protection mechanisms:

- Stopping the growth of hardness salt crystals.

- Destruction of the beginnings of foci of scale crystallization.

- Prevents the connection of scale-forming crystals with each other.

The filter can operate without replacing the filter material for 6 months. Cost 1260 rub.

Anion filter SVOD-AS sbb10

A powerful softener can be used not only in domestic heat and power engineering, but also in industrial boiler houses. The device purifies water from hardness salts, heavy metals and any suspended pollutants and impurities.

Water is processed in a special anion exchange cartridge, the reagent of which is processed using a special technology with chemically active components. As a result, Ca and Mg ions in the water are replaced by Na ions, thereby creating easily soluble sodium salts that do not deposit on hot boiler surfaces.

The filter housing is made of plastic that can withstand medium pressure up to 6 atm. One cartridge can process 262 m3 of water and has a shelf life of three years. Price 6700 rub.

Magnetic filter Caleffi XS

The Italian filter is designed for boiler water treatment and combines two types of cleaning: mechanical and magnetic, using a neodymium magnet and a transparent sludge collection chamber to visually control the process. The device can operate in an environment at a pressure of 3 atm. and hot water temperature 90 C. Hourly productivity for make-up water is 3.5 m3/hour. Warranty - three years. Price: 5600 rub.

How to fill the coolant into the system

Systems can be open or closed.

Open system

When the circuit is open, there are no problems with filling the system:

- Liquids are poured into the expansion tank;

- All air ducts must be open.

The solution itself spreads along its path.

Buried system

There are several ways to fill a closed system:

- 1) Find the highest point, usually a gas outlet. We put a tube into it and let in the solution. At the lowest point, open the plug. When the system is full, coolant will flow from the bottom tap. Next, take a 1.5 meter hose and insert it into the beginning of the system. We will equip this point with a ball valve and a check valve. An adapter for the pump is attached to the second (free) end. Coolant is pumped into the hose. Next, we connect the hose to the system using an adapter, open the tap and start pumping. It is important not to miss the moment when the liquid runs out; you must not allow air to enter the circulation circle. At this point, the hose is disconnected and the tap is closed. Then do it all over again another 5-7 times to start the circulation of the solution in the system.

- 2) Using a submersible pump. We connect it through a ball valve to the lowest point (not drain). We open all gas outlets. We pour the coolant into a basin or other container and begin to pump the solution into the system using a pump. It is important to prevent air from being introduced into the system. When the arrow on the pressure gauge moves, it means the system is full and the pump can be turned off and the air duct valves can be closed. The operation must be carried out until the design pressure value is obtained.

- 3) According to the algorithm described above, you can pump the coolant using a hand pump for pressing.

- Engineering Communication

Connection to the heating system

In order to independently install a filter in the heating system, carefully study the manufacturer’s instructions and the wiring diagram. Typically, boiler filters have threaded connections: ½ or ¾ inches.

Filter connection location in the heating system

It is installed at the inlet in front of the heating boiler on the return line of the heating system. The distance to the boiler should not exceed 2 meters.

Pre-prepare the filter for installation. For example, a polyphosphate filter needs to be washed to remove small particles of filler, and a cation exchanger needs to be regenerated, that is, pass a saline solution through it.

Next, install the filter using a threaded connection, sealing it with fum tape. Before placement, pay attention to the direction of movement of the coolant, the permissible temperature and pressure of the water passed through. To be able to service the filter, it is cut off from the heating return line with two valves and a bypass line is made.

Price list from 06/02/2020*

| Name of works | Unit | Cost, rub. | ||

| 1 | Installation, battery wiring | dot | price 3,500 rub. | |

| 2 | Installation, battery piping (apartment) | dot | price 4,000 rub. | |

| 3 | Installation of manifold cabinet S.O. (built-in) | PC. | price 5,000 rub. | |

| 4 | Installation of manifold cabinet S.O. (open installation) | PC. | price 3,000 rub. | |

| 5 | Installation of heating system risers up to Ø 40 mm | m/n | price 150 rub. | |

| 6 | Installation of a heating system heating system up to Ø 40 mm with insulation, 2 pipes (without excavation work) | m/n | price 700 rub. | |

| 7 | Installing a heating system pump | PC. | price 3,000 rub. | |

| 8 | Installation of a boiler safety group | PC. | price 3,000 rub. | |

| 9 | Installation of RB heating system | PC. | price 3,000 rub. | |

| 10 | Installation of taps, gate valves, balancing valves | PC. | price 600 rub. | |

| 11 | Installation and wiring of a wall-mounted boiler | PC. | price 12,000 rub. | |

| 12 | Installation and wiring of a floor-standing boiler (up to 60 kW) | PC. | price 15,000 rub. | |

| 13 | Installation of a boiler room in a private house | PC. | price from 25,000 rub. | |

| 14 | Installation of a boiler room with weather-compensating automation | PC. | price from 45,000 rub. | |

| 15 | Pressure testing of the heating system of a private house | PC. | price 3,000 rub. | |

| 16 | Diagnostics of the heating system, on-site (up to 50 km) | departure | price from 3,000 rub. | |

| 17 | Repair and modernization of the heating system | PC. | price according to agreement | |

| Installation (replacement) of a gas boiler >> |

Alternative Mitigation Methods

In fact, in well-executed individual heating systems, leaks in the system are very small, and water is practically not replenished throughout the entire heating season. In such a situation, an alternative way to install water purification systems may be to purchase and fill the circuit with already purified water.

To do this, the user can use the following options:

- purchase purified water of the required volume, purified in powerful water treatment plants, for example, in industrial boiler houses;

- purchase distilled water in a retail chain;

- pour boiled water prepared at home.

All boiler manufacturers must indicate in the technical documentation the permissible composition of water for the boiler and methods of its preparation. It is best to follow these recommendations, then the owner will not have problems with either the boiler or warranty service. It is prohibited to independently add any reagents to the water: vinegar, alkali or acids for pre-boiler water purification.

Distilled water for heating - what are its alternatives?

It must be admitted that a perfect heating medium for a heating system has not yet been invented. This means that each modern coolant is effective only in specific technical circumstances. For example, the temperature of the heating water is considered a necessary factor; if it does not match, the environment changes its characteristics, and the heating system will not be able to operate efficiently.

Antifreeze liquid

The best option for feeding main heating networks is softened water, due to the large volumes of recharge. Therefore, in large residential areas it sometimes amounts to hundreds of tons of water per hour. In cases with a compact autonomous heating system, owners often use a non-freezing liquid that can operate even at sub-zero temperatures, which is especially important in houses with temporary occupants, for example, in a country house.

At low negative temperatures, such a composition does not harden, destroying heating systems, but only loses microfluidity, taking on the form of a gel. As soon as the temperature is increased, the antifreeze completely restores all technical and operational properties.

When choosing antifreeze for your heating system, it is very important to purchase a safe option. The use of antifreeze in heating boilers is allowed only if agreed with the manufacturer. Otherwise, the user will lose the warranty on the unit.

The best antifreeze options

Ethylene glycol filler for heating networks is most popular today due to its low price. However, it also has a lot of negative qualities, and the most unsafe is toxicity. Therefore, accidental inhalation of even a small volume of vapor can cause significant harm to the health of the residents of the house, and a large concentration can lead to death. It follows from this that when using it, you must follow all safety rules.

For boilers with a forced heating system that have two heating circuits: heating and DHW, where there is even the smallest chance of ethylene glycol getting into the hot water circuit, the use of such a coolant is strictly prohibited. For safety reasons, it is tinted bright red to detect leaks.

Today, the most commonly used version of the coolant, which is modernized and free of toxicity, is propylene glycol. Its leaks and steam fumes are not hazardous to health. Leaks into hot water cannot equally harm domestic hot water consumers. This substance is for food use and is actively used in the confectionery industry. This coolant covers the internal walls of the heating surfaces of the boiler, thereby protecting them from corrosion. In addition, the composition includes special additives that suppress scale formation.

Thus, we can summarize that today, among all the available liquid coolants for heating systems, distilled water is the most successful and safe solution.

It provides the best heat capacity, which means it creates an effective heat supply system. Treated thermally or chemically to remove hardness salts that are dangerous to the boiler. It ensures trouble-free operation of all components of the heat supply system.