Using a cast iron radiator for homemade work

You can easily make an excellent water boiler for a stove with your own hands - just like you can build such a miracle stove yourself. And an ordinary cast-iron radiator is suitable as a water heater - you can use the M-140, which is often thrown away after the demolition of old five-story buildings. The approximate capacity of such radiators is 1.5 liters, and their surface area is 0.254 sq.m. If you connect 12 sections, you get a heater with an area of 3 sq.m. and 18 liters of capacity. A boiler welded from sheet material with such characteristics would take up a lot of space, which is an undoubted advantage of this particular design.

Such a stove with a water boiler-radiator can even heat a fairly large bathhouse - up to 100 sq.m. But, before installing the boiler itself, you will first need to disassemble the radiators, clean them of dirt and rinse thoroughly with a hot solution of hydrochloric acid - 6%. Then rinse again with water. Next, the cardboard gaskets between the sections are changed, because the temperature in the oven reaches 600? C, with coal it is even higher. The cardboard will simply burn out and the radiator will begin to leak - to prevent this from happening, it is more advisable to use an asbestos cord impregnated with graphite powder and natural drying oil instead.

Now the radiator parts need to be assembled in the following sequence:

- Nipples with their right and left threads are screwed into the sections being connected, after which the same impregnated asbestos cord is wound around them and both nipples are tightened with a wrench - but without any misalignment of the sections.

- As soon as two of them are pulled together, you can connect the third.

- Now you need to compress the radiator to check the quality of the assembly - despite the fact that the water pressure will be low.

- After all this, you can proceed to the installation of risers - their diameter should be 1 and ? inches. The cold water inlet and hot water outlet can be placed diagonally on the radiator battery, and the other two holes can be plugged with plugs to ensure water circulation through the entire volume. Moreover, one of the risers must have a left-hand thread - if it does not exist, then you can do this: screw a regular nipple into the radiator hole, and a coupling with a drive onto it.

But the battery itself must be placed not in the furnace firebox - but directly in the smoke channel, the one behind the firebox. This is necessary in order to heat the boiler not with direct fire, but with hot gases - cast iron, after all. And it is more expedient to place its entrance and exit perpendicular to the floor.

And in order to increase the natural circulation of water in such a furnace, the return line pipe must be routed through its foundation and underground space - this will increase the temperature difference between the return and hot lines, and the battery in the furnace must be installed with a slight slope to allow air to escape and enter the system. It wouldn’t hurt to install an additional cleaning door in the smoke channel of the stove with a heater.

The main advantage of such a stove with a water heating boiler is the overall dimensions of the sauna boiler room: only 1.6 x 0.2 x 0.7 m.

WHAT IS BETTER OVEN OR BOILER?

What to choose for heating your home - fold the stove or install a boiler ? Laying a furnace will not cost much less than installing a boiler. It is necessary to install a foundation under the stove - which will involve dismantling part of the floor and walls of the House. The stove will heat the air around it well, but it will be cold near the walls and windows, because air draft occurs - from the walls of the room into the inside of the stove - to maintain combustion and further into the chimney, along with combustion products. The oven gives off most of the heat through its walls, which can get quite hot - which can be dangerous if children grab onto it. The efficiency of the stove is no more than 30%, while any boiler has an efficiency of 70%. Your benefit lies in significant savings in wood or coal.

Boiler and boiler of indirect heating

Installation of the boiler and radiators ( heated floors ) will require laying pipes, installing collectors and a water distribution system into the heating circuits. As a result, you will receive a heating system in which all rooms in your house will be evenly heated with the same temperature, it will be warm, and, at the same time, you can safely touch the radiator with your hand and pleasantly walk on the heated floor.

This is explained by the fact that the boiler does not heat the air around itself like a furnace, but the coolant (water or antifreeze) that flows through pipes to radiators that are installed under windows or in a warm water floor . Next, radiators or heated floors give off heat to the air, which circulates and heats the room. Another undeniable advantage of any boiler is its ability to automatically maintain the set temperature in the rooms - you set the temperature, for example, 25 degrees Celsius and the system maintains it itself. That is, you don’t need to get up at 2 o’clock at night and at 8 am on a day off to “throw some wood in the stove.” Another advantage of the boiler an indirect heating boiler can be installed in the system , which will have a reserve and provide hot water directly to the kitchen faucet or shower at any time, that is, there is no need to heat pots of water on the stove to wash the dishes.

heating with solid fuel boiler and radiators

The undoubted advantages of the stove will be its ability to “ work without electricity ” and the ability to heat with any type of solid fuel. Stove heating is well suited for those who have a house with an area of up to 70 m2, live in the house on short visits - 1-2 days a week and are ready to throw firewood into the firebox 3-4 times during the day (get up a couple of times at night and come up the same number of times to the stove during the day).

heating by stove

With all the advantages, stove heating requires increased attention to safety . First of all, there is the threat of fire and the threat of carbon monoxide poisoning , which lead to terrible tragedies. Carbon monoxide (CO, carbon monoxide) is a poisonous gas without color, taste or smell, which makes it especially dangerous. Carbon monoxide appears in the stove due to incomplete combustion of wood due to untimely closing of the stove valve. Limited access of fresh air to the firebox, poor draft and a clogged chimney contribute to the formation of CO. It is very difficult to recognize the initial symptoms of poisoning. Carbon monoxide causes severe drowsiness, confusion, hallucinations, even fainting and coma, and possible cardiac arrest. Help for poisoning is fresh air and an emergency doctor. The most dangerous thing is to think that all tragedies happen somewhere and to someone, but nothing like that can happen to us. When heating with stoves, you must always remember to close the stove valve in a timely manner. Before this, you definitely need to stir the coals with a poker - there may still be charred firebrands that need to be broken up and the larger ones thrown into a bucket of water and taken outside. It is necessary to understand that help for carbon monoxide poisoning may not arrive in time, because there will be no one to call it. Monitor your stoves or install pellet boilers in a ventilated, separate room.

Your benefit: Heating with a boiler and a system of radiators or heated floors will be safe, economical and warm, and can also automatically maintain the set temperature!

How to make an autonomous water supply

How to make an autonomous sewer system

The more convenient and cheaper it is to heat

Where is the office located?

How to choose a boiler

Rules for installing a boiler in a brick kiln

Making good boilers for installation in a stove with your own hands is not a difficult task, but there are subtleties and nuances here too. For example, it is better to take a thick-walled and seamless pipe for them, but in the most extreme case, when there are no other options, you can take one with a seam - but be sure to weld it again before that.

It is best to weld the supply near the edge of the upper thick pipe, but the return – wherever your heart desires, it will still work. Further, pipes cannot be butt welded - it is necessary to chamfer along their edges so that the welding seam is the same thickness as that at the pipe walls. But when butt welding, some places can easily turn out to be poorly welded, and therefore the boiler will begin to leak.

The optimal distance between the knees is 5-6 cm, this is the most convenient way to cook. By the way, if it suddenly turns out that the new boiler is leaking into the brick oven like a sieve, it’s okay. All holey places will just need to be cleaned with a grinder, a grinding disc and rinsed again.

It is necessary to place the boiler in the furnace strictly according to the level, although very small errors are still acceptable. But - small.

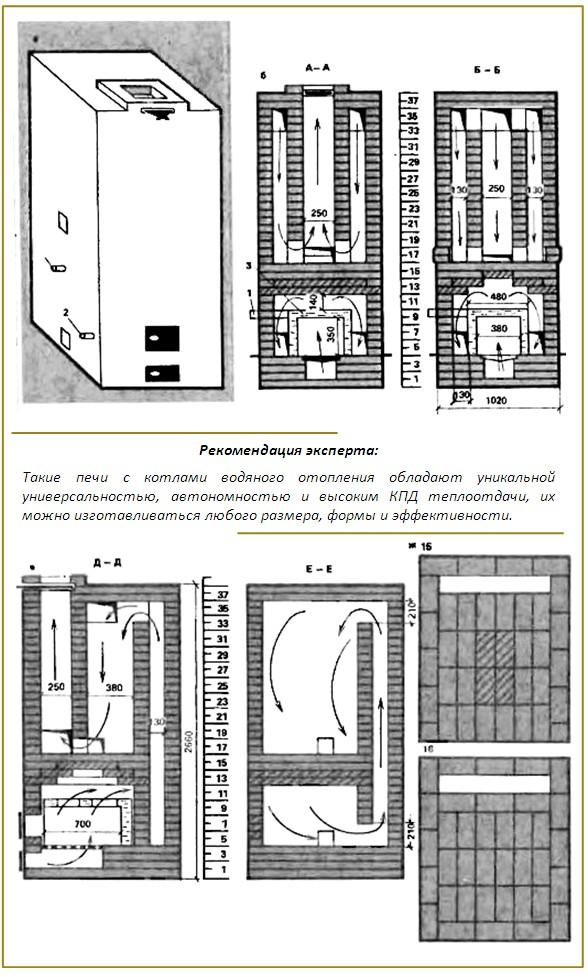

Features of laying a brick stove with a built-in boiler

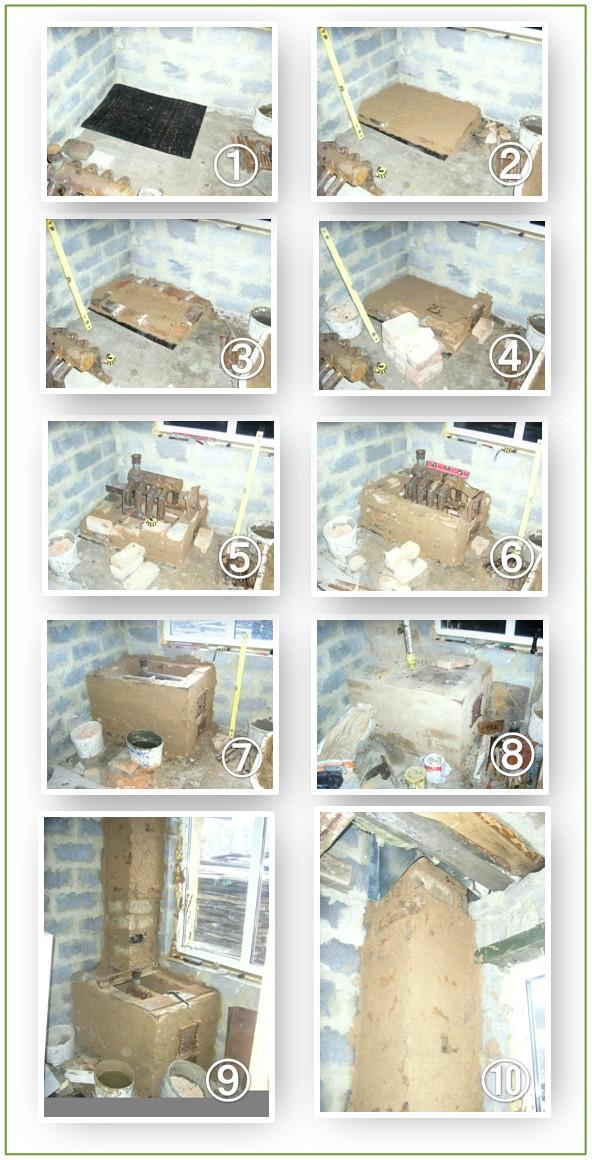

Here's how to lay stoves with a water boiler:

- Step 1. The foundation is poured: pad, reinforcement, cement - everything as usual.

- Step 2. Prepare a solution in a 1:2 proportion of clay and sand. Of course, the proportion may vary slightly depending on the fat content of the clay itself, and it must be soaked overnight, and large lumps must be kneaded with your hands. In the morning, clay and sand need to be mixed with a drill with a special attachment.

- Step 3. A layer of waterproofing is placed on the finished foundation - just a piece of roofing felt according to the size of the calculated stove.

- Step 4. You need to apply a layer of mortar to the roofing felt, level it - and you can lay the contours of the stove from good, beautiful bricks. And you can put both marriage and battle inside.

Stages of constructing a brick stove with a built-in boiler

- Step 5. The top is again covered with a layer of solution. A firebox and ash compartment are made.

- Step 6. The door for the ash pit is installed and a sheet of metal is placed - so that later it will be convenient to remove the ash from the ash pit.

- Step 7. The door is attached with wire to the masonry, and the contour of the blower is placed - the compartment where the ash usually ends up.

- Step 8. The boiler is installed, for which it is advisable to make special brick projections in advance, and place corners under the boiler on them. The combustion door is also placed here, and a special hole is made in it for the wire, with which the door is attached to the walls of the furnace. The boiler itself must be placed at a level so that air pockets cannot form in it. After which the firebox and the back part of the stove are installed - already with a chimney and cleaning.

- Step 9. The chimney and slabs are laid out and you can start heating.

These homemade brick stoves with a boiler are one of the best options for small baths that are used from time to time. Cheap, cheerful and durable.

Types of solid fuel equipment

Industrial samples of long-burning heating and cooking boilers, presented in a wide range in trade organizations, differ from each other in power, type of solid fuel, and other technical characteristics.

Heating and cooking units can operate on coal, peat, wood waste, firewood, and pellets. The duration of heating directly depends on this technical feature: from 3 hours to 12 hours or more (for powerful long-burning boilers).

The area of the heated room depends on the power of the heating device. Boiler models differ in the presence of manual and automatic loading of solid fuel. The hob can be one- or two-burner; everyone will certainly find a model to suit their taste. When choosing a boiler with a hob, the first dilemma is: buy a device with a foreign or domestic stove. Some foreign models have long won the trust of buyers; our Russian models are just beginning to win over consumers.

Rice. 3 Boiler with hob

The most popular are solid fuel heating equipment with cooking functions made in Italy. In addition to excellent technical characteristics and reliability, they stand out from the general background with their spectacular design. Devices from Sideros SPA are manufactured using the latest technologies, which ensure durability, quality, varied functionality and original design.

With a low power of 8 kW, they heat rooms up to 200 square meters. The hob, combustion chamber, and doors are made of polished cast iron. A large, closed combustion chamber helps increase efficiency to 73%, which is a very respectable figure for such solid fuel equipment.

No less worthy models are presented on the market by the Slovak company Thorma. These solid fuel devices are not equipped with an external convection casing; greater power is achieved due to their massiveness. Using wood, such units perfectly heat the house and feed the whole family every day. The presence of a valve allows you to control the flow of air, which ensures the operation of the equipment in long-term combustion mode. A wide palette of colors and unique design solutions allow the boilers to fit into any interior.

Strong brand heating appliances with cooking functions have excellent technical parameters.