Types of fireplaces

Brick fireplace

Fireplaces differ in several characteristics:

- depending on the fuel used;

- by installation method;

- by type of firebox;

- as intended.

You can create a cozy atmosphere even in a city high-rise building without spending a lot of effort on purchasing a decorative model. Another thing is to build a fireplace with your own hands from brick so that it does not smoke, burns well, is economical in fuel consumption, safe and, most importantly, fits well into the interior.

By installation method

Corner fireplace made of stone

A brick fireplace can be corner or wall-mounted. It is important to highlight the masonry decoratively to emphasize the antique style. All structural elements are located in the room and protrude beyond the contour of the wall. The advantage of such models is the possibility of installation after the construction of the house. The disadvantage is that after decorative repairs you will have to raise the floor and install a heat-resistant coating to prevent it from accidentally catching fire. A wall-mounted fireplace looks good in a large room.

All types of finishes are available for wall-mounted models - stone, mosaic, ceramic tiles, artificial stone, plaster.

Central location of the fireplace

The built-in model is planned at the stage of building a house, since all parts of the structure are hidden in the wall. The firebox remains open. The upper part of the wall is a hidden chimney. It will be difficult to carry out such a model after the construction of the house: for this you will have to break down the walls and lay out the chimney, which can be difficult in terms of labor costs.

Island fireplaces are usually located in the center of the room. In this case, the area of the room should take into account the dimensions of the model. According to its design, this product can have any shape - square, round, bowl-shaped. If the fireplace is not decorative, a heat-resistant coating is installed on the floor, and a hood is mounted at the top, which is connected to the chimney. Due to the fact that combustion consumes too much oxygen in the room, it is necessary to provide ways to ventilate or supply fresh air. In this case, it is better to install fireplace models with a closed firebox, but with ventilation.

Island fireplaces come in a variety of designs, including wall-hung fireplaces that do not touch the floor.

By purpose

Decorative electric fireplace

The purpose of the fireplace can be direct - heating, cooking over an open fire, or decorative - to style the room.

For real fireplaces and home stoves, it is necessary to build a chimney. Decorative models are powered by electricity. The tongues of fire in them are not real, but they simulate an open flame well.

A brick fireplace can be built outdoors for summer outdoor recreation in a private home. A stove-heater is used for baking bread - its firebox is located at the bottom, and the cooking compartment is at the top.

In apartment conditions, a working wood-burning fireplace can be part of the layout in luxury buildings, where all safety rules for using the structure are taken into account.

According to the firebox design

Fireplace with one-sided firebox

The design of the firebox can be different:

- One-sided, in which the fire is visible from one side.

- Double-sided – the fire is visible from both sides.

- Three-sided requires a closed firebox. Such fireplaces are most often decorative.

- Corner - with a protruding corner.

Each design has advantages and disadvantages. For example, with a double-sided open-type firebox, the fuel will burn faster, and accordingly the oxygen consumption in the room will increase, so such a complex model must be built according to all the rules.

By type of firebox

Fireplace with closed firebox

The firebox of a working fireplace can be open or closed. With the closed version, the risk that burning coal or wood will enter the room is minimal, but it is difficult to cook anything with the door closed.

When the firebox is open, the flame can be accessed from one side. At the same time, the efficiency is high, since all the heat goes into the room and warms it up well. The construction of fireplaces with an open firebox is more difficult and additional protection must be provided to prevent burning coals from falling onto the floor.

With a closed type of combustion chamber, a door made of heat-resistant glass is installed on the front panel of the fireplace. If desired, it can be moved aside and the firebox will become open. Combustion is regulated using additional levers, so you can reduce or increase the intensity of the flame.

Fireplaces with a closed combustion chamber have more advantages:

- efficiency in fuel consumption;

- safety;

- easier installation;

- high efficiency.

In addition, a closed firebox can be turned into an open firebox at any time.

By style

Country style fireplace

For every interior there is a fireplace that will highlight the style:

- Classic - with columns and forged enclosing bars. Material – marble or natural stone, as well as metal figured elements.

- Country is a rural version of a fireplace, which has compartments for drying and storing firewood.

- Art Nouveau - buildings with a minimum amount of decoration, less massive and noticeable. Often built into the wall.

- High-tech with unusual shapes and design solutions, made from modern materials, most often gray or black.

Before purchasing a fashionable model, it is recommended to thoroughly study how the fireplace will work, since in some cases the emphasis on shape and design has a bad effect on the performance.

By type of fuel burned

Gas fireplace

An important point in the construction of a fireplace is the type of fuel. It needs to be always accessible and inexpensive.

- On wood. Here it is important to correctly calculate and lay out the chimney so that good draft supports combustion and smoke does not enter the room. Carbon dioxide or carbon monoxide is the biggest danger of an improperly built fireplace.

- Gas fireplaces. They operate from a main line or a cylinder. There are models where a small cylinder is built in - they can be moved to another place and warm the room. Such a device also requires a chimney to remove combustion products.

- Electric models are heating devices stylized as a fireplace. Suitable for apartments, since the construction of a chimney is not required. The appearance of fire is obtained using light fabric and air currents.

- Biofireplaces run on fuel that does not emit harmful substances when burned. It can be pure alcohol or bioethanol. The advantage of the models is that they create a picture of a living fire, while additionally warming the room and do not require connection to a chimney.

Biofireplaces are ideal for apartment conditions in terms of safety, speed of installation and low cost of fuel. For combustion there is enough air, which comes in during ventilation.

How many angles? The number of opaque firebox walls.

Here the main selection criterion is the number of open sides of the firebox - one-sided, two-sided and three-sided.

In simple terms, the number of sides is determined by the number of places from which the fire can be seen and the directions of heat release.

One-sided.

These are those fireplaces in which only the front part is open - the most common and simplest types of fireplaces; they can be wall-mounted, corner or built-in. The heat is retained in them by inclined walls, and it enters the room through the opening. This heating method is considered the most effective.

Double-sided.

With such fires, only two parallel or adjacent sides remain opaque, which makes it possible to view the fire from two different ends of the room. This original design is suitable for corner, island and wall fireplaces.

When installing such a fireplace, do not forget about safety, because it has two sides with open fire, so you should pay great attention to the installation site, using heat-resistant materials to protect the floor.

You should also take into account that a double-sided fireplace is primarily an interior decoration and it will not provide the same heat as the classic options.

Three-way.

A three-sided fireplace is practically a fire burning in the room, separated from you only by transparent heat-resistant glass. Such fireplaces are suitable for those who want to surprise with a non-standard style solution.

At the same time, three-sided fireplaces retain all the disadvantages of their predecessors. They require a platform made of fire-resistant flooring, they do not provide enough heat and require additional ventilation and a special chimney.

How the fireplace works

Fireplaces with different types of fireboxes

The principle of operation of the fireplace is that cold air enters the firebox from below, after which it heats up during fuel combustion and rises up the chimney, simultaneously releasing heat into the room, warming up the external structures.

It is important to correctly calculate the height and width of the chimney and correlate it with the size of the firebox so that the draft removes combustion products well.

The chimney design has dampers. If more heat needs to be directed into the room, the damper is closed, so less hot air goes into the chimney. When lighting a fireplace, you need to do the opposite, create an increased air flow to start the combustion process.

To prevent backdraft and smoke from entering the room, the chimney in ordinary fireplaces is regularly cleaned. For electric, bio-fireplaces and false fireplaces, this procedure is not required.

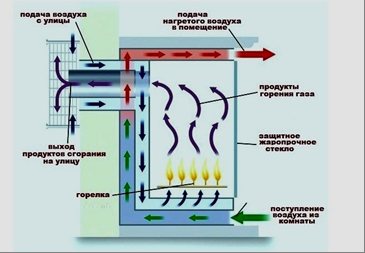

Installation of gas fireplaces

Regardless of whether the fireplace is used only as a design element or serves as a source of thermal energy, the operating principle and composition of its main components are almost the same in all configurations. It consists of a burner device, a combustion chamber, an automatic safety and regulation unit, a housing and a smoke exhaust system. The gas burner device is made in the form of a nozzle through which gas fuel is supplied to the firebox. To do this, it is placed in the lower part of the combustion chamber.

When adjusting the performance of the heating source, change the volume of gas supplied to the nozzle. Ignition is carried out by a piezo igniter. Gas fuel releases thermal energy when burned. Modern high-performance fireplaces are equipped with reflective screens that direct radiation into the room, thereby maximizing heat removal during the combustion process, preventing heat from escaping into the atmosphere with combustion products. The thermal characteristics of such a heating source and its efficiency will depend on the system for organizing the removal of flue gases.

Electronic control and safety unit - coordinates the behavior of control mechanisms and control valves based on the indicators of primary sensors. He is also responsible for turning off the gas supply in case of emergency situations: exceeding the established pressure in the gas network and the appearance of carbon monoxide in the heated room.

The body of the gas device performs two functions: to hold all working units together and decorative. A gas fireplace for a home is usually built into a steel frame. They are also built into a portal covered with heat-resistant materials.

Preparing for construction

You can lay the fireplace yourself. First of all, choose a place. To avoid creating drafts, you should not install a fireplace on the same wall where the windows are located, or build it opposite the front door. The floor must be stable to support the weight of the structure.

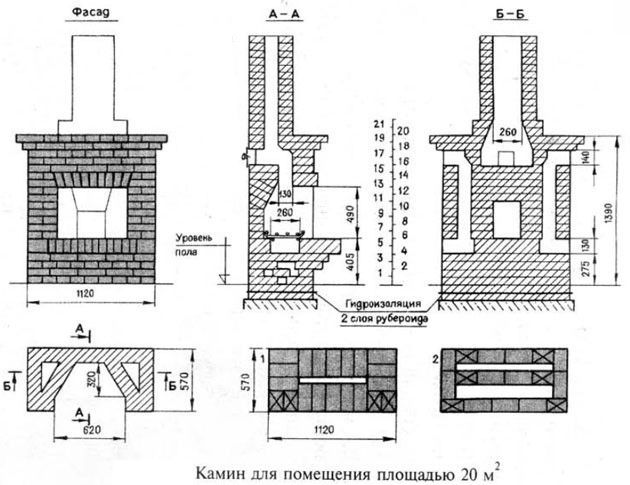

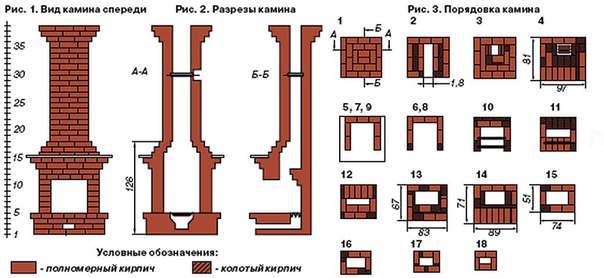

Drawings with dimensions

Fireplace diagram

The dimensions of the fireplace must be calculated so that the firebox is 1/50 of the size of the room. If you make it larger, the efficiency will decrease; if it is smaller, smoke will enter the room.

The cross-sectional area of the chimney should be 10 times less than the area of the firebox. Height from 4 to 5 meters. Rules to consider in advance:

- When installing the doors, they leave a gap between the metal and the brick, since the metal expands when heated. It is necessary to lay an asbestos layer.

- The fuel chamber along the rear wall should be tilted up and back.

The inside of the fuel chamber does not require plaster.

Materials and tools

Fireclay brick

It is necessary to prepare the following materials:

- Fireclay or heat-resistant bricks for laying out the firebox of the highest quality without cracks or chips. The chimney is also made of brick or a metal one is installed.

- Ceramic bricks for external cladding.

- Cast iron for combustion chamber. You can buy a ready-made firebox and line it with bricks.

- Door made of heat-resistant glass.

- Fireplace grates for cutting off hot air and directing it into the room.

- Grate for the firebox.

You will need clay, cement, sand and crushed stone. You can purchase a ready-made mixture for laying stoves with your own hands. Tools – trowel for spreading mortar on brick, tape measure for measurements.

The masonry mortar, if you purchased a ready-made mixture, is made according to the instructions on the package. If you prepare it yourself, you need to achieve the consistency of sour cream so that the solution does not subsequently crack when the moisture evaporates.

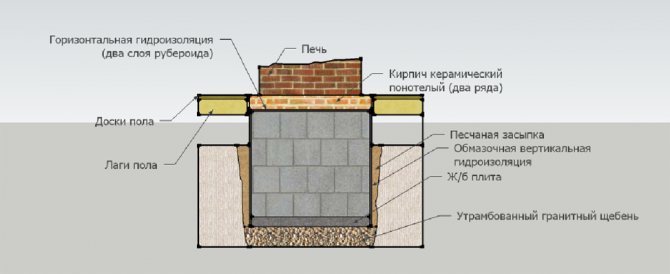

The procedure for arranging the foundation

Fireplace foundation

The weight of a medium-sized structure will be at least 1000 kg, so a separate foundation is installed for the fireplace, which will protect it from deformation and displacement.

Foundation components:

- a bed of compacted crushed stone;

- concrete slab;

- welded metal corners for laying bricks or blocks;

- vertical waterproofing on the sides;

- two layers of roofing felt on top of the foundation blocks.

The brick is first dipped into water so that it absorbs the liquid and does not take it away from the clay mortar.

Brick fireplaces for wood-burning homes must have a sheet of metal underneath them to protect the floor from fire.

You need to check the horizontality of the rows using a level.

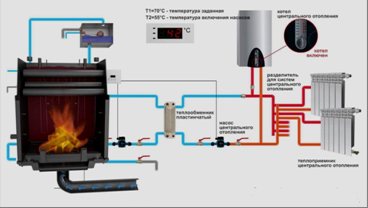

Features of modern thermostats

Older models of electric fireplaces were equipped with a special switch that could turn on or off either of the two spirals. Due to this, the power of the firebox was regulated. Today, such switches have completely lost their relevance. They were replaced by a temperature regulator. With this simple device you can control the power of an electric fireplace with greater efficiency.

The mechanical regulator device is an ordinary rheostat, which is adjusted using a rotating knob. You can control the electronic thermostat in two ways: either set the required indicators on the touch panel, or set them using the remote control. The microprocessor regulates power consumption.

We found out what a thermostat is and what it serves, but do not forget that this device always works together with a thermostat, which is needed to maintain a constant temperature. The thermostat consists of:

- regulator;

- key;

- feedback devices.

The most modern type of thermostat is electronic. The principle of their operation is based on the dependence of resistance on temperature. In this case, the regulator is also regulated electronically. The accuracy of such devices is much superior to mechanical options, since the latter maintain a constant temperature level not of the air, but of the electric heater.

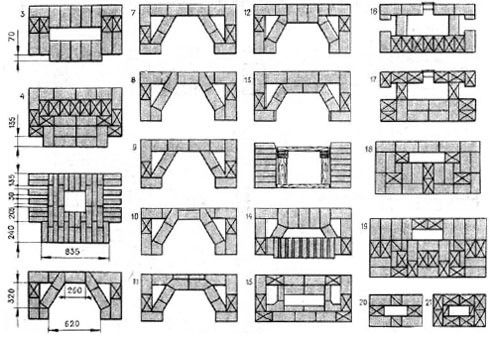

Step-by-step instructions for building a fireplace with your own hands

Order

On the foundation, after all fire safety requirements have been met, the fireplace body is laid out:

- Three rows of solid brick for the base.

- The 4th and 5th rows form an ash pan - a hole for burnt ash. It can be retractable with a metal insert or stationary, in which case you will have to clean it with a broom.

- Row 6 – 7 – bottom of the fireplace. Made from refractory brick.

- Up to 13 rows of the firebox wall. At this stage, the door is installed if the type of closed firebox is selected. To do this, you will need a stove metal tape, which is used to fix the door and secure it with self-tapping screws to the brick walls. To protect the metal from the brick, a layer of basalt cardboard is laid between them.

- From the 14th row a smoke collector is formed. The walls and chimney are laid out especially tightly and evenly, controlling the quality of the solution. The vertical is strictly controlled by level. The slightest deviation can lead to smoke.

Once the chimney has been laid, it is covered with a layer of asbestos-based fireproof insulation to protect the walls, roof and ceilings, especially if they are wooden.

How to calculate the size of a fireplace for your home

Having decided on the location, you can calculate the dimensions of the future fireplace. It's not that complicated here. No science fiction, just mathematics. By the way, calculating the dimensions will also help with choosing a model, because after calculating the permissible and necessary dimensions, it will become clear what the fireplace itself will be like.

Fireplace masonry

The starting point for the calculations will be the volume of the room in which the fireplace will be installed. The dimensions of the firebox are maintained relative to the volume of the room in a ratio of 1:50 (1:70). The ratio between the height of the fuel portal and its depth is assumed to be 1:2 (1:3). The dimensions of the brick are 6.5x12x25cm, and the thickness of the joints is 0.3 - 0.5 cm. By comparing all this data, you can determine the model of the fireplace. After this, you can start organizing. Ordering will allow you to accurately determine the required amount of materials.

It is important to take into account that even hewn bricks must be counted as whole when counting. Bricks are counted by the piece!

For laying a fireplace, choose a solid brick; for laying a firebox, fireproof brick is suitable. The solidity of the structure is achieved by tying the bricks together. But, under no circumstances should you tie up ceramic and sand-lime bricks! They have different coefficients of expansion when exposed to heat. This could destroy the entire structure.

That part of the pipe that is located above the roof of the house must also be taken into account in order!

Fireplace finishing

Joining seams

At the finishing stage you can:

- leave the brickwork exposed;

- plaster or cover with finishing material;

- paint.

To paint the fireplace, only fireproof materials are used that do not crack or change color under the influence of heat. These are used for heating radiators.

The finishing touch can be made from mosaics, ceramic tiles, porcelain tiles, which in appearance resemble natural stone. All finishing materials must be heat-resistant.

How to choose a fireplace

In order to navigate the difficult choice of a fireplace, it is necessary to ensure that it meets a number of criteria. By consistently selecting models for the required parameters, you can settle on the optimal option.

- Select installation location. This setting will dictate the power consumption of the heater. To heat a room of 10 m2 you will need a fireplace with a capacity of at least 1 kW.

- Select installation type. This is a fundamental factor influencing the type of fireplace. It can be mounted on the wall, on the floor, inserted into a plasterboard niche, or have its own frame.

- Decide on a price category. Often, buyers prefer to make a portal themselves and use the saved money to buy a fireplace with a more expensive flame imitation system.

- Select functions. For information to the buyer, we note that not all fireplaces have a heating function. Some models are made for appearance only. If in the room where you plan to install a fireplace it is periodically necessary to use a heater, then be sure to pay attention to this fact when choosing.

Small mobile electrical hearth

Laying a fireplace - step-by-step instructions for beginners

First of all, it is worth noting that there is seasonality in the matter of stove and fireplace masonry. The best time for construction is late spring, summer and early autumn, when the outside temperature is 15-25 degrees and the humidity is moderate.

Foundation

As mentioned above, the foundation of the fireplace should be separate from the foundation of the house. To construct the foundation, dig a pit 60-80 cm deep, 10-15 cm wider than the future base of the fireplace in plan. The bottom of the pit is covered with broken bricks and crushed stone. They are thoroughly compacted and filled with concrete, which is thoroughly leveled. Then they add another layer of rubble stone and fill it with concrete mortar again.

Fireplace foundation

Such layers are laid until 30-35 cm remains to the upper edge of the pit. After this, formwork is installed in the pit 5-7 cm below the floor level. A mixture of stones and sand-cement mortar prepared 1:3 is poured into the formwork. It is especially important to level the last layer. The resulting foundation is covered with polyethylene and left to dry completely for 7-10 days.

Bricks

. While the foundation is drying, you can start sorting out the bricks. It is necessary to carefully inspect each of them for chips and cracks. It is optimal if the entire volume of bricks was purchased from one batch and has the same characteristics in terms of quality and color. Many stove makers first lay the fireplace dry. This means that in accordance with the order, each row is laid out, a serial number is applied to each brick with chalk or pencil, so that later, on the mortar, the rows can be laid out according to the exact pattern and not get lost. Where necessary, bricks are trimmed to the required size. It is better to do this with a butt and not with a grinder, because... Due to the resulting vibration, microcracks may appear in the brick, which will certainly increase in the future.

Before laying, the bricks are immersed in water to ensure a tighter connection with the mortar and to release tiny air bubbles.

Solution

You can prepare the masonry mortar yourself, or you can buy a ready-made oven mixture. In case of independent preparation, mix sand with clay 3:1, dilute with water until sour cream thickens. It is better to buy both sand and clay in the store so that you do not have to strain and sift the mixture for a long time.

By the way, the solution can be prepared for future use. It won't thicken. The main thing is to mix the mixture thoroughly after the break.

Masonry

Waterproofing is laid on the dried foundation and the first row of bricks is placed on it, fastening only the seams between them with mortar. The thickness of the seams should be at least 3-5 mm. The distance between bricks and metal inserts or refractory bricks should be 6-13 mm. This is important for clay mortar.

Fireplace masonry

The masonry is constantly checked against the order and checked for level. The seams must be done very carefully, especially if red brick remains as the exterior finish.

In the place where the pipe goes to the roof, you need to install an “otter” (inlet) to ensure fire safety. For the interfloor ceiling this will be a “barrier”.

Once the fireplace is lined, it is left to dry for 3 weeks at room temperature. Under no circumstances should heating devices be used to dry the fireplace. It is better if it is possible to open the windows in the room, but protect the fresh fireplace from direct sunlight.

The fireplace takes 3 weeks to dry

Foundation

Designing and assembling a fireplace with your own hands always starts with the foundation. This is due to the fact that a fireplace, like any other type of stove and any heating unit in general, is a structure with a huge mass that creates a serious load on the floors of the house. Therefore, all the small details that the fireplace design has must be based on a solid foundation, which, moreover, will be able to withstand the high temperature of fuel combustion without losing its load-bearing characteristics.

At its core, the foundation for a fireplace is almost completely similar to any other foundation on which any serious structure is based. It is very good if the design of the fireplace foundation is carried out in advance, even at the stage of building the house. In this case, a separate section of the base can be allocated for the furnace, and the load on the load-bearing floors of the building structure will be significantly reduced. In addition, when laying a fireplace in this way, you will not have to disassemble the floor coverings.