Range of wood burning fireboxes from Saga. Fireplaces

Inexpensive fireboxes

Wood burning stove Cheminees Diffusion A 1 - French firebox with a power of 14 kW, weight 82 kg, dimensions (WxHxD) - 690x696x351 mm.

The Cheminees Diffusion A 2.2 Etanche firebox is a cast iron firebox with a power of 12 kW, the same dimensions as the previous model, without raising the glass.

Wood-burning firebox Cheminees Philippe B 1-2 with a damper - cast iron assembly body, the presence of a rotary damper to increase the fuel burning time, power 12 kW, weight 112 kg, WxHxD - 695x770x415 mm.

Wood burning firebox Cheminees Diffusion C 6 is a firebox with a nominal power of 15 kW, WxHxD - 770x880x504 mm, weight 143 kg, with the function of adjusting the combustion air supply and a flame cutter-deflector to increase the efficiency of the fireplace.

Cheminees Diffusion B 5-2 firebox with turbine - cast iron firebox with a nominal power of 10 kW, equipped with a retractable ash box, side-opening glass with a self-cleaning function, 2 two-speed fans and 2 nozzles for forced convection. Supports long burning mode.

Compliance with the exact dimensions of the fireplace is the key to its reliability. Despite the variety of appearance, purchased products have standardized sizes. For high-quality combustion and output of the derivative of the process, an oxygen influx is necessary. At the same time, its quantity should ensure that smoke is removed from the firebox exclusively into the chimney.

Other important fireplace sizes

During operation, the correct size of the fireplace insert plays an important role. This applies primarily to the depth of the firebox. A combustion chamber that is too deep on one side will allow more fuel to be stored. But on the other hand, this will not increase the burning time of wood - greater depth increases the rate of removal of combustion products, and therefore the rate of combustion of wood. Simply put, the heat will literally go down the pipe.

The shallow depth of the combustion chamber results in a lack of normal draft. And even with a slight wind, the room will be filled with smoke and soot. Therefore, it is so important to maintain the golden ratio for the size of the firebox - the ratio of the depth to the height of the fireplace is 2/3.

Calculation example

To understand the calculation method, it is worth considering it with an example - this will allow you to later calculate how many bricks are needed for a stove, but for an individual project. Regardless of the perimeter of the stove, its first row is still laid out completely - for example, 4x4 bricks, i.e. for a monolithic first row you will need 32 bricks.

To continue calculating the bricks for the stove, you need to determine the number of rows, for which the height of the room must be known. A standard single brick has a height of 65 mm, and the thickness of the seam between rows is 5 mm. As a result, it turns out that the total thickness of one row is 7 cm. With a room height of 2.8 m, 30 cm is subtracted from this value for the fire protection structure, and the calculated size of the stove is 2.5 m.

The resulting value must be divided by the thickness of one row, and in this case you get 36 rows. By multiplying the calculated number of bricks required to completely lay one row by the number of rows, the result is 1152 bricks. The design of the stove is one-third hollow, so 2/3 of the total number of bricks is calculated - and this is 768 bricks.

The next step to find out how many bricks are needed for the stove in the house is to calculate the number of bricks for the chimney. In a standard square pipe, each row consists of 6 bricks - and for a 4-meter pipe consisting of 57 rows, 342 bricks will be required. Here the calculation method is exactly the same as in the case of the main part of the furnace. Of course, this method is not suitable for determining the number of bricks in the case of round or rectangular chimneys.

When deciding how many bricks you need for a stove, you must take into account the number of bricks that will be used for cutting. This amount directly depends on the design of the stove, its location and the thickness of the wall, if the stove is built into it. For a single wall, the minimum groove width is 25 cm, so a single groove is laid out on each side of the oven. The total is 36 rows on both sides, or 144 bricks. If the stove is not adjacent to the wall, then cutting is only needed near the ceiling and roof elements. In this case, the number of bricks will vary from 30 to 50 pieces.

How much do you need?

After you have managed to figure out the choice of the type of brick for installing a fireplace, the next question arises - how much brick is needed for a fireplace. The question is quite understandable, considering that brick is not cheap.

If the fireplace is made according to a pre-prepared project, then the quantity of all materials must be calculated and indicated. Also, specialists involved in the construction of stoves and fireplaces have several solutions in stock with the required amount of bricks taken into account.

In addition to the above options, there is a fairly simple and universal way to calculate the amount of brick required. Please note that the results will not be 100 percent accurate, please take this into account when purchasing building materials. The calculation formula is as follows:

- the number of bricks from the first row, laid out solidly, is taken as a basis;

- this quantity must be multiplied by the number of rows in height (the average height of one row is 7 centimeters);

- Next, you need to subtract the third part from the result.

Let's look at the example of a fireplace, the first continuous row of which consists of 24 bricks. For further calculations we will need the height of the fireplace. Let’s say the height from floor to ceiling is 2 meters 40 centimeters, from here we subtract 30 centimeters for cutting, and as a result we have 2 meters 10 centimeters. And we already know that the height of one row is 7 centimeters. We divide the height of the fireplace by the height of one row and get 30 rows. From the resulting number of rows we subtract a third (30/3), that is, 10, resulting in 20 rows. We multiply this quantity by 24 (the number of bricks in a row), this gives us 480 pieces. Let's add another 50 to them for cutting, the final figure is 530 bricks.

It is generally accepted that in one linear meter of pipe there are 14 rows of brick. That is, if there are 7 bricks in one row, then there are 98 of them in 14 rows. And if the chimney of the future fireplace is 5 meters high, then another 490 bricks will be required for the entire length of the chimney.

Thanks to this simple formula, you can calculate the required amount of brick for a fireplace. Of course, the calculations are somewhat arbitrary, but nevertheless they will allow you to calculate and plan the budget for building a fireplace.

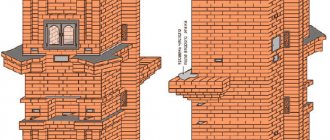

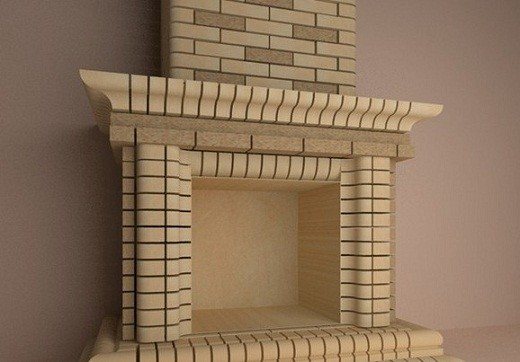

The photo shows an example of finishing a fireplace with facing bricks.

Types of figured bricks for the fireplace in the photo.

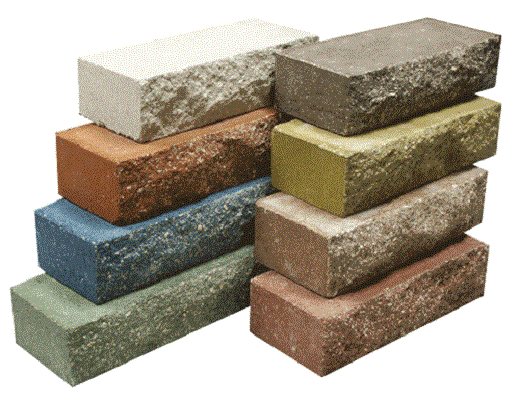

The picture shows decorative bricks for the fireplace.

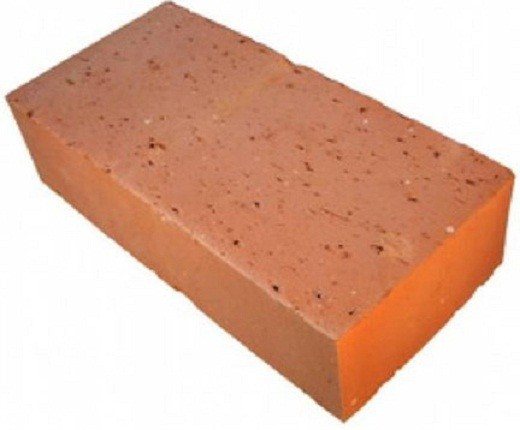

Red solid ceramic brick for laying a fireplace in the picture.

The photo shows an example of finishing a fireplace with shaped bricks.

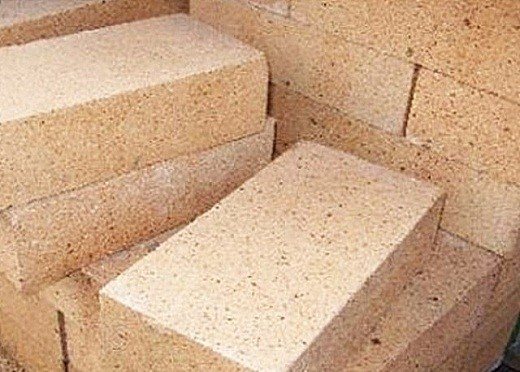

The picture shows fireclay heat-resistant or refractory bricks, which are used to build a fireplace insert.

Furnace departments

Any stove, be it Russian, Dutch, Swedish or a sauna structure, consists of several main sections. For each of them, the material should be selected separately, since certain characteristics required specifically for a specific part of the hearth are important.

Foundation

The first step is to build the foundation. Since the structure is usually located on the ground floor, the proximity of the ground must be taken into account. Therefore, a concrete slab is usually laid as the first layer, below the floor level, and a layer of waterproofing is applied to it.

Thus, we get a layer that will withstand the mass of our future structure, and also will not allow moisture and cold that come from the soil to affect it. Solid brick rows are usually laid on top of the waterproofing layer; there can be from two to four.

This is the second part of our foundation. As a rule, clinker material is used for it. This is due to the fact that it has very high strength, it is not afraid of loads, so such a base will easily support the weight of the entire stove.

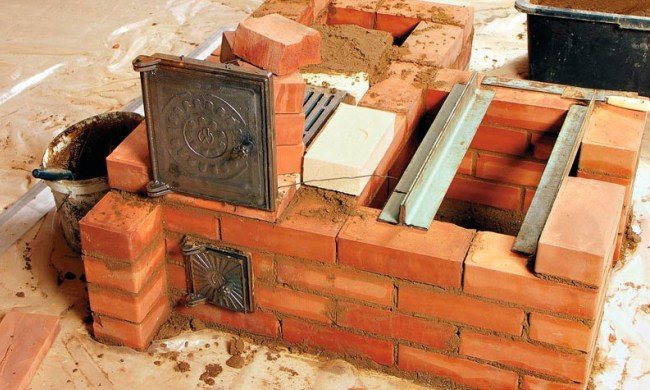

Firebox

Another section of the design that raises the most questions about the selection of material is the firebox. This is the very place where firewood is laid and where the fire is made. The bricks in the firebox are directly exposed to the flame for a long time, and this happens over many years. Therefore, appropriate requirements are imposed on them.

As a rule, fireclay blocks are used to lay out the firebox. They have the highest fire resistance of all possible options, so they quietly perform their functions throughout the entire life of the fireplace.

In principle, the entire structure can be assembled from fireclay. But this is very expensive. In addition, the firebox lined with cream-colored fireclay blocks looks very advantageous when surrounded by red brick blocks, so this solution is optimal from the point of view of not only functionality, but also design.

Chimney and pipe

The chimney does not come into direct contact with the fire and does not carry a particularly high load. However, it also has certain requirements.

Firstly, it is exposed from the inside to aggressive chemicals released during combustion.

They have a detrimental effect on the condition of the building material from which the inside of the chimney is lined, so special attention should be paid to the stability of these bricks in various destructive factors

Secondly, the part of the chimney that is located above the surface of the roof of the house - that is, the pipe - is also subject to attacks from the external environment. Rain and snow, frost, wind, sudden changes in air temperature - all this significantly undermines brick blocks.

Experienced craftsmen recommend using two different materials for this section of the oven. Clinker, as the most resistant to aggressive chemicals, is used for laying out the inner layer. And on the outside, ordinary ceramic bricks are perfect, as they withstand the effects of the external environment very well. It’s not for nothing that many different structures are erected from it, including residential buildings.

Types of loads on various sections of the furnace

To understand which brick can and should be used, you should understand that any fireplace consists of separate modules. Each such module is affected by external factors of a different nature. Therefore, the material needed in each specific case is different. The furnace in its different parts can be influenced by temperatures, mechanical pressure, aggressive environments, and in the upper parts the effect of erosion is inevitable.

The weight of a stove or fireplace made of brick can reach several tons. This design requires a reliable foundation. The foundation is poured with cement mortar, and underneath there are concrete blocks. But the upper layers of the base are lined with brick, so the properties of the brick at the base of the fireplace are subject to certain requirements related to its resistance to mechanical stress.

- The foundation is built under the floor, at a depth of about 60 cm. In this zone, in some houses the temperature in winter reaches negative values. Therefore, the construction of foundations for stoves and fireplaces is made using a durable and frost-resistant type of brick.

- The firebox of modern fireplaces is represented by a metal cassette, which is inserted into the frame. But there are options in which the entire chamber is lined with brick. The temperature inside the combustion chamber reaches several hundred degrees. This is a critical value for most building materials, but not for the special fireclay type, which has increased heat-resistant qualities.

- The area in close proximity to the firebox, where heat is transferred from warm air to the body, is also under the influence of elevated temperature. However, its performance is not so high, but attention is focused on the heat capacity of the material. Heat-resistant ceramic bricks perform the best transfer and accumulation of heat.

- The appearance of the fireplace requires special attention. The portal can be decorated with decorative material, which is presented in a wide variety, but the classic option remains the texture of the brick itself with embroidered seams. In order to leave an aesthetic picture, skill alone is not enough. It is also necessary that the brick be a special facing one, and for decorative finishing it is advisable to choose options with many irregularities for enhanced bonding of the plaster or glue solution.

- What is surprising is that the requirements for the chimney and chimney are not becoming any softer. It would seem that the temperature of the combustion products is no longer the same as in the firebox, the gas has given up a significant part of its energy, and the chimney can be lined with any brick. But it is necessary to take into account the difference in ambient temperature inside the pipe and outside, the constant action of wind and precipitation, and chemical aggression from combustion products. An option to solve this issue is a two-layer masonry made of bricks with different characteristics. Heat-resistant material is used inside, for stoves and fireplaces outside - with low thermal conductivity. This combination will compensate for the destructive effect of temperature differences.

We calculate the combustion hole

A stove, the masonry of which will be done by hand, must have the most accurate and detailed calculations of each structural element. To do this, first of all, we determine the overall dimensions of the firebox.

For example, if the room has an area of 30 square meters and the ceiling height is from 3 to 3.5 meters, then the fuel compartment will have a size of 0.6 square meters. For a space of 20 square meters, this parameter will be 0.4 or 52x77 centimeters. If the living room or bedroom has an area of 10 squares, the firebox will be equal to 0.2 squares or 36x45 centimeters.

It is equally important to take into account and correctly calculate such indicators as the height and depth of the fuel compartment. The depth of the fuel compartment will vary from one second to two thirds of the frame height

If this aspect is not observed, certain difficulties and malfunctions in the operation of this heating equipment may arise. If the selected depth is insufficient, the room may periodically become filled with smoke. If the depth is greater than the maximum indicator, this will negatively affect such an indicator as heat transfer.

To calculate the dimensions of the chimney, it is necessary to take the dimensions of the combustion opening as a basis. The chimney system must have an area that is 10 times smaller than the firebox. There are certain standards for a brick chimney, which are 140 by 140 or 140 by 270 millimeters. For stainless steel pipes, the hole diameter will average about 11 centimeters. In this case, the total height of the chimney system will be about five meters.

It is equally important to determine the dimensions of the entire oven. In this case, the size of the brick used for laying is taken as a basis (65x120x250 millimeters)

Also, when calculating, you should add such a parameter as the thickness of the seams. From this we conclude that one row will have a height of about 70-80 millimeters. The rear partition of the fireplace can be assembled not from a whole brick, but from 1/2 brick: 125 millimeters. The sidewalls must consist of solid elements: 250 millimeters.

The order of the furnace plays a key role and is the key to successful DIY construction work. Having made a drawing, you can first take into account all the nuances and subtleties of the construction, and, if necessary, make all the appropriate adjustments.

The laying of fireplaces, carried out by a beginner, should follow a ready-made diagram. However, even in this case, material consumption may vary. When purchasing, take bricks and building mixtures with a small margin!

Home stoves can have different consumption of materials, which is directly related to their type and the way they are located in the interior. For example, for a corner fireplace measuring one meter by one meter, it will take about 210 units of standard and 120 units of refractory brick. For a wall fireplace measuring 650 by 1150 millimeters, you will need 260 units of red and 120 heat-resistant bricks.

A fireplace, the dimensions of which are determined, will be guaranteed to meet your wishes, if you make sure that the calculations are correct. To do this, even experienced professionals initially lay several rows dry, that is, without masonry mortar.

Height adjustment

To adjust the height of the heating device, special bolts are used, which are installed on its legs, or using supports. To set the required distance from the bottom of the firebox of a brick structure to the floor, lay several rows of bricks. Basic requirements before placing the combustion chamber in height:

you need to ensure a distance to the floor of 300-400 mm; if there is a niche for firewood under the firebox, this distance may be greater; When calculating the placement of the bottom of the combustion chamber, please note that you need to take into account the design of the floor with all its components. Think about this when planning your heating system. Calculating the size of the fireplace

Fireplace size calculation

Correct definition of parameters

A corner fireplace, the dimensions of which have already been calculated, can be made of any materials and have a certain lining of the hearth. Before making your choice, we recommend that you familiarize yourself with the following selection rules:

Criterias of choice

Detailed description

Decorative hearths

The dimensions of a corner fireplace largely depend on the type of hearth chosen for installation and the fuel used for its operation. If you are looking for a purely decorative solution or a firebox that will serve as an additional source of heating for a house or apartment, we recommend that you pay attention to fireplaces that operate using bioethanol or electricity.

Effective foci

Installation instructions for the finished model are always included in the basic package. The most effective fireplaces that can become the main source of heating in rooms are gas and classic wood-burning structures. If installing a gas boiler is possible both in a private and apartment building, then wood-burning fireboxes require a chimney, which is only possible in your own home. It should be noted that the installation of such installations is more complex, costly and time-consuming.

Budget materials

The chosen finish, materials for making the hearth and portal also play a big role. The most inexpensive and budget coatings are plasterboard, metal profiles, ceramic tiles, and decorative plaster. Due to their low cost, the design of portals, fireplaces or such cladding provides lower efficiency and efficiency.

Expensive coatings

The price of materials and coatings that form and provide the furnace with additional heat capacity, efficiency, and heat transfer is quite high. This category includes tiles, natural minerals, cast iron, steel

The distinctive features of the materials are practicality, durability, fire resistance, easy maintenance and environmental friendliness.

Video How to choose the optimal fireplace size

Having your own fireplace is a dream for many, but its realization requires high-quality preparation and thorough implementation. Installing a fireplace yourself is not recommended for smaller rooms, since living in such a place can be quite dangerous. But if you want to create a small hearth in a room with an area of more than 20 square meters, then this can be done.

The most optimal material for creating fireplaces is considered to be brickwork, but there is a simpler solution to this issue - an electric fireplace, which can perform not only decorative, but also practical functions. However, for a suburban building this option will be more expensive and not practical.

First you need to calculate the area of the fuel portal. For the most part, it is no more than 2 percent of the area of the room in which the fireplace is installed. If the area is 15%, then the size of the portal will be approximately 0.3 “square”.

Next you need to calculate the size of the fireplace.

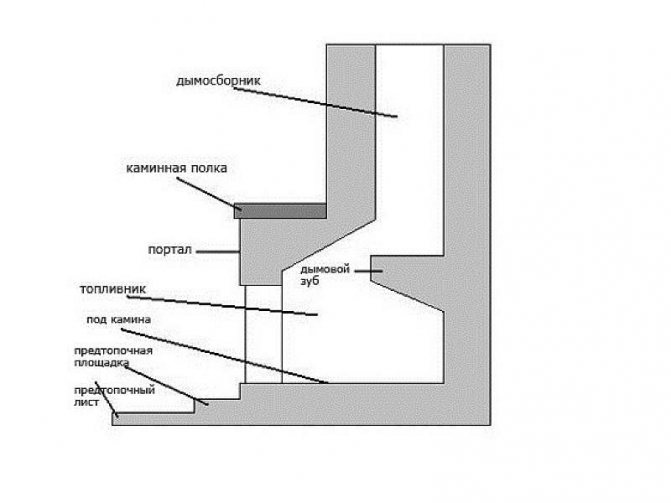

Elements of a brick fireplace

:A is the width of the portal; B - height of the portal; B is the depth of the firebox; 1 - chimney; 2 - mantel; 3 - portal; 4 - firebox; 5 - fireplace step; 6 - floor; 7 - under the fireplace;

The best proportion of height to width is considered to be two to three. The fireplace will be approximately 0.7x04, depending on what parameters the room has, whether you want to get a square-shaped fireplace or create a more elongated shape. Regarding the depth, it should not be very large or not very small. With a room size of 15 square meters, the most optimal solution would be a depth of 20-30 centimeters. More specific figures can only be obtained if you have information about the length and width of the room. To prevent heat from leaving the building completely, the chimney should be made approximately ten times smaller in relation to the area of the portal. Among other things, it is recommended to make the hole round.

Fireplace size chart

can build a high-quality corner fireplace that will work properly and look beautiful. But how can a beginner do all the work on his own

? In this article, I decided to touch on the important issues that stove makers encounter when building corner fireplaces.

This is the source of heat that we expect, even if the fireplace was built for purely aesthetic purposes. And before building a fireplace, the first thing we do is calculate all the necessary parameters of the fireplace: its size, depth, chimney height, cross-section of the smoke duct opening, firebox power, etc.

It is a mistake to think that if a fireplace is decorative, then you can use any one. A fireplace burns oxygen, and, for example, if you take a powerful fireplace for a small room, you can end up with problems with the fireplace and constantly open windows. The size of the hole for the chimney, its height and the material of the firebox and fireplace lining, the location of the fireplace and other factors play a role.

Characteristics of kiln bricks

Fireclay fireproof

Fireclay refractory bricks are made from a mixture of unfired clay and kaolinite, which undergoes a firing procedure at a temperature of 1400°C for 70-120 hours.

High-quality building material is characterized by a straw color and a ringing metallic sound when tapped. Upon impact, it breaks into large fragments. It has a high level of thermal conductivity and can withstand temperatures up to 2000°C.

Full-bodied private

Recommended strength – from M-175. The color of the finished products depends on the clay used in production and ranges from peach to red. Firing is carried out at a temperature of 1000°C. The brick can withstand temperatures up to 1530°C.

Thermal insulation brick

Thermal insulating brick allows you to increase fire safety and, if necessary, limit the area of heat spread. For example, it insulates a partition with an adjacent room or prevents “outdoor heat” if the fireplace is adjacent to an outside wall.

To create a “buffer,” hollow bricks are used, which maintain the temperature inside the air chamber for a long time. Another material - cement-sand brick - has low thermal conductivity.

Facing brick

Depending on the manufacturer and manufacturing technology, the material can withstand temperatures up to 1350°C. Decorative bricks are distinguished by a wide range of colors, different surface structures, and variations in sizes and shapes. It will always be possible to find a solution in which the fireplace will harmoniously fit into the interior of the room.

IMPORTANT TO KNOW: When building a fireplace, it is not recommended to use sand-lime brick, because it has reduced heat resistance.

Dimensions of decorative fireplace

The dimensions for which a corner fireplace is determined according to the area of the room for decorative installations can also be determined based on the following tips and recommendations:

The room chosen for installation and installation of the structure must have suitable dimensions. As a rule, the dimensions of the stove should not exceed one twenty-fifth of the living room;

- Since there is no real flame burning in the hearth of false fireplaces and the structure does not heat up, it is quite possible to make it not only an addition and decoration to the interior, but also add a certain functionality. To do this, equip the frame with various racks, tabletops or shelves on which you can place books, accessories and other necessary, useful little things;

- If you want to install a purchased electric or bio firebox into a decorative portal, all calculations are made according to the existing installation dimensions. If the portal is purchased, you can find its installation dimensions in the instruction manual included with the purchase. For home-made frames, all measurements are taken by hand; choosing a hearth of suitable size in this case is quite difficult and it is quite possible to make it only to order.

You can also view photos of corner fireplaces in various interiors in this article.

How to calculate the dimensions of the combustion chamber

- To calculate such a parameter as width, you will need to add up the width of the firebox itself and its side parts, as well as add up the frame consoles;

- To calculate the height, add up the height of the firewood, mantelpieces and other decorative elements;

Video: brick for fireplaces and stoves

Corner brick fireplaces will be the most acceptable option for the room. After all, here you just need less space for installation and this is extremely good for a small room. You can find out below how corner fireplaces are made from brick and what is involved. After all, construction is a rather painstaking and responsible task, and there are no trifles here. Next, instructions will be given on the specifics of performing this work.

As you know, corner brick fireplaces have been in demand for quite some time. Today, many owners want to build a fireplace in their home, thereby emphasizing the coziness, comfort and original interior. A fireplace is especially valuable in winter, when there is severe frost outside, so in any case, if you want to build a fireplace, it will be the right decision. But to build a fireplace, you need to take into account important nuances and requirements.

Attention: The main rule that should not be forgotten when building a fireplace is the selection of the side of the house, the specific place where you want to build a future fireplace. If the fireplace is placed against a load-bearing wall, then you will need to obtain permission from the fire department.

Laying and preparing the foundation

If we talk about individual models, special attention should be paid to the Elba firebox. This insert is installed in a home-made or store-bought portal

The line of hearths is welded from high-quality thick-walled stainless steel. The pipe is made of cast iron, and the front part is complemented by large transparent tempered glass, which has self-cleaning properties.

The compartment in which fuel combustion occurs is assembled from fireclay refractory bricks. This in turn increases parameters and indicators such as heat transfer and design efficiency. Due to high-quality materials, the service life of such fireboxes is quite long, and use is simple and comfortable. Depending on your wishes, you can choose a fireplace of certain dimensions, shape, with a corner or classic wall arrangement in the interior of the house.

This video looks at laying a simple brick fireplace with your own hands in five days:

Most owners of private houses dream of installing a stylish, romantic and cozy piece of furniture - a fireplace, the size of which largely depends on what function it will perform - heating or decorative.

A living fire is fraught not only with beauty, but also with a high probability of a fire, so laying a fireplace must be preceded by careful calculation.

Varieties

There are few things more conducive to creating a cozy atmosphere in a private home than a real fireplace. Despite its apparent simplicity, building it with your own hands can be quite difficult, since a fireplace is a complex heating device and there are many nuances in its installation, from installing the foundation, choosing a firebox, box material, and ending with choosing the design and shape of the chimney.

The main thing in this matter is to correctly determine the need for heating the room, and based on this data, select the appropriate dimensions of the fireplace.

So, for rooms of 20 and 40 square meters, a fireplace with a base of 150*90 cm is suitable; for a larger area, a larger fireplace is needed. It is worth remembering that a modern fireplace based on a cast-iron firebox with a convection box is much more efficient for heating than old brick fireplaces with an open firebox.

Let's look at the main types of fireplaces available for selection:

Decorative

A decorative or false fireplace is a great find for the interior. You can easily make it yourself and install it even in a small room. You can create such an imitation from a variety of materials, even “junk” ones. From TV or refrigerator boxes, or from sheet cardboard, light, portable models are obtained that do not require much time or special skills. More complex options are made from chipboard, plasterboard, polyurethane or brick. Flash fireplaces for the kitchen have become very popular lately.

Built-in

A fireplace built into the wall is one of the most popular models for the home nowadays. Its main advantage is that it does not occupy useful space and does not require the installation of a foundation. In addition, such a fireplace always looks very stylish. However, it must be remembered that there are significant restrictions for installing such a fireplace, primarily related to the material and thickness of the wall and the design of the chimney. As a rule, such fireplaces should be provided at the design stage of the house, which avoids problems during installation.

Electric fireplace

Installing a real fireplace in a city apartment is an almost impossible task. You can install a fireplace in an apartment only if you live on the top floor, and then you will have to obtain permission from the HOA. Therefore, an electric fireplace is perfect for creating an atmosphere of comfort and additional heating. Installing an electric fireplace does not involve any difficulties, it is very cheap compared to a real fireplace, and modern technologies create the illusion of a flame almost indistinguishable from a real one.

Classical

A classic fireplace, as a rule, is built into the wall and, unlike a modern one, requires strict adherence to proportions and careful selection of the installation location. With its monumentality, a classic fireplace creates a certain “historical” atmosphere in the room and expressively emphasizes the status of its owner.

Suspension

For lovers of original solutions in the interior, a hanging fireplace is perfect. This unusual design, despite its non-standard nature, retained the functions of the hearth. The main part - a lightweight metal body - is mounted to the ceiling or, less often, to the wall using a pipe. There are both solid fuel hanging fireplaces and biofireplaces. The disadvantages of such a device include low heat transfer, high cost and complexity of installation.

Big

When talking about a large fireplace, people usually think of a classic English fireplace made of brick or stone. It is better to design the installation of such a fireplace together with the house, and build it in spacious, well-ventilated rooms.

Average

The medium fireplace is the most common and current model of classic English brick fireplaces. Its size is relatively small - 3 * 5 bricks at the base.

Small

A miniature cast iron fireplace will fit perfectly into the interior of a small room or small house. A device weighing up to 100 kg can be installed not only on the ground floor, but also above and in the attic. A corner or built-in model will not take up much space and will not look bulky in a room smaller than 20 sq.m.

Bilateral

To heat a large room or two adjacent rooms, a double-sided fireplace is perfect. It is a through firebox with glass on both sides. Most often it is installed in a wall between two rooms, or in a decorative partition to zone a room, which allows you to enjoy one fireplace in two different rooms.

or rustic unpretentiousness against the backdrop of modest charm

The etymology of the word “rustic” speaks of the most characteristic features of this style - deliberate “roughness”, “rudeness”, stylization for a rustic interior (this style is also called country). The desire of our ancestors to introduce an element of aesthetics into the arrangement of their primitive home gave rise to this architectural trend, which subsequently began to develop so widely and comprehensively.

Country style is characterized by natural details, components and materials, emphatically “rough” processing and an open shape of the hearth. The most suitable materials are: shell rock, sandstone, tuff stone, etc.

Peculiarities

The structural features of a classic fireplace suggest that air access is provided to the firebox through the fireplace window. Experts have calculated that the optimal traction force speed for a heating device of any size should be less than 0.25 m/sec. In practice, it is difficult to measure thrust speed. Until the fireplace is lit, its presence can be determined by the vibrations of the flame of a lit paper sheet. The user of a fireplace can only verify the adequacy of the traction force in practice.

Its presence or absence is also influenced by such external parameters as:

- indoor and outdoor temperatures;

- chimney condition;

- type, volume and dryness of fuel.

The main condition for the serviceability of the fireplace is to comply with the basic parameters and their relationships in the design of the heating unit. Optimal parameters of the heating design will allow you to organize high-performance operation of the device. An ideal result can be achieved if the basic requirements are met.

To avoid any violations in the device, the fireplace must meet the following tasks:

- provide warmth;

- remove smoke from the room;

- ensure the correct amount of air in the combustion chamber.

The standardization of dimensions mentioned above does not lead to the same appearance of all devices. Among all the device parameters, there are some that really affect its performance.

Certain dimensions must be implemented in projects exactly. These include:

- linear dimensions of the combustion opening;

- chimney dimensions;

- distance from the floor to the first edge of the window;

- tooth location;

- parameters of the pipe width in the area where the tooth is located.

Other parameters do not affect the operation of the device, but only determine the difference between the devices. The dimensions of the portal are often associated with the dimensions of the combustion chamber. They are associated with certain location parameters.

There is no absolute value:

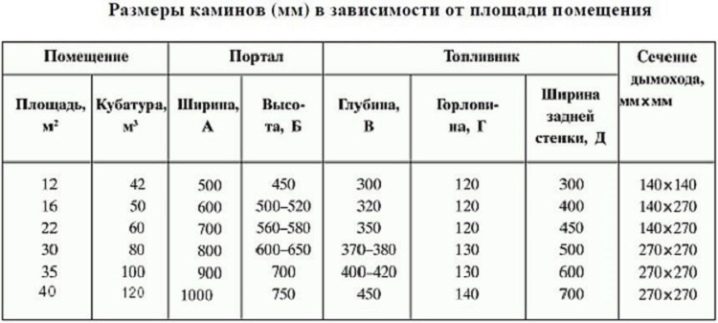

The dimensions of the device are closely related to the volume of the heated room. When implementing your own project, try using the table below. It specifies the conditions for normal operation of the device. Masters use similar tables.

The data presented in the table is formed from certain values. The starting point of calculation for creating a fireplace is always the area of the room. In accordance with this value, the size of the fireplace combustion window is determined. To do this, the area of the room is divided by 50. Next, the dimensions of the furnace are determined by calculating the ratio of width and height. Calculations are expressed as a fractional value of 2/3.

With a buried combustion chamber, the gas removal rate increases.

This is bad, since the warmth in the room cannot be expected in such an outcome. With a shallow combustion chamber, good traction force will not be achieved. Combustion products will begin to enter the room. The depth of the combustion chamber must be related to the height of the windows. Two-thirds of the latter value are proportional sizes that have been verified over the years.

To make it clearer, we give an example of the calculated indicators of a fireplace for a living room with an area of 28 square meters. meters. First, 28 needs to be divided by 50, we get 0.56. These are the parameters of the combustion window. The area of the combustion hole will be 0.61x0.92=0.5612 sq. m., the depth of the fuel chamber is (610x2) /3 = 406.7 mm. The calculated figure can be rounded: you get a fuel chamber 40 cm deep.

In addition to the firebox, a standard fireplace includes a ventilation duct (chimney).

The dimensions of the ventilation duct openings are usually 1/8, 1/15 of the dimensions of the combustion box. In this case, the length of the chimney duct is taken into account. The permissible height is 10 meters. In this case, the design should not be too low. The most optimal height of the chimney structure is 4-5 m. The device is usually supplemented with knee bends.

The required height of the chimney is achieved with a specially laid foundation. Often the pedestal is not connected to the foundation of the house. It also serves as a safety platform for the fireplace. Therefore, it is often made to protrude several centimeters beyond the hearth.

The fuel chamber is placed on a pedestal made of non-combustible materials

, the height of which can be from 30 to 40 cm. An increase in the height of the pedestal is allowed by the structural features of the chimney. In some cases, a place under the pedestal is organized for storing firewood. Calculations of the position of the firebox, as well as the pedestal itself, include the characteristics of the flooring material.

Features of fireplace masonry

Before starting the construction of such a useful invention as a fireplace, the dimensions of which were determined by us earlier, waterproofing should be provided. To do this, you will need roofing felt laid in 2 layers. Laying should start from the corners. In this case, you need to constantly monitor the level. To give the structure an original look, you can lay the bottom row on the edge, and all subsequent ones - flat. External continuous rows require the use of a trowel or trowel. The smoke collector or firebox should be done manually, as this helps to detect small pebbles in the solution.

It is important to remember that when constructing a smoke collector and firebox, a fireplace stove requires removing excess mortar with a damp cloth. We must not forget that the inner wall is not plastered

The seam must be thin, otherwise it can quickly crack. Modern fireplaces require half a brick of seams to be re-tied in each row.

The lining of the firebox and the outer wall should not be connected, otherwise, due to frequent temperature changes, damage to the masonry may occur.