An article about the types and characteristics of heat-resistant tiles. Where heat-resistant tiles are used, production features and what materials they are made from.

Modern trends in interior decor sometimes dictate incredible conditions for creating the ambience of a particular room. Fireplaces and stoves, as a source of heat, a symbol of stability and well-being, should fit organically into the design. It is important that the stove being constructed is properly lined and refined so that the materials do not collapse under high temperature loads and retain their aesthetic characteristics.

An option that optimally satisfies all these requirements is heat-resistant tiles, which have a number of distinctive properties compared to conventional finishing materials.

Properties of heat-resistant materials

Heat-resistant tiles are a high-quality cladding material that has the ability to withstand high temperatures without subsequent damage to the structure and changes (loss) of characteristics. As a rule, the tiles do not have direct contact with fire or hot materials; the temperature is transferred to the tiles through the refractory brickwork.

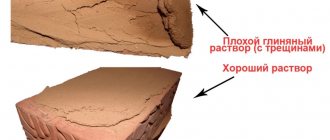

Tiles that are resistant to high temperatures are made from special raw materials - special refractory clay. The technological process of tile production involves hardening the product at a temperature in the range of 1250-15500C.

This production ensures guaranteed stability of the cladding at temperature loads of 1000-11000C.

Finishing elements that are heat-resistant, despite different types that differ in external (decorative) parameters, have almost identical functionality - the absolute ability to withstand critical temperature changes without physical destruction. It is this quality that is decisive when choosing such a material for the external cladding of fireplace and barbecue stoves. In addition, such tiles are wear-resistant and highly durable.

The production of heat-resistant tiles involves the use of materials:

- clay with fire-resistant properties;

- water;

— color pigments with glaze;

— additives that stabilize the shape.

White clay tiles

The chemical composition of white clay includes a large number of trace elements. Its main component is aluminum oxide, which provides plasticity and high fire-resistant properties. White clay is used to produce high-quality ceramic tiles that meet the highest international standards. To obtain certain properties, impurities and additives are added to the composition of white clay. The technology for making white clay tiles is as follows:

- Processing of white clay: grinding, obtaining slip and powder.

- Pressing products of the required shape and density.

- Firing pressed products in a special oven.

- Coating tiles with glaze.

- Applying a drawing or pattern.

The tiles obtained in this way have a high level of resistance to acids, high humidity, and have high mechanical strength and wear resistance. Thus, jade ceramic tiles are made using modern equipment and high-quality white clay. Thanks to this, the products of this manufacturer have excellent performance qualities and are in high demand.

Basic requirements (characteristics) for heat-resistant tiles

The operating conditions for finishing heat-resistant tiles require that they have the following properties:

- excellent heat resistance;

— a base that has a finely porous structure that prevents expansion when heated;

— resistance to damage and mechanical pressure;

- increased strength;

— good heat dissipation;

- environmental friendliness. No harmful gaseous or evaporating emissions;

— sufficient thickness to ensure preservation of properties and performance of basic functions.

The best representatives of heat-resistant materials

1. Terracotta is a durable and stylish material that has a highly porous structure that is as close as possible to its natural counterparts. Of all the facing materials, it is the oldest used by man. Depending on the place of extraction and initial processing, it can have a color from black to dirty gray. It is also used for the production of tiles, which are especially popular in China and Vietnam.

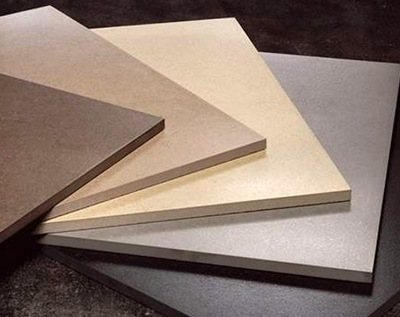

2. Fire-resistant porcelain tiles. It is distinguished by excellent hardness and strength, together with an amazing ability to imitate various types of finishing materials and natural stone. It has been used relatively recently and, in all its properties and characteristics, is a next generation material. Due to its advantages, it has one drawback - it is difficult to cut compared to other materials, but this is a technical problem for manufacturing enterprises.

3. Tiles. Box-shaped tiles with voids in the center, which have unique heat-resistant properties. The main feature is its long-lasting, heat-saving ability. In addition, it is distinguished by the following applied to the front surface: stucco, glaze, drawings, ornaments, etc.

4. Majolica. Essentially glazed terracotta tiles, but with some features that are still unknown. Properties: strength, high porosity and low thermal conductivity. On the island of Mallorca, only 4 family-owned enterprises produce such tiles throughout the world. In this regard, it is an expensive and rare finishing material.

5. Fireclay clay tiles. High-quality and, accordingly, expensive products made from fireclay clay. A particularly fire-resistant material that is added to concrete compositions during the construction of melting furnaces. The tiles are used to line fireplaces in areas of potential flame contact.

6. Clinker tiles. This is the cheapest of the finishing materials that are heat resistant. Such tiles are the most common and are more of a decorative element, since they have the largest range of shapes, colors and shades. It is used more to create a special or unusual ambiance for a room.

What are terracotta tiles

Terracotta is a classic finishing material that is used for cladding facades, basements, and interior spaces. Fireplace makers recognize tiles made from natural materials as having the best technical parameters.

Terracotta tiles can be made by hand. Such products are distinguished by a variety of shades, which are obtained by mixing different types of raw materials. The porosity of tiles increases due to drying technology and the use of kaolin clay in the manufacturing process. As a result, the tiles are less moisture resistant, but pleasant to the touch.

Industrial production involves the use of the stamping method. Such products are distinguished by a uniform color and smooth surface. The use of glaze makes the products look like handmade tiles. The surface covered with a protective layer is easy to clean and resistant to reagents.

Tile production

Like all other heat-resistant materials, heat-resistant ceramic tiles are subjected to double or single firing at the production stages, as required by production technology. The most important condition is the preservation of the structure without the slightest splits, cracks or loss of pattern and shape. Do not underestimate the use of natural materials for environmental friendliness and ergonomics.

Important! The materials under consideration demonstrate the advantages of tiles, which are used to decorate not only immediately adjacent walls and partitions, but also those located near walls. This ensures fire safety and avoids accidental burns.

Features of labeling from manufacturers

Special symbols are applied to the packaging to make it easier to understand whether the buyer needs this product.

The following signs will become indispensable assistants when choosing:

- EN122 and letters between AD. Thanks to them, it is easier to understand whether chemical exposures are harmful.

- The presence of the letters A or B indicates that computer technology was used to create the products.

- The letter A indicates that the stated characteristics are more accurately observed.

- PEI is a combination that indicates the degree of porosity. The numbers following it show the degree. The higher the better.

- The letter E is used for water absorption information. The main thing is that it should be no more than 3%. Granite has the highest moisture resistance - 0.5%. Such tiles for stoves and fireplaces will withstand anything.

Materials used for heat resistant tiles

To make heat-resistant tiles, clay that has a certain composition, especially mineral, is used. From geography lessons, everyone knows that soil layers have the same structure everywhere, which necessarily includes a clay layer. The main composition of this rock is aluminosilicates, which in addition include:

— kaolin is a ubiquitous clay containing remnants of feldspars;

— metal oxides of copper, aluminum, iron;

— magnesium is a metal that gives a porous structure;

- potassium, sodium, etc.

Modern science does not know what exactly gives clay its fire-resistant properties. But the minimum known to us is precisely those properties for which we love, prefer and choose tiles that have thermal, sound, and bio-insulation. Manufacturers introduce certain compounds into the composition, but this process needs to be controlled.

Of course, modern manufacturers have a greater arsenal of knowledge and capabilities; for example, in the modern process of mixing clay, certain crushed particles are added, which burn out during firing, creating additional voids in the thickness of the tile. These voids provide additional heat retention properties. To implement this “trick” use:

- peat, ground into the smallest particles;

— small sawdust from wood production;

- coal powder;

- organic waste;

- crumbs of waste from organic production (usually synthetics).

Heat-resistant tile options

Cladding tiles with heat-resistant properties have many different designs, which differ:

— texture of the front (facing the room) side;

— geometric parameters, in particular, dimensions and thickness;

- texture properties of the surface - rough or glossy;

- glaze pattern and figured elements.

If you want to decorate areas that will not be very hot in the future, then the best option would be tiles with a glossy glassy surface. Usually where the layer of refractory brick is 2, less often 3 layers. This is due not only to its beauty, but also to the fact that the glass coating does not withstand temperature changes well, but despite this, the stoves in Petrodvorets are lined with fire-resistant tiles, decorated with blue and white designs.

As for the shape, laying masters, of course, love standard (rectangular) elements, no more than 10 cm in size. Such tiles are easy to lay, varying the size of the joints, creating an additional range for creativity. In addition, for each type of heat-resistant tile a certain gap should be created, for example, for clinker elements that imitate brickwork, a “gap” of 0.5 cm would be ideal.

It can be confidently noted that all options for heat-resistant tiles can be purchased, without a doubt, regarding the occurrence of fires. There is no need to fake heat-resistant tiles, since any tile is already protective to a certain extent.

Conclusion

The finishing of fireplaces and stoves designed by a competent architect only increases the heat output. Ceramic tiles with fire-resistant properties are a stable, durable material that can easily withstand reasonable temperature changes.

Tiles made by skilled craftsmen can have unique decorative properties, so try to use inexpensive glossy tiles for fireplaces and stoves that are often used. It will cost orders of magnitude lower, and it will be easier to care for (clean) it.

Tips for choosing

Terracotta tiles in the interior help to implement design solutions. A wide range of textures allows you to stylishly decorate the room and stylize the interior decoration as antique. To imitate ancient brickwork, tiles with the appropriate surface are used.

To create the texture of a rough crushed boulder, tiles with a torn stone surface are used. Country style finishing is best done using the Tyson collection. Terracotta flagstone allows you to create a finish that imitates single-color or multi-colored stone.

The building materials market is represented by tiles with a surface that imitates a cut of wood, a careless scattering of stones, and sandstone. For cladding the facade, it is better to use clinker with a matte rough surface, coated with a layer of glaze.

When choosing terracotta, it is important to pay attention to the adhesive base that will be used for cladding. When installing tiles on the surface of stoves, fireplaces, and heated floors, heat-resistant mixtures are used.

Reinforced adhesive “Terracotta” has a high adhesion force to the surface and plasticity. In its production, fireclay kaolin dust, astringent and special additives are used.