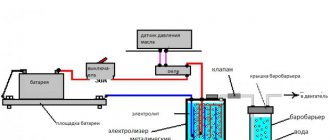

The following equipment is arranged inside the mini-boiler room:

- boiler – electric, liquid, solid fuel, gas

- control unit – no operator attention required

- piping – circulation pump, membrane expansion tank, safety devices

- automation unit - sensors for monitoring system characteristics

- collectors - distribution of coolant along the circuits

- chimney - through the wall or the classic scheme through the roof

The power of boiler houses is enough to heat 500 - 30 square meters of area; the choice is made during the design.

Mini boiler room for home

The advantages of mini-boiler houses are:

- minimization of space - the units are small in size and weight, no reinforcement/construction of the foundation is required

- high efficiency – equipment designed and assembled by professionals fully complies with the declared characteristics

- minimal noise – the environmental friendliness of the units is confirmed by relevant documents

- installation variability - boiler rooms can be installed in a special room, outside the home

- practicality - easy installation, operation, service

- resource – service life exceeds self-assembly from individual components

- functionality – the user can choose the operating mode depending on his own needs

A mini boiler room for a summer residence is located inside metal cabinets, insulated with mineral wool boards and thermal protection. Boiler copper piping is the most reliable technology.

Despite the high initial costs, service life and maintainability increase sharply, and there are no operating costs. Copper is not subject to deformation, aging, withstands significant water hammer, and is not afraid of accidental mechanical damage. The tubes are connected by crimping, soldering, and press fittings.

Mini boiler room ZOTA

The manufacturer produces several modifications for heating buildings 360 - 30 square meters. They are equipped with electric heating elements 36 - 3 kW, sensors, circulation pumps and membrane tanks. At the customer's request, solid fuel boilers from the same manufacturer Master, Carbon, Mix, Topl-M, Dymok-M can be used instead of electric heaters.

Mini solid fuel boiler houses are combined and operate on liquid fuel, liquefied/natural gas, briquettes, wood, and coal. Most models provide for the installation of 9 - 3 kW heating elements controlled from an electronic remote control.

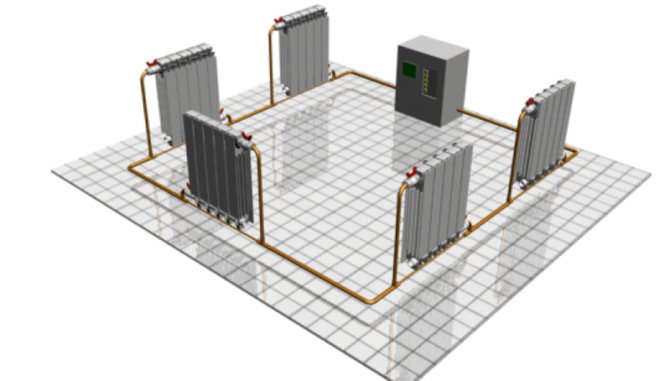

The boiler plant equipment is mounted in a common housing with piping, control, and power unit. Compact layout, budget reduction, and saving of working space make these boiler rooms in demand among individual developers, owners of apartments in townhouses and duplexes.

Electric mini boiler rooms

Mini boiler rooms for a private home using heating devices with heating elements are autonomous heating systems. However, it is widely practiced to replace central heating with electric boilers for the period of repair. Cheap equipment, minimal weight, and dimensions reduce the budget for repairs and operation.

The cost of the energy carrier is higher than natural gas, however, lower than other types of fuel. There is practically no maintenance, which is also beneficial for the family budget. In addition, there are ways to operate economically:

- installation of a two-tariff meter

- installation of a buffer tank for heat accumulation

At night the cottage is heated, the buffer tank is charged with heat, during the day the boiler is turned off, heating occurs with the buffer tank. The units are highly mobile due to their modular design:

- in the first sector there are electrical power units

- the thief contains electrode boilers

- the third contains additional equipment

The unit is assembled within half an hour, after connecting the electricity and water supply it is ready for operation.

Repair of a boiler room in a private house

In the process of building a private house, many questions arise: layout, organization of water and electricity supply, interior; but first of all, it is necessary to resolve the issue of the design of the heating system. Properly organized heat supply is the key to not only comfort and coziness, but also safety in the home.

Repair and organization of the heating system in the house is carried out in several stages: 1. The first stage is choosing the type of heating system. Based on the heat source, heating systems for an individual home are divided into the following types: Water heating; ? Steam heating; ? Air heating; ? Electric heating.

The most popular and economical is the use of a water heating system with the installation of a gas boiler. This is explained by the relatively inexpensive tariffs for this energy carrier, as well as the availability of connection to the gas supply network. 2. The second stage is selecting a location for boiler room equipment.

An important issue in organizing home heating is the location of the boiler room. In new construction, a separate room or room is usually allocated for the boiler room. If the house has been in use for a long time, it is possible to add a separate room. The location of the boiler room occurs individually in each case, based on the specifics of construction and the financial capabilities of the owner. 3. The third stage is the arrangement of the premises for the boiler room, in accordance with the standards and requirements that apply to them. The requirements for the room are determined by the type of fuel used to generate heat, as well as its location relative to the residential part of the house. More detailed information is available on the website of Rostechnadzor of Russia.

There is a separate list of conditions, standard for all types: • It is unacceptable to place more than two boilers in one room; • Storage of flammable substances in the boiler room is not permitted; • Walls and flooring must be made of non-combustible materials; • Access to the boiler must be free from any side; • It is necessary to provide for the organization of the ventilation system in the room in accordance with the boiler power. • At the entrance, it is necessary to install a door, observing fire safety regulations. 4. The fourth stage is installation of a gas boiler.

Having equipped the boiler room in accordance with the requirements, installation of gas equipment is carried out. First of all, the boiler is mounted by wall mounting and all the necessary additional elements: chimney, expansion tanks, manifold, boiler. Then the pipeline is laid to the radiator locations.

The final stage is the installation of radiators, as well as the installation of shut-off and control valves. It is mandatory to carry out the first start-up in the presence of gas service specialists.

Boiler room repair is one of the most complex and time-consuming processes in the construction of a private house. It must be approached with all responsibility and seriousness.

Mini boiler rooms on gas

Autonomous heating and hot water supply systems are in demand among residents of cottage villages. A mini boiler room for a home using natural gas, propane-butane mixture is an economical solution. In the event of a power loss, the automation will turn off the boiler and restart it automatically when the power supply is restored. The main advantages of the boiler room are:

- readiness for operation – after installing the cabinet, connecting the energy carrier, water supply, the system is ready for use

- ergonomics – automation ensures minimal user participation, remote control, fuel economy

- maintainability - a failed unit is replaced with a similar one in the shortest possible time

- practicality - a reasonable quality/price ratio is an undeniable advantage of the equipment

- variability - chimneys can be discharged through the roof, wall, the boiler room can be installed outside the house, in a separate room inside the cottage

The quality of the equipment is confirmed by warranty obligations and the brand’s reputation in the market. Installation and service are provided at the request of the customer; the service of replacing centralized heating with an autonomous one during the period of repair of the first one is gaining popularity.

My works:

Mini boiler room in a private house in Nakhabino (Istrinsky district)

Which ones to choose

15 hidden heat leaks in a private home that you didn't know about. Why is there a cold floor in a private house?

If you have doubts about which material to choose, you should pay attention to where this ceiling will be installed. For example, wooden flooring in the bathroom or kitchen is not a very good idea, since the likelihood of fungus increases significantly

In this case, it is better to choose tension fabrics.

When choosing ceilings for a private home, you need to focus not only on their beauty, but also on practicality. If, for example, a country house is used only in summer, and in winter it is not heated, then ceilings made of wood and plasterboard should not be installed, because dampness and cold will contribute to the rapid destruction of the materials. For such rooms, plastic panels or PVC structures are more suitable.

Provided that the house is used all year round and heated in winter, you can choose wood trim. Its advantages are strength, safety and environmental friendliness. With proper care, this ceiling will last a long time.

In this case, drywall is also suitable - it will hide all the imperfections. And after installing it, you can decorate the ceiling in different ways: use plaster, paint or wallpaper. Stretch ceilings are resistant to moisture, which is why they are suitable for any room. If you can choose, for example, glossy or matte options for the kitchen or bathroom, then fabric coverings will look more comfortable in the bedroom or office.

There is no need to create special beauty in the boiler room, switchboard and other utility rooms. There must be cleanliness and order, and compliance with all safety measures comes first. In a boiler room, all kinds of pipes usually run along the ceiling. You don’t have to cover them, but simply plaster and whitewash the ceiling. But if you really need to hide all communications from view, then you should use fire-resistant plasterboard.

It is also necessary to consider the fact that access to all pipes should be available at any moment. Therefore, you should leave holes in the required places and provide them with gratings, which, if necessary, can be easily opened and the required work can be carried out.

There are a lot of materials for decorating the ceiling, as well as options for combining different textures. All that remains is to think through the design of the room and decide which ceiling is suitable for a particular home, taking into account all the factors described above.

To learn how to decorate ceilings in a private house, see the following video.