Insulation of a balcony with aluminum glazing

Almost all apartment owners in modern buildings benefit from cold aluminum glazing.

Along with the obvious advantages of an aluminum profile, it is not able to provide sufficient heat retention, and in some cases, residents want to use a balcony or loggia not only as a cold storage room. Before deciding how to insulate a balcony with aluminum glazing, you should clearly define what it is for. Often our customers want the temperature on the balcony to be higher than outside in cold weather, so that frost does not spoil preserved food and other things. However, sometimes there is a desire to turn the balcony into a full-fledged warm room, where you can be comfortable even in severe frosts.

Needless to say, the amount of work and costs for implementing these two solutions will differ dramatically? We recommend not to do the insulation yourself and not to look for step-by-step instructions for insulating a loggia with aluminum glazing. After all, only specialists will help achieve maximum efficiency when carrying out work, and also know which materials and technologies should be preferred.

We insulate a balcony with panoramic glazing yourself

Important nuances

There are significant differences in the insulation of panoramic balconies and loggias, caused by the peculiarities of these structures. The balcony is always located on a slab protruding beyond the load-bearing walls of the building and remains open on several sides. The loggia is built into the facade of the house so that only its front part borders on the street space. From the point of view of openness, a balcony is a colder room and therefore requires more costs for thermal insulation.

The structure of the loggia is reinforced with capital walls, which avoids its deformation during thermal insulation work.

Organization of balcony insulation at the design stage

Despite the fundamental differences in the structure of a panoramic balcony and a loggia, the same technologies are used to insulate them. Some of them are used at the stage of building a house, others - when it has already been put into operation.

To prevent heat loss, the main source of which is the glass surface, it is necessary to choose the right light transmitting structure. The best option would be “warm windows”. This term should be understood as enclosing structures with:

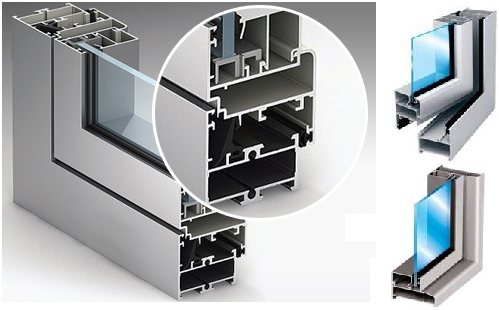

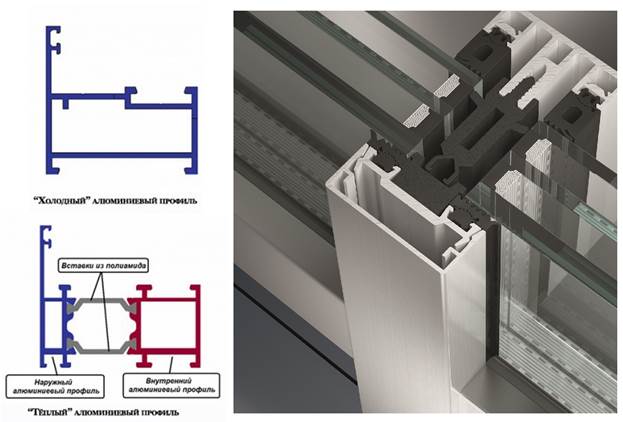

- insulated profiles. Standard window systems use aluminum frames, which are cold frames. For additional thermal insulation, they are equipped with thermal bridges - inserts made of polymer materials with low thermal conductivity. Also “warm” are windows with a plastic profile whose thickness is at least 80 mm;

- energy-saving double-glazed windows with optimal heat transfer resistance - 0.78 m²·K/W. They use at least double low-e glass and the chamber is filled with argon. This prevents heat loss from the premises and improves sound insulation.

Windows with single-chamber double-glazed windows have a heat transfer resistance of 0.35 m²·K/W, which is half the required value. It is not recommended to glass a panoramic balcony with them, as they will be cold. Single-chamber double-glazed windows are used only if there is a risk of overloading the base of the balcony. In this case, glass with an energy-saving coating, argon chamber filling and a thermal bridge is used.

Organization of insulation of a balcony using “warm” glazing

Thermal insulation of a balcony with “warm” window systems is carried out in the following sequence:

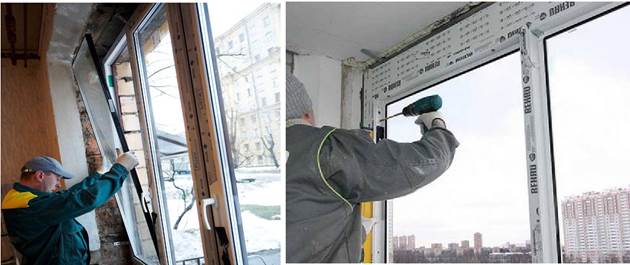

- dismantling old glazing. Cold windows are removed along with their frames, the opening is cleaned, and it is leveled/adjusted for the installation of a new structure;

- installation of “warm” frames. In this case, you need to take care of their correct installation. It involves the use of dowels to secure the structure. This will ensure a strong and tight fit of the frames to the walls;

- installation of double-glazed windows. Their upper part is inserted into an H-shaped guide, and the lower part is supported on a rubberized profile. To ensure the tightness of the structure, the glass is pressed to the frame with rubber seals.

A properly installed “warm” window is the key to preventing heat from escaping into the street.

After installing the structure, all cracks and gaps are filled with polyurethane foam. If the panoramic balcony is long, it is recommended to equip it with thermal compensators - elements of linear expansion. They are necessary to prevent deformation of the structure over time under the influence of external factors. Thanks to them, a gap of 5 mm is formed in the frame, allowing the glass to slightly expand/contract under the influence of ambient temperature, without compromising their appearance or the tightness of the structure.

The thermal compensator is installed in increments of 4 m for white profiles and 2.5 m for colored ones

How to insulate a balcony with already installed panoramic windows

If the balcony is already glazed, but the structure is cold, reducing heat loss will be problematic. In order to maintain a stable temperature inside the apartment, you can use the following insulation methods:

- thermal insulation of all non-glass surfaces of the structure - floor, walls and ceiling. Then the balcony will become a kind of layer between the apartment and the street, preventing heat loss from the living space. But you shouldn’t expect that it will be comfortable to stay on it during the cold season; the temperature there will be only a few degrees higher than the street temperature;

- connecting space to room. This is convenient because the balcony is automatically included in the central heating system of the apartment. But this option is complicated by the need to obtain permits for redevelopment, financial costs for refurbishing the premises, and its further heating;

- installation of a heated floor system. This method of thermally insulating a balcony structure is convenient to use if it is not possible to connect it to a room due to the complexity of the process or lack of funds.

Insulation of a balcony or loggia that will not be heated

If the balcony or loggia is not planned to be heated, but the goal is to increase the temperature in the room as much as possible, then, as a rule, replacing the aluminum profile is not required. There are ways to reduce heat loss:

- pasting the aluminum frame with heat-insulating material;

- covering glass with energy-saving film;

- use of a “warm” aluminum profile, which has plastic disconnecting elements (in this case, the glazing will need to be replaced).

What happens next when insulating a loggia with aluminum glazing? Now you need to focus on reducing heat loss from the walls, floors and ceilings. First of all, you should close, insulate and waterproof the seams between the frame and the balcony structure, as well as seal the cracks in the walls.

Insulation can be carried out from the outside and from the inside. In the first case, you will most likely need to obtain permits, but in the second, you can insulate a balcony or loggia with your own hands.

After all the seams have been processed, we insulate the floor, which is characterized by significant heat loss. First, you should level the base of the floor, for example, by making a screed. Then the sheathing is installed, on which the insulation is placed. It is advisable to place a waterproofing film on top. After this, the floor is sewn up and linoleum or laminate is laid on top.

The walls and ceiling are insulated using the same technology: a sheathing is made into which the insulation is placed, and then the sheathing is installed. If the apartment is located on the top floor, then the question “How to insulate a loggia with aluminum glazing?” will also include a search for ways to insulate the ceiling with high quality.

One of the described methods or a combination of them will allow you to insulate the balcony and prevent it from freezing. However, we are not talking about creating a cozy and warm room. To install the latter, the glazing will have to be replaced.

Key subtleties

It is important to draw up a plan and adhere to an integrated approach to insulating a balcony or loggia. Factors to consider:

- thermal insulation parameters of window profiles;

- selection of optimal insulation, taking into account the type and characteristics;

- Since the base slab is essentially a suspended structure, care must be taken not to overload it with heavy building materials and not to exceed the permissible load.

In a new building, in order for the insulation of the balcony to be done conscientiously, it is important not to skimp on installing windows. Give preference to multi-chamber energy-saving double-glazed windows with low-emission glass from well-known manufacturers - Rehau, Veka, KBE, Salamander, etc. They will protect your balcony from the penetration of noise and dust.

There are two types of panoramic glazing:

- Balconies with three-sided glazing;

Related article: Is it possible to lay laminate flooring on the balcony?

- Loggias with a glass facade.

In the first case, it is not so easy to choose the necessary insulation scheme for a cold panoramic balcony so that it is effective, especially if the windows occupy the entire surface to the floor. Heat losses will be large, because two- or three-chamber double-glazed windows cannot be mounted on such a balcony due to their weight (limitation on the load on the base).

The most effective way to compensate for heat loss is a heated floor. Moreover, it is advisable to install it before installing the windows, so that you do not have to limit yourself in the thickness of the installed insulation layers, and without replacing the structures of the installed window unit, you will have to work with what you have.

It is much easier to provide a warm and comfortable environment on attached loggias with glazing only along the facade. Most often, you can choose any double-glazed windows and materials, since the load-bearing slab in such loggias can withstand heavy loads. If the area of the room is small and the loggia is adjacent to the warm room of the apartment, then you can limit yourself to ordinary insulation on the floor, as on the walls and ceiling.

If it is better to entrust work such as installing double-glazed windows and installing heated floors to professionals, then insulating walls, floors and ceilings is quite feasible to do with your own hands, with a maximum of one assistant.

Insulation of the balcony by replacing the aluminum profile

How is a balcony or loggia with aluminum glazing insulated so that it can be used as an office, library, greenhouse, etc.? This will require a complete replacement of glazing and the use of heating.

It is worth noting that when replacing glazing, the appearance of the building should not change, that is, the new profile should not differ from neighboring ones. This cannot be achieved using standard PVC windows. Therefore, preference is given to wooden-aluminum windows. They can be of two types:

- made of aluminum and have wooden linings on the inside of the room;

- made of wood with aluminum overlays on the outside.

Using such frames with suitable double-glazed windows, you can insulate a loggia or balcony with aluminum glazing. In this case, the façade will not undergo any changes.

The next step will be the installation of a heating system, which can be a heated floor, wall convectors, etc. In some cases, a good solution would be to connect a balcony and a room.

How can you insulate a balcony with cold glazing?

Developers of residential neighborhoods in large cities, regional centers and even small towns commission houses with standard glazing for balconies and loggias. The standard scheme for its implementation is the installation of a frame made of aluminum profile and installation of single sheet glass into window sashes. This is due to the fact that, according to existing standards and building codes, balconies and loggias are not residential premises, but perform auxiliary functions and therefore do not require insulation. This design, from a financial point of view, is the most economical for the developer and relieves him of responsibility for deficiencies that may arise during the installation of more expensive and quality-demanding warm glazing.

Recently, a fashionable trend is the insulation of balconies with cold glazing, which allows residents not only to save thermal energy, which is subject to accounting and appropriate payment, but also to expand the usable living area of the apartment. On a warm balcony you can set up a workshop, create a study, or create a flower or vegetable greenhouse.

At the same time, homeowners are faced with the question: how to insulate balconies with cold glazing. If the walls and parapet can be covered with effective modern insulation and topped with finishing from a number of common and popular materials, then solving the problem of cold glazing is much more difficult.

The situation is aggravated by the fact that any changes and alterations to standard glazing may lead to a change in the appearance of the building's facade, and the reconstruction may not be approved by the relevant services. As a result, replacing cold glazing with warm glazing may be prohibited. And if work is carried out without permission, penalties and litigation may follow, which usually results in a decision to dismantle the installed glazing.

Replacing a profile

To insulate the frame of the structure, you can replace the existing aluminum profile with the same analogue, but with a special polyamide insert. This method is quite expensive, since you will have to completely replace the entire frame of the glazing wall.

Insulating a balcony, which was originally designed by the designer as a cold room, is a rather costly and time-consuming task. It is advisable to obtain competent advice from specialists in the field of construction before making a decision on insulation.

When carrying out repairs, many owners of a balcony with cold glazing think whether it is necessary to insulate the balcony. Does it make sense to spend additional funds if heating is not planned there?

It all depends on how the balcony will be used. If this is a loggia, then you can make an additional room out of it or make an office. But in this case, the owner must first change the glazing. A high-quality double-glazed window is installed, and then the balcony itself is insulated.

In this case, the investment is justified, since the additional living space does not fit, and it is also possible to improve the comfort of living in the apartment, eliminating cold and drafts.

Moreover, you don’t have to carry out any redevelopment, you don’t have to move the radiators, but you can put a heated floor on the loggias or install an oil heater.

If there is a balcony in a Khrushchev or panel house, the issue of insulation is controversial. If the balcony is used as a storage room for skis, sleds, a place for smoking and drying clothes, then insulation may not be necessary, but if you want to make a cozy balcony, then the investment is justified.

What must be done when insulating a balcony:

- use modern materials that will provide warmth but will not waste the usable space inside. This can be polystyrene foam or regular foam. Be sure to waterproof the structure so that the structure does not become damp and condensation does not appear;

- they insulate not only the floor and walls, but also the ceiling so that the box becomes airtight;

- all seams must be filled with polyurethane foam;

- Cover the sealant with a protective layer so that UV rays do not destroy the mounting foam. Acrylate paint, putty or construction tape are suitable here;

- We do not overload the floor slab, so we use modern materials for steam and thermal insulation. They are all very light;

- We do not insulate the wall between the hall and the balcony. This makes no sense if everything else is well insulated.

For finishing you can use various materials, but if there is wood, then it is worth impregnating it with protective agents. Plastic is the most popular and is easier to clean.

The main heat is lost through the windows, so with cold glazing, even with high-quality insulation of the floor, walls and ceiling, it will not be hot. The temperature difference will be only a few degrees, the only thing is that there will be no condensation, and the windows will fog up less. The more chambers there are, the warmer the window profile is. This means that with warm glazing there should be from 3 to 5.

That is why, in order to create comfort in the apartment and make the balcony warm, it is worth changing the frames or at least installing energy-saving glass.

As you can see, insulating a balcony is justified in two cases: if warm glazing is installed, and then insulation is carried out, and if you want to reduce the appearance of condensation on the glass, reduce drafts and noise in the apartment.

Otherwise, investing in a balcony is not justified, as it is quite labor-intensive and costly. Moreover, such expenses are inappropriate in old houses, where the balconies are very dilapidated.

Applying for permission to glaze a balcony

There is no clear legal regulatory framework on the issue of glazing balconies, so it is difficult to answer whether it is necessary to declare this and whether there is any point in the costly preparation of permits. Current legislation provides for a procedure for official registration of repair work in a number of authorities when redevelopment is carried out in apartments. Installation, dismantling, repainting and changing the configuration of balcony frames do not relate to reconstruction or redevelopment work, therefore the possibility of carrying them out and the legality of installation is determined by local officials or representatives of architectural services. Complaints to the owners may arise in cases where during the modernization the color of the entire profile frame or the shape of the window frames are changed.

Cold glazing conversion methods

An aluminum frame with cold single glasses on the balcony protects the room from precipitation, street dirt, wind and dust, but not from cold air in winter. Most residents do not face the question of whether it is necessary to insulate a balcony or loggia; they would all like to insulate the balcony with cold glazing. There are a considerable number of ideas and methods for solving this issue from folk craftsmen and reputable window companies; reconstruction concerns the insulation of the profile itself and replacement of glazing; the main methods consist of the following work:

- Insulation of aluminum profile. Most often, it is covered with Penoizol or Penofol on the inside; the effectiveness of this method is close to zero, the only plus is that the insulator will prevent hands and other parts of the body from sticking to the frozen aluminum frame in winter.

- Covering single glass with heat-insulating film or replacing it with heat-saving types. In the first case, the film can reduce heat loss through glass by 30%; when installing glazing that reflects thermal radiation, heat loss can be reduced by one and a half to two times. However, these advantages are minimized when the glass and metal balcony frame freeze in winter.

- Replacement of window sashes. Some craftsmen, due to the fact that it is technically difficult to replace single glass with a warm multi-chamber double-glazed window in a casement, remove window sashes with cold glazing and install windows with multi-chamber double-glazed windows in their place. Since the aluminum frame is replaced with a PVC structure, the windows differ in color from the aluminum frame and disrupt the aesthetic appearance of the building facade. Another disadvantage of the design is the installation of heavy windows with multi-chamber double-glazed windows in an aluminum frame that is not designed for heavy weight - this can lead to breakage of the fragile aluminum frame, weakening of its fasteners and collapse of the glazing.

- Installation of the second glazing circuit. A radical method of insulating cold balconies and loggias is to install a second frame with warm glass inside the room. The method requires significant financial expenses, leads to a decrease in usable area, disruption of the aesthetics of the appearance from the inside of the room, difficulty in ventilation and the accumulation of dirt between the two glazing contours in places that are difficult to access.

- Replacing a cold aluminum profile with a warm one. The method allows you to maintain the typical appearance of the glazing, which does not cause any complaints from housing and architectural services, and reduce heat loss through the aluminum profile during finishing to a minimum. A warm aluminum profile consists of an external and internal aluminum frame, separated from each other by a plastic insert, which is a cold bridge. Reconstruction results in a complete replacement of all cold glazing on a balcony or loggia, so the costs are maximum compared to other methods. The design is better used in southern latitudes than in cold climates - the insulating plastic partition does not protect the aluminum frame well from freezing and frost appears on the window glass.

An analogue of replacing cold aluminum frames with warm ones is the use of wooden structures trimmed on the outside with aluminum profiles. In this case, old cold aluminum glazing needs to be replaced; wooden frames will cost even more, but will provide high thermal protection for the room in cold northern latitudes.

In this case, double or triple glazed windows are installed in wooden sashes; their advantage over standard wooden frames is the finishing of the outer part with aluminum, which protects the wood from the harmful effects of the external environment (moisture, solar radiation).

Professional insulation of balcony frames

Some window companies glaze and insulate balconies with cold frames using modern technologies and materials. When carrying out work, the main stages are:

- Sealing cracks in the ceiling using metal plates and polyurethane foam.

- Insulation of frames around the perimeter with Vilaterm 60 mm, polyurethane foam and Penofol

- Insulation with Penofol and sandwich panels for balcony parapet

Standard glazing and insulation of balconies and loggias of modern high-rise buildings currently does not satisfy many residents due to its budget and cold indoors in winter. It is better to insulate a loggia or balcony with the installation of new, warm, high-quality glazing with the help of window companies that perform these types of work, while new multi-chamber double-glazed windows are installed and the aluminum frame is insulated.

Insulation of the ceiling slab

Relevant for balconies on the top floor. Also where the next balcony is not insulated. In other cases, it is enough to cover it with clapboard, plaster or paint. Insulation is done according to the same scheme as the walls.

- Covering the outside of the balcony with a profiled sheet will help reduce wind permeability;

- It is better to cut foam plastic with a tool with a fine tooth, the cut is smooth, without chips;

- Before insulating a loggia or balcony, it is necessary to inspect the balcony from above; if it is not glazed and not insulated, then it is not recommended to carry out the work at home.

By strictly following the advice, even with cold glazing you can achieve a comfortable temperature on the loggia. The temperature inside the apartment partly depends on how to insulate the balcony. For maximum protection from the cold, you need to replace single - cold glazing with double - warm glazing.

When buying an apartment, we often think about how to insulate a balcony with cold glazing without replacing the glazing. However, the problem is that developers often do not use expensive materials, so the glazing is installed cold, and the balcony itself is not insulated in any way. In this case, the homeowner may want to replace the cold glazing with warm one. This will help eliminate the heat loss that occurs through the window frames. The end result will be significantly improved.

Options for cold glazing of balconies

Two main options:

- Cold plastic glazing

- Cold aluminum glazing.

Both of these materials are ideal. They are environmentally sustainable and modern, and the designs, manufactured and installed to individual dimensions, can satisfy every individual request. Everything will be done solely at the request of the customer. Either an insulated, heat-retaining structure with a full double-glazed window, or regular cold glazing to protect against dirt and wind.

Aluminum

This type of glazing is ideal if there is no client’s request to retain heat on the balcony, and the purpose of the installed structures is only to protect them from natural precipitation: wind, snow, rain and hail, as well as from debris flying from the upper floors getting onto the balcony.

However, it will not retain heat due to the high thermal conductivity of aluminum, and therefore is called “cold” glazing. The advantages of using these materials are:

- Lightweight structures made from this profile.

- High strength and resistance to environmental influences.

- Simplicity of installation, as well as the possibility of installation even in wooden frame systems, due to the lightness of the structures.

- Installation is done quite quickly. After preliminary measurements have been taken, the number of sashes and the upper and lower ebbs ordered in advance have been determined. And also with a minimal list of preparatory work, since the load on the railings or other structures is minimal and usually does not require serious reinforcement.

- Another advantage is that there are no limitations in color variations.

The warranty period of over ten years is incredibly encouraging.

These structures are not subject to combustion, and accordingly have a high class of environmental friendliness.

The ease of maintenance and operation is also impressive, since these structures do not require anything other than periodic lubrication of the rollers and maintaining cleanliness.

Particularly popular is the option of using a provenal aluminum profile; this profile has the highest resistance to temperature changes, is anti-corrosion in its properties, durable, and the fittings are protected from external penetration. But you need to remember that along with the advantages, it has a number of disadvantages.

This design option does not have protection to retain heat and the sashes may freeze during a sharp drop in temperature, as well as a low level of sound insulation. If there are no plans to attach the balcony part to the living room, then you can safely use this option for the balcony.

Aluminum glazing options include:

- Frameless glazing, the most modern and popular in new buildings, will again protect your balcony from debris and dirt, but not at all from the cold. Since it does not have any seals, except for a silicone cord along the edge of the sash. Its advantages are an unrestricted view and the possibility of almost completely opening the space if necessary, since the doors on runners slide one after another.

- Balcony glazing with extension: an ideal method for very small balconies and allows you to somehow expand the space and add the treasured half a meter. During installation, brackets and a frame are used, on which a lightweight aluminum structure is attached.

Plastic

If the customer’s glazing requirements for heat on the balcony are slightly higher, then a sliding plastic system can be used.

Unlike aluminum glazing, here it is possible to increase the number of installed glasses to two, which of course will increase energy saving on the balcony. It has better parameters in terms of tightness and sound insulation. They slide easily, and the rebate at the junction of the frame and profile provides much better protection from blowing. This glazing is the most affordable on the market, which is what attracts the customer’s attention.

A quick process from measurement to installation will not cause inconvenience and will not delay repair work. Cost and size calculations are made on an individual basis; managers can do it for you when you receive a consultation in the office or by phone, or when you fill out a preliminary calculation form on the website.

During installation, all work on dismantling old structures, strengthening the facade and installing new structures is carried out at the same time. With the exception of very old and unreliable frames that require complete replacement. After installation, insulation and sealing are carried out, after which all seams are closed with decorative inserts. And before you appears a single structure without any reminders of unevenness or distortion.

Insulation

If the option of installing cold aluminum glazing structures is made, then finishing materials must be selected taking into account resistance to temperature and humidity.

When glazing is cold, it is necessary to carry out waterproofing work on all joints and seams on the balcony. Typically, polyurethane foam is used for this in combination with liquid waterproofing. It is ideal to use roll insulation, especially if there is a need for additional protection of the materials used for finishing. High-quality insulation work in combination with cold glazing will increase the temperature on the balcony by more than 5 degrees compared to the outside, and will also reduce heat transfer rates, and accordingly this is already a serious application for insulation.

The level of humidity also decreases, which will allow the use of finishing materials such as eurolining (coated with additional protective compounds) or plastic panels, under which insulation can also be laid, but unfortunately this will not have a serious effect on increasing the temperature. In addition, the use of decorative plasters used for facade work also becomes available.

External railings, if any, can also be insulated by laying insulating materials, and the facade part is finished with materials for external work, for example, siding.

By insulating the floor, you will be able to go out onto the balcony in slippers at any time of the year, without compromising your health.

The main materials for insulation are mineral wool and penoplex, in addition to waterproofing, you get an excellent complex with low thermal conductivity. Insulating balcony walls has additional advantages. This increases sound insulation. It becomes much quieter on the balcony, and the noise level in the room is noticeably reduced. Otherwise, the main materials remain the materials used for floor insulation.

Floor insulation

An important component in obtaining a warm room is floor insulation. For better thermal insulation, you can use the following materials:

- Penofol.

- Electrical floor insulation.

- Wooden beam.

- Polystyrene foam or mineral wool.

- Polyurethane foam.

- Floor board.

Foiled foam foil is laid on the surface of the concrete floor. This material has excellent insulating properties. It will not allow condensation to accumulate in the thickness of the floor, providing access to oxygen to prevent the appearance of moisture and fungus. The next step is to install the electric heated floor.

Warm floors are one of the options for insulating a balcony

The thickness of the lag determines the size of the insulation layer. The larger its layer, the better the thermal insulation. When installing, it is necessary to take into account the height from the future floor to the parapet. In the standard version, it ranges from 95 to 105 cm. The safety of a person on the balcony is always in the foreground, so you need to choose the thickness of the joists, taking into account the height of the floor structure.

Wooden blocks are installed parallel to each other in one plane with a pitch of 30-40 cm. Mineral wool or foam plastic is laid between them. All cracks formed during the installation process can be sealed with polyurethane foam. In the winter season, a special polyurethane foam is used, which has hardening properties at low air temperatures.

A floorboard is laid on the laid joists for painting and varnishing. You can use rough wood and then lay some finishing material on it.

Finishing

This question, how to further finish the balcony, arises after the installation of the façade structures, and becomes the next step in bringing the balcony to its cherished goal, that is, to a usable space. When using cold glazing, it is necessary to carefully select finishing materials, take into account high humidity, and also, the materials must be resistant to both high and low temperatures.

There is no possibility to use materials such as drywall or wallpaper, and not all options for plastic panels are suitable here. However, even with cold glazing, you can finish it and get a space that looks no worse than the room.

The preliminary work carried out on waterproofing and insulation will make it possible to use not only plastic panels, but also natural materials, such as Euro-panels, or will allow finishing with decorative facade plaster for walls. And for the floor you can use, for example, a laminate with a high level of moisture resistance.

Price

All these works - cold aluminum glazing and interior finishing without serious insulation - are the most budget options and are available to almost everyone.

But remember, serious insulation is not possible when using cold glazing.

As you understand, there are a huge number of options, but glazing, insulation and finishing of the balcony are more than affordable on the glazing market. All necessary consultations and preliminary calculations can be carried out over the phone, and the final figures will be announced after the measurement.

We wish you a pleasant choice and a new balcony.

Glazing

Balcony insulation, as a rule, begins simultaneously with work on panoramic glazing. A typical glazing option of this type involves one glass and “cold” aluminum frames. Heat loss can be reduced by almost three times if this design is replaced with a window system with a thermal bridge (inserts made of a material with lower thermal conductivity) in the frame. This will also significantly reduce the amount of noise entering the loggia from the street.

If a significant modification of the balcony structure is planned, it is necessary to first approve the project with special licensing authorities.

It is advisable to insulate a balcony with panoramic glazing using “warm” window systems with PVC profiles.

What is special about “warm” glazing?

Insulation of a panoramic balcony is carried out by glazing it with systems with a profile of 70 mm thick. The most famous brands are REHAU, KBE, TROCAL, VEKA, SALAMANDER. As for fittings, give preference to such reputable manufacturers as ROTO, WINKHAUS, MACO, SIEGENIA-AUBI.

Multi-chamber double-glazed windows - why not?

It is not recommended to carry out insulation by equipping a large panoramic loggia with multi-chamber double-glazed windows. For comparison: the difference in the load that single- and double-chamber double-glazed windows create on the base slab of the loggia is about 10 kg per square meter, that is, up to 220 kg for the entire slab.

It is better to order single-chamber double-glazed windows, the glass in which will be covered with an energy-saving film, connected by a “warm” frame, and the internal space filled with argon gas.

Thermal compensators

If you plan to insulate a long stained glass balcony, then a thermal compensator is installed every 4 meters of glazing. It is necessary to protect window systems from thermal deformation. Thanks to a gap of 5 mm, the glazing can slightly expand/contract during operation without losing its tightness and attractive appearance.

For colored PVC profiles, the installation step of thermal compensators is reduced to 2.5 meters.

French balcony: features of panoramic glazing

Modern housing is multifunctional, maximum comfort and pleasure. An apartment is a limited space with a certain number of square meters. However, with the advent of French windows, it became possible to visually expand the walls of the room and go far beyond its limits.

Read also: 60 Main mistakes in apartment renovation. A must read.

A French balcony is a structure that has a slightly different design than ordinary balconies. Today, experts offer several options for this glazing. All technological aspects largely depend on the design features of the room, its area and the customer’s wishes regarding decoration and insulation. But one point remains unchanged - floor-to-ceiling glazing.

There is an opinion that installing a panoramic structure in our climate is not always justified, since the Russian winter is radically different from the French climate. However, innovative heat saving technologies help overcome this problem.

When installing a French balcony, you should clearly understand that the bulk of the heat will be lost through a large glazing area. But glass cannot be insulated. What can be done in this case?

Warm panoramic glazing technology

Before insulating the balcony, you need to deal with the existing “cold” glazing. It is dismantled, the window opening is cleaned of old finishing materials and, if necessary, leveled. Next, they install new “warm” frames and proceed to installing double-glazed windows.

The lower part of the glass unit should rest on the rubber profile, and the upper part should be inserted into the H-shaped guide. Next, the glass is attached to the vertical bars using profile pieces about 20 cm long, and then finally mounted by laying rubber seals.

These rubber profiles are responsible not only for fastening the glass, but also for effective insulation and reliable sealing of facade glazing.

Walls

Foiled polystyrene foam performs well as a heat insulator. It is attached to the walls using polyurethane glue and dowels. The joints of expanded polystyrene boards, as well as areas where the material adjoins the floor and elements of the window system, are glued with aluminum adhesive tape.

The next layer of the “thermal insulation cake” is thicker polystyrene foam.

The joints are also taped with metal tape. When insulating the side and inner walls of a stained glass balcony, you can limit yourself to these two layers (foiled polystyrene foam and thick polystyrene foam). If we are talking about an external wall, then a third layer is also needed - again foil-coated polystyrene foam.

Regardless of whether the insulation is carried out for a semicircular, rectangular or architecturally complex loggia, pay special attention to sealing the areas where the insulation meets the frame of the window system.

The ideal option is to fill the gaps with foam and finish with metal tape. Before applying the tape, make sure that the foam is completely dry, otherwise it may shrink under the layer of adhesive tape.

"Warm floor"

A conversation about how to insulate and landscape a large glass balcony would be incomplete without an emphasis on installing a “warm floor”. We recommend using Hemstedt BR-IM heating cable for these purposes. Hemstedt DH, ALU-Z or DH-Z heating mats are not suitable as they are too thin. If you use a cable of a different brand, then be guided by the fact that its power should vary in the range from 180 to 200 W/sq.m, but not higher! To ensure efficient heating, the cable must be laid over at least 70% of the floor area.

Before laying the cable, it is necessary to insulate the floor that serves as the basis for the stained glass glazing. We recommend laying penoplex, and then pouring an intermediate screed 4-5 cm thick.

Another option is laying foil foam. It will slightly raise the floor - this is its advantage, but the thermal insulation characteristics of penofol are worse than those of penoplex.

Next, a mounting tape is laid out on the floor, on which the heating cable is placed along a predetermined path. In addition to it, they also install a temperature sensor in a special corrugated tube, and “cold” wires, which are then brought to the installation site of the thermostat. When laying out the cable, do not forget to leave a space of about 5 cm from the walls.

When all communications are laid, proceed to pouring the screed. Its thickness is 3-5 cm around the entire perimeter of the loggia. A damper tape 1 cm thick and 10 cm wide is mounted at the base of the wall.

When the screed is dry, check that all parameters of the “warm” floor comply with safety requirements using an ohmmeter (to determine the resistance of the heating cable). If everything is in order, you can complete the insulation work on the loggia and lay the final floor covering.

An integrated approach to the insulation of panoramic balconies and loggias

The highest heat transfer resistance that an energy-saving double-glazed window can provide is 0.78 m²·K/W (low-emissivity glass and argon are used to fill the chambers).

A regular single-chamber package is approximately 2 times cooler - 0.35 m²·K/W. To understand the conditions of insulation work, you should compare the given indicators with the values typical for structural building materials and heat insulators. Thus, a load-bearing wall made of two bricks has an indicator of 0.586 m²·K/W, and extruded polystyrene foam with a thickness of 30 mm has an indicator of 0.882 mm²·K/W.

For non-insulated rooms with walls of two bricks, the heating rate in winter is 100 W/m² (with a ceiling height of no more than 2.7 m). Using the similarity method, we can approximately calculate the necessary qualitative and quantitative measures for insulating rooms with panoramic structures.