When heating a new home or replacing an old boiler with a new one, the question arises: which heating device should you prefer: a wall-mounted or a floor-standing gas boiler? Let's look at their characteristics to understand in which case this or that boiler is suitable.

To begin with, it is worth noting that everything depends on the size of the room that needs to be kept warm. This is exactly what you need to start from when making a decision.

Wall-mounted heating boilers

Let's begin the question of choosing a floor-standing or wall-mounted gas boiler with a detailed consideration of each boiler.

Wall-mounted gas boilers are a great solution for lovers of stylish solutions. In terms of their assembly, they resemble a small independent boiler room. If you have a small private house, cottage, or apartment, then a wall-mounted boiler is what you need. After all, it is intended specifically for heating rooms with a small area or for hot water supply. Their power does not exceed 100 kW.

However, if your area experiences frequent power outages, this type of boiler may not be suitable for you. It is completely dependent on electricity. The built-in circulation pump will also not work. This concerns significant shortcomings.

There are many more advantages.

Advantages of wall-mounted boilers:

- Compactness;

- Ease of installation;

- Easy to operate;

- The price is much lower than floor ones;

- Built-in automation;

- Nice neat design.

All wall-mounted gas boilers include steel heat exchangers. Equipped with an atmospheric burner.

For the boiler to work properly, all processes inside must proceed properly. Monitoring this manually is extremely difficult. The built-in automation will do this for you. Namely:

- Will ignite the gas

- Provides the required thermal power

- The draft in the chimney will be kept at the desired level

- Turn the coolant on and off when the minimum and maximum temperature levels are reached.

If you have a small area, then choosing between a wall-mounted or floor-standing gas boiler, you can choose a wall-mounted one.

Watch a video example of a wall-mounted gas boiler

Which boiler is better: wall-mounted or floor-standing - detailed comparison

Most of us associate the words “gas boiler” with a massive unit, which, perhaps, precisely due to its dimensions, creates a feeling of reliability.

Floor-standing boilers really have not undergone major changes over the many decades of their existence. However, today we have an alternative - a wall-mounted gas boiler.

Unlike its “big brother”, it is lightweight, compact and very flexible in use.

Let's try to figure out which gas boiler - wall-mounted or floor-standing - is better to install in a private house for heating. To do this, we will make an extended comparison of floor and wall units in all respects.

Dimensions are one of the most important differences between wall-mounted and floor-standing gas boilers. The dimensions and weight of wall-mounted models are much more modest, otherwise it would simply be impossible to mount them on the wall without the risk of collapse. The lightness of the design is achieved not only by the overall compactness of wall-mounted models, but also by the material from which the heat exchanger is made.

For wall-mounted models, the heat exchanger is made only of steel; floor-standing models may have heat exchangers made of cast iron, which is significantly heavier, or steel.

Wall-mounted boilers are often called mini-boiler rooms.

And this is no coincidence, because a relatively small-sized housing houses not only the burner, heat exchanger and control system components, but a circulation pump, expansion tank and other elements without which the operation of a conventional boiler room is indispensable. The compactness of the wall-mounted boiler is its main and undeniable advantage. There is no need to allocate a separate room for such a device, because it can be placed anywhere, for example, in the kitchen.

Wall-mounted gas boiler with a coaxial chimney, located in the kitchen.

Floor-standing models inspire confidence with their size. This is exactly what a powerful boiler should be, providing the ability to heat a large building. However, the dimensions of floor-standing boilers often turn into a problem for their owners.

Sometimes, in order to bring such a “giant” into a room, you have to dismantle the doorways.

There were cases when, due to the impossibility of bringing equipment into the boiler room, the purchased floor-standing gas boiler had to be replaced with two smaller ones.

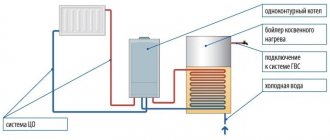

Floor-standing gas boiler and indirect heating boiler.

Equipment

The factory configuration of a wall-mounted gas boiler, as a rule, includes not only the heating device itself, but also a circulation pump, an expansion tank, control system elements, and all the necessary sensors and valves. Moreover, all this is hidden in the body of the boiler itself.

By purchasing a wall-mounted gas boiler, you get a miniature boiler room for your use, that is, the minimum set that, after connecting to the heating system, is able to begin full-fledged work on heating your home.

Of course, if you wish, you can additionally purchase all kinds of room thermostats and regulators, outside temperature sensors, a GSM communication module and much more, improving the heating system of your home and increasing the comfort of its control.

A floor standing boiler is usually just a boiler. Circulation pumps, an expansion tank and many other related equipment are not included in the delivery package - you will have to purchase everything you need separately.

Wall-mounted gas boiler with lid removed.

Easy to install

Which boiler, wall-mounted or floor-mounted, is easier to install? It would seem that this question should concern not potential owners of the unit, but exclusively the craftsmen who will be involved in deploying the heating system. However, do not forget that the buyer, that is, you, will have to pay for this, and the more labor-intensive the work, the more money you will have to part with.

In terms of ease of installation, the wall-mounted boiler is the undisputed leader. In the case of a floor-standing unit, you will have to equip an entire boiler room, because in addition to the boiler itself, you will have to install circulation pumps, an expansion tank and, perhaps, a boiler. The scope of work, as you might guess, differs very significantly, and the cost of the work will vary just as much.

Life time

When purchasing any equipment, especially expensive equipment, we want it to serve, if not always, then at least for as long as possible. This fully applies to gas boilers. Which boiler, wall-mounted or floor-mounted, will properly heat our home for many years?

The service life of a gas boiler is primarily determined by the service life of its heat exchanger. There is currently no consensus on which heat exchanger material is better - each has its own advantages and disadvantages.

In floor-standing models, cast iron heat exchangers are usually installed. Cast iron is less susceptible to corrosion, but at the same time it is fragile, which means there is a risk of microcracks forming during transportation.

In addition, it does not tolerate sudden changes in temperature.

When hard water is used as a coolant, the cast iron heat exchanger slowly deteriorates as a result of scale formation and, as a consequence, local overheating of the material.

Cast iron heat exchanger.

Cast iron heat exchangers are not suitable for wall-mounted gas boilers, because they are too heavy. The most preferred material in this case is steel. The latter is not afraid of shocks during transportation, but is highly corroded during operation, especially incorrectly.

Steel heat exchanger for a gas boiler.

So which heat exchanger is better? Since the boiler does not have to be transported very often, the factor that has the greatest impact on the service life of this structural element can be considered corrosion resistance. From this we can conclude that a longer period of normal operation can be expected from a floor-standing boiler with a cast iron heat exchanger.

We should not forget that the service life of the boiler is also affected by the wear of other structural elements - circulation pumps, gas valve, electronics, etc. The quality of the unit depends on the quality of each of its individual components.

Practice shows that the average boiler from a well-known manufacturer who cares about the reputation of the brand will serve you well for 15-20 years, no matter whether it is wall-mounted or floor-mounted.

No one knows what to expect from a “no name” unit.

Of course, in order for heating equipment to work long enough, you should follow all the manufacturer’s recommendations regarding operating conditions and carry out the necessary maintenance in a timely manner. The user can cope with many problems that arise on his own thanks to the self-diagnosis tools available in modern equipment.

Coolant quality

The service life of a gas boiler and its output directly depend on the quality of the coolant. Using water with increased hardness as a coolant leads to the formation of scale inside the heat exchanger. Scale, in turn, causes a significant decrease in boiler efficiency and, as a consequence, an increase in fuel consumption.

The heat exchanger of the gas boiler is clogged with lime.

Both floor-standing and wall-mounted boilers “suffer” from scale to approximately the same extent; only the level of difficulty in solving an existing problem differs. The ease of disassembling and washing the steel heat exchanger of a wall-mounted boiler allows you to quickly restore the functionality of heating equipment right at the installation site.

Washing the cast-iron heat exchanger of a floor-standing boiler is difficult and, moreover, not always possible (many manufacturers insist that its disassembly and assembly be carried out exclusively in the factory). Most often, a faulty or clogged cast iron heat exchanger simply has to be replaced, and this part is by no means cheap.

It follows from this that installing a floor-standing boiler with a cast iron heat exchanger requires that you have a chemical water treatment plant. This device is not cheap, but in this case it is extremely necessary.

Power modulation

Depending on the implemented method of regulating the flame intensity, all boilers are divided into boilers with a stepped or modulating burner.

One- and two-stage burners have one or two operating modes, respectively (usually 100% and 70% of maximum). The power of modulating burners can be smoothly adjusted over a fairly wide range, which allows fine-tuning the operation of the boiler.

Modulating burners provide fuel savings and allow you to maintain the set temperature with minimal deviations.

A significant part of floor-standing gas boilers are equipped with one- or two-stage burners. Most wall-mounted models have a wide range of power modulation (from 40 to 100%), due to which they operate “softer” - they turn on and off much less frequently than boilers with stepped burners.

Energy independence

For some consumers, an important parameter of a gas boiler may be the dependence of its operation on electricity.

The energy independence of heating equipment is relevant for those whose house or cottage is located at a considerable distance from large populated areas, i.e.

in places where power outages or power surges in the network are possible, leading to the failure of expensive automation.

Autonomy of a gas boiler can be achieved in two ways. The first is to simplify the boiler control system as much as possible. That is

it is necessary to use a unit in which there is no electronics at all. All automation of such a boiler is mechanical.

A heating system that uses a similar boiler that operates without electricity must have natural circulation.

The second method is to use an electric generator, which converts the heat obtained by burning gas into electricity necessary for the operation of the boiler automation. This option is preferable for most users because it creates fewer restrictions.

You can find energy-independent models only among floor-standing gas boilers, which for some buyers will be a strong argument in favor of the latter.

Installation site requirements

Before choosing a floor-standing or wall-mounted gas boiler, you should resolve the issue regarding its installation location.

Due to its compactness, the wall-mounted boiler can be placed in almost any room.

The main thing is that a number of requirements are met to guarantee the safety of its operation: a closed combustion chamber, connection to a coaxial chimney, forced removal of flue gases and injection of air to maintain the combustion process.

Installing a boiler with an open combustion chamber in a kitchen where there is a hood is unacceptable, since in this case a so-called “draft reversal” is possible, in which the smoke from the boiler will not go into the chimney, but into the room.

There are not many options for placing a floor-standing gas boiler. Due to the size of the boiler itself, as well as all kinds of related equipment, we can only talk about a separate room - the boiler room. Despite the fact that the boiler room does not belong to residential premises, when installing a gas boiler, it is necessary to ensure normal removal of fuel combustion products and air flow.

Power

The power of wall-mounted gas boilers, as a rule, varies from 10 to 40 kW. This, according to a rough estimate, is enough to heat a home with an area of 100 to 400 square meters. m. However, if part of the heat is used to heat water for domestic needs, then this power will be enough to heat only a relatively small house.

The capabilities of floor-standing gas boilers are significantly higher. The power of floor-standing models can reach 80-100 kW, and if it is equipped with a forced-air burner rather than an atmospheric one, then even more. If you need to heat a huge house or industrial facility, then a floor-standing boiler is exactly what you need.

Price

The electronic “brains” of a wall-mounted gas boiler are more advanced, and it itself is more functional than the average floor-standing unit.

However, despite this, wall-mounted models very often turn out to be 1.5-2 times cheaper.

This is explained by the fact that the cost of heating equipment is determined primarily by its power and reliability of individual components, while the comfort of handling it is secondary.

Final comparison of wall-mounted and floor-standing gas boilers

| Wall-mounted gas boiler | Floor standing gas boiler | |

| Dimensions | Less | More |

| Weight | Less | More |

| Equipment | The boiler is equipped with additional equipment | Additional equipment must be purchased separately |

| Easy to install | Easier | More difficult |

| Life time | Steel heat exchangers are more susceptible to corrosion, which reduces service life | Units with a cast iron heat exchanger can operate for a longer time |

| Coolant quality | The dependence on the quality of the coolant is high, but it is easier to flush the heat exchanger | The dependence on the quality of the coolant is average, but it is more difficult to flush the heat exchanger |

| Power modulation | More possibilities | Fewer features |

| Energy independence | Fully volatile units | There are non-volatile units |

| Installation site requirements | Less | More |

| power, kWt | 10 – 40 | 80 – 100 |

| Price | Below | Higher |

Floor standing gas boilers

Unlike its wall-mounted counterpart, a floor-standing boiler has more capabilities due to its high power. High power is also accompanied by impressive dimensions. Floor-standing boilers take up significantly more space. Accordingly, they are recommended to be installed in medium and large rooms. Without thinking and installing a large floor-standing boiler in a small apartment, you will regret it later. After all, in apartments with a small area, every meter is valuable.

Advantages of floor-standing boilers

- They can have both cast iron and steel heat exchanger;

- Do not rust longer;

- More wear-resistant;

- You can increase the power using a special burner;

- Does not depend on electricity.

When choosing between a wall-mounted and floor-standing gas boiler, after reading this comparison, we can conclude that for large areas you will not find a better solution than a floor-standing gas boiler.

Rating of the top 10 floor-standing gas boilers for heating a private home

Well, we got to the rating. Now we will find out what are the best floor-standing gas boilers worth purchasing for heating and hot water in a private home.

Protherm Bear 30 klom

Gas heating devices from the Klom line of the Slovak manufacturer Proterm have one circuit, an open combustion chamber and a cast iron heat exchanger, which allows them to extend their service life. Their power is small, up to 26 kW, but with the help of additional devices you can increase the power to 50 kW. To organize domestic hot water, you can connect an indirect heating boiler. The efficiency is not bad - 92%. Suitable for heating rooms up to 260 m². It is possible to connect external control.

The disadvantages include: the presence of only one circuit and the need for a natural chimney. Having analyzed the negative reviews on this model, I can say that there really is a shortage of competent boiler tuning specialists. As for the high cost of spare parts, this is an imported boiler. People complain about expensive spare parts for all foreign models, without exception.

And finally, I’ll say that I also own a “Bear”, but a dual-circuit one. It's been standing for about 8 years now. The area of the heated room is about 200 m². There have never been any problems with adjusting the temperature of the coolant and hot water. But! It took a very long time to set it up, literally! Almost every winter I periodically went into error. And while there was no one at home. The house almost froze several times. Specialists come, perform shamanism and leave. And history, like in the movie “Groundhog Day,” repeats itself. In general, we installed a UPS and batteries for autonomous power supply in case of a power outage, and on the plus side, there was a competent person who said that he had adjusted everything (when asked what exactly, the answer was everything!) and the next winter and summer there were no outages at all. Hence the conclusion: the boiler is good, but it needs proper tuning. Well, there’s one more minus: it’s too dependent on the correct settings.

Read more: Malfunctions and errors of Protherm gas heating devices

Vaillant ecovit vkk int 366/4

German floor-standing gas boilers Vaillant are already a premium brand. The ecovit vkk int 366/4 model refers to condensing boilers, hence the declared efficiency of 109%. Another plus is the closed combustion chamber, the ability to run on liquefied gas and various bells and whistles with automation. The heat exchanger is made of stainless steel. Let's immediately write down the high cost as a disadvantage. Even if we emphasize that the boiler is a condensing boiler, not everyone is ready to shell out 280 thousand rubles. The power of this model is up to 34 kW, which allows you to heat a room up to 350 m². If you want to buy a reliable, high-quality, highly interactive, environmentally friendly and economical gas boiler with a good design and don’t worry about the cost, then take it, you won’t regret it.

Read about Vaillant errors and malfunctions now.

Protherm Wolf 16 kso

So, we come down from heaven to earth. Another Slovakian animal is the Wolf model. I’ll say right away that it is smaller in size than the Bear. Single-circuit with a steel heat exchanger 2 mm thick. Well, to the main advantage. The boiler is non-volatile. The average price is about 25 thousand rubles, which is very good. Not fancy, works like a Kalashnikov assault rifle.

The disadvantages include a 2 mm thick steel heat exchanger, an open combustion chamber (though it simply cannot be any other, since the boiler is non-volatile), and the inability to operate on liquefied gas. The heating system must be designed in such a way that water circulation occurs naturally, because... This model does not have a pump. The pump can be installed separately. The device also does not have an electronic control system.

Read more: Malfunctions and errors of Protherm gas heating devices

Lemax premium 12.5

Single-circuit, with an open combustion chamber and natural smoke removal. Despite its floor-standing location, it is quite compact. The price is around 20 – 23 thousand rubles. Another non-volatile model. The downside is the steel heat exchanger, but the price with cast iron would be different. Suitable for heating a small area up to 120 m². Few bad reviews from consumers.

Lemax premium 20

The Premium 20 line from Lemax is essentially different from the previous model with a power of 20 kW versus 12 kW. Just as simple and unpretentious. The cost is a little more expensive, because... power is higher. Negative reviews from consumers included a defective traction sensor after installing the device. People also wrote about the regular extinguishing of the boiler. But maybe it's a matter of setup, because... The buyer installed the unit himself.

There are 4 more modifications in the Premium 20 line.

- Premium 20 – single-circuit, non-volatile, steel heat exchanger.

- With the letter N (Premium 20N) - with an improved gas valve SIT 820 NOVA for a smooth start of the device. This model also has the ability to connect a room thermostat and a turbo nozzle for forced removal of exhaust gases.

- Model Premium 20B is a double-circuit floor-standing gas boiler for heating and hot water. The difference from Lemax Premium 20 is the presence of contours. As in the first option, non-volatile.

- And the last hodgepodge Premium 20NB. Combines improved characteristics, letter N and dual-circuit design, letter B.

Baxi slim 1 230 in 22.1 kW

This model is no longer non-volatile, but is packed with various types of electronics, self-diagnosis and the ability to connect remotely. The number 1 after slim means that the boiler is single-circuit. The power of the device is 22 kW, i.e. the unit is suitable for heating a room up to 220 m². Italian quality speaks for itself. Has a cast iron heat exchanger. There are not many complaints about these boilers. One of the disadvantages is the flimsy aluminum deflector (chimney pipe). At the same time, we must pay tribute, it does not burn out, but it is better to avoid the chimney structure so as not to touch or distort any part of it.

If you need a floor-standing double-circuit gas boiler of the Baxi slim brand, then I advise you to take a closer look at the BAXI SLIM 2.300 i 29.7 kW model. In addition to the second circuit, you can also notice a higher power, almost 30 kW. The price of this model is two times higher than that of the Baxi slim 1,230 in 22.1 kW.

To familiarize yourself with common malfunctions and errors of the Baxi gas boiler, follow this link.

Lemax Premium 25n

Another brand from Lemax Premium takes 7th place in our hit parade. This device consists of a single circuit, completely energy independent, with an open combustion chamber and a power of up to 25 kW. An excellent option for heating a house up to 250 m². Lemax floor-standing gas heating boilers with their Premium model range have, in principle, proven themselves well on the Russian market. And if you consider that the components come from Europe, then we can talk about the quality of the products. I didn't find anything wrong with this particular model. But the downside is, of course, a steel heat exchanger.

If you pay an additional 6-7 thousand rubles, you will get the same, but dual-circuit model.

Siberia 11, 17k

Device, production. Non-volatile unit with steel heat exchanger. There are two options worth paying attention to. Single-circuit with prefix 11 and double-circuit 17k.

Respectively, with powers of 11 and 17 kW.

Flaws. A steel heat exchanger leaks over time, for some after 3 years, for others after 6 years. But in general, the gas boiler is not bad and no worse than Lemax.

For a double-circuit floor-standing gas boiler Siberia 17k, you should pay an additional 3–4 thousand. And I think it's worth it. Since we get a second circuit and a power of 17 kW.

Mora-top SA60

Do you need a high-power underfloor gas heating device? Perhaps it is worth paying attention to the Czech manufacturer Mora-Top. This modification has one circuit, an open combustion chamber, a cast iron heat exchanger and a power of up to 50 kW. I have not found floor-standing 2-circuit gas boilers from this manufacturer on our market. The automation was installed by the well-known company Honeywell, which is a definite plus. I think the price of 100 thousand rubles is worthy. The device has the ability to automatically turn off when pressure drops in the gas pipeline.

Among the disadvantages, if we are to nitpick, we can point out the large weight of the structure due to the cast iron heat exchanger.

Lemax Premium 10, 10 kW

Let's move from a high-power device to a low-power one. Our top ten is closed by the floor-standing, non-volatile boiler Lemax Premium 10 with a power of 10 kW, which is very popular among buyers. The most important thing that attracts buyers is the combination of price and quality. Quite a lot of positive consumer reviews. But the most important thing I would like to say is that the device is very easy to use. Especially suitable for those who do not like to understand technology and live by the motto - The simpler, the better! The advantages and disadvantages, as with the entire Premium line, read above.

Bottom line: the choice of a floor-standing gas boiler depends on many factors. I'm repeating myself, but still:

- From the area of the heated room. The choice of power plays a role here: 8, 16, 24, 45, 60, 100 or 150 kW, etc., there are a lot of options.

- It is for floor-standing devices that it is better to choose a cast iron heat exchanger; it is more reliable and durable than steel.

- Most of the floor-standing units exist with an open combustion chamber. There is one boiler with a closed chamber on our list, but its cost is obscenely high.

- A double-circuit boiler, especially one made in Russia, is not much different in price from a single-circuit boiler, so before buying a single-circuit boiler, you need to weigh the pros and cons.

- Non-volatile. This is a big advantage when the boiler does not need to be plugged into an outlet, but it is not the main thing. Even if there are power outages, there is no need to focus on this. Uninterruptible power supplies have not yet been canceled. If the electricity goes out for a week, then a non-volatile boiler will save everyone.

Types of gas boilers

General gas boiler systems can be single-circuit or double-circuit.

A single-circuit boiler only heats the house, while a double-circuit boiler solves two problems at once: heating and water heating. In this case, the choice should be made based on your everyday needs.

Floor-standing and wall-mounted gas boilers can be single-stage, two-stage and modulating. The latter of these are more profitable to use, as they allow the boiler to operate at less than full capacity even in severe frosts. This will significantly save your money, especially in regions with cold winters.

Another boiler can be connected to a boiler with a two-stage system. Also, this type of boiler will save gas and last much longer, unlike a single-stage one.

Dual-fuel boilers can operate on both gas and diesel fuel. These models are the most popular. They are economical, safe and silent. However, the owner of such a device must constantly monitor the pressure gauge readings so that the pressure in the system corresponds to the norm.

On the wall or on the floor?

Most often, the boiler provides heat and hot water to one family, and therefore is small in size and can be mounted on the wall. This does not apply to the case when a boiler is built into the boiler; the boiler itself is quite large in volume and has a power above 30 kW. You can also see small floor-standing boilers on sale.

Floor-standing boilers are units with built-in additional equipment including a boiler. It is clear that if the boiler has a capacity of over a hundred liters, and the boiler itself is large in all respects, then you cannot hang it on the wall. But all the elements are hidden in a single body, which makes this unit quite attractive in terms of design. It can be installed not only in the house, but also in a workshop or storage room.

Another type of floor-standing boilers - without a boiler, have a cast iron heat exchanger, which is larger and much heavier than a metal one. Thanks to this, the weight of the product is significantly increased, but the boiler also lasts longer. The design of such a heat exchanger provides for placing the boiler in houses with an old type of heating, when it is intended to replace the outdated boiler with a new, more reliable one. The design itself involves integrating such boilers into an old heating system.

If you have a small apartment or house, a wall-mounted double-circuit boiler is perfect.

Considering that it contains all the necessary elements, including a flow-through heater, it takes up little space and at the same time successfully supplies hot water with heat, saving space.

If you have a separate area for a boiler, you can purchase a wall-mounted boiler along with a large boiler or a boiler with a capacity of less than 100 liters, which can be hung on the wall.

Boilers with a boiler capacity of less than 100 liters can themselves be designed as wall-mounted.

Advantages and disadvantages of floor-standing boilers

Designs of this type are endowed with a large number of positive characteristics:

- The system has high efficiency indicators;

- Despite the low cost, the units are very high quality;

- Easy to care and use;

- Boilers are able to maintain the required temperature even in houses with a large area. Manufacturers offer a large number of models with different capacities.

In the photo: the operation of a floor heating boiler.

Like most heating devices, gas boilers have several disadvantages:

- Floor-standing units require special permission for installation, which not everyone can obtain;

- It is recommended to install the structure in a room with a separate exit from the house.

Functionality of floor-standing boilers

Gas boilers installed in private homes are divided into two types:

- single-circuit, which consist of one circuit. It is in it that the process of heating the coolant takes place. A boiler of this type does not supply the water necessary for technical needs, so when installing this model, you will need to install a boiler. Despite the fact that the boiler is convenient to use, it consumes too much electricity and therefore becomes unprofitable. If the equipment is not needed, it is recommended to turn off the equipment, since over time the water will evaporate and sediment will appear inside the tank. It can negatively affect the water, giving the liquid an unpleasant odor.

In the photo: the principle of operation of a floor-standing gas heating boiler.

- have two heat exchangers, one of which is designed to heat water entering the heating system, and the second for liquid used in household matters. It is necessary to monitor carbonate hardness, as its increased level can cause scale to appear in the heat exchanger. To avoid boiler breakdown, it is recommended to regularly remove scale and clean the coil. The cleaning process requires special skills, so it is worth preparing before starting work.

Manufacturers of heat exchangers offer several design options made from different materials.

- Steel. The equipment is manufactured in the form of a cylinder. It consists of a large number of pipes that have a small diameter and are responsible for the conductivity of water. The weight of the unit is not too massive, and it is also protected from mechanical stress that may occur during transportation.

- Cast iron. This material is heavy, not resistant to damage, but lasts a long time.