permits...

Page 5

- Image

- Text

3

permits). In case of possible transportation of the boiler, its original packaging must be kept until the boiler is put into operation!

Safety instructions/regulations

•

When designing, installing and operating, you must be guided by the following documents that have legislative force in the territory of the Russian Federation:

— SNiPs for heating, ventilation and

air conditioning;

— Gas supply standards; — Regulatory requirements for fire

security;

— PUE/PTE of consumer electrical installations; - in the area of removal of combustion products and

air supply should be guided by the proprietary material - “Catalog of coaxial and separate chimneys” (when using the extension “Protherm PT 20, 30, 40, 50”).

•

In addition to complying with the requirements contained in the above documents, when operating the boiler, it is necessary to comply with the requirements of this manual and the accompanying documentation for the boiler provided by the manufacturer. It is necessary to exclude possible interference in the operation of the boiler by children, persons under the influence of drugs or alcohol, incapacitated persons, etc.

• In practice, situations may arise where

when necessary:

disconnect the boiler from the electrical network and

take measures to eliminate the possibility of unauthorized

supplying voltage to the boiler when performing the following operations: —

during boiler repair and maintenance;

—

when servicing the chimney and air duct;

— when carrying out gas hazardous work; — during system repair and maintenance

heating and hot water supply;

• If you smell gas in the room,

where the boiler is installed, the following safety measures must be observed: -

do not turn on or off electrical appliances and room lighting;

- do not smoke or use open

fire indoors;

—

do not use the telephone indoors;

- close the shut-off valve on the supply

gas pipeline;

- ventilate the room; — notify the emergency gas station about the smell

service and your service organization;

• in the room where the boiler is installed,

it is prohibited to store and use explosive or flammable materials (for example, gasoline, paper, paints, etc.);

•

When draining coolant from the boiler

make sure that the coolant temperature is low, otherwise there is a risk of getting burned;

• check the system pressure regularly

heating. It is prohibited to operate the boiler if the heating system is defrosted or coolant leaks are detected from the heating system;

• if the gas supply stops, it is necessary

turn off the boiler, close the gas supply and contact the gas service or service organization.

*For example. TPG 800 01

Your Plumber's Catalog

| specialist consultation: we will answer your questions 8 (4942) 502-502 |

| quality guarantee: we are an official dealer |

| your region: |

| Recommended delivery: transport company SDEK, to one of the terminals. |

| Recommended payment: Sberbank-online via QR code on the account, how to do this? |

| delivery cost (up to 10 kg): |

Solid fuel boiler KVR-20

with top ignition.

Firewood and sawdust briquettes are used as fuel. APPLICATION

The solid fuel boiler KVR-20 is designed for heating various rooms equipped with a central heating system, which can have parallel connected boilers (diesel, gas, electric), radiators, a water heating boiler for domestic purposes, heated floors, or a heater, or together. The boilers are designed for open and closed systems, both with natural circulation and forced circulation. Compatible with complexes of renewable energy systems, including: - Solar collectors; — Heat pumps;

TECHNICAL SPECIFICATIONS

| Thermal power, kW | 20 |

| Efficiency | 91% |

| Area of the heated room with a ceiling height of no more than 3 m, m2 | 110-220 |

| Heated volume of the room, m3 | 480-660 |

| Recommended boiler outlet temperature, °C | ~85 |

| Volume of water in the boiler, l | 38 |

| Maximum coolant flow, m3/hour | 0,5 |

| Volume of loaded fuel (wood), kg | 50 |

| Firebox volume, m3 | 0,21 |

| Maximum length of wooden logs, mm | 400 |

| Preferred moisture content of firewood | 15-30% |

| Firewood consumption, kg/hour | ~1,93 |

| Heating system water inlet/outlet diameter, DN | 32 |

| Heating system pipe connection threaded, G | 1 1/4″ |

| Burning time, hour | 6-25 |

| Maximum operating pressure, bar | until 3 |

| Chimney connection diameter, mm | 159 |

| Minimum chimney height, m | 7 |

| Required chimney draft (Pa) | 20-30 |

| Fire door size (WxH), mm | 232x390 |

| Weight, kg | 270 |

| Size: | |

| height, mm | 1920 |

| width, mm | 620 |

| Fuel | firewood, wood processing waste, sawdust briquettes |

| Coolant | water, non-freezing liquid for heating systems |

| Completeness | Boiler, thermomanometer, draft regulator, scoop, poker, grate, 1/2″ water tap with hose fitting, technical data sheet. |

INSTALLATION AND OPERATION

— The boiler is installed in buildings and premises, the design of which must comply with the requirements of the project, technical regulations and legislation of the Russian Federation on urban planning, as well as ensure the safe operation of boilers in accordance with the requirements of the legislation of the Russian Federation in the field of industrial safety and these FNP. — The quality and composition of the coolant must comply with GOST 20995. The water used to fill the boiler and heating system must be clean and colorless, without suspensions, oil and chemically aggressive substances, with a total hardness of no more than 2 mg. eq/dm3. — To ensure safe operation of the boiler, use additional equipment.

ANTI-CONDENSATION UNITS ADJUSTABLE +40...+70°С FOR WOOD-WOOD, PYROLYSIS, COMBINATION BOILERS 20 - 60 kW

| Parameters\Node Models | ||

| Setting the boiler return temperature | +40…+70°C | +40…+70°C |

| Diameter (DN) | 25 | 25 |

| Accession | internal thread 1″-1″-1″ | internal thread 1″-1″-1″ |

| Manual boiler return temperature setting | YES | YES |

| Forced circulation | YES | YES |

| Forced/gravity circulation | YES | YES |

| Setting the water flow in the boiler | NO | YES |

| Circulation pump | ENERGY EFFICIENT | ORDINARY |

| price, rub. | from 29714 RUR | from 26709 RUR |

Three-way valves to maintain boiler return water temperature

| Parameters\Order number | 7761T742101 | 7761T742102 | 7761T742103 | 7761T742104 |

| Regulation range, °C | + 40 … + 70 | + 40 … + 70 | + 40 … + 70 | + 40 … + 70 |

| Maximum ambient temperature, °C | 120 | 120 | 120 | 120 |

| Maximum medium pressure, (PN) bar | 10 | 10 | 10 | 10 |

| Valve diameter, (DN) mm | 15 | 20 | 25 | 32 |

| Capacity, (Kvs) m3/hour | 3,0 | 3,0 | 6,27 | 6,44 |

| Pipe connection, G (flat seal) | 3/4″ HP | 1″ HP | 1 1/4″ HP | 1 1/2″ HP |

| Price, rub. VAT included | from 4399 RUR | from 4622 RUR | from 5537 RUR | from 5623 RUR |

Thermal accumulators for unloading solid fuel boilers 10 kW

| Technical parameters \ Heat accumulator model | |||

| Tank volume, liter | 500 | 500 | 500 |

| Diameter (without thermal insulation), mm | 650 | 650 | 650 |

| Diameter (with thermal insulation), mm | 850 | 850 | 850 |

| Height, mm | 1675 | 1675 | 1675 |

| Maximum operating pressure in the tank, bar | 3 | 3 | 3 |

| Maximum operating pressure in the coil, bar | No | 6 | 6 |

| Water supply connection, G | 1 1/2″ BP | 1 1/2″ BP | 1 1/2″ BP |

| Connecting the heating element, G | 1 1/2″ BP | 1 1/2″ BP | 1 1/2″ BP |

| Temperature sensor connection, G | 1/2″ BP | 1/2″ BP | 1/2″ BP |

| Coil connection, G | No | 1″ VR | 1″ VR |

| Area of the lower coil, m2 | No | 1,7 | 1,7 |

| Area of the upper coil, m2 | No | No | 1 |

| Weight, kg | 99 | 129 | 140 |

| price, rub. (retail/constant/wholesale) | from 33603 RUR | from 41562 RUR | from 56300 rub. |

ACCESSORIES

1261101 HERZ|Safety relief valve for boilers and water heaters 0..110°С, DN 15, 2.5 bar, up to 75 kW 1261201 HERZ|Safety relief valve for boilers and water heaters 0..110°С, DN 15, 3 bar , up to 75 kW 1263001 HERZ|Automatic air vent 1/2″, with check valve

SPARE PARTS

RT-4 REGULUS|Thermostatic draft regulator

Our dictionary:

DHW supply pipeline is a pipeline that supplies hot water to consumers.

Previously visited

Our offers in other categories

19108 GEYSER Auto Automatic pellet boiler 150 kW To order

Price: 390,000 rub.

your discount: 0 rub.

06886 Honeywell, ATF100 Table stand for ATC928G1000 (EvoTouch) with electrical connection and Euro plug. To order

Price: 4,997 rub.

your discount: 0 rub.

18447 LEMAKS 104078 Ionization electrode cable, To order

Price: 343.00 rub.

your discount: 0.00 rub.

19168 Honeywell CMT901A1044 Room chronothermostat CM901, 5-35C, SPDT, 230V, 8(3)A, eco mode, daily program for 24 hours, PI controller To order

Price: 6,187 rub.

your discount: 0 rub.

20338 Upper distributor H2801-B (for housings 06-12″) To order

Price: 174.00 rub.

your discount: 0.00 rub.

Selection of reading mode selection of setting mode

Page 7

- Image

- Text

5

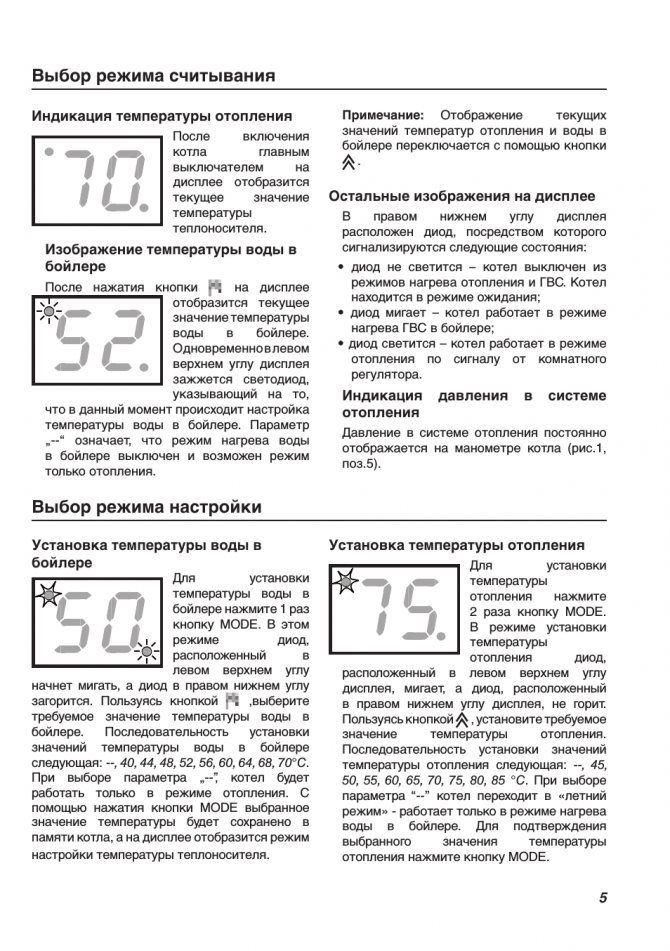

Reading mode selection

Selecting Setting Mode

Setting the water temperature in the boiler

To set the water temperature in the boiler, press the MODE button once. In this mode, the diode located in the upper left corner

will begin to flash and the LED in the lower right corner will light up. Using the button

,select

the required water temperature in the boiler. The sequence for setting the water temperature values in the boiler is as follows: -, 40, 44, 48, 52, 56, 60, 64, 68, 70°C

. When selecting the “—” parameter, the boiler will only operate in heating mode. By pressing the MODE button, the selected temperature value will be saved in the boiler memory, and the display will show the mode for setting the coolant temperature.

Setting the heating temperature

To set the heating temperature, press the MODE button 2 times. In heating temperature setting mode, the diode

located in the upper left corner of the display blinks, and the LED located in the lower right corner of the display does not light up.

Using the button

, install the required

heating temperature value. The sequence for setting the heating temperature values is as follows: -, 45, 50, 55, 60, 65, 70, 75, 80, 85 °C

. When you select the “—” parameter, the boiler goes into “summer mode” - it works only in the mode of heating water in the boiler. To confirm the selected heating temperature, press the MODE button.

Heating temperature display

After turning on the boiler with the main switch, the display will show the current value of the coolant temperature.

Image of the water temperature in the boiler

After pressing the button

on display

The current value of the water temperature in the boiler will be displayed. At the same time, the LED in the upper left corner of the display will light up, indicating that

that the water temperature in the boiler is currently being adjusted. The “—” parameter means that the water heating mode in the boiler is turned off and only heating mode is possible.

Note:

The display of current heating and water temperature values in the boiler can be switched using the button

.

Other images on the display

In the lower right corner of the display there is a diode, through which the following conditions are signaled:

• the diode does not light – the boiler is switched off

heating and hot water heating modes. The boiler is in standby mode;

• the diode is blinking – the boiler is operating in

heating hot water in the boiler;

• the diode lights up – the boiler is operating in

heating based on a signal from the room regulator.

Indication of pressure in the heating system

The pressure in the heating system is constantly displayed on the boiler pressure gauge (Fig. 1, item 5).

Equithermal mode Setting the equithermal mode, t….

Page 8

- Image

- Text

6

Equithermal mode

Setting the equithermal mode, i.e. selection of the inclination angle of the equithermal curve “E” and its parallel offset

“P” is only possible if an external temperature sensor is connected to the boiler. Note:

If there is no external temperature sensor, the boiler will not allow the user to enter the mode for setting parameters E and P.

Setting the slope of the curve

Press the MODE button until parameter “E” appears on the display. Simultaneously in the upper left

corner the diode blinks. Using a button

set the desired curve slope from E1 to E9 and confirm your choice by pressing the MODE button. The required coolant temperature at the boiler outlet is adjusted depending on the external temperature and the corresponding curve setting (Fig. 2). If you select the “E-” parameter, the equithermal mode will be turned off.

Parallel curve offset

Press the MODE button until the parameter “P” appears on the display. In this case, the diode in the upper left corner of the display

will start flashing. Using the button

,

set the curve offset with a value from P1 to P9 and confirm the selected value by pressing the MODE button. Parallel characteristic offset value: P1 – offset by -15 °C P2 – offset by -9 °C P3 – offset by -6 °C P4 – offset by -3 °C P5 – offset by +3 °C P6 – offset by + 6 °C P7 – offset by +9 °C P8 – offset by +15 °C P9 – offset by +21 °CP– – no offset

Rice. 2

Curve steepness

Rice. 3

Parallel curve offset

The coolant temperature, according to the pre-selected characteristic, will increase (P5 - P9) or decrease (P1 - P4) by the specified offset or remain unchanged (P-).

Instructions for connecting and starting

After delivery, the boiler must be installed on the floor or a special stand in the designated area.

It is recommended to allocate a separate ventilated room for the equipment . After installation, all communications supplying gas, coolant, and power are connected. Then the system is filled with water by smoothly opening the feed tap.

Exhaust pressure is controlled using display readings or a pressure gauge.

The first start is made after connecting all communications, checking the tightness of connections and filling the system with water. A short-term performance test is needed to determine the degree of readiness of the equipment for operation and to identify possible malfunctions, which are immediately eliminated.

The first start may be unsuccessful due to air remaining in the circulation pump or radiators.

The attempt is repeated until all the air is removed from the system, after which the boiler is put into permanent operation.

NOTE!

Preparation, configuration and first start-up must be carried out by service center specialists.