Where are Ursa materials used?

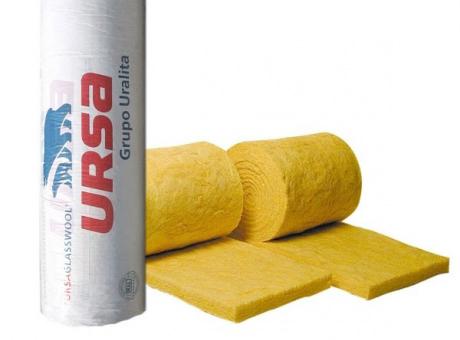

"Ursa" is an insulation material used not only in the construction of buildings, but also in the assembly of water supply systems, heating systems, other communications, as well as in the construction of roads, bridges, airfield runways and in many other areas. In each specific case, varieties of this insulation are used, the technical characteristics of which most accurately correspond to this specific purpose. Next, we will consider what types of this material are currently produced by the company.

Method of manufacturing fiberglass variety

Ursa wall insulation, as well as materials intended for insulating floors, ceilings, roofs, etc., are made from a mixture of soda, sand and dolomite. The latter melts under the influence of very high temperatures. Long fibers are drawn from the resulting mass, from which mats or slabs are made. Gluing glass “threads” into a single sheet is done using environmentally friendly binders.

Advantages and disadvantages of fiberglass materials

This is the most popular variety, especially among owners of suburban areas who build houses on them. Their main advantages include:

- Very low thermal conductivity coefficient - 0.032-0.046 W. For comparison, for the same foam plastic this figure varies from 0.037 to 0.005 W.

- Convenient sizes. Ursa fiberglass insulation is available in both mats and slabs. In the first case, the most popular type is Ursa roll insulation, the dimensions of which are 1200 * 4200 mm and a thickness of 150 mm. The standard size between roof rafters and house frame posts is 60 cm. In this case, the canvas is simply cut in half lengthwise. If the pitch between the elements is different, it is cut across, measuring the required distance along the length.

- Environmental Safety. In the production of some varieties, formaldehyde-containing materials are not used.

- Easy to install. Unlike many other, cheaper types of glass wool, Ursa has a very strong structure, and therefore it is very difficult to tear.

- Fire resistance. Ursa glass wool does not burn at all.

- Durability. This insulation can withstand temperature changes from -60 to +220 degrees. It serves for about 50 years.

"Ursa" is an insulation material, the disadvantages of which include only its relatively high cost.

URSA GEO

Modern insulation must meet high requirements for thermal conductivity and durability. It is worth noting that it is fiberglass products under the URSA brand that have all the required indicators.

When selecting thermal insulation, many people look at basalt products, believing that fiberglass materials are inferior to basalt slabs and rolls. This is wrong. URSA insulation is a non-flammable material and has more elasticity compared to materials made from basalt. Also, URSA slabs and rolls are light in weight, which is convenient for transporting and carrying packages at a construction site.

Note:

— URSA M-25 “F” is insulation with a one-sided foil coating. The temperature on the surface covered with foil should not exceed +100ºС

— Pickup from our warehouse in Reutov M.O. multiples of packages

— Pickup from the plant in Serpukhov M.O. only possible in multiples of pallets

TU 5763-001-71451657-2004

Let's consider the option of insulating the partition:

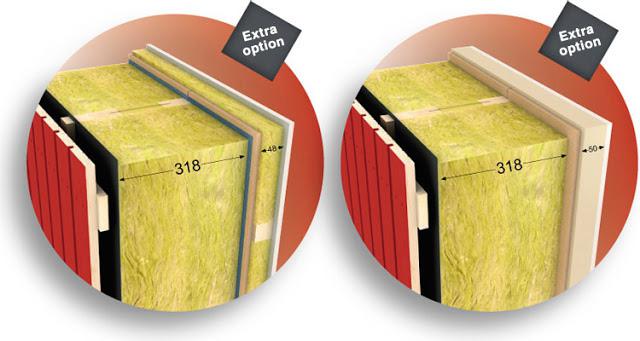

Installation of the partition begins with marking its design position. The quality of the partition directly depends on the quality of the markings. The next step is to install guide profiles and frame posts that are applied to the wall surfaces. The structure is made of durable materials, such as monolithic reinforced concrete or solid brick; it is most effective to fire the frame element with a powder pistol. When attaching to walls made of hollow bricks or aerated concrete blocks, anchors are used in pre-drilled holes. The pitch of the frame posts is determined depending on the height of the partition and the bending rigidity of the partition sheets, but should not be more than 60 millimeters. After assembling the partition frame, it is covered on one side with plasterboard or gypsum fiber sheets, and the joint of the sheets should be located exactly in the middle of the frame post. Filling the internal space of the partition with sound-absorbing materials can significantly improve its soundproofing properties. Ursa insulation meets the following requirements;

- Ensure dense, void-free filling of the internal space of the partition and application to frame elements

- Do not sit down while the structure is in use

- Be convenient during installation.

“URSA Noise Protection” mats meet the best requirements in this design. The mats have a width of 610 mm, which makes it possible to install them sideways, with a standard frame pitch. Installation of mats in a spacer, combined with their low weight and high elasticity, ensures reliable fixation of the material in the partition frame, both during installation and for the entire period of operation. In addition, mats of this width do not require preliminary cutting lengthwise. Using the state of compression and all-round compression of the URSA thermal insulation material, we can use even the lightest products in partition structures, such as; URSA GEO M-11.

And so, we use a mat that is not much larger than the width of the vertical guides. When installing the second sheet of cladding, due to the high elasticity of the Ursa M-11 material, friction forces arise along both planes of the cladding, ensuring that the sound insulation in the structure remains stable during its entire service life. URSA fiberglass insulation is a non-flammable material, which allows wiring of electrical networks directly into the thickness of the material without compromising the fire safety of the structure. To lay the cable, you just need to make a cut where it passes. High compressibility and flexibility of the material will ensure the absence of voids in the places where communications pass. After filling the frame with soundproofing material, the cladding sheets are installed on the second side of the partition.

Popular designs and materials used in them Frame wall - URSA GEO Frame, URSA GEO P-15, URSA Terra, URSA PureOne 34 PN Walls with siding - URSA GEO P-20, URSA GEO M-15 Ceilings and floors - URSA GEO M -11, URSA GEO Noise protection, URSA PureOne 37 RN Pitched roof - URSA GEO Pitched roof, URSA PureOne 34 PN Partition - URSA GEO P-15, URSA PureOne 34 PN Three-layer masonry - URSA GEO P-30, URSA Terra

URSA insulation dimensions and packaging

| Product brand | Thickness, mm | Length, mm | Width, mm | Pack/m2 | Pack/m3 |

| Pitched roof | 150 | 3900 | 1200 | 4,68 | 0,702 |

| Pitched roof | 200 | 3000 | 1200 | 3,6 | 0,72 |

| Frame | 100 | 4000 | 1200 | 4,8 | 0,48 |

| Frame | 150 | 3900 | 1200 | 4,68 | 0,702 |

| Frame | 200 | 3000 | 1200 | 3,6 | 0,72 |

| Terra | 50 | 1000 | 600 | 6,0 | 0,3 |

| Noise protection | 50 | 8 000 | 610 | 17,08 | 0,854 |

| Pure One 37 RN | 50 | 10 000 | 1200 | 24,0 | 1,2 |

| Pure One 37 RN | 100 | 10 000 | 1200 | 12,0 | 1,2 |

| Pure One 34 PN | 50 | 1250 | 600 | 9,0 | 0,45 |

| Pure One 34 PN | 100 | 1250 | 600 | 4,5 | 0,45 |

| Pure One 35 QN | 150 | 1200 | 3900 | 4,58 | 0,702 |

| M-11 | 50 | 10 000 | 1200 | 24 | 1,2 |

| M-11 | 100 | 10 000 | 1200 | 12 | 1,2 |

| M-15 | 50 | 8 500 | 1200 | 20,4 | 1,02 |

| M-15 | 80 | 12 500 | 1200 | 15,0 | 1,2 |

| M-15 | 100 | 8 500 | 1200 | 10,2 | 1,02 |

| P-15 | 50 | 1250 | 600 | 18,0 | 0,9 |

| P-15 | 100 | 1250 | 600 | 9,0 | 0,9 |

| P-20 | 50 | 1250 | 600 | 18,0 | 0,9 |

| P-20 | 70 | 1250 | 600 | 13,5 | 0,945 |

| P-20 | 100 | 1250 | 600 | 9,0 | 0,9 |

| P-30 | 50 | 1250 | 600 | 15,0 | 0,75 |

| P-30 | 60 | 1250 | 600 | 12,0 | 0,72 |

| P-30 | 70 | 1250 | 600 | 10,5 | 0,735 |

| P-30 | 100 | 1250 | 600 | 7,5 | 0,75 |

| M-25 "F" | 50 | 9 000 | 1200 | 10,8 | 0,54 |

| P-25 "F" | 100 | 4 500 | 1200 | 5,4 | 0,54 |

Video about URSA GEO products

You can send your application by email [email protected]

This might be interesting:

| |

| |

| |

| |

|

LLC GC "TEPLOSILA" - together with you since 2005!

Varieties of fiberglass "Ursa"

Thermal insulators of this brand are divided according to density, degree of thermal conductivity and area of application into several main classes:

- URSA Geo. Used for thermal insulation of pipelines and sewer pipes. However, most often it is used in private and industrial housing construction to insulate walls, floors, ceilings and roofs from the cold. The most popular among owners of suburban areas is the Ursa M 11 insulation, which, among other things, can be used on the floor and in interfloor ceilings. These are mini-slabs for universal use. The “Light” type is intended mainly for covering unloaded structures - roofs and walls. The URSA Geo line also includes soundproofing varieties designed for rooms with high humidity, for pipes, raised floors, etc.

- PureOn. This variety consists of 95% natural ingredients. At the same time, in terms of softness and fineness of the fiber, it is not inferior to cotton wool.

- TERRA. These are high-density boards of small sizes, very convenient for use in private housing construction.

Advantages

- Effective thermal insulation and sound insulation. Ursa's Terra material has the best thermal conductivity in its class, which means even greater protection from the cold and reliable retention of heat in the home. In addition, thanks to the use of Terra, it is possible to significantly reduce the noise level in the room and increase acoustic comfort.

- Increased rigidity. Terra slabs offer increased rigidity while maintaining the flexibility of mineral fiberglass insulation. Thanks to this property, the material adheres tightly to the insulated surface and to the frame, creating a continuous thermal insulation layer.

- Non-flammability. Terra is a non-flammable material and has no restrictions on its use in terms of fire safety. The non-flammable nature of the material is explained by the fact that the basis for production is quartz sand, which, as you know, is often used to extinguish fires. Enhanced moisture resistance. Terra slabs are treated with a water-repellent compound.

- Environmentally friendly. The main raw materials in the production of Terra material are minerals that are widespread in nature and have a natural origin. Terra does not contain blast furnace slag products. The material meets all mandatory safety requirements for humans and the environment.

- Ease of use. Terra material is supplied in compact, convenient packaging, making it easy to transport. Terra slabs do not break or crumble, and are simply and reliably installed in a structure. The convenient dimensions of the slabs make it easy to calculate the required amount of material.

- Biostability. Terra material is inorganic in nature, does not rot and does not contain nutrients for the life of insects, rodents and microorganisms.

Fiberglass insulation "Ursa": reviews

The opinions of those who have already used this type of insulation are mostly more than positive about it. In particular, owners of country houses like the fact that when installing slabs and sheets, virtually no glass dust harmful to health is generated. Private developers also like the fact that the Ursa material, unlike ordinary glass wool, does not wrinkle or lose its shape. It is also noted that when working with slabs and mats, pieces do not come off the canvas.

Those homeowners who have small children highly praise the PureOn variety, since it is completely free of phenol and other poisons. Ursa insulation, reviews of which are only positive, is, among other things, very easy to cut.

Technical parameters of Ursa insulation types

Silicone Ursa Geo

Ursa roll insulation has the ability to save heat, and very well. The fact is that its fibers are long and elastic, and because many air layers appear between them. By insulating a house with such a heat insulator, you can be sure that its wall surfaces will not freeze in the winter season. The thermal conductivity coefficient will determine how good this type of insulation is. The lower the value of this parameter, the better the material will conserve heat. If we talk about Ursa Geo, then the figure is 0.035-0.044 W*m*K, depending on the type of insulation. In terms of the degree of noise attenuation, such insulation is also excellent, and it can have a sound absorption class of either “A” or “B”. This has been proven by both practical results and laboratory studies. In general, all fiberglass materials are excellent at blocking sound waves. For this reason, if you need to create a partition for sound insulation in an apartment, then we suggest considering one of these materials as one of the variations.

Now what about environmental friendliness? Even at the moment of preparation of raw materials, a thorough check of each of the components will take place. Ursa Geo insulation in its finished form is still tested for safety for nature and humans. Let us take as an example the emission of volatile compounds in such a material. And it is 10-15 times less than European and Russian regulatory indicators. So with this type of insulation, your home will always have clean air and a pleasant microclimate. At the same time, it is necessary to remember that all fiberglass-type materials generate a little dust and therefore the walls of the internal parts of the room must be covered with membranes for waterproofing. The mineral thermal insulator Ursa Geo does not take fire - it is made on the basis of quartz sand. Such natural material is not capable of catching fire. And if he encounters an open fire, he will not let him go further into the room.

This type of insulation is not at risk of old age. Even after a long time, it will remain the same as it was at the very beginning. Neither its various positive qualities nor its strength will change. And manufacturers guarantee a service life of at least 50 years. Biological stability - since this substance is of an inorganic type, mice, beauties and insects definitely do not like it. It also does not harbor harmful microscopic organisms, such as mold. The fact is that all such living creatures simply have nothing to eat, so they do not live in Ursa Geo, avoiding it. Please note that all materials in this group are fiberglass with all the attendant advantages and disadvantages.

Innovative insulation Ursa PureOne

This is the latest technology, which was primarily used by Europe and Russia, and it began to successfully spread throughout the world. It is through it that such material is made. The essence of the technology is that acrylic is used as one of the binding components - it is a chemically safe and neutral polymer for human health. For this reason, fiberglass is not very prickly as with conventional production technology and produces less dust. Acrylic is a very inert material; it is not dissolved by water and will not oxidize the air. For this reason, insulation of this type can be used in hospitals and kindergartens.

As for noise absorption as characteristics of the Ursa PureOne insulating material, they were confirmed by tests of scientists from the NIISF of the Russian Scientific Academy. According to research, a slab-type material has a sound absorption class of “A”, and a material that looks like cotton wool has a class “B”. The elastic acrylic included in the composition can perfectly absorb sound waves. For this reason, partitions made of such material protect against noise better than stone wool or glass fibers. The difference can be 2 dB. In addition, such insulation material is more elastic than simple fiberglass. They even talk about a special “spring effect” that appears inside it. For this reason, it is tightly fixed in wall cavities, rigidly installed in the spacer, and its shape will not change over time. The properties that distinguish it favorably from GEO insulation are listed above.

Expanded polystyrene insulation XPS

Ursa insulation in rolls or slabs is very durable. This material has an excellent degree of strength, as well as increased resistance to wear and deformation. At the same time, it can withstand not only stretching and compression with honor, but will also resist bending perfectly. Ursa XPS can withstand 50 tons of load applied to one square meter. The material is also environmentally friendly. In the manufacture of such a thermal insulator, carbon dioxide CO2 is used, which is not a toxic substance at all. All breathing living organisms (including you and me) secrete it. For this reason, neither the production process of this type of insulation nor the finished product poses any harm to nature and humans. But we must not forget that this is polystyrene foam, which releases toxic substances when exposed to high temperatures.

Waterproof - Ursa XPS thermal insulation material will not absorb water. For this reason, its ability to retain heat is not reduced when exposed to wet soil or groundwater. Freezing and thawing again (more than 500 times), it will remain the same. For this reason, where the temperature in the environment often changes, it is even advisable to use such insulation. So it will compare favorably with fiberglass heat insulators, which are discussed above. Service life - slabs made from this type of insulation can last at least fifty years. In this case, neither the dimensions of the slabs, nor the shape, nor the parameters of the material will change at all. Such material is not dangerous from direct contact with soil or plants - this is a big plus. And the question of flammability. Fire retardants are substances that help increase resistance to fire and are part of XPS. They block the paths for oxygen, and due to this, combustion will not be possible. But as mentioned earlier, such a material is polystyrene foam, which, even if it does not support combustion, very easily melts under the influence of temperature, releasing toxic substances.

Extruded polystyrene foam boards

This type of Ursa insulation also enjoys well-deserved popularity among private developers and large construction companies. Most often, expanded polystyrene slabs of this brand are used to insulate the foundations of buildings and structures. The fact is that they are not at all afraid of moisture and the effects of various types of aggressive chemical elements present in any soil. Ursa slabs can be installed completely without any additional protective material.

Ursa insulation and their varieties

This thermal insulation material is based on treated spatula-type glass fiber. So this material is the closest relative of glass wool. When creating it, soda, sand, dolomite and other types of additives are taken in certain proportions. The mixture must be heated to the melting point and passed through a special unit. The result is a fibrous substance, the thin threads of which are glued with a special agent. There are several products that were manufactured by the Ursa company.

The most popular are insulation from the Ursa Geo series, which are made of fiberglass. Moreover, the company produces polystyrene foam thermal insulator Ursa XPS, which is made by extrusion. A new product from the manufacturer, made using new technologies, is PureOne insulation. Let's take a closer look at these materials.

- Ursa Geo mineral-type fiberglass insulation is distinguished by the fact that only environmental elements are used in its creation. This is strictly regulated at each stage of the production process. So you can be fully confident that neither the finished material nor the raw materials contain harmful additives. All materials from this group are fiberglass, but each of them is endowed with certain unique qualities and is intended for use in certain conditions and for insulating various objects. The appearance of Ursa Geo will be no different from glass wool.

Thermal insulator Ursa XPS also has certain advantages and is an extruded polystyrene foam, which is made using a special technology. Its thermal conductivity coefficient is very small, especially in comparison with other thermal insulators. Plates made from this substance last for many years; they are very durable and hard. For this reason, it is more advisable to use it when insulating flat-shaped roofs, first-floor floors, plastered facades, plinths and basements. Ursa XPS can easily withstand multi-ton loads - it can be used to insulate railway embankments, airport landing strips and the bases of highways.- As for the new PureOne material, this high-quality mineral-type thermal insulator is ideal for both insulating structures and protecting them from extraneous noise. In all technical parameters it produces excellent results. In addition, it is convenient to work with because it is not scratchy, does not attract dust and is similar to materials of natural origin - wool or cotton. This material is a new type of fiberglass type product that does not activate the irritation effect. The photo shows what the new type of PureOne looks like.

- There is another very new product from Ursa, and this is Terra mineral insulation, positioned by the manufacturer as a material with an increased degree of rigidity and resistance to moisture, and is also required for thermal insulation of country houses.

But in terms of its performance, it is close to professional thermal insulators, and this material is very elastic, does not get wet, and does not burn.

Now let's look at their parameters.

Cost of Ursa materials

The price of insulation of this brand depends solely on the variety. The cheapest is the “Geo” insulation “Ursa”. The price for it is about 900 rubles per cubic meter. But in this case, the cost also depends on the type. The above price is valid for “Light” insulation. The most expensive material in the Geo line, P-60, costs 4,600 rubles per cubic meter.

PureOne insulation can be purchased at a price of 1500-1600 rubles per cubic meter. The expanded polystyrene option costs about 3500-5500 rubles per m3.

As you can see, Ursa insulation, the price of which is quite high, is actually distinguished by simply excellent performance characteristics. The money spent will not be wasted in any case.