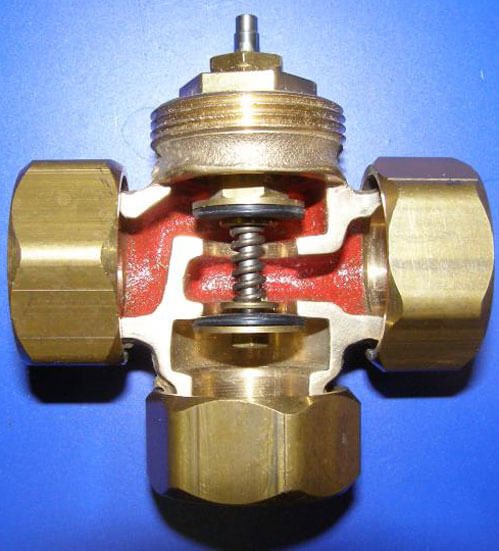

A three-way zonal valve with a thermal head, an immersion sensor and a contact thermostat Emmeti 3/4″ external thread H is a ready-made kit for organizing a low-temperature heating circuit. The main elements of the kit are made of brass. The valve temperature control range is 20-65 °C, the length of the capillary tube is 2 meters, the operating pressure is up to 16 bar. The finished kit includes: a thermostatic head, a three-way mixing valve, a protective thermostat and an immersion sensor with a recess. The valve is focused on controlling, changing and maintaining the temperature in the supply pipeline of underfloor heating systems.

The temperature of the water supply to the floor system is set on the thermostatic head and is maintained constantly by acting on the mixing valve. The thermostatic element of the head is connected via a capillary to an immersion sensor, which detects the temperature of the liquid from below the circulator. A protective thermostat, adjusted to 50 °C, interrupts the electrical supply to the circulator in the event of an excessive increase in water temperature. You can buy a three-way zonal valve with a thermal head, immersion sensor and contact thermostat Emmeti 3/4″ external thread H in the online store duim24.ru at the best price with delivery.

Specifications:

Country Italy Manufacturer Emmeti Model 28130056 Category control valves Type zonal three-way mixing valve included Scope of application underfloor heating system Functions temperature control of underfloor heating Manual / automatic control Automatic control via thermal head and immersion sensor Connection size G 3/4″ Connection type cylindrical thread H " male" brass Dimensions (WxHxW) 40x100x100 mm Weight 380 g Kvs (throughput) 2.5 cubic m/h Maximum operating temperature of the valve 120 oC Valve temperature setting range 20-70 oC Maximum operating pressure of the valve 16 bar Maximum pressure drop 0. 7 bar Leakage less than 0.02% of capacity Capillary length 2 m Stroke 2.5 mm Thermal head yes Thermal head regulation range 20-70 °C Thermostatic liquid expansion sensor Maximum thermal head pressure 10 bar Safety thermostat yes Immersion sensor yes Check valve no Mechanical cleaning filters no Body material brass Spindle material brass with chemical nickel plating Spring material stainless steel Seal material EPDM Medium water and glycol mixture (30%) 12 month warranty

Thermal shut-off valve KTZ

Thermal shut-off valve ( KTZ ), the price of a wide range of different modifications of which is presented on this page of our catalog, is a reliable and effective mechanism for automatically shutting off the gas supply in the event of heating. When the temperature of the gas pipeline exceeds 80-100°C, the thermal gas valve KTZ

shuts off the gas supply to consumer devices, thereby reducing the likelihood of an explosion and facilitating the task of fighting the spread of fire.

KTZ

valve , classified as a shut-off valve, is installed on gas pipelines with an operating pressure in the range of 0.6-1.6 MPa.

For gas pipelines with a lower pressure limit, thermal shut-off valves with a threaded connection (KTZ couplings) are used; closer to the upper limit, KTZ valves with a flange connection are used.

Safety precautions when installing a thermal shut-off valve

When installing a thermal shut-off valve, you must follow the safety instructions:

- The position of the axis during installation can be free.

- First of all, a thermal shut-off valve is installed, and then other equipment.

- The valve must not be installed in a room where the temperature may be above 52 degrees.

- The direction of gas flow must match the direction of the arrow on the valve body.

- Once the valve has been installed, it must not be subjected to pipeline loads, compression, torsion, etc. There is no need for verification or maintenance during use.

- During transportation, storage, installation and operation, the thermal shut-off valve must not be exposed to heat, strong or sharp impacts.

Rules for operation and installation of KTZ

- Thermal shut-off valve (KTZ) is installed only indoors.

- KTP is installed at the entrance of the gas pipeline to the premises.

- The thermal shut-off valve (TZ) is installed first on the gas pipeline, after which all other gas equipment is installed.

- The position of the installation axis is free.

- The direction of the arrow on the KTP body must coincide with the direction of the gas in the gas pipeline.

- It is prohibited to use KTZ in rooms where the temperature can rise above 60°C.

- Before installation, the KTZ valve should not be exposed to heat or strong shocks.

- The service life of KTZ valves is 30 years.

- The thermal shut-off valve KTZ is a single-acting, but reusable device. It cannot be restored after a fire.

The installation of KTZ thermal shut-off valves on gas pipelines (at the entrance to premises) in Russia is prescribed by the “Fire Safety Rules” PPB-01-03, clause 84.

Purpose and design of a thermal shut-off valve

In the event of a fire, the thermal shut-off valve must automatically stop the gas supply to gas-consuming devices. This is necessary to reduce injuries to citizens, fire crews, the severity of the consequences of a fire and prevent a gas explosion.

According to fire safety regulations, it is necessary to install a thermal shut-off valve to automatically shut off the gas supply. Valves must be installed primarily at the outlet from the riser or at the entrance of the gas pipeline into the room. You cannot install the device after installing gas fittings, on bypasses, in other rooms, in places where the temperature can be more than 60 degrees.

Due to the location and shape of the valve in the housing, free movement of gas is ensured when the valve is open. Such valves should be installed on gas pipelines that lead to domestic and industrial facilities. First, a thermal shut-off valve is installed on the gas pipeline, and then the rest of the gas fittings, instruments and then equipment. The valve can be installed in any position, but the indicator shown on the body must correspond to the direction of gas flow. After the KTP has been installed, it should not take the load from the pipeline in compression, torsion, bending, etc.

The valve must not be installed in rooms where the temperature may be more than 52 degrees. There is no need to check or service the valve during use. If the device was in the source of a fire, then it cannot be replaced, and, therefore, it is necessary to install a new one.

During transportation, storage, installation and use, the thermal shut-off valve must not be exposed to heat, shock or sudden mechanical influences.

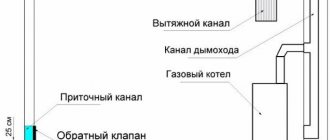

Subtleties of installing a thermostatic mixing valve

The three-way mixing valve can be installed in heating systems with one or more circuits by placing it in the mixing unit. It is noteworthy that the connection diagram for a three-way valve for a heated floor will not change depending on the number of circuits (read: “How a three-way mixing valve for a heated floor works, types, application”). The only difference is that the system will be equipped with additional parts.

Additional circuits are needed just to connect the warm water floor pipes to the heating. Please note that according to the connection diagram for a heated floor with a three-way valve, it is mounted in front of the pressure pump. This is a prerequisite for the high-quality functioning of the heating system.

When performing tapping work, it is important to ensure that the valve is not clogged with slag or splashes of molten metal left by the welding machine. In addition, the valve must be removable so that it can be checked and, if necessary, replaced.

If you do not have the appropriate skills, it is better to leave the tapping of the control valve to professionals.

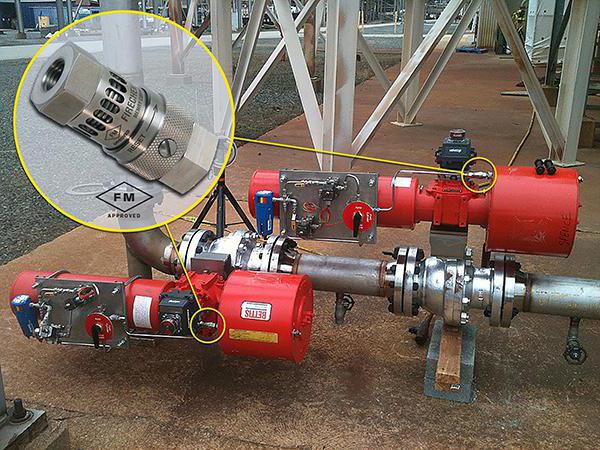

Gas valve KTZ: design and principle of operation

The design of the KTZ valve is a profiled steel body with a bypass valve and a spring with a locking element. In the compressed position, the spring is held by a fusible insert-stopper, which provides throughput. When the temperature in the room or on the gas pipeline reaches 90°C, the fusible stopper melts, releasing the compressed spring. A cone-shaped shut-off element is lowered onto the valve seat, thus sealing it and cutting off the gas supply through the pipeline.

Operating principle

The thermal shut-off valve consists of a body with a threaded connection, a fusible insert, a spring mechanism and an element (shutter) in the form of a plate or ball that locks the channel.

In the initial state, at normal room temperature, the valve shut-off element is cocked and held by a fusible link. When a fire occurs, the overall temperature rises, reaching 85-100 degrees, causing the insert to melt and releasing the cut-off mechanism. The latter, in turn, under the action of a spring, blocks the gas movement channel.

Thermal shut-off valve (KTZ) can operate with any gases. After operation, it is replaced with a new one. It is possible to replace the fuse-link with another one and continue using the product.

Design features

The control valve for radiators has the following design:

Design and principle of operation

Thermostat structure

| Designation in the figure | Item name |

| 1 | Fastener |

| 2 | Bellows |

| 3 | Handle for setting the temperature |

| 4 | Restriction label |

| 5 | Temperature setting limiter |

| 6 | Setting spring |

| 7 | Heat sensitive liquid |

| 8 | Stock |

| 9 | Return spring |

The operating principle of such devices is very simple. In the event of an excessive increase in ambient temperature, the heat-sensitive liquid expands, pulling out the bellows, which in turn moves the rod in contact with it in the valve, due to which the supply channel narrows.

As a result, the amount of coolant is reduced and the radiator is cooled, normalizing the microclimate in the room.

After conditions return to normal, the entire process occurs in reverse order, increasing the heating of the equipment.

Variations

Radiator valve for bottom connection or corner thermostat are the most common models.

But it’s worth considering a couple more possible options:

- Internal spring, which, as the name suggests, is hidden inside the battery. If the pressure in the system increases, the spring is compressed and the spool shuts off the coolant supply.

Safety internal spring valve for radiator

- Electronic thermostat.

This option is much more expensive than its mechanical counterparts described above, but it has significantly expanded functionality:

- Firstly, it has a display showing the exact temperature of the battery.

- Secondly, its sensitivity is much higher, which allows it to respond to thermal changes much faster.

- Thirdly, such devices can be programmed. That is, you can, for example, set a lower temperature during your absence, which will lead to tangible savings.

Thermoelectric radiator valve actuator has additional functions

Installation Rules

In order for the thermal shut-off valve to work reliably, you must adhere to the rules for its installation:

- Valves with threaded connections must be installed in lines with a pressure no higher than 0.6 MPa. Valves with flange connections can withstand pressures up to 1.6 MPa.

- The flow capacity of the valve must be no less than the flow capacity of the gas line.

- It is necessary to install a thermal shut-off valve on the gas pipeline first, and then the rest of the fittings.

- KTZ must be installed indoors and protect fittings not designed for high heating.

- The valve axis can be located in any direction.

- The gas flow, the direction of which is indicated on the device body, should be taken into account.

- Installing the valve in places close to heating elements, where the air temperature near which may exceed 53 degrees, is excluded.

- The built-in thermal shut-off valve must be checked for leaks.

- After installing the KTZ, the pipes should not exert additional pressure on it, bending or twisting the device.

- Access to the valve must be free and unobstructed.

Thermostatic fittings for single-pipe heating systems

| In 2020, Sanext.Pro launched the production of thermostatic valves for single-pipe CO SANEXT RV1. The valve has increased throughput and low hydraulic resistance. In combination with a thermal head, it ensures maintaining a comfortable temperature in the room. |

Over the past few years, it has been dynamically developing its product range. For more than 2 years we have been a comprehensive supplier of equipment for two-pipe heating systems, both horizontal and vertical, supplying the market with pipeline systems, automatic and manual balancing valves, heat meters, radiators, distribution floor and apartment manifold assemblies, thermostatic equipment for two-pipe heating systems.

The task of a thermostatic valve in single-pipe heating systems is to allow the maximum amount of coolant to pass through itself so that the surface area of the heating devices is used with the greatest efficiency. Valve RV1 satisfies this requirement.

When used in conjunction with a thermoelement standard for Russia (Xp=20C), the valve capacity reaches 1.83 m3/h. This means that in a system where SANEXT RV1 valves are installed, the coefficient of coolant flow into the heating devices is optimal, and the surface of the devices is used efficiently.

Thermostatic valve SANEXT RV1

Let us especially focus on the phrase “When used in conjunction with a thermoelement.” Like any thermostatic valve intended for use in single-pipe heating systems, the SANEXT RV1 valve does not have a presetting scale. That is, regulation of the amount of coolant flowing into heating devices occurs only when using the “Valve + thermal head” combination.

Installing a valve without a thermoelement is meaningless from a hydraulic point of view, and may even lead to deregulation of the heating system as a whole (the heat transfer of radiators located closer to the distribution line will be overestimated, the coolant will quickly cool down, and remote radiators will be underheated). Therefore, we recommend using the SANEXT RV1 valve only in conjunction with a thermostatic head.

Thermostatic head SANEXT TH

The SANEXT TH thermal head has an ergonomic design and will organically fit into the interior of any room. Can be used in conjunction with valves SANEXT RV1, SANEXT RV2, as well as with other thermostatic valves with a thread for connecting a thermoelement m30x1.5.

The quality of the supplied equipment, as before, remains one of the most important priorities, together with our foreign partners, we tried to create thermostatic equipment, the technical characteristics of which fully satisfy the requirements of the Russian construction market.