A clear example of the principle of operation of an electrode installation is a homemade boiler made from two razor blades held together with matches. Such devices were widely used by business travelers, students, and soldiers during the Soviet era.

Electrode boilers are more complex, but the principle of their operation is similar.

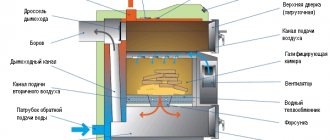

The installation consists of an oblong-shaped tank, inside of which water is heated under the influence of electric current. Due to the difference in the densities of cold and hot liquid, the coolant circulates in the heating system. Some models use a pump to provide forced movement of water in the circuit.

How the equipment works and how it works

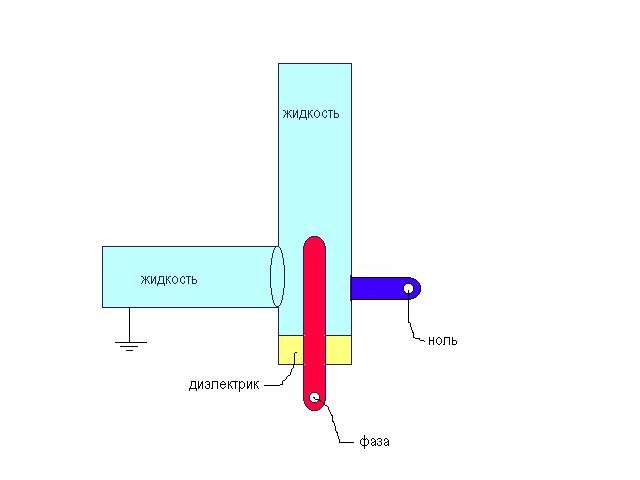

By placing the anode and cathode in an electrolyte and applying direct current, the electrolysis process is initiated. Anions and cations are formed, which begin to move towards oppositely charged poles. In the case of an alternating current connection, the polarity of the anode and cathode electrodes oscillates at a frequency of 50 Hz.

Ordered movement is replaced by chaotic movement of charged particles. Due to the force of friction in a liquid medium, the temperature rises sharply.

Distilled water is not used as a coolant in such electrical installations. It is a dielectric because it contains no metal salts. Therefore, the heating circuit is filled with water with additives that provide the desired properties, or antifreeze. For effective operation of the device, the specific resistance of the liquid should not exceed 13 Ohms. Manufacturers of electrode boilers recommend using their own coolant compositions.

The devices are classified as direct-acting installations, since the water is heated without the use of a heating element. During operation, scale does not form, so the efficiency of the boiler does not change during its service life. Electrode installations are connected to alternating current. There are units designed for two- and three-phase networks.

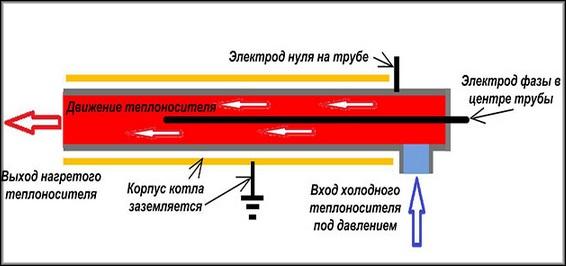

Structurally, the device is a cylinder in which the coolant is heated. The walls of the housing act as an electrode and are connected to the neutral wire. On one side, the cylinder ends with a pipe for the outlet of heated liquid into the heating circuit. To supply cold water, there is another outlet located perpendicular to the axis of the device. In the central part there is a second electrode, which is a metal rod. It is connected to the phase wire.

The operation of the boiler is controlled by an automation unit. Voltage is periodically applied to the electrodes. After heating the coolant to the set temperature, the boiler turns off. When the water in the circuit cools down, the device starts working again.

In three-phase installations, three electrodes are placed in the housing. Such devices are characterized by greater productivity and are used in powerful models of heat generators.

Device

Structurally, the electrode boiler is an all-metal pipe with polyamide insulating coating. On the case there are power terminals and coolant input/output (water or other liquid). At one end of the cylinder, electrodes are inserted into the boiler, and the other has an outlet into the heating system.

On the picture:

- 1 - pipe for supplying hot coolant to the external system;

- 2 — steel body;

- 3 - layer of electrically insulating material;

- 4 - coolant heated by current;

- 5 — electrode block;

- 6 - pipe for introducing cold liquid for subsequent heating;

- 7 - insulation and seal;

- 8 - power input.

The composition also usually includes an electronic control unit. There are samples of ready-made automation units for factory boilers on the market; they can also be adapted to a homemade “water heater”.

These boilers received the name “electrode” precisely because of the two electrodes located inside - the anode and the cathode. “Minus” goes to the cathode, and “plus” goes to the anode. When current is applied to the electrodes, the heat-carrying medium heats up and enters external systems. The electrical charge passes directly through the liquid, causing it to quickly become hot.

In industrial boilers, the following device diagram is usually used:

- cylindrical body with a round electrode inside;

- “zero” is connected to this electrode;

- the second contact is the housing itself - the phase is connected to it.

With such a scheme, the case is certainly grounded, for which a ground contact is placed on it. Homemade samples also adhere to this method of manufacturing electrode boilers.

Average parameters of factory products:

- pipe length - up to 60 centimeters, diameter - up to 32 centimeters;

- power - from 2 to 50 kW. The most powerful ones heat rooms up to 1500 square meters. m.;

- the current used is three- or single-phase. The latter operates relatively low-power household appliances, and three-phase current powers productive high-power boilers in commercial buildings, workshops and industrial facilities;

- The ideal temperature of the working fluid is 75 degrees. At this level, optimal energy consumption is established. At a higher temperature, the boiler consumes too much current, and at a low temperature it drops, since as it cools, the thermal conductivity of the medium decreases.

Boilers are divided according to the method of supplying water or other liquid:

- open - the movement of the working fluid is carried out naturally: it leaves the heat generator, transfers heat to the environment and returns back;

- closed - equipped with an expansion pump and tank. The pump provides circulation, and the tank serves for initial heating of the coolant.

Interesting: modern industrial boilers not only have advanced control automation, but are also often equipped with remote control systems and GSM communication modules. Such a device can be controlled via an application from anywhere in the world with Internet access.

Advantages and disadvantages

The main advantages of electrode-type EOU are:

- high reliability of equipment - units often last more than 10-12 years without repair;

- safety of devices - in case of depressurization and leakage of coolant or power outage, the boiler stops working;

- small dimensions allowing the unit to be installed in a convenient place;

- silent and vibration-free operation;

- there is no need for a hood and chimney;

- environmental friendliness - there are no combustion products generated, characteristic of gas and solid fuel generators;

- low price - installation is cheaper than that of heating element boilers, but you will additionally need to purchase a pump and an expansion tank.

Disadvantages of units:

- high energy consumption;

- high requirements for coolant characteristics;

- the ability to use devices only in closed circuits;

- dependence of heating of a private house or cottage on uninterrupted power supply;

- mandatory grounding.

Pros and cons of ion boilers

An important advantage of an electrode heater is its resistance to voltage drops. Ionization will be carried out even if the voltage drops to 180 V. This is very important in places with unstable power supply.

Another plus is compactness. Electrode boilers can be very small, suitable even for small homes.

The third advantage is safety. It is based on the principle of operation: if water/other coolant suddenly disappears from the system, the electrode electric heating boiler will simply stop working, which cannot be said about solid fuel or gas options. Emergency situations are excluded - which also excludes the introduction of expensive control and measuring automation into the circuit.

In addition, electrode equipment is free from the standard problem of devices based on heating elements - scale. Thanks to this, they have a long service life. And it works almost silently, which cannot be said, for example, about induction options.

Other benefits include:

- the ability to remotely control the device, if such functionality is provided and supported;

- speed of work. Thanks to minimal thermal inertia, water heats up very quickly;

- ease of installation;

- the ion boiler does not require a separate room;

- on its basis you can make a full-fledged efficient hot water supply system in a house or apartment;

- environmental friendliness - the complex does not produce exhaust emissions, does not emit combustion products and does not burn any fuel;

- installation does not require special permits or permits;

- high efficiency - up to 98%.

But there are also some disadvantages. Among them:

- specific requirements for the quality of the working fluid. In pure water without impurities, ionization is impossible. Therefore, distilled water diluted with salt or soda is poured into the system, which you have to buy or prepare yourself. The additive is mixed with water in an amount of approximately 6–8 mg per 100 liters;

- It is possible that current leaks to metal parts of the heating system - for example, radiators. This is due to the principle of operation, because the current flows directly through the coolant. If installed incorrectly, the device poses a great danger, therefore, the installer of such equipment must strictly follow the grounding rules and provide protection against the occurrence of dangerous differential leakage currents. A residual current device in a circuit by itself will not provide sufficient reliability and safety due to the large length of the heating route;

- Although scale does not form on the electrodes, over time they decrease in size as particles are constantly “knocked out” of them. Therefore, the elements need to be periodically replaced. The service interval is different for each boiler, but on average it is about five years;

- the need for constant power supply. In regions where electricity is expensive, this may become inconvenient or unacceptable;

- if the circuit is not closed, it is necessary to use containers and pipes with a special anti-corrosion coating to protect against air oxygen.

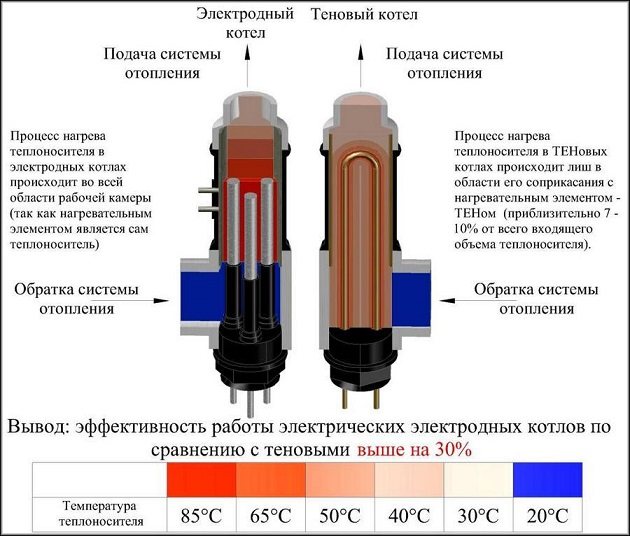

Economical

The ion boiler has low inertia both during startup and while maintaining the set temperature. There are no intermediate carriers - incoming electricity is immediately transferred to the liquid. The process begins instantly, while a classic heating element takes up to several minutes to reach operating temperature. The same goes for turning off: after interrupting the current supply, heating stops, energy is not wasted. Thanks to this, the device is significantly less energy-consuming compared to a heating element boiler: reviews give figures of up to 30% less electricity consumption.

Important: to achieve this result you need specialized control automation.

But over time, power can decrease. This happens for reasons:

- wear of electrodes;

- incorrect composition of the prepared mixture for pouring into the circuit;

- degradation of the components of the control electronic unit, and so on.

Practice shows that after approximately 2.5–3 years of operation, the efficiency of the heating system begins to decline. This is usually due to wear of the electrodes or failures in the control automation, but sometimes it is possible to adjust the power by changing the composition of the heat-carrying mixture.

Difficulties in operation

During use, the consumer may encounter some problems characteristic of electrode heaters:

- The quality of the coolant plays an important role. The service life of the product and reliability of operation depend on this. The use of tap fluid can lead to increased corrosion of metal pipes and radiators and a decrease in efficiency. Manufacturers recommend that owners of electrode boilers use ready-made compositions that have the necessary physical and chemical characteristics. The liquid changes its properties over time, so after 3-4 years the system needs to be filled with fresh coolant.

- It is necessary to pay attention to ensuring the electrical safety of the unit. The body of the device is connected to the neutral cable, the phase is connected to the electrodes. During installation, grounding must be provided. Electric boilers create a large load on the network, so before installing the heating device you should make sure that the wiring is reliable throughout the room.

- Under the constant influence of current, the processes of electrocorrosion of steel and cast iron are accelerated, which reduces the service life of the system several times. Aluminum or bimetallic communications and radiators should be used with electrode units. To provide heat to a cottage or home, you need to make sure that the elements of the heating system are made of recommended materials.

About the advantages

Electrode boiler ROMSTAR 2 smart (set)

- The main advantage of ion boilers is their high efficiency (up to 98%), which is explained by the relative simplicity of the device’s operation.

- Their small size allows them to be used even in small houses.

- Electrode boilers do not have a “dry run”. The liquid is a full-fledged “participant” in the working process, so its absence will not cause overheating of the system - only the circuit will open.

- Voltage drops in this case are not dangerous - if it drops, the device will not turn off, it will simply work with less power.

- Cost-effectiveness is another advantage of electrode boilers.

- Finally, they reach the set temperature quickly and cool down just as quickly, allowing for more efficient use of automatic control.

Operating principle

Drawing of an ion electric boiler

Rating of the best manufacturers

Many foreign and Russian companies produce ion heaters.

The following manufacturers have the best combination of characteristics:

- Galan is a Russian company offering a wide range of boilers of different capacities. The devices are low cost and reliable. Disadvantages - expensive branded coolant and a stepwise power control system.

- EOU is a Ukrainian brand. The company produces equipment with power from 1 to 36 kW. The declared service life of the products is 30 years. The disadvantages of boilers are high prices, frequent problems with automation.

- Coterm is a Russian company engaged in the production of electrical equipment. It produces devices characterized by fast heating of the working fluid, high-quality assembly and compact dimensions. Typical disadvantages are the limited functionality of the automation, the need to fill the heating system with its own Coterm Eco coolant.

- Beril is a Latvian company whose products stand out for their reliability and advanced functionality. The automation system is equipped with several operating modes, degree-by-degree power adjustment, and overheating protection. Provision is made for connecting a GSM module and external temperature sensors. The main disadvantage is the high cost.

- Buderus is a German brand that produces a wide range of gas equipment. The devices are distinguished by their reliability and long service life. Among the electrode models there are two- and three-phase units. The main disadvantage is the price, which is higher than that of Russian devices.

Installation of an ion heater

Do-it-yourself electrode heating boilers are assembled taking into account the remaining heating elements. To do this, you should develop a sequence of actions and install the devices one by one. The boiler is not installed separately, but integrated into the system.

You should prepare the materials and install the heater sequentially

Work order:

- Determine the type of heating circuit - single-circuit or double-circuit, with water heating for household needs. Select and install suitable radiators.

- The boiler is assembled and connected to the main line.

- Observe the operation of the device in test mode. Make sure that the device’s characteristics are maintained at the required level.

- Automate the operation of the boiler.

It is necessary to adhere to this sequence of work. The heating device does not need to be assembled first, since it will not be possible to test the operation of the coolant line. They begin work by creating drawings of an electrode boiler with their own hands.

The procedure for assembling an electrode boiler:

- A coupling is screwed onto the steel pipe, which will act as the body of the device, on one side, and a tee on the other. Tighten tightly to prevent further coolant leaks. Through the tee, liquid will flow from the boiler into the system, and vice versa.

- An electrode is inserted into the body from the end of the tee. It is important to prevent contact between it and the body. Secure the electrode with a plug from the radiator. He must stand still. To do this, fixation is performed with a nut. The insulator also plays a sealing role. If there is no suitable material, then it is better to turn to professionals to make the part.

- Pour some liquid into the assembled housing and check the reliability of the connections. There should be no leaks. If any, the seals are adjusted. If there are no leaks, then the water is poured out.

- 2 steel bolts are welded to the boiler body. The optimal choice is M8 and M10. They are needed to connect wires - grounding and neutral. The nuts should be covered with an insulator to avoid electric shock during operation.

- The device is installed in the heating system.

This is important: standards and requirements for installing heating boilers in a private home .

Additional equipment is required for safe operation and cannot be ignored.

For safety reasons, the boiler is equipped with additional elements. During operation, electrolysis gas is released from the liquid, so it should be removed from the system. For this you will need:

- air removal valves, automatic;

- safety valve;

- a pressure gauge that will allow you to control the power of the device;

- expansion tank;

- shut-off valves.

The devices prevent a critical increase in pressure in the system. The gas will gradually come out.

The most popular and sought-after models of electrode boilers

The following units are in greatest demand among consumers:

- “Ochag Galan” is a 6 kW heat generator designed for heating private houses and cottages. The model provides a single-phase connection to the electrical network. The recommended volume of coolant in the system is up to 70 liters. The device is characterized by its low price, light weight and compact size.

- “Geyser 15 Galan” is an electrode-type heating unit for floor mounting with a power of 15 kW. The device can cope with heating a room up to 150 square meters. m. The electric boiler is designed for connection to a three-phase network. Geyser 15 is equipped with mechanical control. It is possible to connect an external control unit. The device is easy to install and has a small size.

- Buderus Logamax E213-10 is an electric heat generator from the famous German company with a capacity of 9.9 kW. It is reliable and easy to use. The model is intended for wall mounting. The basic package includes a circulation pump and an expansion tank with a capacity of 7 liters. The efficiency of the installation is 99%. The outer casing is made of stainless steel and equipped with thermal insulation. The device is sensitive to voltage changes, so it is recommended to use a stabilizer.

- “RusNIT 208 M” is a device from a Russian manufacturer from Ryazan. Designed for heating residential and domestic premises with an area of up to 80 sq.m. The installation power is 8 kW. The body is made of stainless steel. An external pump can be connected to ensure reliable coolant circulation. Power adjustment is three-stage. There is protection against overheating of water in the heating circuit. The disadvantage is the difficulty of installing and connecting the unit to communications.

- “Protherm Skat 24KR 13” is a device from a Czech company with a power of 24 kW. Supplied with 7 liter expansion tank, circulation pump and 4 heating elements. The device can be connected to an external boiler for preparing hot water and operating the “warm floor” system. Electronic control, with 4 power levels. An LCD display is used to control and adjust parameters. The device is equipped with a “soft start” function and a shutdown system when the coolant overheats.

Electrode boilers can be an affordable solution for creating reliable home heating. To ensure long service life of the installations, operating conditions must be observed and routine maintenance must be carried out on time.

Types of heating boilers

Before you begin work on optimizing your heating system, you need to become familiar with the concept of “passive house” and, if possible, implement its elements in your apartment or house. We are talking, of course, about insulating walls, ceilings and floors, installing energy-saving windows, and only after that – about optimizing the heating system. The ideal passive house option involves using natural thermal energy to maintain the ideal air temperature. For example, to keep the apartment warm, you need to use darker wallpaper and insulate the walls with a double coating of plasterboard. For winter, it is better to choose massive curtains made of thick, warm fabric. These simple methods will help reduce energy consumption.

Taking into account all the listed parameters, you can begin to select an option for heating your home. For these purposes, we will consider the types of heating boilers that are widely represented on the market. The classic case of a boiler is a single-circuit model, in which only the coolant is heated. To simultaneously heat water for water supply, another circuit will be required; such models are known as dual-circuit. At the same time, there are a number of offers from manufacturers for the mentioned models, and boilers for heating using other heat sources are also presented. Each of these options is worth considering in more detail.

Gas floor boilers

Gas floor-mounted boilers for home heating are well known to consumers. Buyers mainly choose single-circuit models due to their lower price. At the same time, dual-circuit models, also implemented in a floor-standing version, can be more economical and provide high efficiency at low gas consumption. At the moment, it makes sense to buy floor-standing boilers for heating only large houses. If the area of the house does not exceed the size of the apartment, a conventional wall-mounted boiler will cope with the heating tasks of such a room.

The most reliable and popular floor-standing models are boilers Biasi, Ferroli, Pro Tech, Buderus, Danko, Baxi. When choosing, you should take into account their power and the area recommended for heating. It is necessary to pay attention to gas costs and output efficiency; it is always better to choose a more economical model. The mentioned floor-standing gas heating boilers have quite different prices, a lot depends on the brand.

It is better to choose a boiler on a tight budget with a specialist who installs the system.

He will give the necessary recommendations. The optimal choice for a large house would, of course, be economical double-circuit floor-standing gas boilers with a heat accumulator. They solve a number of problems at once and meet most of the requirements for modern individual heating systems.

Gas wall-mounted heating boilers

Wall-mounted gas heating boilers differ in the number of circuits, as well as in efficiency and power. In fact, they differ from floor-mounted options only in the installation method, duplicating other possibilities. In this case, the design of the boiler may also differ. Depending on it, the technical parameters will be different.

Boilers can be flow-through and optionally have a storage tank; systems with a storage tank rarely appear on the market. They are disadvantageous primarily due to their large size and are more often used in floor-standing versions, but, nevertheless, they are more suitable for large houses, primarily because the installation of additional structures for tanks is not required, and in addition, efficiency increases. Also, such boilers have a built-in pump, which has a positive effect on the overall efficiency of the boiler.

The wall-mounted gas heating boiler recommended by experts is, first of all, a model with an efficient plate heat exchanger. According to the experience of the craftsmen, these are the most compact, relatively inexpensive and optimal models for home use. We recommend purchasing a double-circuit gas boiler with high efficiency and low consumption, designed for the required area. At the same time, quite low gas costs are guaranteed at a comfortable temperature in the house in any frost.

Electric boilers with pump and expansion tank

When choosing a system, you should not lose sight of the numerous electric boilers with a pump and expansion tank. The operating principle is similar to gas versions except for the energy source. For heating in such boilers, TEN is used; single-circuit and double-circuit versions are available for sale, that is, designed simultaneously for heating and hot water supply.

Heating boilers cannot be considered the most economical in terms of costs; they cannot always provide sufficient heating of the room in severe frosts. In this case, you need to use other types of heating, for example, underfloor heating technology. These boilers are most effective in conditions where there is no gas, constant use of the system is not required, and the house is located in a warm region.

Additionally, it should be noted that single-phase electric heating boilers are not only the most convenient to connect, but also the most profitable in the initial installation of a heating system.

If you need to install something as soon as possible before winter with a limited budget, you can safely choose an electric boiler, and subsequently optimize the heating system.

Such optimal options, for example, include the Russian Zota electric boiler. Its main advantage is its compact size. In addition, due to the use of stainless steel tubes with a diameter of 7.4 mm for the manufacture of heating elements, it is possible to achieve a lower watt load. There is also weather-compensated control of parameters and a built-in chronotremostat for a two-tariff meter. Zota electric boilers are offered in various versions and based on the use of different types of fuel.

Consumers will certainly be attracted by the Nevsky electric boiler, whose price is very competitive. Experts recommend these heating systems due to their compactness and multi-stage protection of heating elements. Models are offered for private houses with a small area, for houses, offices and kindergartens with an area of 150-200 sq. m, as well as models for warehouses and production facilities. It should be noted that this company has an excellent level of consumer management, allowing customers to quickly select the right model.

Electrolysis heating boilers

An alternative method is electrolysis heating boilers. Their power is 1 kW per 20 sq. m, which is quite uneconomical compared to all other technologies on the market. Reduced cost of ownership is typical only for expensive high-tech models, for example, for the Galan model range.

Features of such boilers include the appearance of scale on the plates, which significantly reduces efficiency and requires regular and rather labor-intensive maintenance. An electrolyzer is suitable for heating a country house; it copes well with occasional use and heating a small area with low installation costs.

Solid fuel heating boilers

Solid fuel heating boilers are used in boiler rooms, industrial premises and individual houses. This is especially true in cases where there is no main gas and electricity, and the house is supplied by solar panels. Solid fuel boilers are purchased by owners of individual houses to save on fuel and to be able to use firewood, pellets and coal for heating. This is the best option for replacing the stove, especially in those rooms where it is not possible to install it.

Interesting offers from Czech manufacturers who produce solid fuel boilers of various functionality. For example, the family company ATMOS offers consumers high-tech models based on its own developments, protected by patents. In addition to high efficiency, these models have such a functional advantage as separate containers for burning wood and coal. For home use and heating small spaces, a highly efficient, compact and easy-to-use cast iron boiler VIADRUS may be suitable.

You should pay attention to the inexpensive automatic coal boiler from Zota; it is interesting due to its low heating costs and the absence of the need to constantly monitor combustion. Among solid fuel boilers, it is worth highlighting pyrolysis models, the peculiarity of which is the combustion of gases released during combustion, due to this a higher efficiency is achieved - the combustion temperature in the chamber reaches 1200 C in some models. Many craftsmen recommend ATMOS boilers or models from other Czech manufacturers.

Multi-fuel heating boilers

A multi-fuel heating boiler is used to use various types of energy raw materials, which generally follows from the name. Typically, new types of gas boilers appear as a result of changing consumer requirements and the emergence of new technologies. This also applies to multi-fuel models. We can talk about the use of various energy resources - for example, solid fuel and oil. We recommend a waste oil boiler, the price of which is quite low, and the method of use and speed of installation are well suited for utility rooms, garages, kiosks and other work or residential premises.

Solid fuel boilers are recommended for homes in rural areas where gas supplies are difficult and power lines are rather weak, and firewood and coal are also available at fairly low prices. When choosing a model, you need to pay attention to the footage of the room for which it is designed, efficiency, and its functional characteristics to ensure comfort of use. Some companies like VIADRUS make models for wood and coal, which can be converted to gas without high costs using an additional module.

A universal option for households is a boiler that runs on gas and diesel fuel. Boilers for these types of fuel differ only in the type of burner and can be combined. The most practical are boilers for gas, diesel and solid fuel, however, this option implies firewood or coal as the main energy resource, and gas and diesel as an additional one. As a result, the model has a minimum of automation and may be unsafe. You can read more about combination boilers in our article “Universal heating boilers for a private home: types and characteristics.”

The best option for multi-fuel boilers is considered to be those models that combine three or more types of fuel: electricity, diesel and gas. This option is suitable for heating country cottages of any size, while maintaining efficiency when switching to another energy resource.