This question always arises among those who are choosing a heating boiler for the first time.

If space allows, at first glance, a cast iron heat exchanger is preferable. But this is only at first glance. Let's look at some misconceptions that guide people when choosing a bulky, expensive and heavy floor-standing cast-iron boiler, ignoring lightweight wall-mounted boilers, which are also cheaper. At the same time, we will not focus on the psychology of such a choice.

- The main arguments of cast iron advocates:

- Easy to install and commission.

- The gas consumption of a cast iron boiler is the same as that of a wall-mounted one, since the efficiency of the boilers is the same.

- Such boilers are cheaper to operate (there is no need to periodically flush the heat exchanger).

- The cast iron heat exchanger is not subject to corrosion.

- The boiler will last 50 years, or even more.

Point one.

On the first point. Cast iron is very sensitive to temperature changes. Therefore, it is very important to correctly design the connection of such a boiler. For example, the heating system should under no circumstances be fed in front of the boiler. The difference between the supply and return should not exceed 20°C; to ensure this parameter, it is necessary to provide a system for automatically mixing water from the supply to the return. The choice of circulation pump plays an important role. It must completely match the boiler, otherwise the boiler will either overheat or switch on and off frequently. Both are unacceptable.

A wall-mounted boiler is not afraid of temperature changes. The feed tap for many wall-mounted models is already provided in the boiler design, as well as the circulation pump, which is selected during the design of the boiler and fully complies with the design parameters.

Point two.

The fact is that the passport indicates the efficiency values of the boiler when operating under ideal conditions. Those. the water temperature in the boiler is 60°C, there are no deposits on the heat exchanger, no soot or scale. When the temperature of the heating water increases or decreases, the efficiency will decrease, since in the first case, with a decrease in the temperature difference, heat transfer will decrease, in the second case, the flue gases will be colder, which will lead to a decrease in draft and under-burning of gas.

To combat this phenomenon, modulating (with varying gas flow) burners were designed. Boilers with a cast iron heat exchanger have burners with power adjustment from 70 to 100%, and boilers with a copper heat exchanger - from 30 to 100%. As a result, the efficiency of a wall-mounted boiler in real conditions turns out to be higher than that of a cast iron boiler.

In addition, the large mass of the boiler and the large volume of water in it leads to high thermal inertia of the system as a whole. Such a system takes a long time to heat up and takes a long time to cool down, i.e. When the heating mode changes, the boiler either sits idle for a long time or operates with reduced efficiency. It should be noted that boiler downtime, paradoxically, increases gas consumption in general. This happens because the air in the combustion chamber is heated by the heat exchanger, a draft is created through the chimney and the heated air rushes into the atmosphere, removing heat from the heating system.

Point three.

Here they are right. It makes no sense to wash a cast iron heat exchanger with connecting dimensions of 2″ in the field. The scale will still remain on the walls. But it should be remembered that the deposition of 1 mm of sediment on the walls of the heat exchanger reduces the boiler’s performance by 5%, and you will not notice anything; a decrease in efficiency can only be determined using instruments. In a copper heat exchanger, when such a layer of deposits builds up, the flow will decrease, which will signal the need for maintenance. By spending 1 - 2 thousand rubles you will completely restore the operation of the boiler.

Point four.

This is also correct. Although, if you do not flush the boiler, deposits inside the heat exchanger cause uneven cooling of the walls with water, which in turn leads to thermal deformation of the cast iron, which can lead to the formation of cracks.

Point five.

Yes. A cast-iron boiler can last 50 years, but a wall-mounted one can only last 15. Only technology and legislation do not stand still. Who knows whether in 10 years all boilers except condensing boilers will be outlawed?

The gas heat exchanger is the main component of a gas boiler, but most often it is the first to fail due to the constant aggressive loads it is subjected to during operation. As a key element of the boiler, the heat exchanger ensures the transfer of heat from the heating substance to the heated medium. Evaluate for yourself how aggressive the loads placed on it are:

- Externally, the coil heats up to high temperatures as a result of gas combustion. Often, heat exchange equipment fails precisely because of “burnout”.

- From the inside, its walls are exposed to hot water, the temperature of which rises to 90 °C. As a result, scale settles on them, the diameter of the pipes narrows, and the performance characteristics of the boiler deteriorate.

- Sudden temperature changes also do not go unnoticed, often leading to the appearance of cracks in the metal.

Taking this into account, you need to choose a boiler whose gas heat exchanger is capable of withstanding such loads for a long time without destruction. The gas equipment market offers various boilers of a wide range of prices, but this is not the case when low price or impressive design should become factors that determine the choice. It is much more important, for example, to pay attention to the weight of the boiler. Heavy boilers last much longer than lighter models. Everything is very simple - the main weight of the heating unit - over 90% - falls on the recuperator, and the heavier the boiler, the thicker the walls of the coil and the longer it will work in the heating system without repair. You should not choose the most inexpensive models - there is a high probability that they will soon require cleaning the pipes to remove lime deposits from the walls, as well as replacing individual components.

Gas boilers with a heat exchanger have many advantages: they are economical, efficient, and comfortable to use. But at the same time, using gas as a fuel carries certain risks, and in order to minimize them, it is necessary to correctly select all elements of the heating system and carry out their installation efficiently.

Types of heat exchangers for boilers

Manufacturers offer various heat exchange equipment, which, according to the method of heat transfer, is divided into three types:

- Primary. In heat exchangers of this type, heat is transferred from a gaseous medium to a liquid. The design of the primary recuperator consists of a copper alloy pipe bent into a coil, coated on the outside with many copper plates. Its length and the number of elbows determine the power of the device. Some models are equipped with an anti-corrosion coating that protects the pipe walls from the aggressive effects of almost boiling water. At the same time, the protective coating is not able to protect the gas heat exchanger from the appearance of limescale deposits. Such deposits interfere with the normal functioning and reduce the efficiency of the heating system. As a result, the boiler simply fails if there is a significant accumulation of deposits.

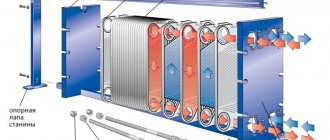

- Secondary. In products of this type, thermal energy is transferred according to the “liquid-liquid” principle. Secondary recuperators consist of thin plates made of stainless steel. Reliability is one of the important advantages of heat exchange equipment of this type. Other advantages include a large heat transfer area and high speed. These two factors provide the device with high wear resistance, since salts and other harmful substances simply do not have time to settle in its cavity. A larger number of plates gives higher power to the recuperator and increases its efficiency.

- Combined. This is the optimal type of such devices in terms of structure. Its design provides for the combination of processes of heat transfer from heated gas to the coolant and from it to water in heating radiators. The design of a combined gas heat exchanger consists of a pipe with copper fin plates soldered on it. The pipe of the combined recuperator itself is double - water passes through the inner one, and the heating substance passes through the outer one. The price of boilers with combined heat exchangers is relatively low, since there is no need to use additional hydraulic units in the design of such a unit. Heat exchange equipment of a combined type often fails if the water used in the heating system contains a large amount of salts that settle on the walls of the pipes and complicate its operation.

If you want the purchased boiler to serve for a long time and efficiently, it is advisable to conduct a chemical analysis of the water that you will use in your home heating system before purchasing it, and choose a model based on its results.

Depending on the material used, gas recuperators can be made of steel, cast iron or copper.

Cast iron heat exchanger

It is not subject to corrosion, therefore more durable than steel. Requires special attention to operating conditions. The most vulnerable spot is the boundary between the hot and warm parts of the recuperator. Operational errors increase the risk of cracks in the metal in this area. To prevent this from happening, you should regularly flush the gas heat exchanger. Installing a three-way mixer tap on the return line near the heat exchange unit, which pre-mixes hot and already cooled water and supplies liquid of moderate temperature into the cavity, will also help to minimize risks. It should be remembered that boilers from foreign manufacturers with cast iron recuperators are not adapted to Russian operating conditions and are therefore very vulnerable.

Copper heat exchanger

Its advantages include the low specific gravity and small capacity of the device, compactness, corrosion resistance, low fuel consumption for heating to operating temperature. The main disadvantages of such heat exchange equipment are high cost and lack of reliability.

Cast iron

Cast iron heat exchangers appeared much earlier than steel ones. They have the following performance characteristics:

- heavy weight - due to this, the equipment cannot be placed on the wall. The weight of the boiler is also significantly affected by its power: low-power models are lighter, but to install a boiler with high productivity you will even have to strengthen the foundation;

- ease of installation - the device consists of several sections, which greatly facilitates its assembly. Thus, the heat exchanger can be delivered to the site disassembled and then assembled;

- fragility - a material such as cast iron requires careful handling. Even a small impact can cause a crack to appear on its surface. Also, thermal shock should not be allowed when cold water enters a hot heat exchanger - this can cause it to crack;

- susceptibility to corrosion - cast iron becomes rusty over time. It can be dry and wet. Wet is considered the most dangerous, as it progresses and corrodes the metal surface;

- good heat transfer - cast iron takes a long time to heat up and releases heat slowly. Thanks to this property, the heat exchanger uses fuel economically and provides good heating of the coolant.

Thus, a cast iron heat exchanger has both advantages and disadvantages.

Flushing the heat exchanger will extend the life of the boiler

Even a correctly chosen boiler can last a long time or not very long, depending on the operating conditions. Today there is no need to talk about the high quality of coolants used in heating systems, so timely and regular cleaning will help extend the life of the boiler and gas heat exchanger.

Boiler flushing can be done manually, as well as using hydraulic and chemical methods. In the first case, deposits are removed using scrapers after opening the boiler. Hydraulic flushing is carried out using a pump that supplies the heating unit with tap water under pressure, which removes deposits and is discharged into the sewer system using a hose. In the third option, washing is carried out using chemical reagents that soften and decompose sediment on the surfaces of the plate heat exchanger.

A gas heating boiler is a device that uses fuel combustion (natural or liquefied gas) to heat the coolant.

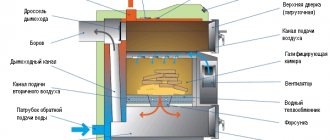

Design (design) of a gas boiler

: burner, heat exchanger, thermally insulated housing, hydraulic unit, as well as safety and control devices. Such gas boilers require a chimney connection to remove combustion products. The chimney can be either ordinary vertical or coaxial (“pipe in pipe”) for boilers with a closed combustion chamber. Many modern boilers are equipped with built-in pumps for forced water circulation.

The principle of operation of a gas boiler

— the coolant, passing through the heat exchanger, heats up and then circulates through the heating system, releasing the resulting thermal energy through radiators, heated floors, heated towel rails, and also providing water heating in an indirect heating boiler (if it is connected to a gas boiler).

A heat exchanger is a metal container in which the coolant (water or antifreeze) is heated - can be made of steel, cast iron, copper, etc. The reliability and durability of a gas boiler depend primarily on the quality of the heat exchanger. Cast iron heat exchangers are resistant to corrosion and have a long service life, but are sensitive to sudden temperature changes and are heavy. Steel containers can suffer from rust, so their internal surfaces are protected with various anti-corrosion coatings to extend the “life” of the device. Steel heat exchangers are the most common in boiler production. Copper heat exchangers are not susceptible to corrosion, and due to their high heat transfer coefficient, low weight and dimensions, such heat exchangers are often used in wall-mounted boilers, but the downside is that they are more expensive than steel ones. In addition to the heat exchanger, an important part of gas boilers is the burner, which can be of various types: atmospheric or fan, single-stage or two-stage, with smooth modulation, double.

To control a gas boiler, automation is used with various settings and functions (for example, a weather-dependent control system), as well as devices for programming operation and remote control of the boiler.

The main technical characteristics of gas heating boilers are: power, number of heating circuits, fuel type, type of combustion chamber, type of burner, installation method, presence of a pump and expansion tank, automatic boiler control.

To determine the required power

For a gas heating boiler for a private country house or apartment, a simple formula is used - 1 kW of boiler power to heat 10 m 2 of a well-insulated room with a ceiling height of up to 3 m. If heating is required for a basement, glassed-in winter garden, rooms with non-standard ceilings, etc. The power of the gas boiler must be increased. It is also necessary to increase the power (about 20-50%) when providing a gas boiler and hot water supply (especially if it is necessary to heat the water in the pool).

Feature of power calculation for gas boilers: the nominal gas pressure at which the boiler operates at 100% of the power declared by the manufacturer, for most boilers is from 13 to 20 mbar, and the actual pressure in gas networks in Russia can be 10 mbar, and sometimes lower . Accordingly, a gas boiler often operates at only 2/3 of its capacity and this must be taken into account when calculating. For more details, see the table for calculating the power of a heating boiler.

Most gas boilers can be converted from natural gas to liquefied gas

(cylindered propane). Many models switch to liquefied gas at the factory (when purchasing, check these characteristics of the model), or the gas boiler is additionally supplied with nozzles (nozzles) for switching to bottled gas.

Pros and cons of gas boilers:

Boiler piping

- These are devices for the full operation of the heating and water supply system. It includes: pumps, expansion tanks, filters (if necessary), manifolds, check and safety valves, air valves, valves, etc. You will also need to purchase radiators, connecting pipes and valves, thermostats, a boiler, etc. The issue of choosing a boiler is quite serious, so it is better to entrust the selection of equipment and its complete set to professionals.

Which boiler is the best? The Russian market of gas boiler equipment has its own leaders in quality and reliability. The best manufacturers and brands of gas boilers are presented in the assortment:

“Premium class” or “Lux” are the most reliable and durable, easy to use, the kit is assembled like a “construction set”, more expensive than others. Such manufacturers include the German companies Buderus and Viessmann.

“Middle class” - good performance, average price, not so prestigious, but quite reliable, standard standard solutions are presented. These are Italian boilers

Floor-standing gas boilers for home heating have been used for quite a long time and have proven themselves well. A huge selection of single-circuit and double-circuit models presented on the heating equipment market will allow even the most capricious buyer to select a unit with the necessary technical parameters and characteristics.

Like any technology, gas boilers have their positive and negative sides.

A floor standing gas boiler requires sufficient space for installation

To the benefits

floor-standing gas boilers include:

- Easy to use. Gas boilers do not require continuous monitoring and are easy to maintain.

- Sufficiently high efficiency with inexpensive fuel.

- Large coverage area. The boiler is capable of heating large houses.

Flaws

:

- A fair amount of documents and permits, without which it is impossible to install the boiler.

- The need to construct a chimney before installation.

- Installation should only be carried out in sufficiently ventilated areas.

- It cannot be installed tightly against a wall or placed between two walls, so as not to disrupt the flow of oxygen to the burner.

Heat exchangers for gas water heaters

radiators for geysers

Heat exchanger NEVA 4510

Heat exchanger VPG 18

Heat exchanger "Canord"

Heat exchanger PG 6

Heat exchanger KGI-56

Heat exchanger Astra VPG 21

Beretta heat exchanger

Heat exchanger VPG 23

Heat exchanger Astra VPG 18

Heat exchanger -Vaillant 19 - 2 XZ

Heat exchanger Ladogaz VPG 10M

Heat exchanger Ladogaz VPG 10A

Heat exchanger Electrolux GWH275RN

Heat exchanger VPG 18

The heat exchanger is designed for a gas water heater: manufactured in St. Petersburg

The heat exchanger is made of thick high quality copper. And if the heat exchanger leaks, we exchange it for a new heat exchanger.

Specifications:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Connecting dimensions of the union nut | inch | 1/2 |

| 2 | Overall dimensions: - length - width - height | mm mm mm | 350 210 440 |

| 3 | Heat exchanger weight | kg | 3,23 |

The heat exchanger is designed for the water circuit of manufactured boilers. The heat exchanger is made of high quality copper pipe

Specifications:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Overall dimensions: - length - width - height | mm mm mm | 360 240 240 |

| 2 | Heat exchanger weight | kg | 2,97 |

Heat exchanger PG 6 is designed for a geyser manufactured in: Poland

The heat exchanger is made of thick high quality copper. The outside of the heat exchanger is coated with special heat-resistant paint.

Specifications:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Connecting dimensions of the union nut | inch | 1/2″ |

| 2 | Overall dimensions: - length - width - height | mm mm mm | 380 180 530 |

| 3 | Heat exchanger weight | kg | 3,92 |

The KGI-56 heat exchanger is designed for a gas water heater: “Tula”, manufactured in Tula. In the event of a heat exchanger leak or a manufacturing defect, we exchange it for a new heat exchanger.

Specifications:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Connecting dimensions of fittings | inch | 1/2″ |

| 2 | Overall dimensions: - length - width - height | mm mm mm | 350 180 420 |

| 3 | Heat exchanger weight | kg | 4,8 |

Heat exchanger Astra VPG 21 is designed for geysers Astra model 8910 Astra model 8910 version 06

Specifications:

| № | Name of parameters | Unit change | Magnitude |

| 1 | Connecting dimensions of fittings | inch | 1/2″ |

| 2 | Overall dimensions: - length - width - height | mm mm mm | 340 190 300 |

| 3 | Heat exchanger weight | kg | 3,5 |

The heat exchanger is designed for a gas water heater: “Beretta” model Idrabagno 11, Idrabagno 11i

The heat exchanger is made of thick high quality copper. The outside of the heat exchanger is coated with special heat-resistant paint.

If the heat exchanger leaks or a manufacturing defect is detected, we will exchange it for a new heat exchanger.

Specifications:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Connecting dimensions of the union nut | inch | 3/8″ |

| 2 | Hot water outlet | inch | 1/2″ |

| 3 | Overall dimensions: - length - width - height | mm mm mm | 290 170 360 |

| 4 | Heat exchanger weight | kg | 2,94 |

Heat exchanger VPG 23m is designed for a gas water heater manufactured in St. Petersburg

The heat exchanger is made of thick high quality copper.

If the heat exchanger leaks or a manufacturing defect is detected, we will exchange it for a new heat exchanger.

Specifications:

| № | Name of parameters | Unit change | Magnitude |

| 1 | Connecting dimensions of fittings | inch | 1/2″ |

| 2 | Overall dimensions: - length - width - height | mm mm mm | 370 190 100 |

| 3 | Heat exchanger weight | kg | 2,83 |

The Astra VPG 18 heat exchanger is designed for the Astra geyser model 8910 version 08. The heat exchanger is made of thick high quality copper. The Astra heat exchanger has a certificate of conformity

If the heat exchanger leaks or a manufacturing defect is detected, we will exchange it for a new heat exchanger.

Technical characteristics of the heat exchanger:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Connecting dimensions of fittings | ||

| 2 | Overall dimensions: - length - width - height | mm mm mm | 350 150 130 |

| 3 | Heat exchanger weight | kg | 2,33 |

The heat exchanger is designed for a geyser: -Vaillant 192 XZ-C+

-Vaillant premium SOE 19/2

The heat exchanger is made of thick high quality copper. The outside of the heat exchanger is coated with special heat-resistant paint.

The heat exchanger has a 1-year warranty; in the event of a heat exchanger leak or a manufacturing defect, we will exchange it for a new heat exchanger.

Specifications:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Connecting dimensions of the union nut | inch | 3/8″ |

| 2 | Hot water outlet | inch | 1/2″ |

| 3 | Overall dimensions: - length - width - height | mm mm mm | 290 170 360 |

| 4 | Heat exchanger weight | kg | 2,94 |

The heat exchanger is designed for an energy-saving gas water heater: Ladogaz VPG 10M The heat exchanger is made of thick, high-quality copper. The heat exchanger is soldered using hard copper-phosphorus solder MF9, which increases the service life of the heat exchanger.

The product has a 1-year warranty; in the event of a heat exchanger leak or a manufacturing defect, we will exchange it for a new heat exchanger.

Technical characteristics of the heat exchanger:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Connecting dimensions of the fitting | inch | 1/2″ |

| 2 | Overall dimensions: - length - width - height | mm mm mm | 310 160 470 |

| 3 | Heat exchanger weight | kg | 3.51 |

The heat exchanger is designed for a gas water heater: Ladogaz VPG 10A

The heat exchanger is made of thick high quality copper. The heat exchanger is soldered using hard copper-phosphorus solder MF9, which increases the service life of the heat exchanger.

The product has a 1-year warranty; in the event of a heat exchanger leak or a manufacturing defect, we will exchange it for a new heat exchanger.

Technical characteristics of the heat exchanger:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Connecting dimensions of the fitting | inch | 1/2″ |

| 2 | Overall dimensions: - length - width - height | mm mm mm | 290 170 440 |

| 3 | Heat exchanger weight | kg | 3.04 |

The heat exchanger is designed for a geyser: Electrolux GWH275RN

The heat exchanger is made of thick high quality copper. The outside of the heat exchanger is coated with special heat-resistant paint. The heat exchanger has a certificate of conformity.

Our service center provides a guarantee for this product; in the event of a heat exchanger leak or a manufacturing defect, we will exchange it for a new heat exchanger. 1 year warranty. Only when installed by our service center

Specifications:

| № | Name of characteristics | Unit change | Magnitude |

| 1 | Connecting dimensions of the union nut | inch | 3/8″ |

| 2 | Hot water outlet | inch | 1/2″ |

| 3 | Overall dimensions: - length - width - height | mm mm mm | 290 170 360 |

| 4 | Heat exchanger weight | kg | 2,94 |

Principle of operation

The operating principle of a floor-standing gas boiler is quite simple: natural gas produces heat during combustion and transfers it to a heat exchanger located inside the structure. Then water passes through the heat exchanger and, heating up during the operation of the boiler, is transferred to the room heating system.

Installation of a floor-standing gas boiler

To make the right choice, you should pay attention to the heat exchanger. The efficiency of your boiler will directly depend on its quality.

Type of heat exchangers

Heat exchangers are manufactured in three types:

Advice. Study consumer reviews and consult with installers. As practice shows, time-tested modifications can last a very long time.

What types of burners are there?

Based on the type of burner, floor-standing boilers are divided into two types: boilers with a forced-air burner and atmospheric boilers.

An atmospheric boiler has a simpler design, is a little cheaper and makes virtually no noise.

The type of boiler burner will influence its final cost

A boiler with a pressurized burner (it can also be called a replaceable, fan-driven, mounted) has a higher price due to the burner, but also higher efficiency.

Attention! Such a boiler can use not only gas, but also liquid fuel.

The basic package often includes only atmospheric burners, but if you decide to install a forced-air burner, you will have to purchase it separately.

Single-circuit floor-standing gas boilers

Such boilers are intended only to create a heating system. At the same time, such a system cannot provide the room with hot water. This requires separate heating elements. Single-circuit boilers in our time can be arranged as an economical or optimal option.

Scheme: energy-dependent floor-standing gas boiler

- An economical option involves the addition of a gas instantaneous water heater. Such a system will allow two water supply elements to operate simultaneously with low fuel consumption.

- In the optimal option, the heat exchanger is installed in an indirect heating boiler. This method requires proper coordination of the power of both devices for operation.

Floor-standing gas boilers, double-circuit

Such units are of the flow type and combined with a boiler.

Flow-through boilers are used quite rarely, because their ability to provide hot water is small, only up to 15 liters per minute.

Electricity-independent floor-standing gas boiler

Most often, they use a boiler with a boiler, the volume of which is selected independently and depends on the needs of the residents. The disadvantage of such a unit is that they take up quite a lot of space in the room. However, they will be able to fully provide hot water to those living in the house.

Selecting boiler power

To select the right boiler, it is also necessary to take into account the power you need. It is calculated depending on the area that needs to be heated and possible heat loss. Typically, the technical specifications of the boiler contain information about the area of the house this model is designed for. However, it is worth considering that it is better to choose a boiler with a power reserve, and the reserve should not exceed 25%, otherwise no one can guarantee the stable operation of the boiler. On average, for houses with normal heat loss, power is calculated using a simple method: 1 kW of power for every 10 square meters. m. area. If heat loss is higher than usual, then it is best to entrust the selection to specialists.

Gas boiler connected to the heating and water supply system

It is also worth paying attention to the possibility of adjusting the boiler power. It happens:

Advice. The boiler operates at full power only in winter, so boilers with continuously adjustable or two-stage boilers are considered more economical.

How to improve security

There are a number of auxiliary elements that will help ensure the safety of using a floor-standing gas boiler, but will increase its cost.

Protect yourself by connecting protection systems to the boiler

These include:

- Flame sensor. Necessary for automatically turning off the gas if the fire goes out.

- Thermostat that turns off the boiler if the water temperature rises to an emergency level.

- Boiler blocking in case of gas shutdown.

- Traction control sensor.

Dependence of boilers on automation

In modern conditions, no less important is such a factor as the dependence of a gas boiler on automation, because there are still areas where power outages are not uncommon. Most domestic units with atmospheric burners can operate without electricity, while imported models most often require its presence.

Some models of gas boilers can only operate with an uninterrupted supply of electricity

Achieve energy independence

boiler in two ways:

- Maximum simplification of the control system by completely eliminating automation from it. This design will maintain the specified coolant temperature, but will not take into account the ambient temperature.

- Using a heat generator. This method is more progressive and consists of using a device that will generate the electricity necessary for the operation of the automation from the heat produced by the boiler itself.

The difference between boilers with forced draft and natural

Natural draft boilers are preferable to use in small spaces. The principle of removing combustion products in such boilers is similar to the principle of operation of a fireplace - combustion products are removed due to natural movement.

Boilers with forced draft receive air from the outside through the chimney. The combustion chamber in such boilers is closed, and the chimney is a pipe within a pipe. The internal circuit is used to remove burnt gases, and the external circuit provides air access to the boiler.

Scheme: operation of an atmospheric gas boiler

Forced draft boilers have a number of positive aspects:

- they do not burn oxygen in the room;

- do not require auxiliary air flow;

- installation does not require the construction of a chimney.

Ignition

In addition to all the above differences, there are also two boiler ignition systems.

Piezo ignition is a practical manual ignition; it is activated by pressing the corresponding button.

Floor standing atmospheric gas boiler

Electric ignition of the boiler is automated. If there is a power failure in the system, the boiler will turn on automatically after it is restored. This type of ignition is considered more economical, since it does not have a constantly burning igniter.

Cast iron or steel – which boiler heat exchanger is “better”?

Buying a heating boiler is the first thing a consumer does after deciding on the choice of heating system. And, thanks to the huge range of boilers that exist today, everyone can choose the best option for themselves. But, nevertheless, it is quite difficult for an inexperienced person to figure out which boiler has the best characteristics. After all, these devices can differ not only in their appearance, but also in the materials used in their manufacture. So, it is quite difficult to decide which boiler heat exchanger - cast iron or steel - has the best characteristics.

In fact, it is quite difficult to decide which material, cast iron or steel, is better. After all, each of these materials has both disadvantages and very significant advantages.

Cast iron is practically not subject to corrosion and has a long service life. But at the same time, cast iron does not tolerate transportation very well, since it is a rather fragile material. Therefore, during transportation, microcracks may form on the surface of the material. In addition, the use of hard water can also negatively affect the condition of the cast iron heat exchanger.

As for the use of a steel heat exchanger, it is important to strictly follow the rules regarding its operation, otherwise the steel will very quickly begin to corrode. The same can be said for a cast iron heat exchanger. Therefore, no matter what choice you make, the key to extending the service life of the boiler is to create normal operating conditions for it. And it is better to entrust this work to a specialist. Only a good designer with sufficient knowledge and experience can create a reliable system that will maximize the service life of your boiler.

Related Posts

Standard bathtubs: sizes and configurations of plumbing…

Bathtubs for the bathroom: types, characteristics and…

The recently appeared model of forced draft boilers has already managed to interest many consumers. But, if the chimney above the roof no longer surprises anyone, then consumers regard the absence of it with some caution. Experts say that there is no danger in the fact that the boiler is designed in such a way that exhaust gases are removed from it using a built-in fan - forcibly.

In fact, forced draft boilers have many advantages, namely:

• can be used in rooms without a traditional chimney - combustion products are discharged through a coaxial chimney. To install a coaxial chimney, you just need to make a hole in the wall;

• forced draft boilers do not require an influx of additional cold air to maintain the combustion process, and also do not burn oxygen from the room;

• installation of boilers of this type is more economically profitable, since it does not require the manufacture of an expensive traditional chimney.

Nanocomposite pipes: what is it? A new era in production!

How to choose the right pipes for a heating system?

Condensing boilers

When burning fuel, conventional boilers do not use all the energy it contains. There is also the so-called latent heat, which is lost in such boilers, leaving along with water vapor into the chimney. To use latent heat, there are condensing boilers. They cause steam to condense, cooling the exhaust gas to a low temperature. Manufacturers of such boilers indicate their increased efficiency, which, according to the documentation, is above 100%.

Condensing gas boiler

Practice shows that the real efficiency of such units is higher than the efficiency of conventional boilers by about 10%, therefore these boilers consume approximately the same amount less gas when heating the house.

Installation of floor-standing boilers

Before starting installation, you must select a room, taking into account all installation requirements. Double-circuit floor-standing boilers have a number of necessary parameters:

- at least 15 sq. m should be the area of the room in which the boiler will be installed;

- not 2.5 sq. m. should be the height of this room;

- window of suitable size;

- doorway at least 80 cm;

- free access to all systems and devices.

- the presence of a chimney that meets technical requirements.

A modern floor-standing gas boiler will not spoil the interior of your bathroom or kitchen

. Installation steps:

- preparing the foundation for the boiler;

- connecting the boiler to the chimney;

- connecting the boiler to the internal heating system;

- mandatory installation of a water purification filter;

- connecting the cold water supply to the boiler;

- connecting the gas pipeline to the boiler.

The choice of a floor-standing gas boiler is obvious if you have mains gas and a desire to save on heating and hot water supply. But do not forget that to install a boiler you must obtain a whole set of permits.

Before going to the store, it is best to make a list of criteria by which the model will be selected:

Construction of an energy-saving gas boiler

- Functionality

. Double-circuit water heaters operate on the principle of instantaneous water heaters. If this does not suit you, choose boilers with one circuit and additional connections for water heating devices. - Adaptation to domestic realities

. The pressure in the gas main and the voltage in our network do not always meet the standards. Therefore, it is better to choose a model that does not lose power even in extreme conditions. - Service maintenance

. First of all, pay attention to those brands whose service centers are located near your home. Thus, in case of breakdowns, repairs will be faster and cheaper. - After selecting and purchasing a boiler, leave all concerns related to its installation to specialists, because this is the only way to ensure a highly qualified approach to the work, take all necessary safety measures and carry out the installation in accordance with accepted standards.

Modern floor-standing gas boilers are a rather conservative and traditional thing. Over the years, they have not undergone major technological changes, which once again proves their reliability.

Our company produces cheap and reliable heat exchangers for industrial and domestic climate control systems, as well as special equipment made to order with maximum heat transfer and minimal air resistance on the lamellas. Air heaters and air coolers are bought mainly for supply ventilation systems; medium ones for ventilation units and large ones for cooling towers where they install heat exchange equipment from lamellas and copper-aluminum tubes running on water, but for cooling systems glycol is poured into the supply machine circuit, which is ultimately safer in the winter. Manufactured steel and stainless steel heat exchangers are more suitable for specialized equipment; their heat transfer is lower than that of aluminum and copper. As for refrigeration freon condensers and evaporators that are used in air conditioners, split and multi-split systems, and such precision air conditioners as precision ones in which the temperature fluctuates +-1 degree, freon condensers and evaporators are used.

On large buildings, chillers are often installed on the roofs; this is a more economical approach compared to freon systems, and cassette or duct fan coils and others are located inside individual rooms.

The model range of standard duct heat exchangers operating on water, oil, steam, glycol, propylene glycol, antifreeze, freon, which are mounted directly in air ducts or in small air handling units in the catalog and price list, corresponds to the basic sizes.

Also, the number of rows of the heat exchanger affects the air resistance in the channel, as well as the liquid pressure difference in the circuit between the supply and return pipes. The more rows in the heat exchanger, the lower the temperature of the water or glycol will be at the outlet, but the air in the channel will heat up more.

The manifolds are made of steel and can be bimental, depending on the customer’s needs, and with connection by welding, we install flanges similar to those that you had previously if this is a replacement heat exchanger, but the most convenient parts for connection are American ones.

We mainly use single-row, double-row, three-row, four-row, five-row, six-row, seven-row, eight-row, nine-row, ten-row, eleven-row, eleven-row, others are less common.

We also calculate and manufacture any non-standard heat exchangers for drying installations, for printing presses, greenhouses for industrial and household equipment.

Currently, recuperative systems are gaining popularity, one of the recuperation options is glycol, they use one heat exchanger for the exhaust and a second for the supply inside a closed circuit, glycol circulates in the circuit using a pump.

If you want to choose a heater, evaporator or condenser or any other heat exchanger simply with a fan of similar power and size as yours, then we will calculate it literally online. During our telephone conversation with you, we will advise you on all the features, compare the characteristics of different brands and the parameters of what you can purchase from us, we also often have different promotions, if you buy heat exchange equipment from us, you can get installation or delivery in present.

Our company can produce high-quality heaters to replace any broken equipment of brands such as 2VV (2ВВ); 3DVent (3D vent); ABF (ABF); AClima Rostec (Aklima Rostek); Aermec (Aermek, Aermek); Aerotek (Aerotek); Air SC (Air SC); AirCut (Air Cut); Amalva (Amalva, Amalva); Benson Heating (Benson Heating); Breezart (Brizart, Brezart); Clima Gold (Klima Gold); Clivet; Daikin (Clivent Daikin); DencoHappel (Denko Happel); Dimmax (Dimmax); Dospel Professional (Dospel Professional); Dunham-Bush (Dunhan Bush); DVS (ICE); Electrolux (Electrolux; Ensto (Ensto); Ett (Ett); Euroclima (Euroclima); EVR (EUR); Ferroli (Ferroli, Feroli); Flakt Woods (Flakt Woods); Frapol (Frapol); Frivent (Frivent); Fujitsu ( Fujitsu); General Climate (General Climate); General Vent (General Vent); GlobalVent (Global Vent); Hoval (Hoval); Jizer (Zhizer); Kampmann (Kampmann); Koja (Leather); Komfovent (Komfovent); Korf ( Korf); Lennox (Lenox); Lessar (Lessar); LMF (LMF); Lufberg (Lufberg); Luftmeer (Luftmeer); Maico (Maiko); McQuay (MC Kuay); MDV (MDV); Mekar (Mekar); Menerga (Menerga); Meptek (Meptek); Mitsubishi Electric (Mitsubishi Electric); Mitsubishi Heavy Industries (Mitsubishi Heavy); NED (Ned, Ned); Novair (Novair); Promservice (Promservice); Quattroclima (Kvatroklima); Remak (Remak) ; Rhoss (Ross); Rosenberg (Rosenberg); Rover (Rover); Ruck (Hand); Salda (Salda); Samp (Samp); Samsung (Samsung); Shuft (Shuft); Sigma (Sigma); Soler&Palau (Soler Palai ); Swegon (Svegon); Systemair (Systemair); Tecnoclima (Technoclima); Termovent (Termovent); Thermocold (Thermocold); Trane (Tran); Turkov (Turkov); Utek (Leak); VBW Engineering (VBV Engineering); VentMachine (Vent Machine); Ventrex (Vertex); Vents (Vents); Venttorg (Vent Torg); Vertex (Vertex); Vertro (Vertro); VKT (VKT); VsV (VSV); VTS (VTS); Weiss Klimatechnik (Weiss Klimatekhnik); Wheil (Veil); Zehnder (Zender); AMS MZMO; Arktos; Atri; Bastion; Blagovest; Veza; Venta; Air engineering; NEPT Plant; Klimatventmash; Climatic engineering; NEMZ "Tayra"; SVOC; Teploenergoprom; Titanium; Turbovent; Fanber; Cyclone Cyclone.

Channel heat exchangers that are in the catalog and with prices in the price list are 400 200 (40 20); 500 250 (50 25); 500 300 (50 30); 600 350 (60 35); 700 400 (70 40); 800 500 (80 50); 900 500 (90 50); 1000 500 (100 50), others with sides 1050 (105); 1100 (110); 1150 (115); 1200 (120); 1250 (125); 1300 (130); 1350 (135); 1400 (140); 1450 (145); 1500 (150); 1550 (155); 1600 (160); 1650 (165); 1700 (170); 1750 (175); 1800 (180); 1850 (185); 1900 (190); 1950 (195); 2000 (200); 2050 (205); 2100 (210); 2150 (215); 2200 (220); 2250 (225); 2300 (230); 2350 (235); 2400 (240); 2450 (245); 2500 (250); 2550 (255); 2600 (260); 2650 (265); 2700 (270); 2750 (275); 2800 (280); 2850 (285); 2900 (290); 2950 (295); 3000 (300) - made to order.

Advantages of a copper heat exchanger

In hydronic gas boilers

where

copper heat exchangers

, the coolant flows through the system at a speed of 2.1 m/s. The fast-moving fluid removes solid particles from the pipes, which prevents the formation of scale and blockages from mechanical deposits. This also ensures constant boiler efficiency and allows the use of coolant with any chemical characteristics.

A gas boiler

, in which

a copper heat exchanger

, has a number of other advantages:

- The copper heat exchanger has compact dimensions and low weight. Compared to steel or cast iron, such boilers are 2-3 times smaller and lighter;

- As a metal, copper is virtually resistant to corrosion;

- The copper heat exchanger has low inertia, due to which it quickly heats up and cools down just as quickly. Uniform heating leads to a complete absence of mechanical stress in the pipes (compression, tension, rupture);

- Easy to repair and replace components;

- Due to the small capacity, it does not require a large amount of coolant, which significantly saves the budget;

- Absolutely explosion-proof.

Copper heat exchanger: traditions and technologies

The use of copper with its extraordinary thermal conductivity allows us to abandon the heat exchanger design in the form of a finned tube in favor of a simpler and more reliable design. Its principle is borrowed from a traditional samovar, in which the smoke pipe passes through a water container.

boiler HYDROMOTRIX

“Since 1948, when inventor Maurice Friske released the first French gas boiler HYDROMOTRIX, the copper tubular heat exchanger has become the hallmark of our company’s products,” says Roman Gladkikh, technical director of FRISQUET, the leader in the French heating equipment market. – Its design is fundamentally different from the so common tubular heat exchangers with fins. The basis of the heat exchanger is a large-capacity copper boiler body, inside of which there are tubes for removing flue gases. They contain stainless steel turbulators (dividers), which reduce the speed of flue gases to increase heat transfer.”

The result is a massive cylindrical heat exchanger, the production of which requires 25 kg of pure copper. For comparison: steel analogues with fins of comparable power weigh up to 5 kg. Such a heat exchanger operates without temperature shocks in softer and more gentle conditions than a thin tube with fins.

double-circuit boiler FRISQUET

The described heat exchanger design has a number of important consequences. Due to the resistance to corrosion and ductility of copper, the service life of this unit exceeds 20 years. The diameter of each smoke tube is 30 mm, which makes them much less susceptible to soot accumulation. During one heating season, the narrowing of the clearance in heat exchangers with fins can reach 40% (versus 3% for tubular ones). Based on data accumulated in European countries over several decades of operation of copper tubular heat exchangers, it can be concluded that they have on average twice the service life compared to finned steel counterparts.

In addition, it is copper tubular heat exchangers that make it possible to achieve maximum efficiency - 95%, which leads to significant savings in energy resources and reduced boiler operating costs.

The unique design with a large-capacity boiler body significantly expands the functionality of heating equipment. Thus, in double-circuit FRISQUET boilers, secondary heat exchangers are made in the form of copper coils located inside the boiler body. As a result, all boilers from this manufacturer, as standard, allow you to connect an additional boiler or second and third heating circuits. For example, one heating circuit can provide heat to wall-mounted radiators (coolant temperature - up to + 85 oC), and the second - to underfloor heating systems (+20–45 oC).

Consumer choice

The presence of a copper tubular heat exchanger in the boiler is a good guide for those who are looking for a reliable and economical solution for their property. However, to make a responsible choice, you need to pay attention to other nuances.

Manufacturer certification according to ISO 9001 standard. For the buyer, this means that the boiler has passed multi-stage quality control during production.

“In our ISO 9001 certified plant, all stages, from the acceptance of components and raw materials from third-party suppliers to the final assembly of units, are subject to multi-stage control. Each operation performed is marked with the personal mark of the worker who performed it, says Roman Gladkikh (FRISQUET). – After assembly is completed, each assembled boiler goes to a test stand, where it is tested according to 15 parameters. In addition, in a certified laboratory according to the ISO45001 standard, not only the initial components are tested, but also life tests of the equipment are carried out continuously on special stands.”

The presence of safety systems in the boiler design, including coolant pressure, coolant temperature, gas and draft overturn sensors, as well as ionization flame control.

The presence of intelligent functions - the ability to select scenarios, program and remotely control the operation of the boiler, which significantly increases the efficiency of the heating system and increases its service life.

Availability of a network of authorized distributors in Russia who can install, carry out commissioning and then carry out maintenance and warranty repairs of the boiler.

As we can see, copper as a structural material for boiler heat exchangers has many undeniable advantages. Such equipment is of interest to private and corporate consumers, for whom reliability, low operating costs and long service life of the boiler are of paramount importance.

Added: 10/11/2018 17:43:27

Boiler equipment with copper heat exchangers from HYDRONMASH

Together with the American company they design, manufacture and install gas water heating equipment. All devices can be used for autonomous heating and supply of hot water to buildings, industrial and residential facilities, kindergartens, schools, hospitals and even swimming pools. Based on the installation principle, boilers can be divided into two groups:

- Gas boilers with a copper heat exchanger

become more compact and easily fit into doorways. That is why they are most often used in public utilities. - A floor-standing gas boiler with a copper heat exchanger is

a device that is widely used in heating industrial complexes, factories, greenhouses, administrative buildings, etc.

Due to its light weight and dimensions, it can be installed by two specialists within a day. The absence of the need to use heavy lifting equipment made it possible to install it on the roofs of houses

or high floors.

Models of heating units with copper heat exchangers

Highly efficient copper heat exchangers are used in gas heating units BAXI COPPER and Italian Hermann Habitat models.

Russian-made modular STG-Classic and STG-Premier are equipped with modern bimetallic copper-cast iron heat exchangers. The heat exchanger is a structure with copper finned tubes connected by two annular cast iron manifolds. This heat exchanger design ensures good transfer of heat from fuel combustion to water circulating through the pipes.

This equipment is an ideal option for boiler houses that are located on the roof of a building.

Through which the coolant circulates, more. As a result, they become less clogged with salt deposits. Consequently, cleaning the internal cavities of mono-devices will have to be done much less frequently than servicing a bithermic heat exchanger. First of all, this applies to the DHW circuit device; he gets involved when needed.

- High maintainability. Depressurization of separate heat exchangers is easier to eliminate, even at home (by soldering). Moreover, this can be done many times; you just need to be able to use a soldering iron and know how different brands of solder differ.

- Convenience. If the DHW heat exchanger requires repair or replacement, it is not necessary to stop the boiler. The device is dismantled after measures have been taken to prevent the three-way valve from operating. The importance of this during the heating season needs no explanation.

- Low cost. A monoheat exchanger is much cheaper than its bithermic counterpart.

- Tight boiler layout. Other elements of the circuit are added to the two heat exchangers; Maintenance of the heating installation becomes more complicated.

- The likelihood of breakdowns increases. The more structural elements there are, the higher the risk of failure of any of them. The “weak link” in wall-mounted boilers is the already mentioned tap (three-way).

- The cost of equipment increases precisely because of the large number of components.