Advantages of plywood floors

Plywood is usually used to make a high-quality intermediate base for a heated floor system. In the event that the final finishing is a parquet board or piece parquet, fixed to the rough surface with screws or glue, this addition in the form of plywood sheets is simply necessary.

Professionals also advise creating such a “pie” even if you plan to use linoleum or laminate as the surface layer. In this option, the plywood sheets will play a role in sound insulation and moisture insulation.

As for the general advantages of using plywood in the construction of rough surfaces and heated floors:

- This material has excellent strength characteristics.

- Among numerous varieties and types, completely environmentally friendly options are available for indoor use.

- It is quite affordable even for the middle class of the population, both with regard to purchase and installation work.

- Floors covered with plywood have excellent sound and thermal insulation characteristics.

- If the material is to be placed in rooms with high humidity, you can always purchase moisture-resistant options on the market.

- Material of any type and grade is easy to maintain and easy to process.

Often, on the eve of repair work, inexperienced citizens receive questions about what types and grades of materials are more relevant to use, and is it possible to use the first available plywood for the rough surface?

In fact, there are many varieties, types and varieties and all of them are, in principle, suitable for installation, but you should make a start in each individual case.

There are 5 types of material in total. Also, one type may be moisture resistant while another is not. For grade 1, only oak, birch and beech veneers are used, and mostly without knots. Such sheets can be laid, but this is a costly task.

To install a heated floor under plywood, it is more important to install a covering made of second-rate material. In this case, the quality will not suffer and will not hurt your pocket.

Video description

This video clearly shows the process of installing joists instead of the old floor that was removed:

The main thing to remember is that the seams between the sheets should run exactly in the middle above the joists so that their edges do not sag. We also must not forget that the thickness of the plywood for the floor along the joists depends on the frequency of laying the joists. Typically, plywood sheets with a thickness of 16-20 mm are used.

The only drawback of the method is that the floor on the joists “eats” about 10 centimeters from the height of the room, depending on the thickness of the joists and plywood. However, if it is installed in a large country house, such a loss will not be decisive. Therefore, to the question of what kind of plywood is best to lay on the floor in a house made of timber, the answer is unequivocal - as thick as possible.

Tips for carrying out work

Depending on the choice of material for the rough coating, the installation method also changes. For example, with a plywood base, the use of conventional dowels is not recommended. To ensure that the wood veneer can expand unhindered, mounting brackets should be used when installing plywood.

This is especially true when there is potential moisture. This method of fastening allows you to install a heated floor system under the tiles with complete confidence that the subfloor will not swell.

In total, it is possible to use several acceptable options for installing a rough coating:

- If plywood sheets are mounted on a concrete screed, you should take material no thinner than 12 millimeters.

- In the case where there is wiring, pipes or other communications running along the floor, it is more important to install a covering with a lag device. To do this, you can use 2 options for installing “subfloors”, either a double coating of thin sheets, or a single layer of 2 centimeters in thickness.

- If the base is boards or any other wood floor, the thickness of the plywood covering can be any. The main thing is that it does not creak or bend.

Choosing a installation method

There are 2 main ways to properly lay plywood on a wooden floor:

- Laying on an old wooden base

The method is used if the horizontal difference of the old base is less than 1 cm, and also if it has sufficient strength. This method is simple, but can be used only in limited cases, since the difference in the old floor is often more than 1 cm

Laying over old coating Source chudopol.ru

See also: Catalog of companies that specialize in home renovation

- Laying on joists

If the difference in height of the old base is significant, plywood is laid on logs made of timber. This method is longer and more labor-intensive, but it allows you to deal with significant horizontal differences and damage to the base. Can also be used if the old floor has failed and cannot serve as a solid base for a plywood underlay

Laying on pre-prepared joists Source slavasozidatelyam.ru

Next, we’ll take a closer look at which method to choose in a particular case and how to properly lay plywood on the floor.

Video installation of heated floors

Warm floors have become commonplace these days and are not a new invention. Heated floors are often used when covering the floor with ceramic tiles, but is it possible to install a heated floor on plywood?

When installing heated floors in the traditional way, large gaps may appear. Plywood reacts to temperature changes, which can lead to its separation from the concrete base. To prevent this from happening, they use twice as many dowels to fasten plywood, but there is another way.

The use of heated floors has long been used by the Scandinavians, who came up with a method of laying heated floors on plywood. This is the so-called “floating floor”. Laying by this method is done using metal staples to assemble the boards together. And the warm floor is laid on plywood without fixing it to the base.

Such a floor is in no way connected to the base and will not be able to tear it off. In addition, staples regulate the natural contraction and expansion of wood during temperature and humidity changes. This coating is also environmentally friendly, which is especially important in a residential area.

Warm floors on plywood: how to make and what to pay attention to

The installation of heated floors in residential premises has long ceased to be a novelty and is regularly used during renovation work. This popularity is due to the ability to independently install a heated floor on plywood, its versatility (can be laid on concrete, wood or even plywood) and comfort, which improves living conditions.

Features of laying heated floors

Unlike standard installation of heated floors, installation of heated floors on plywood is done without fixing it to the base of the floor, that is, to the plywood. Sheets of plywood are connected using metal staples, rather than attached with dowels. This approach prevents the appearance of cracks and allows you to regulate the expansion of wood with changes in humidity and temperature conditions.

Installation of plywood under heated floors

There are several ways to install plywood:

- on a concrete screed - plywood with a thickness of 12 mm is used;

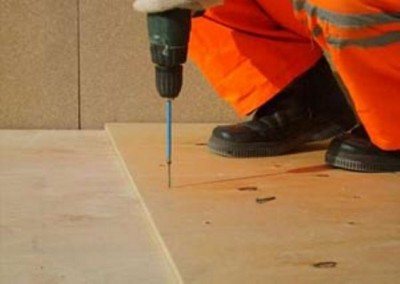

- similar to a wooden floor - plywood of any thickness is similar, attached with self-tapping screws;

- for wooden logs - use a sheet of plywood 20 mm thick, or two layers of plywood, 9 mm thick.

How to lay a heated floor under linoleum or carpet?

When installing an electric heated floor under plywood, and then linoleum or carpet, it is also necessary to take into account all the subtleties. It is recommended to use all components from the same manufacturer, this will help prevent problems in the future when using heated floors.

Thermal film (warm film floor)

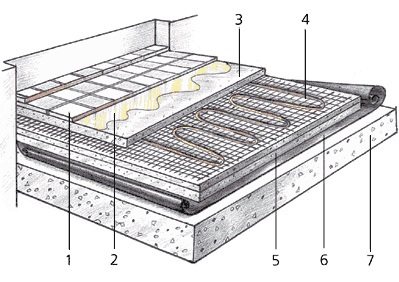

Under the floor covering, a film heated floor on plywood is used. Its assembly somewhat resembles a “sandwich”:

Laying scheme for heated floors

- Placed on the main floor

- Then a layer of thermal film is laid.

- Polyethylene film is placed on the thermal film.

- A rigid floor is constructed on top using plywood or chipboard, and at the same time ensures leveling of the floor.

Important!

It is not recommended to use fiberboard or OSB sheets, since they do not provide a flat floor surface, and fiberboard tends to sag under the pressure of gravity.

- Plywood sheets are attached to the main floor using screws or dowels. It is necessary to “flood” their caps so that the floor surface is free of unevenness. All joints between the sheets will be puttied and after 48 hours you can lay linoleum or carpet.

Laying heated floors under tiles

Often in the kitchen, due to the use of tiles, the floors are cold, but laying tiles on plywood for a warm floor helps to cope with this disadvantage. It is necessary to lay heated floors under the tiles in compliance with all instructions, this will help to avoid adverse consequences in the future. Before laying the tiles, the plywood must be thoroughly processed - cleaned of minor defects, dust and sanded. Warm floors allow you not to worry about the health of your household and create a cozy atmosphere in the house.

Scheme for laying heated floors under tiles

Methods for installing plywood floors

Plywood sheets can be mounted on a wooden floor, a cement base or on wooden joists. The most reliable way to lay a plywood floor is to install it on a cement coating. If the quality of the concrete base is high, it is recommended to use plywood with a thickness of 12 mm.

And fastening to classic logs is considered the most difficult and expensive method. Installation is carried out on logs in one layer of at least 20 mm or in two layers, each 9 mm thick. The space between the joists is filled with soundproofing materials.

Fastening to a wooden floor is done using self-tapping screws, which create increased stability and reliability. Installing a plywood floor using this method is the simplest and most economical.

But, in any case, in conditions of high humidity and temperature changes, for example, in a bathroom, it is not recommended to install plywood floors. Plywood floors are considered the most convenient way to make the base of the room level, without instability or creaks. After all, walking on a reinforced and level floor is so important for a comfortable life, due to the fact that you feel a solid base. And floors are the basis of everything. Therefore, the installation of plywood floors is carried out with very high quality, which will subsequently create comfort in the house.

Floor insulation technology

When insulating a floor with plywood, you must follow some rules.

Plywood sheets are attached to a wooden or concrete base.

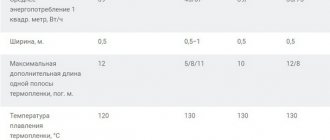

Characteristics of plywood.

In this case, concrete or wood must be dried and cleaned. All wooden surfaces on which the coating will be laid must be treated with an antiseptic to avoid damage and rotting of the wood.

Thermal insulation material is placed under the subfloor. This can be mineral wool, glass wool, expanded clay, etc. For dry concrete screed, use thermal insulation material - foil-coated polyethylene foam. The material is convenient because the foil is placed upward and the heat is pushed back into the house. If you make a reserve of 7-10 cm near the walls, and then throw the baseboard onto the floor, all the heat will remain in the room. There are a lot of insulation materials on the construction market; decide on the main indicators: thermal conductivity, density, flammability, water absorption and ease of installation.

Thermal insulation is laid under the plywood and secured with self-tapping screws every 20 cm from each other. Plywood sheets should be separated by 3 mm gaps, which are then primed.

The finishing coating can be laminate, linoleum, parquet, carpet, ceramic tiles and even cork.

You may be interested in: The process of insulating a floor with foam plastic

Briefly about the main thing

Laying plywood over an old wood floor is a great way to quickly and inexpensively prepare the flooring for laying linoleum, laminate or parquet. The plywood floor creates a flat surface for laying the final floor covering. There are 2 main ways of how and what kind of plywood to lay on the floor: laying directly on the old covering and laying on joists. The choice of method primarily depends on the condition of the old floor covering. Regardless of the chosen method, when laying it is necessary to comply with technological requirements: leave damping gaps, arrange the sheets in a checkerboard pattern, use high-quality materials. If all requirements are met, flooring laid on a plywood subfloor will last for many years.

Ratings 0

An alternative method is laying with self-tapping screws and polyurethane foam.

There is an alternative version of how to lay plywood on a wooden floor. This method is applicable if the old coating has sufficient strength, but the horizontal difference is too large.

The essence of the method is as follows: self-tapping screws are screwed into the old coating so that the ends of their heads are located exactly on the same plane. The distance between adjacent screws should not exceed 10-15 cm. The free space is filled with polyurethane foam. The result is a cushion on which plywood sheets are attached.