If you are wondering what is the best way to insulate the outside walls of a house with foam plastic or mineral wool, you have come to the right place, we will help you find the right answer. But know that polystyrene foam has some pros and cons, mineral wool has others, in the end, you decide what to use.

We will just introduce you to their cost and efficiency ratios so that you can make your home ideal for keeping cool in summer and reducing heat loss in winter.

There is no ideal insulation

You are not the first person interested in such information. Unfortunately, experts admit that it is only planned to create an ideal insulation in the future; now work is underway for this at world-class production facilities. And in order to insulate your home, you need to take into account the design features and the advantages and disadvantages of materials that may affect the installation process and further operation.

Foam plastic, as well as penoplex, are such familiar, inexpensive materials that many people choose for insulation. Or mineral wool - more expensive, but also more durable as insulation. It is necessary to consider each individual case in detail, and then decide whether polystyrene foam or mineral wool is better.

There were situations when people, having chosen one of the insulation materials, were later disappointed. Often the reason is hidden not in the material, but in the installation method, the conscientiousness of the work performer, so you should also pay attention to this. Regarding the parameters of materials, we will consider what you need to pay attention to when choosing insulation that is used to insulate the external facade.

Lifetime

When deciding whether to insulate the outside of a house with foam plastic or mineral wool, it is worth considering the issue also from the standpoint of the durability of the material.

In this parameter, mineral wool certainly wins. With proper installation and appropriate quality, it can last up to 40 years.

The foam is slightly inferior here. Especially in cases where there is no proper protection of the insulation from external influences. In such conditions, foam insulation can collapse in 7-8 years. On the contrary, with proper installation, such a contour will last for decades.

Features of selecting the characteristics of thermal insulation material

Deciding whether it is better to insulate the outside walls of a house with foam plastic or mineral wool involves discussing the following characteristics of the materials:

- Strength.

- Low moisture absorption coefficient.

- Low thermal conductivity coefficient.

- Length of service life.

- Weight/efficiency ratio.

- Weather resistance.

- Safety.

- Easy to install.

- Resistance to biological influences.

- Possibility of reinstallation at any time of the year if necessary.

We will consider a list of these properties that polystyrene foam and mineral wool have below; this information will help in deciding whether it is better to insulate a house with polystyrene foam or mineral wool, relative to your current needs.

If we take as a basis the ratio of the thickness of the material and the thermal insulation effect that is achieved with its help, then penoplex is superior to other insulation materials. However, we must remember that, for example, for old clay houses, insulation with brickwork is more suitable - this will give additional stability to the building.

Advantages

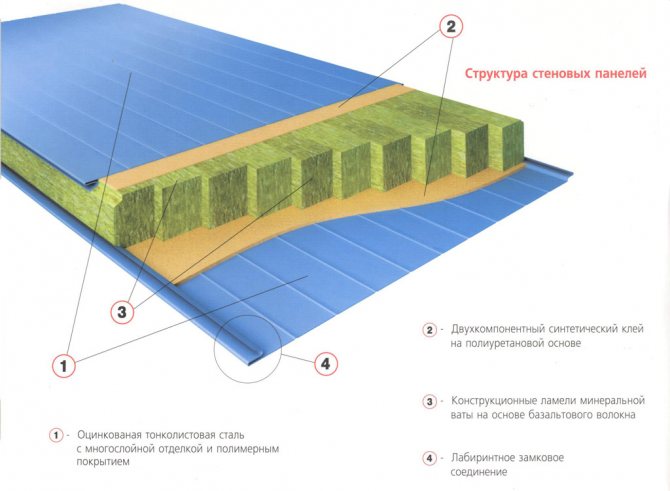

Composite LSU sandwich structures have an amazing list of advantages:

- partially vapor permeable. Protection against moisture penetration into the room and steam removal to the outside are guaranteed;

- improved thermal insulation performance, SML constructs surpass the standard technology of composites with OSB-3 in terms of characteristics;

- absolutely non-flammable. SIP with mineral wool lined with magnesite slabs is the only composite material in this class that has an NG class certificate;

- absolutely impervious to moisture. During testing of the technology, samples were soaked for up to 100 days, and no changes in characteristics were observed;

- complete environmental safety, low weight, sound insulation level is higher than that of SIP products with polystyrene foam as insulation;

- the coverage indicators for the area of gluing layers to each other inside the structure are almost 100%, while the connection with an OSB board shows only 25-35%.

Such technical characteristics make SIP structures with mineral wool the best material from which to build modern houses.

Details about mineral wool

Stone wool began to spread in the insulation of houses relatively recently, over the past few years. Features of its production provide the following advantages:

- Non-flammability (withstands up to 950 degrees C).

- Low thermal conductivity coefficient.

- Soundproofing.

- Excellent thermal insulation and vapor permeability.

- Resistance to biological effects (rodents and fungus do not spread).

Like any insulation currently on the market, mineral wool also has disadvantages:

- High price.

- It is relatively heavy.

- Upon contact, it can cause allergies, as it is dust of organic origin.

- Harmful substances in the composition.

- Absorbs moisture and condensation.

What is the advantage of using mineral wool

SIP panels, produced using standard technology using polystyrene foam and oriented strand boards, are the most common product on the market. Such products are quite cheap, produced by many companies and offer very good user characteristics.

However, this technology occupies the middle of the overall coverage of the needs and operating conditions of products. For example, noticeable disadvantages of sandwich panels made of OSB and expanded polystyrene are:

- non-flammability class - III, that is, the structure can withstand exposure to open fire for an hour;

- The SIP panel is absolutely vapor-tight;

- at marginal humidity levels, the OSB board is destroyed.

The last point is the most significant for users. It is impossible to build a bathhouse from sandwich composites without additional high-quality protection; there are also restrictions on use when there is a combination of high temperature and humidity.

[ads-pc-1]

Details about foam

To understand the properties of the material, let's analyze its structure. Expanded polystyrene in the form of plates consists of a large number of small balls filled with air.

It follows from this that there is no circulation or movement of air in it, due to which it perfectly performs the function of a heat insulator. Its advantages include the following parameters:

- noise suppression;

- service life even in conditions of high humidity and low temperature;

- lightness of slabs;

- ease of installation;

- resistance to biological influences.

The disadvantages of polystyrene foam are partially neutralized by the constant improvement of its varieties, for example, they invented penoplex, extruded polystyrene foam, the properties of which are very different from conventional polystyrene foam. The main disadvantage continues to be its decomposition at temperatures above 60 degrees. C, and why use insulation, which releases harmful substances when heated. Mice also love to chew on it; they don’t feed on it, but they chew on it with great joy.

Peculiarities

Despite the somewhat higher cost of constructs, SIP technology with mineral wool is conquering the market. There is a simple explanation for this - users really like the panels because they make construction even faster and even offer the opportunity to save on the subsequent finishing of the finished building.

If you were to list the notable benefits for users in a short list, it would look like this:

- SIP panels with mineral wool, lined with magnesite, are extremely light, designed for use in aggressive conditions, ideal for the construction of baths and saunas. The houses look simply beautiful, very neat and stylish, they are even called “trimmed with white stone.” This is a very attractive feature for companies involved in the construction and subsequent sale of housing;

- SML composites using magnesite sheets for cladding are ideal for building a house; the walls do not require secondary plasterboard covering. You can apply paint or finishing materials directly to the surface of the panel;

- the technology immediately takes into account the typical problems that users of standard SIP panels with OSB have encountered, so cable channels are provided in the designs during manufacturing.

Important to know: SIP panels made of polyurethane

But the main reason why users choose SIP panels with mineral wool is partial vapor permeability, when moisture from inside the room escapes to the outside.

Polyurethane foam

The synthetic polymer polyurethane foam (PUF) is formed as a result of a chemical reaction of two liquid components. The material has a cellular structure, which ensures its low thermal conductivity and lightness.

Polyurethane foam is resistant to microorganisms, aggressive environments and moisture. Durability and ease of use allow the material to be used both during construction and during repairs.

Polyurethane foam is applied by spraying, has excellent adhesion to various materials and does not require special surface preparation.

Penoplex - polystyrene foam insulation with good prospects for the future

Therefore, it has a dense, closed-cell, moisture- and frost-resistant structure, resistance to compression loads, and a resource more than three times longer than that of foam plastic. As for the disadvantages, a higher cost was added to the previous two. True, it was possible to significantly increase the heat resistance of Penoplex. We can say that extruded polystyrene foam for foundation insulation is an unaffordable luxury. It is more rational to use materials with approximately the same assigned resource.

On what to glue Penoplex insulation, read the article at the link.

The service life of foundation waterproofing is on average 8-10 years. Therefore, it is not economically feasible to equip a short-lived coating with cladding with a service life of half a century. The material will show its best properties in difficult operating conditions, for example, as part of a flat roof.

Technical features

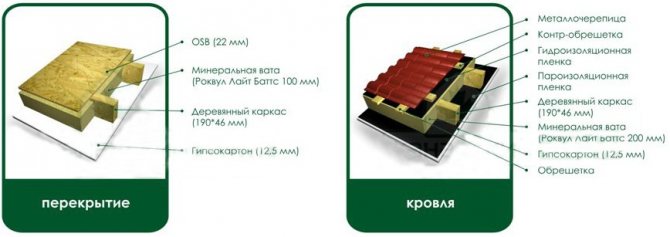

Mineral wool is a porous material, the raw materials for which are mineral components: glass, natural stone, slag.

The production technology is as follows:

- Mineral raw materials are melted at high temperatures in special furnaces.

- The melt is fed under pressure into high-speed centrifuges, while being blown with compressed air.

- The result is a structure with long fibers, the space between which is filled with air.

Mineral wool can be supplied to the market in the form of rolled material with low density, or in the form of compacted mineral slabs with densities up to 200 kg/cub.m.

Polystyrene foam is produced by extrusion - hot pressing of polystyrene, pre-foamed in a special apparatus. Porous round granules filled with air come out of this apparatus. They are pressed by stamping into sheets and plates.

Foam sheets, like mini-slabs, can be of different densities. Highly extruded polystyrene foam, which appeared on the finishing materials market relatively recently, has the highest density.

In some cases, polystyrene granules can be used without pressing as a filler, most often in the production of various building structures to give them thermal insulation properties.