Peculiarities

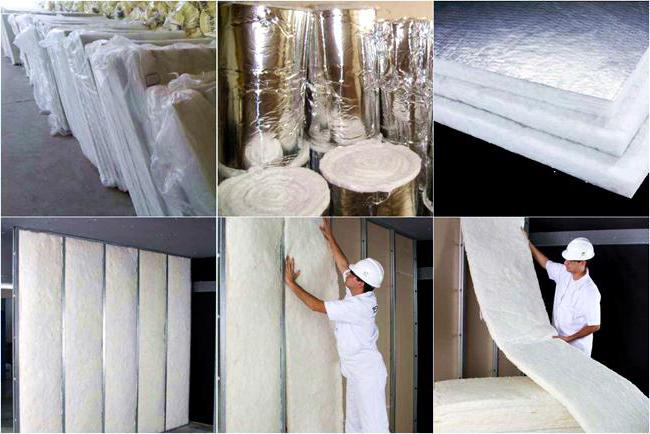

If you were looking for insulation a couple of decades ago, glass wool would have been the most logical and affordable material. It is based on glass waste, which is transformed into fibers during technological processing. The latter, in turn, are formed into mats and slabs.

Currently, glass wool is gradually being replaced by more modern materials, but still remains quite popular due to its good balance of properties and price.

Glass wool ISOVER

Izover glass wool is produced in slabs. In packaging, the material is compressed to 2 times its original volume, which can significantly reduce transportation and warehousing costs. The unpacked material quickly returns to its original size.

The shape of the slab allows the use of glass wool for insulating the walls of a house from the inside, thermal insulation of a pitched roof, insulation of the attic floor and floors between floors. In addition, the material is excellent for soundproofing interior partitions.

Izover glass wool slabs can be installed effortlessly into both wooden and metal sheathing, without the use of special fasteners. The elasticity of the material ensures a tight fit of the slab to the frame, thereby achieving maximum heat-insulating effect.

Production

The raw material for glass wool is broken glass, that is, waste. The final chemical composition of the insulation differs little from ordinary glass, which makes it environmentally friendly.

The production process looks something like this:

- The collected broken glass is crushed and mixed with modifying fillers;

- All this is poured into a bunker, where it melts at a temperature of about 1,400 degrees;

- The softened mass is blown with steam, which ensures the formation of individual fibers (thickness about 10 microns, length 15-50);

- The fibers are sent to special rolls, where they are aligned;

- The fibers form a “web”;

- Next, the material cools or polymerizes;

- The cooled glass wool is used for further molding, cutting and pressing.

The material can be produced in the form of mats, slabs or rolls.

Miscellaneous production

Mineral wool or glass wool are materials of mineral origin identical in structure and characteristics.

Broken glass and naturally occurring quartz are the main components of glass wool. Fiberglass is formed by melting both components in furnaces.

Stone wool or mineral wool is made from various rocks, but the highest quality material is considered to be one based on basalt fibers. After heat treatment, cotton wool with a specific structure is obtained that can withstand high temperatures well.

Differences from mineral wool

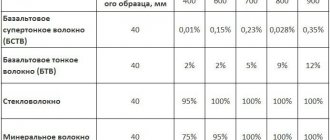

Due to their somewhat similar appearance and comparable properties, many are interested in the question: glass wool and mineral wool - what is the difference?

- In raw materials. Mineral wool consists of fibers that are made from molten rocks or silicates. The raw material for glass wool is broken glass.

- In fiber size. On average, the thickness of the fibers of mineral insulation is less, as is the length. Hence, there are some differences in insulating properties in favor of glass wool. On the other hand, material based on glass fibers is more susceptible to shrinkage and deformation.

- In cost. Mineral material is more expensive.

- In the specifics of the work. Glass wool is more difficult to work with, also because its fibers are somewhat dangerous.

Let's talk about the advantages of glass wool

Glass wool has many advantages

The situation is approximately similar with glass wool insulation.

Many developers do not see a significant difference between these heat insulators and Rockwool mineral wool, so they prefer cheaper insulation - glass wool.

Without detracting from the undeniable advantages of this heat insulator, it should be noted that such a choice is not always a good one.

- Indeed, glass fiber obtained from quartz sand or broken glass is characterized by relatively low thermal conductivity and elasticity, which makes it possible to use the source material for the production of flexible coatings, mats, rigid and semi-rigid panels.

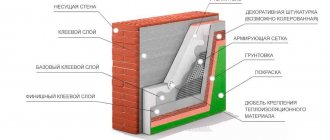

- The suitability of fiberglass insulation has been determined for the insulation of suspended ventilated facades, external thermal insulation of walls using the “wet plaster” technology: several quite popular insulation technologies are based on glass wool.

- With the introduction of frame-panel construction technologies, glass wool began to be used to fill frame structures, using protective film coatings against weathering and waterlogging. As an insulation material, glass wool, whose price is more than affordable, fully justifies itself, but its widespread use is limited by a number of significant disadvantages.

You can order excellent Rockwool mineral thermal insulation, which has no disadvantages, right now!

Floor insulation

Floor insulation has always been a separate issue. What is better – glass wool or expanded clay? Each of these materials has its own pros and cons, so the final choice largely depends on the specific situation. In particular, it depends on the expected maximum thickness of the insulation and the available budget.

However, based on a combination of factors, it can be argued that expanded clay is better. It holds deformation loads well and is also not at all interesting to mice. Glass wool guarantees you problems on both the first and second points.

How to clean clothes after laying glass wool

If glass wool gets on your skin, under no circumstances should you rub the area. Crystals must be carefully shaken off or blown away. After finishing the work, the hair is thoroughly shaken off and the coolest possible shower is taken with strong pressure without washcloths or soaps. If you take a hot shower, fiberglass particles penetrate into the pores enlarged by water. After the shower, dry without wiping with a towel, and wash again with soap and a washcloth.

After completing the installation of glass wool, work clothes are cleaned with a vacuum cleaner and washed (rinsed) 3-4 times in a soapy solution and under running water. It is recommended to use rubber gloves for cleaning and washing. Dried clothes are cleaned with a vacuum cleaner again. If clothes are not clean, dry cleaning sometimes helps. More often, unnecessary old clothes are used to work with glass wool and are thrown away when the work is completed.

Material advantages

Let's take a closer look at the positive properties of glass wool:

- Good thermal insulation. 5 cm of glass wool approximately corresponds to 1 meter of brick.

- Water resistance. This material practically does not absorb water, which has made it popular for insulating pipelines.

- No harmful emissions.

- Resistance to negative factors of biological origin, such as mold, mildew and the like. However, it is worth noting that mice can build their nests in glass wool, although it is of no food interest to them.

- Low cost.

- Long service life of glass wool. If there are no deforming influences, then the material can easily perform its functions for decades. Despite the fact that glass wool may compact over time, high-quality mats do not have this problem.

- Fire safety.

Rules for working with glass wool

- Before working with glass wool, it is necessary to straighten it and clean it of all crumbling parts. The insulated structure itself is treated with antiseptic compounds;

- In case of insulation of the ceiling, you can use lathing or do without it. In the latter case, a lubricating polymer waterproofing is applied to the ceiling. In addition to its main properties, this component improves adhesion with the adhesive composition, which we will apply to the ceiling and cotton wool after drying. As soon as the glue is applied to the surface, it is necessary to press the insulation against the ceiling and hold for several minutes;

- If the material is highly flowable, you cannot work with it without a respirator. Otherwise, glass fibers entering the lungs may cause health problems. These problems can be very different, ranging from shortness of breath and allergies to respiratory diseases, even cancer. If you don’t have a respirator at hand, create a high-quality gauze bandage;

- When working, it is necessary to avoid rubbing cotton fiber particles into the skin. If these fragments come into contact with the skin, rinse with water. After work, it is recommended to take a shower;

- Washing clothes after use is not recommended as this will not remove dust. The ideal solution is shaking.

Glass wool is a fibrous mineral thermal insulation material, a type of mineral wool. To obtain glass fiber, the same raw materials are used as for the production of ordinary glass or waste from the glass industry.

Flaws

The popularity of glass wool is falling for a reason. The reason for this is the following:

- Increased fragility. The insulation fibers are still glass. Therefore, working with glass wool requires caution.

- Need for additional insulation. The material itself needs to be separated from other structural elements. If glass wool has direct access to residential premises, the result will be sad.

- Lack of UV resistance. When exposed to sunlight, the material is destroyed.

- Tendency to deformation. This circumstance greatly reduces the service life of the insulation, limiting it to ten years.

- Difficult to dismantle. Disposal of glass wool requires a special approach, since the fragility of the particles causes a high risk of their spread.

- Health hazard under certain circumstances. More about this.

Effect on humans [edit | edit code]

The disadvantage of glass wool is the increased fragility of the fibers, sharp and thin fragments of which easily penetrate clothing (from which they are difficult to remove) and further into the skin, causing itching. Inhaling air containing debris from glass wool fibers can cause long-term irritation to the lungs because they exit the lungs very slowly. It is also dangerous for glass wool fibers to get into your eyes.

To prevent these phenomena, work with glass wool should be carried out in thick protective clothing that does not leave exposed areas of the body, canvas gloves, safety glasses and a respirator.

First aid for vitreous lesions [edit | edit code]

- If glass wool gets on your skin, you should never itch it, as this will only drive the debris into the skin.

- Try to gently shake the glass wool out of your hair by placing your head in a bathtub (without water), closing your eyes and shaking your head.

- Take a cold shower with strong water pressure without detergents. Do not rub the skin with washcloths, sponges, or use hot water, as it dilates the pores of the skin.

- After taking a shower, do not dry yourself with a towel. Wait until your body is dry and take a cold shower again, this time with soap.

- If glass wool gets into your eyes, rinse them with a strong stream of cold water. If irritation does not go away, immediately contact an ophthalmologist, preferably an eye surgery clinic, or call an ambulance.

- If you inhale broken glass wool fibers, if you have persistent coughing, difficulty breathing, etc., consult a doctor immediately.

- It is better to throw away clothes contaminated with glass wool. Even careful repeated washing does not completely guarantee the removal of fibers.