- Posted by Svetlana

- Date: September 19, 2014

As you know, in winter it is through the windows that the most heat escapes from the room, which means they need to be insulated as quickly as possible. In addition, it is quite easy to do it yourself, and such insulation is inexpensive.

Our ancestors also knew how to properly seal the cracks in the windows so that the house would be warm in winter, and this would require little firewood. Nowadays, plastic double-glazed windows are used much more often, and manufacturers claim that they do not release heat at all, however, buyers have a completely different opinion on this matter: “It still blows from plastic windows.”

It's already getting colder, and it's time to take care of staying warm. Therefore, today we will look at insulation options for all types of windows so that comfort does not leave your home in winter.

- 2 What if the windows are old? Insulation of old wooden windows

- 3 Insulation of plastic windows

- 4 Insulation of window slopes: choice of materials

- 5 The process of slope insulation

- 6 Window insulation using Swedish technology

How to tighten the fittings of plastic windows so that it does not blow

The tightness of the sash rebate to the frame is determined by the eccentrics, which engage with the strikers. Installers leave them in the neutral position by default. But with the onset of cold weather or strong gusty winds, such pressure is not always enough. You have to install it yourself.

There are pins on the side that need to be adjusted to achieve the desired result. They have three provisions:

- Neutral. Installed at the manufacturing plant. The mark (dot or tick) is located along the vertical axis.

- Winter. The mark on the trunnion is turned towards the rubber. This position provides maximum pressure.

- Summer. The point or mark faces the street. This way the pressure is loosened for the summer season, which increases the service life of the sealing rubber bands.

The trunnions are turned using a No. 4 hex key, an asterisk or a screwdriver. There are several of them around the entire perimeter. The exact quantity depends on the size of the sash.

When a house shrinks or structural elements sag over time, you may encounter misalignment of parts relative to each other. Eliminate it by adjusting the hinges. We'll show you more details on how to do this correctly in the video.

How to eliminate blowing from under the glazing bead

The problem is rare and is a manufacturing defect. Therefore, if the warranty has not yet passed, contact the installers. There may be several defects.

Usually the glazing bead simply does not match the dimensions. If its length is less than necessary, cracks will form at the corners at the joint. When the glazing bead turns out to be longer, after installation it does not fit well and bulges. A defect may appear during operation. A pressure bar installed with excessive tension snaps off due to thermal expansion.

In both cases, the bead must be replaced. You buy a new clamp strip from a window company and cut it to size. It is easy to cut down at an angle using a hacksaw and a miter box. It is useless to shorten an old long rail. Most often it is already deformed. And if not, carefully trimming it a couple of millimeters turns out to be very difficult.

What to do if a plastic window is blowing from below from under the sash

If the adjustments described above did not resolve the problem, it means that the rubber seal is worn out. In this case, you can see the following defects: rubbing, jamming, loss of elasticity. We select new tires according to the sample or type of profile system. We change in the following sequence:

- Use the handle to open the door.

- In the corner we pry up the seal and tighten it around the perimeter until we reach the top loop.

- We move the sash to the “ventilation” position.

- We take out the remaining part of the sealing rubber.

- Carefully clean and wash the installation groove.

- We place the beginning of the new rubber at the top in the middle. We completely go around the perimeter with a single contour. It is important to avoid excessive tension at the corners.

- At the junction we cut the rubber without excessive tension or overlap.

- Pull out both ends of the elastic. Apply a drop of Moment glue to their lower parts and install them back.

Be sure to change the second sealing contour, which is located on the frame. The principle of operation remains the same.

How to get rid of a draft from under the windowsill

Cold air can come directly from under the window sill board or from the junction of the lower frame profile with the window sill. Both defects indicate irregularities in the construction of the foam seam. In new buildings, installers save foam by filling large gaps with construction waste.

The most correct solution is to dismantle the window sill and reinstall it with careful foaming of the seam. In this case, it is necessary to break the lower part of the slopes and restore them after repair. Therefore, this method is rarely used. To avoid the least damage, we carry out the work in the following order:

- We break the plaster layer under the window sill to a height of 5-10 cm.

- We clean the mounting foam and construction debris from the seam. We leave only the support bars on which the window sill board rests.

- Carefully foam the seam to its full depth.

- After hardening, we restore the plaster and wallpaper.

Foam expands as it hardens. To prevent the window sill from lifting up, we place something heavy on it.

This method is only suitable for shallow window sill depths. If it is more than 20-25 cm, it is very difficult to reach the frame installation plane. In some cases, the defect can be eliminated from the street side.

Methods for insulating windows

Depending on the type of windows and financial capabilities, a variety of materials can be used to insulate them. The most economical option is insulation using paper strips. For many years, windows have been insulated in winter using pieces of fabric or cotton wool. You can also use tape (both regular stationery and special) or sealant for this purpose.

If you do the window insulation work correctly, you can increase the room temperature by 5-6 degrees.

One of the old and cheap ways to insulate a window is to use plastic film. Of course, this means sacrificing the aesthetic appearance of the entire structure. You can purchase either regular film or a special, more expensive one. In most cases, it is mounted on the outside of the window, occasionally on the inside. Using film, you should cover the entire surface of the window, trying to fix it as close as possible to the edge of the frame. During work, you should constantly stretch the polyethylene evenly to avoid the formation of leaks. The weakest points of the structure will be in places with poor fixation.

What to do when a plastic window blows from the hinge side

If a tight fit of the sealing rubbers is ensured, the only possible defect is damage to the slopes. There are practically no blows in plastered junctions. Therefore, we will tell you how to repair prefabricated slopes made of sandwich panels. First we dismantle them:

- We remove the outer framing corners or profiles.

- Using a long knife or wood hacksaw, cut the foam seam around the perimeter.

- We remove the panels.

- We clean the remaining foam from the wall and plastic.

After dismantling, we see the quality of the installation of the window unit itself. We evaluate it visually and establish the points through which cold air enters the apartment. We remove the old foam from them and foam the joints again.

After sealing the problem areas, we restore the slopes.

The problem may lie not only in the interior, but also in the exterior decoration. In urban development, the outer slope is formed by a quarter in reinforced concrete panels or brickwork. But between the wall and the PVC window profile there is always a foam expansion joint.

The most common mistake is improper sealing. The installers do not cover the foam, leaving it in direct sunlight. Over time, it collapses and crumbles. Fixing a damaged junction unit is simple:

- Using a knife or spatula, remove the insulation from the gap.

- Re-foam the seam.

- After the composition has completely dried, cut off its protruding parts.

- We close the gap with a stripping or plaster it.

These were the main faults that you can fix yourself. You have learned how to adjust plastic windows so that it does not blow and you can now repair them if minor defects appear. Let's give a few more recommendations that will help keep your home warm.

Proper insulation of a plastic window

Windows made of metal-plastic are easy to use and elegant. One of the advantages of such windows is the thermal insulation system - no problems are expected with retaining heat in cold weather. If the windows are installed poorly, then the plastic windows will let in the cold. Here you can use two solutions to problems: you can contact the company and place an order for additional insulation (and this is not cheap!) or carry out the insulation personally.

How to make an additional camera on a double-glazed window

Modern two-chamber systems reliably protect the house from any frost. The energy efficiency of older frames lags far behind. Eliminating this shortcoming requires a complete replacement of the glazing, which is very expensive. A budget solution to the problem is a special thermal film. It is installed on the PVC profile in the following sequence:

- Wash the glass and frame thoroughly.

- We glue double-sided tape along the perimeter around the glazing beads in a single outline.

- Remove the top protective strip from the tape and glue the film.

- Cut off the excess with a utility knife.

- We heat the material until the folds are completely smoothed out.

Thermal film creates an additional sealed chamber that accumulates heat and reduces thermal conductivity. It retains light transmission and remains virtually invisible.

What will you need?

What is needed to insulate windows? The set of tools and materials is standard, regardless of what materials are used for thermal insulation or what material the windows themselves are. So, to insulate windows with your own hands, you need to prepare:

- putty (it is best to use a special window putty, but you can also use silicone);

- sealing rope;

- old rags;

- water;

- detergents (they will be needed for cleaning window glass and frames);

- large capacity;

- adhesive tape;

- flour;

- suitable window insulation or ordinary foam rubber as an analogue;

- laundry soap (you can also use cosmetic soap).

Alternative ways to save energy

Technologies do not stand still. Instead of increasing the number of chambers, increasing their volume and using expensive fillers, experts turned their attention to more budget-friendly solutions.

Thanks to the application of special coatings, multifunctional glasses are produced. On the inside, they create a barrier to thermal energy, reflecting it back into the room. A lightweight tinting film blocks ultraviolet radiation and prevents the room from overheating in hot weather. At the same time, good light transmission is maintained.

An innovative development that is becoming increasingly popular is heated glass. On balconies and loggias they can be used instead of heating radiators.

Source: www.ivd.ru

Where to begin

Properly carried out measures for insulating plastic windows will additionally correct errors made during its installation. If desired, you can make changes to the design - insert a window, change the functionality, swap blind and opening doors. Window insulation begins with the selection of technology, materials, drawing up a detailed work plan, and for this it is necessary to assess the true state of the system as a whole.

Important! Work on insulating metal-plastic windows can be carried out year-round, but correctly - in the warm season. Another condition is dry, windless weather.

On frosty days, it is convenient to locate the cracks through which cold air enters the room. So, the most “weak” points of the metal-plastic structure:

- opening sash seal;

- glazing bead area;

- window fittings;

- the area where the window frame adjoins the window sill, ebb, slopes, walls;

- space under the window sill, ebb, slopes.

You should definitely pay attention to the width of the window sill - it should not completely “cover” the heating radiators located under the window. A wide window sill is convenient, but not right.

Insulation of plastic windows: what you need to know

As a rule, problems with the thermal insulation of plastic windows arise in the following cases:

- Errors at the stage of choosing a window design. Often the consumer himself is responsible for them. When choosing a window and profile, it is necessary to take into account the climatic operating conditions, correctly approaching the assessment of the double-glazed window, profile, and fittings.

- Quality of window construction. Inconsistency between the characteristics of the product declared by the seller and the actual indicators. In this case, the question of how to insulate fiberglass windows if it is blowing cannot be resolved on your own. The entire product needs to be replaced. To avoid this problem, it is better to opt for time-tested manufacturers.

- In some cases, thermal insulation deficiencies are caused by individual component failures. In this case, window replacement is not required. It is not recommended to solve such problems on your own. It is enough to contact a company that specializes in the installation and installation of window structures.

- Problems associated with violations of the product installation technology: the use of low-quality sealants or seals during installation, insufficient surface treatment, incorrect measurements It is advisable to prevent such problems even at the stage of window installation. If this was not done in time, some shortcomings can be corrected on your own.

- Poor quality fittings, incorrect adjustment of fittings. In this case, you can consult with specialists on how to adjust metal-plastic windows yourself, or resort to the services of professionals.

- In some cases, drafts and depressurization are associated with the destruction of polyurethane foam. This deficiency can be eliminated on your own. To do this, you need to know how to insulate plastic windows from the outside. .

- The destruction of the insulation layer is caused by the absence or insufficient insulation of the external slopes and window sill. In this case, the polyurethane foam lags behind the wall and gaps are formed through which cold air freely penetrates into the room. If you want to insulate the slopes of plastic windows from the street, you need to know how to replace the mounting layer.

- Often, insulating plastic windows may be associated with the need for additional energy saving in cold climates or emergency situations. Here you can take advice from professionals or resort to everyday experience. In both cases, you will need knowledge of the structure of a metal-plastic window.

Construction of a metal-plastic window

- Frame is the supporting structure of the product, made of reinforced steel profile. The formation of drafts and freezing of the window depends on how tightly the frame is fixed in the opening.

- Double-glazed window. Energy saving and indoor microclimate depend on its characteristics. The more chambers a glass unit contains, the higher the thermal insulation properties of the window. In the climatic conditions of Russia, the standard is the use of structures with two-chamber double-glazed windows with a gap between them of up to 18 mm. An air cushion of heated dry air between the chambers acts as thermal insulation. If you are looking for a way to insulate a plastic window with your own hands , treat it with a special anti-moisture compound. As a rule, sealants are used for these purposes. This will protect against dampness and freezing in winter.

- Accessories. Should ensure smooth opening and closing of the window. If the fittings are chosen incorrectly, the doors will not close tightly. This leads to additional heat loss.

- Glazing bead. Designed for fastening double-glazed windows to the profile. Insufficiently strong fit of the glass unit to the profile is one of the design flaws, which is the cause of constant heat loss. For tightness, the stamp must be rubberized.

- Low tide and visor. Distortions during the installation of the tide contribute to the accumulation of moisture in hard-to-reach places, which leads to ice and contributes to the freezing of the window in winter.

- Slopes and window sill. They are an important energy-saving part of the window structure. Insulating the slopes and window sill outside the window will help increase the period during which the polyurethane foam does not lose its insulating properties. This will save you from drafts in your house and apartment.

- Seals. High-quality seals protect against moisture, drafts, and promote reliable thermal insulation. To ensure the tightness of window products, they must be installed at each attachment point and joint.

The right choice of window designs

When choosing a window, you should remember that the quality of thermal insulation and energy saving will depend on:

- on the characteristics and properties of the glass unit;

- from the correct installation of window structures;

- availability of high-quality seals;

- from fittings, all parts of which must be rubberized;

- application of innovative technologies - special compositions for processing; frames and glass, sealants, know-how;

- defects in parts and components that reduce the quality of the product;

Depending on the thickness of the glass and the number of chambers, double-glazed windows are:

- With one camera. Such double-glazed windows consist of two glasses with a thickness of 4 to 6 mm and a gap between them.

- Double-chamber is the most common type of double-glazed window. Includes three glasses and two gaps and has a reinforced air insulating layer.

- Three-chamber with reinforced double-glazed windows have three gaps between four glasses with an air cushion of 45 mm.

Adjusting fittings

In a broad sense, fittings are usually understood as the mechanism for opening and closing a window, the modes and parts that provide it. The main function of the fittings is reliable sealing. To prevent cold air and moisture from penetrating into the room, and to prevent the window from freezing, the structure must be completely sealed. Therefore, for energy saving of an apartment or private house, fittings are as important as a reliable double-glazed window.

The fittings must provide:

- Smooth and complete opening and closing;

- Fixing the window in various modes and positions;

- Ventilation of the room with minimal heat loss;

- Protection against unauthorized entry and hacking;

- Removing the load from the hinges. This prevents the sashes from sagging, jamming and depressurization.

Rules for installing metal-plastic windows

Improper installation of window structures can lead to serious problems that cannot be eliminated without repeating the entire procedure. Therefore, compliance with the installation requirements and stages must be approached very carefully, starting with choosing the brand of polyurethane foam and sealant and taking measurements. If you decide to entrust this procedure to professionals, then first you need to make sure that the entire procedure will be carried out in accordance with GOST. Compliance with GOST is a guarantor of the quality of work and the effective functioning of the product. The installation and installation of plastic windows is regulated by the main GOST 30 971– — 2002. If the installation will be carried out by the same company where you purchased the product, it will be useful to find out the GOST compliance of the product itself. The requirements for thermal insulation of plastic windows are established by GOST 26 602.1 Heat transfer and SNiP Thermal protection of buildings.

In order to ensure the quality of the work performed, it is necessary to control the implementation of the following operations:

- preparation of the window opening: thorough cleaning of the surface, alignment of the horizontal level.

- Gaps between frame and mounting surface. In accordance with the requirements, the gaps should not exceed 5 cm. It is also better not to leave them too small. In this case, it will not be possible to evenly distribute the foam along the entire length to the depth of the gap, which in the future can lead to the formation of drafts.

- The quality of the assembly seam, the uniformity and density of its application. Polyurethane foam should be applied in stages at intervals of three layers.

- The quality of the sealants and polyurethane foam used.

- Installation of additional insulation elements: external slopes.

How to insulate plastic windows for the winter

As already mentioned, there is no need to specially insulate windows. However, in the fall, before the onset of winter cold, you should check the condition of the window and the serviceability of the locking mechanisms. Noticed malfunctions should be promptly eliminated, and the mechanism adjusted if necessary. Yes, and washing the window before the cold season will also be a good decision - how to do this without damage to the plastic window, see our video:

Work is carried out both inside and outside the premises. Inspect the window, check the condition of the connections, the operation of the locks, etc. If you find any problems, write them down. Depending on their complexity, prepare the necessary materials and tools to fix window faults yourself, or invite a specialist.

Methods for insulating plastic windows

If you come to the conclusion that your window needs additional insulation, you can resort to the following simple methods.

The procedure is carried out in the following sequence:

- First, remove the layer of old polyurethane foam in the resulting gaps;

- We apply a material to its surface to hold the materials together; you can simply spray the gap with water;

- Next, we form a new layer using sealant or polyurethane foam;

- We seal the work area with construction tape for a few minutes;

- After this, you can install new insulated slopes.

In specialized stores, ready-made insulated slopes will save a lot of time. The material used is extruded polystyrene foam. The energy efficiency of expanded polystyrene is 2-3 times higher than that of polystyrene foam.

Polystyrene foam as a filling material is suitable for insulating a window sill. The window sill is removed, a layer of foam is laid, the cracks are sealed with polyurethane foam and the window sill is installed in place.

Source: uteplenieplus.ru

Insulation of plastic windows for the winter

Insulating plastic windows for the winter may be necessary if it is frosty outside.

The most common methods include:

- Heat-saving film. This is a modern method. The film prevents heat from escaping from the room, allowing sunlight to pass through normally. Fastening is carried out with the metallized side facing the street. The product is attached to the frame with an overlap. Fixation should be done using adhesive tape.

- Sealant. It is suitable for small gaps. The material should be selected so that it matches the color of the windows. This will make the thermal insulation as aesthetically pleasing and invisible as possible. The service life is 2-3 years.

- Tubular thermal insulation. It is considered one of the most reliable. But it is quite difficult to implement. It is necessary to remove the window from its hinges, select a place for the groove, make a groove using a cutter and push the insulation into the groove, placing it on the glue. This insulation lasts 15-20 years.

- EuroStrip material. This is a Swedish material that resembles tubular insulation. The peculiarity is the simplicity of installation work. Simply push the EuroStrip into the cracks. Service life 15-20 years.

Is it possible to insulate plastic windows?

There is generally little material about the repair of plastic windows, even on the Internet. Mainly because in our country such a product is used in everyday life for a short time, is quite durable and, as a rule, does not suffer from the main disadvantage of wooden analogues.

When a plastic window blows out, it seems that there is only one option - to call specialists. But not everyone knows that it is sometimes possible to correct the situation on their own using improvised means. When and in what cases can you act independently in this matter? What is the action plan and actual forecast regarding the results of repairing such a technological product with your own hands? Let's try to briefly understand all this. Along the way, assessing the degree of expediency in certain circumstances.

First of all, we note the main problem areas of plastic window structures, taking into account the possible use of inappropriate and cheap plastic and types of rubber, as well as wear and tear in case of long-term use. The following items are most at risk:

- Glazing beads: mechanical damage, wear.

- Rubber seal: cracking, loss of elasticity.

- Poor quality or improperly secured fittings.

- Places of contact between the glass unit and the wall or window sill. For example, the reason is often excessive savings on insulation and foam when installing a window.

Now let’s figure out what to do if there is a suspicion that the window has lost its seal. The reason is, first of all, determined by the localization of the faulty element. This can be done in several simple ways:

- Run your hand over the contact points between the window and the frame.

- Carry a burning candle or lighter around the perimeter of the window. This is a more sensitive technique. Allows you to identify the weakest breath.

- Insert a sheet of paper between the sashes, close the window and pull the paper towards you. The procedure will have to be repeated several times in the main areas. But if in some place the sheet easily slips out, a clear sign of a lack of proper adhesion and, therefore, a problem area will be found.

Plastic windows in a wooden house can be a source of draft when, due to shrinkage or skew of the wooden wall, gaps form between it and the glass unit. In this case, we need to talk about a violation of the technology for installing the window itself.

Now that the main points have become clear, let's try to classify both methods of elimination using available means, and the permissible degree of intervention, accessible and reasonable for the average home owner.

Video on the topic:

How to care for plastic windows so that they retain heat for as long as possible?

Plastic windows are easy to use, but they still require some maintenance. According to Alexey Dubik, once a year it is necessary to treat the mechanisms with a special lubricant, which can be purchased at a hardware store. You also need to lubricate the rubber seal twice a year. This must be done before the onset of summer and winter. “The elastic band is destroyed by external factors: heat and frost. It dries out, and the seal is no longer the same, but heat is retained due to the seal,” said the foreman. According to him, if the rules of care are followed, plastic windows can last 15 years or more.

Do-it-yourself insulation of plastic windows

The most affordable way to increase the thermal insulation properties of a window yourself is the insulation procedure. It does not require any special equipment. Everything you need can be purchased at any hardware store for little money.

First of all, you will need insulation, which can be:

- Polyurethane foam. It consists of frozen small bubbles filled with air and, thanks to this, is an excellent barrier to the cold. Easily fills voids, expanding and closing all small cracks. It is better to use it for indoor insulation: it cannot withstand extreme temperatures. Ultraviolet radiation is also harmful to her.

- Mineral wool. The most suitable place for it is window sills and slopes. It can and should be used, but covered with other materials from the side of the room so that the small particles of which it consists do not get inside.

- Polystyrene foam and its analogues.

You may also need:

- Silicone sealant and construction tape used in conjunction with it.

- For exterior finishing - building mixtures.

It is necessary to make a reservation right away. A non-specialist can only insulate windows from the outside on the first floor. As altitude increases, the risk of falling increases. Anyone can do work inside the room, albeit with a certain degree of caution. Since breaking a window and flying out of it under unfortunate circumstances is also possible.

The insulation process itself comes down to filling the installation seam with heat-insulating material. Rigid insulation is best used when its width is small - up to 3 mm. Otherwise, mineral wool is a better choice. Each section of the window requires a special approach and requires slightly different insulation techniques. Therefore, we will analyze each element separately.

Slopes of plastic windows

Despite the advice not to work at heights, we need to briefly touch on the topic of insulating window slopes from the outside. This will make it clearer how the window works in principle, which won’t hurt. In addition, residents of lower floors may find this information useful.

During the cold season, cold air leaks into the room from the street through poorly insulated external slopes. And the slopes on the side of the room can freeze during the season of especially low temperatures. It is better to insulate this outer part of the window so as not to burden the internal structure.

So, first of all, you need to remove unreliable plaster and dirt around the perimeter of the window. Large holes and cracks are sealed with polyurethane foam or any other heat insulator. Then the protruding parts of the insulation are carefully trimmed and slopes are attached on top. If the space between them and the wall is large enough, it is best to fill it with mineral wool. Filling with foam plastic or penoplex is suitable. An important detail is the ebb. During installation, the space underneath is especially reliably filled with insulation, and the ebb surface itself must have a slope of at least 5˚ to allow water to drain during precipitation.

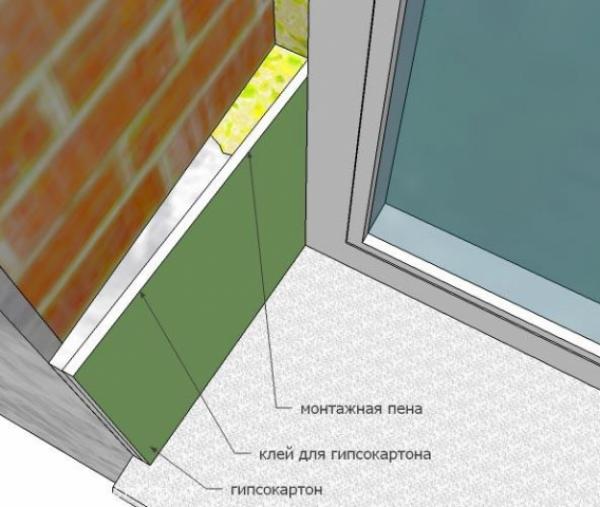

Installation of slopes inside the house is carried out in the same way. The differences are in the placement of the window sill instead of the ebb and in the finishing materials used, which, as a rule, try to choose better ones that have high aesthetic properties.

The scheme of work is as follows:

- The surface is prepared: cleaned of insulation residues, crumbs and dust.

- It is leveled with plaster and then primed.

- Sheets of insulation are placed on top, and the corresponding elements are placed on them: slopes, window sill, corners.

Both ready-made plastic structures and frame-fixed drywall are used as finishing. The surface is puttied if the material requires it.

When repairing a window that was installed a long time ago, you should check the condition of the old polyurethane foam. Over time, it loses its thermal insulation properties and crumbles. Areas with such worn-out filler, after its removal, are filled with new ones.

Window sill insulation

Under the window sill there is an area of possible heat loss. Poor-quality installation, a decrease in the thermal insulation properties of old insulating material are just some of the reasons leading to the permeability of this area.

The so-called cold window sill most often has two main areas through which low temperatures are transferred into the apartment:

- The space between the wall and the window sill. In this case, the window sill is removed. Then insulation is added or completely replaced with a new one. After installation, the distance between the two surfaces is foamed.

- The line of contact between the window sill and the frame. Cold air flows may be observed due to insufficiently precise fitting during installation or lack of insulation. In this case, a sealant that fills the cracks often helps to insulate the window sill of a plastic window.

Profile

The window profile itself is a fairly dense and solid structure, there are no cracks or gaps in it. Even the mounting points for the fittings are quite sealed. There is no point in waiting for cold air to seep in from this side.

You can decide how to insulate the profile only by paying close attention to the following details:

- The tightness of the junction of the seal and glazing beads in the double-glazed window.

- The tightness of the external seal by examining the frame of the plastic window at the points of contact with the profile adjacent to the wall.

- No frame distortions relative to the wall profile.

The correct location and adjustment of the operation of the fittings are also important here. Shrinkage of the house and aging of the window material lead to imbalance of the clamping mechanism. Careful setup corrects the situation. There are special eccentrics along the sashes that require adjustment. Using a hex key, these eccentrics regulate the degree of pressing of the sashes. The ability to adjust the pressing force is also provided by the loop mechanism. To adjust it, you will need a hex wrench.

You can check whether the insulation procedures were successful in the same way that is used in the process of initially identifying problem areas of the window. If the problem is not corrected by adjustment, there is a high probability that the defect is present in the glass unit itself. The following sections are just about this.

Rubber bands on plastic windows

The so-called seal, a perimeter edge, which is most often inserted into special grooves and serves to tightly and airtightly close the window. According to strict operating standards, it must be regularly cleaned and lubricated with a special softening compound. Of course, rarely does anyone perform such maintenance. Therefore, eventually the rubber dries out and has to be replaced in order to properly insulate the structure.

It is not recommended to change the window seal yourself. Still, it will be difficult for a non-specialist, deprived of the necessary tools, to carry out the entire required amount of work efficiently. But replacing the edging, which follows the contour of the frame and ensures tightness when closing the window, is a task that the average owner can do.

The whole process looks like this:

- Decorative plugs are removed from the hinges.

- Using pliers or a screwdriver, remove the pins.

- The frame is carefully tilted and removed from its hinges.

- The old seal is removed from the groove and replaced with a new one.

- The previous steps are performed in reverse order.

Double-glazed window

In addition to direct insulation for the winter, there are additional options that will increase its thermal insulation properties.

Not letting cool air into your apartment is not all; you can also prevent heat from escaping. For these purposes, insulating film can be used - a material that reflects heat back into the room. In addition to reflection, the film creates an air cushion between itself and the glass, which provides additional thermal insulation.

If you are just planning to install a window and the funds allow, the best solution would be to immediately buy an insulated option or, in other words, a heat-saving package. But if you have standard plastic windows, it will not be superfluous to insulate the windows with film.

This is done quite simply:

- The surface of the glass is cleaned and degreased.

- The frames are covered with thin double-sided tape, onto which the film is stretched.

- It is made of heat-shrinkable material and, after heating with a hairdryer, it flattens out so much that it becomes completely invisible.

There is an even more advanced insulation option - electric heating. If the question is urgent, you can contact a specialized workshop, whose specialist will install this device.

Source: fermersadovod.ru

Insulation of plastic windows

Scheme of insulation of window slopes.

Many people are faced with the problem of insulating plastic windows, which at first glance represent a solid structure with no cracks. It is difficult to install leaky areas and decide on the material for insulation. To insulate plastic windows for winter, you can use special glue. It can be used to fill all possible cracks and joints of the window, seal seams and perform other similar work.

The first step in insulating plastic windows is to thoroughly clean them. Any debris, dust or moisture will prevent the window from being properly sealed. When working with glue, the sealant does not need to be smeared; it is better to leave a small bead, which will disappear after the glue dries. You should be prepared for the fact that such glue can dry for quite a long time, up to eight weeks. This glue is produced in tubes; to apply it, you should use a construction gun.

Window insulation scheme using Swedish technology - option 2.

This material can be used to insulate white plastic windows for the winter: it itself is usually light in color and the layer of glue not only does not catch the eye, but also allows you to mask unflattering cracks.

When insulating windows with glue, you should follow some safety rules. So, there must be access to fresh air into the room. Do not use open fire or smoke during work. It is strictly forbidden to pour the remaining glue down the drain. If glue gets into your eyes, it can cause serious burns.