Home / Other

Back

Published: March 29, 2020

Reading time: 12 min

0

5

- 1 Video instructions for cladding a wooden house

- 2 Basic rules

- 3 Preparatory work and installation of vapor barrier

- 4 Features of thermal and waterproofing of a wooden house

- 5 Fiber cement boards and siding 5.1 Vinyl

- 5.2 Metal

- 5.3 Basement

Video instructions for cladding a wooden house

First of all, it is necessary to remember that all work related to finishing a wooden house can only be carried out after a certain time has passed after its construction. This is due to the shrinkage of the house, the period of which depends on the wood of the constructed structure. So, for a house made from wild felled trees, cladding can be done no earlier than 2 years.

Very often, owners of wooden houses, in which residence is seasonal, generally refuse to sheath the house. And this is, in principle, correct, since wood, in the case of high-quality processing, is beautiful in itself, and accordingly it simply does not make sense to insulate this kind of house. In all other cases, cladding the house is advisable and will not only give it a well-groomed and beautiful appearance for many years, but also protect the wood from the negative effects of the environment. The technology of cladding a wooden house can be divided into the following stages:

- treatment of the external surface of the walls with special means;

- laying a vapor barrier layer;

- installation of a frame system;

- application of thermal insulation layers;

- laying waterproofing film;

- decorative exterior decoration of the house.

Insulation of the house and subsequent finishing work are usually carried out in the summer. Sheathing a house can be done with your own hands without resorting to the help of professionals, since there are no particular difficulties in this process. You just need to select all the materials correctly and strictly follow the step-by-step instructions for each block of work, which are described in detail below.

Wood has been used in construction and decoration for centuries, and it seems that it will be relevant for a long time. All thanks to its excellent appearance and ability to regulate indoor humidity. This is perhaps the only material that will remove excess moisture without problems, regardless of what material the walls are made of.

Wooden cladding can have a completely non-standard appearance: different colors and sizes, different directions. It's simple, but the effect is amazing

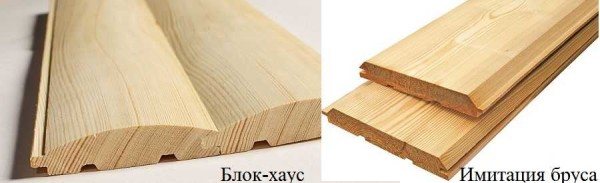

The most popular materials for wall cladding are block house and imitation timber. There is also lining for exterior decoration - it is thicker than that intended for interior decoration of a house, but otherwise it is no different.

The block house imitates the surface of a rounded log - the front part has a rounded shape. Imitation timber is very similar to planed timber. Both types of cladding are attached to the sheathing, then sanded and coated with protective impregnations, and optionally varnished or painted.

What does lumber look like for exterior cladding of a house?

If you can't decide how to cover the outside of a foam block house, consider wood cladding. In this case, lathing (metal or wood) is nailed to the walls. If necessary, insulation is laid between the slats - basalt wool (foam or polystyrene foam cannot be used), and then wooden sheathing is nailed.

This building is sheathed with imitation timber. Under the skin there can be brick, log frame, frame or any of the building blocks

If you need the cheapest option, for most regions of Russia this is an ordinary planed board. Its thickness is from 40 mm, it is stuffed in the same way as a lining or block house onto the sheathing, the lower end of the upper board extends 10-20 mm onto the one located underneath it. It turns out the principle of the cone. This way you can cheaply cladding a country house or even a residential one. When properly processed, such cladding has a very good appearance.

How to cheaply cover the outside of a house? For central Russia - planed wooden boards

The disadvantages of such finishing are the same as with any wood: it can be damaged by pests, rot, without proper care it quickly loses its decorative effect, becomes dark and ugly. If you want to cover your house and not think about it for years, this is not your choice. Wooden cladding requires maintenance, and, most often, annually.

Read how to cover a house with bricks here.

Different ways of cladding a wooden house

The building materials market can offer a lot of options for covering a wooden structure with various materials.

All of them have numerous advantages and have their disadvantages. You can cover the walls with façade bricks; this will indeed significantly strengthen and decorate the building, but the costs of this undertaking will be comparable to the construction of another small building, and the main obstacle will be the significantly increased load on the foundation, which may not be able to bear the almost doubled weight of the walls. The same applies to facing stone if it is a natural material. The artificial analogue is much lighter and can be used for cladding a house with any type of foundation.

The technology of cladding external walls with façade thermal panels lined with clinker tiles is still little known among the population. Most likely, this is due to its high cost. But for a wooden building, this type of exterior finishing is only possible with forced ventilation of the facade, since moisture will accumulate between the wood and the cladding.

Basic Rules

When selecting materials for cladding a house from the street, be sure to remember that in order to maintain normal humidity in the rooms, the vapor permeability of the materials must decrease from inside the room to the outside. That is, the exterior finishing should conduct steam better than the wall material. Then the increased humidity, which is typical for our homes, will be removed through the walls naturally (explanations in the photo).

When deciding what is best to sheathe the outside of the house, do not forget to take into account the vapor permeability of the materials

If this principle is violated, moisture will accumulate at the interface of materials with different vapor permeability. It condenses, creating conditions for rotting and the development of fungi and mold. In winter it freezes, destroying the wall material and/or finishing. Sooner or later such a system will have to be dismantled and rebuilt.

We invite you to familiarize yourself with Chubushnik at the dacha

The trouble is that only wood meets this requirement. Most other materials for exterior decoration of a house have low vapor permeability. The problem is solved in two ways:

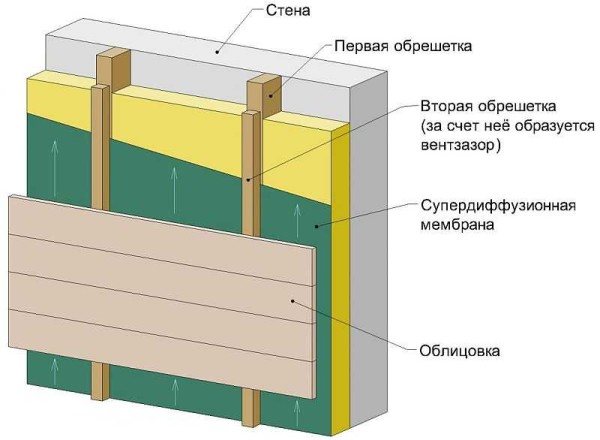

- A ventilated facade is being installed. A ventilated gap with a width of 60 mm to 150 mm is left between the wall or insulation layer (with high vapor permeability) and the finishing. Ventilation holes are left at the bottom of the cladding at the rate of 75 cm2 for every 20 m2 of wall, including windows and doors. Air will enter through them. There are exit holes at the top. With this device, moisture will be removed from the wall material or insulation, and the outer cladding will protect from precipitation and perform a decorative function.

The principle of finishing a house using a ventilated facade - The finishing material is attached directly to the wall. But from the inside the wall must be protected by a layer of vapor barrier. In this case, the penetration of vapors into the wall material is prevented and it remains dry. Excess moisture is removed by the ventilation system.

Today the second option is becoming increasingly popular. Very effective thermal insulation materials have appeared that can significantly reduce heating costs. But they have very low vapor permeability (expanded polystyrene and extruded polystyrene foam). When using them, only the second humidity control scheme is possible. When choosing what to cover your house with, consider these points.

Preparatory work and installation of vapor barrier

Preparatory work consists of treating the wooden walls of the house with special emulsions that prevent the infection and spread of various fungi and harmful insects. Such procedures are necessary, first of all, because after applying all layers of insulation and finishing, subsequent access to the walls will be closed, so it is very important to maintain the safety and integrity of the wood.

In order to maintain natural air circulation in the walls of a wooden house, a vapor barrier layer is installed, which can be polyethylene film, aluminum foil, bitumen roofing felt and a special vapor barrier. As a rule, the first option is used for a wooden house, since it combines an acceptable cost and the fulfillment of all the tasks assigned to such a material.

You should pay attention to the fact that there must be a certain free space between the walls and such a layer. Therefore, if the house is built from flat logs, and not from round ones, it is necessary to build a frame from slats, 2-3 cm thick, which are nailed to the walls in a vertical position at a distance of 40-50 cm and install film on them.

The vapor barrier layer is laid according to the following algorithm:

- Special holes for ventilation are made on the top, bottom and side slats, the diameter of which is 20 cm;

- Using nails or, better yet, a construction stapler, the vapor barrier is attached to the frame (round logs) with an overlap of 15 cm;

- Absolutely all joints and places where staples and nails are fastened must be taped with special tape.

Cladding a wooden house with facade tiles

Facade tiles, which are most often used for cladding wooden houses, are called clinker tiles. Clinker tiles are durable and strong. It will perfectly protect a wooden structure. Gives a very good thermal insulation effect.

Regarding the installation of clinker tiles, you can easily do it yourself. Installation, as a rule, does not cause any difficulties. The cost of facade tiles is affordable for almost everyone. This material is quite accessible.

Under the influence of heat, moisture, temperature changes, clinker tiles do not change their properties and appearance.

Subscribe to our Yandex.Zen channel

Features of thermal and waterproofing of a wooden house

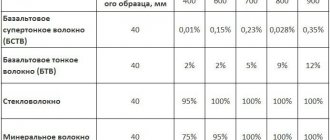

Before you start insulating your house, you need to select a suitable heat insulator and calculate its required quantity. Considering the characteristics of a material such as wood, the choice of suitable insulation is quite small and comes down to almost one most rational option. For the purpose of a more detailed visual perception, we present to your attention several types of heat insulator for a wooden house:

- Foam boards. This material has high heat retention and sound insulation properties. Quite easy to install and not susceptible to various pests. Despite all the advantages, many experts consider it a very serious mistake to use polystyrene foam as insulation for a wooden house. This is due to the inability to allow air to pass through, which over time can cause wood to rot. In addition, it is not fire resistant and not environmentally friendly, which is also not entirely suitable for such a natural material as wood;

- Penoplex. This is a relatively new material that is made by extrusion. It has a very high level of thermal insulation, is fire resistant, and is not susceptible to the spread of bacteria and fungi. But penoplex has the same disadvantage as the previous material, namely, it is vapor-tight and, moreover, difficult to cut and install.

- Mineral wool. The most commonly used material for external insulation of a wooden house. Air flows pass well through the insulation, which has a beneficial effect on the condition of the tree. Quite easy to install and adjustable. Mineral wool is an environmentally friendly and non-flammable material. The disadvantage is that the slightest ingress of moisture due to a violation of the laying technology of this material can lead to the loss of all thermal insulation properties throughout the year.

Based on the above, the most acceptable option for insulating a wooden house is mineral wool, for installation of which the tiled form is best suited.

It is necessary to install a frame system onto the already installed vapor barrier layer, into which the mineral wool slabs will be installed. This will require vertically nailed wooden boards (thickness and width approximately 50 and 100 mm, respectively), the distance between which is 2-3 cm less than the width of the mineral wool slab.

Thus, the heat insulator will fit tightly to the base without any additional fasteners. Mineral wool is very easy to install, and inserting the slabs into the frame will not be difficult. If desired, you can use two layers of insulation. In this case, the second level of heat insulation must be installed at the joints of the slabs of the first layer.

We suggest that you familiarize yourself with Liquid glass solution on water

After the entire frame is filled with insulation, a special waterproofing film is laid. It is worth paying attention to the correct location of this material in relation to the mineral wool. The uneven rough side must be adjacent to the heat insulator, and the smooth side must face outward.

The film is attached in the same way as the vapor barrier layer using a stapler to the frame with an overlap, and all joints and staples are sealed with self-adhesive tape. Boards are nailed onto the existing frame system (width - 50 mm, height - 40 mm). This sheathing will perform two functions. Firstly, this creates additional space for air circulation, and secondly, such a system will serve as a frame for finishing the house.

Block house for cladding a wooden house

The block house is used for cladding a wooden house for the purpose, among other things, of imitating timber. Therefore, it is often used for cladding frame buildings.

- The block house has good thermal insulation properties

- Tolerates temperature changes, moisture and exposure to ultraviolet rays well

- The ease of installation of a block house is also one of the advantages of the material. Installation can be done independently, without the involvement of professionals.

The block house is made from coniferous trees. Mainly such as spruce and pine. But, like any wood, the house block must be periodically processed to protect it from external influences. The occurrence of mold, fungi, moisture, pests.

Fiber cement boards and siding

In some regions, planks and other lumber are not the most affordable materials. In this case, it is cheaper to cover the house with siding. This is the option when you can finish it once and forget about it for a long time.

If you are thinking about how to decorate the outside of a timber house, perhaps your option is siding

Since the sheathing is nailed onto the sheathing, the façade is ventilated. If you need to inexpensively decorate wooden walls (from timber, logs, panels), siding is one of the options. It can also be used for buildings made of any other material: foam block, aerated concrete, slag-filled concrete, etc. This cladding is universal.

Vinyl

Siding is made from polyvinyl chloride (PVC) and is therefore also called vinyl. It consists of strips of material 205 and 255 mm wide, 1.1 mm and 1.2 mm thick. The longitudinal edges have a lock on one side and perforation for fasteners on the other (self-tapping screws are more often used).

The siding is also attached to the sheathing. It is recommended to use a special metal one, but impregnated wooden blocks are quite suitable. Only standard starting and side stripes will be required. The only caveat: the screws need to be “undertightened” a little, leaving some play in order to compensate for temperature changes in the materials. With this installation, the siding will not crack due to stress.

The advantages of this material for exterior cladding of a house: low prices, easy installation.

The disadvantage of vinyl siding is that it quickly fades in the sun, so it is advisable to use soft colors. It has a fairly wide operating temperature range: from 50°C to -35°C, but even in slight frosts it becomes brittle and easily damaged.

One more point: houses covered with siding and having a broken configuration look good. If the building is rectangular, without architectural frills, it does not have the most attractive appearance (as evidenced by the photo below).

If the building is simply long, without reliefs or protrusions, covering the walls with sading will not embellish it very much

Metal

Metal siding consists of strips of thin aluminum or galvanized steel, onto which a protective and decorative coating is applied. It has the same fastening system as vinyl.

Sheathing a house with metal siding is simple: you can do it yourself even without much construction experience

The coating can be made of polymers. It is distinguished by its reliability, resistance to burnout and other climatic factors. Its disadvantage is the limited choice of colors. The second coating option is powder coating. The color range is much wider, the paint lasts for years without signs of peeling.

If you are looking for something to clad the outside of your home for a durable and vibrant finish, one of the metal siding options may be right for you. It can be bent, it is very difficult to break, installation is not very difficult: you need good metal scissors, self-tapping screws, a screwdriver or a screwdriver. All installation features are the same as for vinyl, with the only difference being that metal can be installed at sub-zero temperatures.

It is not easy to harmoniously decorate a building covered with metal siding

From the point of view of durability, this is a good option, but from the point of view of aesthetics, it is difficult to work with: it looks too “manufactured”. The building no longer resembles a residential building, but rather a warehouse or some kind of workshop.

Tsokolny

This is one of the varieties of vinyl siding, but it has a completely different configuration, appearance and greater panel thickness. It was developed specifically for decorating and protecting the plinths of buildings, but I liked it so much that it began to be used for cladding facades. External design - brickwork of different types and colors, with or without drawings, wild stone. Sometimes the imitation is so successful that you can understand that it is not brick cladding, but vinyl, only by touching the wall.

In this house, the walls and gables are covered with basement siding; different collections are simply used

It is mounted, like other types, on the sheathing, there are perforations and locks. The difference is that the basement siding panel does not look like a long rectangle, but a certain section of the wall with curly edges. These curly edges are used to join. Accordingly, the sheathing must be adjusted to the size of the fragment.

We invite you to familiarize yourself with Soda against aphids

You can read about installation of basement siding here (one of the points).

The sheathing can be made of treated wooden blocks (with protective impregnation) or from plasterboard profiles (galvanized). How to install basement siding on a basement, watch the video. It is mounted on the wall in the same way. The difference is in area.

Features of finishing a house made of aerated concrete are described here.

Relatively recently, a new cladding appeared on our market: fiber cement boards and siding made of the same material. They consist of wood fiber, quartz, mica, cement, and may contain chlorine and asbestos (some materials used only for exterior decoration). This mixture is formed into sheets, then dehydrated in several stages, and fired using some technologies. Then a protective and decorative coating is applied to the surface:

- acrylic - inexpensive, fade-resistant;

- hydrofilceramic - high resistance to abrasion and fading (30 years), very low percentage of water absorption, but expensive;

- photoceramic - retains color for a long time, dirt is easily washed off, price - average.

Don’t know what is the best way to cover the outside of your house? There are fiber cement boards, decorative and reliable, mounted on the frame. It is easy to install on a log house, frame or brick. Any

The coating can be smooth - glossy or matte, or can imitate brickwork, wood and other finishing materials. It is installed on guide mounting strips and secured to the wall with clamps. This material may be suitable for you if you do not know how to cover the outside of a frame house: it creates a continuous surface, the panel joints are airtight and precipitation will not get inside.

This house is also lined with fiber cement slabs

Watch the video to see how to attach fiber cement boards.

Fiber cement siding is produced using the same technology, only it is molded into long strips. They are basically standard: 3600*190*12 mm. This material is cut with a jigsaw, installed on a wooden sheathing with an overlap (like a cone) and nailed to it or screwed with self-tapping screws.

Options for exterior finishing of a wooden house

The choice of finishing material depends entirely on the taste preferences of the owner of the house and the aesthetic goals pursued. There are two ways to move forward. The first is to preserve the appearance of a real wooden house and give it a well-groomed appearance. The second implies more modern external finishing solutions, both color and texture, which will not be related to wood in any way. So, let's look at the most popular ways to give a particular appearance to a house:

- Wooden lining. This material is well suited for recreating the wooden essence of a house. In appearance, it is a wooden flat board that can be given various shades. This finishing material is easily installed using special tenons that connect the boards along their length. It is environmentally friendly, durable, and has heat and sound insulating properties. The disadvantage of wooden lining is its susceptibility to various insects, which necessitates the need to coat this material with a special protective agent. This finish also needs to be repainted approximately once every three years;

- Block house. A very beautiful finish, which can be called a type of wooden lining, imitating a rounded log on the outside, and having a smooth surface on the inside. Made only from coniferous trees. This material is durable, protected from the negative influence of the external environment in the form of weather conditions and insects, and is also easy to install using a tenon phase. The only disadvantage is the high cost of this material;

- Vinyl siding. This material is durable, has an affordable price, and is light in weight and installation. Available in various colors, which allows you to make the decoration of your home modern and unusual. Easy to care for, as it does not require periodic painting and is easy to clean. Vinyl panels can be either screwed or nailed with regular nails. The disadvantage of siding is its low strength and unnatural appearance. Therefore, this type of finishing will appeal to those who want to transform a wooden house and give it a modern appearance;

- PVC panels. In terms of its technical characteristics, it is almost identical to vinyl siding and is its variety. The main difference is its interesting appearance, which imitates surfaces such as marble, brick and stone. It looks very interesting and impressive. This material is often combined with vinyl siding to create interesting design solutions.

There are many more different finishing materials, but as practice shows, the options described above are the most suitable for cladding a wooden house. The main thing is to decide whether you want to maintain the wooden appearance of the tree or bring in something new and interesting. We hope that our tips and recommendations for carrying out all stages of work on cladding a wooden house will help you in this difficult, but at the same time enjoyable task.

Cladding a wooden house with masonry

The stonework undoubtedly has a very beautiful and aristocratic appearance. In addition to the aesthetic component, natural stone has many advantages from a practical point of view.

Stone masonry used as house cladding is made from both natural and artificial stone.

Natural stone has excellent thermal insulation properties. And it’s probably not worth talking about the durability of natural stone. And it is clear that natural stone will last a very, very long time. In addition, natural stone is a natural material. And absolutely safe for human health and the environment. The disadvantages of natural stone, in terms of cladding a wooden house, are:

- High cost of the material itself

- Most likely, you will need to spend money on strengthening the foundation, due to the large weight of natural stone.

- It will take a lot of time and effort to complete the installation of natural stone. This is not an easy job

The stone is artificial and in appearance is in no way inferior to natural stone. In addition, artificial stone is much lighter. This greatly simplifies the installation of the material.

The disadvantages of artificial stone, in comparison with natural stone, are its fragility and low strength. In addition, in severe frosts, it can crack and crumble.