A private building has a lot of differences from the same type of urban housing.

There is more room for imagination, but large financial investments will also be required.

What does it cost to install a pipeline? Laying pipes is necessary in several cases: when organizing sewerage, heating, water supply, ventilation, etc.

Types of pipes

Pipes are different. Let's highlight the most common types of pipes used in private buildings.

Steel products are recognized as the most durable pipes. Until recently, they were the most popular precisely because of their long service life, availability and affordable price.

Copper pipes were also used, which have proven themselves very well in the operation of the heating system. But, if we take into account the cost of copper pipes, then all the advantages of using them disappear.

Finned pipes are also used, which have received favorable reviews due to the uncomplicated subsequent operation and installation. Their only drawback is their heavy weight.

And for water supply, polypropylene pipes are often used, which have restrictions on heating temperature and internal pressure.

Polypropylene pipes can be reinforced with fiberglass laid between two layers of base material.

And the most popular pipes in the last decade are metal-plastic pipes, also called metal-polymer pipes. They are easy to install, light in weight, and have a long service life.

If pipes are purchased for installation of a heating system, the number of floors in the house, the financial ability of the owner, the qualifications of the craftsman and the size of the building should be taken into account.

Requirements for underground pipes

What qualities should pipes laid in a trench have:

- Not afraid of wet soil and not subject to corrosion.

- Do not interact with alkalis and acids in the soil.

- Have reliable installation connections.

- Withstand soil pressure.

- Guarantee long service life.

In seismically unstable areas, it is necessary to use pipes that are flexible so that they do not collapse when the soil moves.

If there is a need to install the main line in winter, the frost resistance of the material used will be required.

Which pipe to choose for underground water supply?

Pros and cons of pipes

Each type of pipe in this case has its own pros and cons. So, it is not recommended to install copper and steel pipes inside floor screeds or walls. They are quite difficult to install than metal-plastic ones (welding work is required).

When organizing heated floors and installing pipes in walls, it is recommended to use reinforced polypropylene pipes, which have a high rigidity of the product, preventing their deformation and rupture. Their sufficient thermal conductivity should also be highlighted.

But even higher thermal conductivity can be expected from metal pipes. Especially for finned tubes. Despite the fact that metal pipes can be called unaesthetic, they will provide greater heat transfer to the room than other types of pipes. For this reason, metal pipes can be placed in areas where aesthetics do not play a big role, such as a garage or utility room.

Laying polyethylene pipes. Digging and filling trenches

Laying polyethylene pipes in a trench. To lay a pipe, a trench is dug and backfilled at several levels, with different placement of material in the trench. First you need to prepare the bed (bottom), usually it has a thickness of less than 10 - 15 cm and is used as a support for the pipeline along its entire length.

The next step is to fill the free space between the walls of the trench and the pipe. In this case, backfilling is carried out from the base of the bed to a point located approximately at half the diameter of the pipe - this is the initial backfilling. Then the final filling of the entire pipe is carried out.

Sewage pipes

Sewer pipes can be made of metal, polymer material, asbestos cement or concrete. In addition, a ceramic or fiberglass pipe can be used, but in rarer cases. The strength of metal pipes has already been mentioned, but in a sewer system they are susceptible to corrosive wear. Steel and metal pipes in modern construction are used in the industrial, rather than private, sector. If there is a need for high-temperature sewerage, then there are all the prerequisites for using cast iron pipes. For example, for an external drainage system for the petrochemical industry, etc.

Pipes made of polymer materials have become the most popular in recent years. They can be produced from three types of materials - polypropylene, polyvinyl chloride, unplasticized polyvinyl chloride.

So, for gravity sewer systems, PVC pipes are used to a greater extent. After all, they are durable and resistant to temperature changes. But at extreme temperatures, they are prone to losing their properties - in frost they become brittle, and at temperatures above 70 degrees they become deformed. Such pipes are defenseless against the chemical environment,

If PVC NP pipes were used in the sewer system, then they may also be appropriate for a pressure type system. Pipes made of this material are more durable and can last for about a century. Simple installation can also be considered one of the advantages of the material. Sufficient elasticity and tolerance to high temperatures. But it is worth noting that such pipes are used only for internal sewerage systems, and not for external purposes.

Suitable materials

The above requirements are better met by polymer pipes:

- polyethylene;

- metal-plastic;

- polypropylene.

Their service life exceeds 50 years. Polyvinyl chloride (PVC) products are usually used for sewage systems.

Polyethylene

Water pipes for laying in the ground, made of polyethylene, are used most often. They are not only able to withstand external soil pressure, but also shock loads. This allows them to be buried to a depth of up to 15 m.

Polyethylene pipes tolerate frost up to 60 °C, but at 10 °C they begin to lose their elasticity. They do not burst when water freezes in them, they just swell.

Polyethylene is resistant to aggressive environments, but is afraid of ultraviolet rays.

Thanks to the ability to bend pipes, the main can be laid without intermediate joints. But they are required at the exit from the source and at the entrance to the house.

For such connections, HDPE fittings are used, which have proven themselves well in summer cottages. But for home plumbing it is better to use more durable structures.

Installation of water supply in the house

Installing a water supply system using a pumping system is not very difficult. Moreover, taking into account the need to install various equipment, it will cost about $800. First of all, this is a boiler.

On top of these costs, you need a 220W outlet. Usually a scheme is used that can significantly facilitate the installation of water supply in a house. Usually attached to an already purchased pumping station. It quite specifically outlines all the main points for installing water supply in a cottage. Often, water is drawn from a nearby well using a pumping station. From the well, water enters the water supply system through the outlet pipe.

It is imperative to secure the entrance of the outlet pipe to the selected well. To do this, you can use silicone, and on top you can cover it with bitumen mastic for reliability.

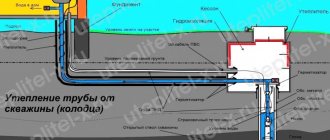

Thus, water from the well will flow into the house through a pipe. This pipe should be located in the soil below the freezing level during the cold season. Taking into account the climatic conditions in our country, the optimal level is about 2 meters.

However, it is not always possible to lay the pipe to the specified depth. In this case, you need to think in advance about how the pipe will be heated. Owners of village houses use a heating cable for this. Such a cable can be laid both inside and outside the pipe. To this end, in order to create a water supply system in a country house, you must have a clear mind and skilled hands.

Plastic pipe laying technology

Installation of an external sewer system first begins with the construction of a trench, which can be dug manually with a shovel or using an excavator. The depth of the furrows will depend on the depth of soil freezing in a particular region. The depth of laying the sewerage pipeline (established standards SNiP P-G.3-62) should be 0.5 m less than the ground freezing level and is approximately:

- for the northern regions of the Russian Federation from 3 m to 3.5 m;

- for central Russia from 2.5 m to 3 m;

- on the Black Sea coast from 1.25 m to 2 m.

These figures are not categorical; they can vary within certain limits depending on the characteristics of the region and the level of groundwater. But it should be taken into account that the laying of plastic sewer pipes in the ground must be carried out at least at a distance of 0.5 m from its surface.

When using pipes with a diameter of 110 mm, it is necessary to dig a hole in the ground with a width of 60 cm and a depth of 5 cm more than the depth of its laying.

Features of trench construction:

- the bottom of the trench must be leveled in such a way that a slight slope is created, as a rule, for each linear m of the pipeline network it should be 1 - 2 cm;

- after the necessary slope has been created, the soil must be thoroughly compacted at the bottom and a cushion of sand or gravel approximately 10–15 cm high must be built;

- the gravel or sand cushion must be compacted in the area that is located 2 m before the inspection well, as well as at the junction of the pipeline with the inlet element;

- At the location of the sockets, it is necessary to form pits in the sewer system.

After creating the necessary trenches, it is necessary to carefully compact the soil and create a cushion of gravel and sand.

Pipeline construction

Next comes the actual construction of the pipeline. Laying a sewerage system in the ground must begin from the foundation of the building.

The technology for laying plastic sewer pipes is as follows:

- Products are laid in prepared trenches with the socket down.

- Before connecting pipes to each other, the smooth end of one and the socket of the other must be cleaned of dirt.

- To facilitate the connection and increase its sealing, all joints must be lubricated with a special compound.

- When connecting products, make sure that the pipe is inserted all the way into the socket.

- All pipeline elements are combined in a similar way. In order for the connection of products to be high-quality and reliable, it is recommended to first measure the depth to which the pipe will enter the socket and make a mark at this point. After this, we insert the product until it “sits” to the applied mark.

- If necessary, bends are available (15°, 30°, 45° and 90°).

- If the length of the sewer pipeline is more than 15 m, an inspection must be installed in such a section.

- If there is an outlet structure in the foundation, the pipeline socket is connected to it; if one is not provided, then it is necessary to make an outlet hole. Diamond drill bits are ideal for this purpose.

Upon completion of pipe laying, it is necessary to check the slope angle again. If everything is done correctly, you can start filling the trench. To do this, it is allowed to use the soil that was formed when digging furrows, but then you need to remove large stones from it and split dense blocks of soil.

The trench must be gradually filled in layers of 5 cm, to a height of 30 cm. Each layer must be well compacted on both sides of the pipe; compacting the area above the pipe is strictly prohibited.

Insulation of plastic pipes

The need to thermally insulate plastic pipes arises when they are laid above the freezing depth of the ground or at its exit from the building. According to experts, in this case it is best to use energyflex or stenoflex insulation.

Sewer pipes are wrapped with heat-insulating material along the entire length of the pipeline, after which it is securely fixed; for this, self-adhesive aluminum tape can be used. Upon completion of installation of the insulating material, you should check the correctness of the slope and only after that backfilling is carried out.

The best and most correct option would be to backfill the pipeline with a layer of sand (10 - 15 cm), which is compacted tightly around the edges. You can pour soil on top of it.

If it is necessary to carry out partial repairs of an already functioning sewer pipeline, it is safer and more correct to completely dismantle the old sewer pipes, and then lay new pipes. In fact, by making this decision, you will spend much less time than replacing individual sections of the sewer system.

Defrosting the water supply

In city apartments, the water supply comes from the central water supply system. The pipes are hidden in the basement and frost rarely reaches them. On a personal plot and in a village, the situation is different. Sometimes the water supply system is hidden underground, but at the depth of freezing of the soil, or the pipe runs directly above the surface of the earth. If the water supply is frozen, then stopping the water supply to the house is not the only problem that you have to face.

Under a layer of ice, pipes deteriorate much faster. In addition, equipment, such as a boiler, may burn out. How to thaw a frozen propylene water supply and restore water supply faster?

There are several ways to thaw frozen polypropylene pipes without harm to the system or long-term suffering. Let's look at methods for defrosting pipes.

Selection of pipes depending on the water source

In the event that the direct source of water is a highway, it is only necessary to take into account the presence of communications. Remember that in this case, the pipe must be buried slightly below the depth of soil freezing. This is a requirement.

If you want to place your water supply from a well, you must remember that it is quite rarely laid underground, and even at the required depth. In this case, the entire pipeline must be properly insulated. In this situation, steel pipes are best suited. The fact is that, unlike all the others, they are more resistant to cold.

Warm up with boiling water

If the water supply is frozen in the area or in the basement, then hot water can be used to restore its operation. Initially, in the place where the piece of ice is supposed to be located, you need to wrap a rag that absorbs water well.

It will serve as a kind of compress. Next, boiling water is poured onto the rag. The rag will absorb water, thereby prolonging its contact with the pipe. A little later, the tap opens, if the water begins to flow gradually, it means the ice has broken.

This method can be used to heat water supply if the pipes are located in open areas. Pay attention to the quality of pipe materials. There is propylene, which is afraid of very hot water. When the water supply is located underground, this method of defrosting it will not work. The fact is that by the time the boiling water reaches the pipe, it will cool down and the action will be useless. Fortunately, there are other ways to cope with the problem.

Chapter 53. PLASTIC PIPELINES

Overhead installation includes the laying of pipelines inside buildings and workshops, as well as between workshops.Pipelines can be attached to the structural elements of buildings in various ways: by resting on consoles and brackets, by hanging under the ceiling on hangers, by fastening to the surface of the walls.

The pipelines are assembled according to the project. When assembling, special attention should be paid to the reliable fastening of water and shut-off and control valves to building structures, to the exact observance of the distances between supports, to the observance of the clear distances required by the project between polyethylene pipes and steel heating and hot water supply pipes when they are laid together or intersect with them, as well as to protect the pipeline from clogging.

Metal fastening means must not have sharp edges or burrs. Between the fasteners and polyethylene pipes, as a rule, gaskets made of rubber, felt or other soft material are placed.

Painting polyethylene pipes with oil paint is not allowed.

Polypropylene. Properties and applications of polypropylene

Pipes

for the sewer network.

Polymer sewer pipes

…

| Cast iron non-pressure sewer pipes used for their intended purpose since 1465, ... temperature 60°C. |

Power supply Layout and marking Methods for laying wires

| It is better to use as a protective sheath for electrical wires. polyethylene or |

Other materials - drywall, siding, sound insulation...

| There are also copper pipes with |

Wastewater

| Such pipes made from polyvinyl chloride (PVC), |

Installation of an autonomous water supply system. Communications. Water supply and...

| For laying an autonomous water supply system, you can use pipes , ... copper, |

Warm up with a hairdryer

In order to defrost the water supply, you can use a construction or household hair dryer. You need to build something like a box over the section of the pipe where the water has frozen.

This is necessary so that the warm air does not spread further than necessary. Next, you need to apply a wave of heat to the pipe and be sure to open the tap so that the melt water runs off the pipe. Additionally, you need to treat pipe bends, fittings and other parts where pieces of ice could remain.

This method is great for dealing with the problem if you can reach the pipes. If the water supply is underground, then you need to use a different method.

Hose and hot water

A rather specific way to heat the water supply, but effective if you can’t get to the pipes any other way. You need to insert a thin rubber hose into the water supply to the very place where the ice plug has formed.

Then you need to pour water into the hose, and it will melt the ice with temperature. The water tap is opened to allow water to flow normally. It will be convenient to work if you insert a watering can into the end of the hose where you will pour water.

This way, the water will fill in faster, and it will completely reach the blockage. As you can see, it’s quite easy to deal with frozen water pipes on your own.