Sooner or later the time comes when you have to change the batteries. It doesn’t matter if general repairs are being carried out in the apartment, updating the interior or replacing broken elements of the heating system. Any of these situations lead some people to a dead end. If previously the domestic market was not famous for the abundance of choice of heating elements and offered only cast iron radiators, now when visiting a hardware store, your eyes literally run wide. The choice of devices is now very wide, and you want to purchase the highest quality and most durable product. In order to accurately determine which heating radiators are better, cast iron or bimetallic, you need to compare their main functions and characteristics.

Which heating radiators are better?

What criteria should be considered when choosing heating batteries?

Why are only bimetal and cast iron considered? Products made from them meet more user requirements. To decide which of them will work better and last longer, you will have to compare their qualities.

- Price. For some, this moment is unimportant. Unfortunately, for most of the population of our country it is one of the most important. Many people, coming to the store to make a long-awaited purchase, first of all pay attention to the price, and only then to the technical characteristics and appearance of the products.

- Lifetime. Since heating batteries are stationary elements, you want them to last a long time and work flawlessly. And after a couple of seasons, there was no need to dismantle, buy new products, and install batteries from scratch, while performing all the dirty and difficult processes.

- Heat dissipation. In order for the battery to perform its functions as well as possible, it must deliver the maximum amount of energy it receives from the coolant. Products with better heat transfer rates heat the room faster to the desired temperature.

Heat transfer of cast iron and bimetallic radiators.

- Durability, the ability to withstand high pressure and withstand pressure changes. To prevent the radiator from leaking, it must be able to withstand water hammer and be resistant to various types of mechanical stress.

- Difficult to install. The more difficult the installation, the greater the risk of doing it incorrectly and thereby damaging the battery itself and other elements of the heating system.

- Reaction to bad coolant. The water supplied to the pipes may be of very poor quality. This moment will have a negative impact on heating radiators. Products that are less resistant to the effects of low-quality coolant will last much less.

- Maximum coolant temperature. The water circulating in domestic heating systems is not temperature stable. Therefore, it is very important that the radiator is able to withstand changes.

Criteria for choosing batteries

Features and differences

Aluminum

Radiators made of aluminum are very often used for heating systems in private houses due to their modern design and high heat transfer. You can choose radiators to suit every taste. Products from Russian manufacturers are cheaper than batteries from foreign suppliers.

When choosing aluminum heaters, the following conditions must be met:

- It is important to maintain a low level of water acidity, since aluminum radiators are sensitive to the parameters of the liquid circulating in them. At high levels of negative substances, they can collapse within a few years.

- Warm air in such heating devices rises quickly, often causing a sharp temperature difference between the ceiling and the floor. You need to have an accurate calculation of the area of the room, otherwise the floor may be cold even if the climate in the room as a whole is quite hot.

Service life

In this category, cast iron leads by a huge margin. This fact does not even require confirmation. It’s worth remembering what types of radiators were popular in the last century and everything will become clear. Cast iron batteries in many apartments serve faithfully for 30-50 years. And in ancient houses, heating elements that are more than a hundred years old still exist and operate.

Cast iron radiators

The service life of bimetallic batteries of sectional structures is 15-20 years, monolithic type devices are 25 years.

Bimetallic batteries

Manufacturers provide a 50-year guarantee on modern cast iron products. Of course, you need to regularly and promptly carry out their maintenance, periodically wash them and care for them properly.

Models of modern cast iron radiators.

Heat dissipation

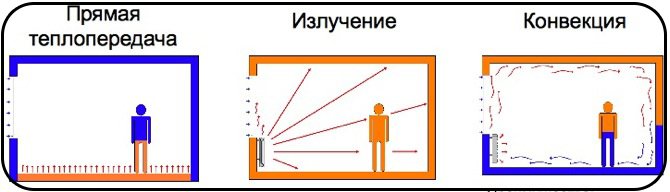

In this category, both materials have both pros and cons. The main disadvantage of cast iron is that it takes a very long time to heat up. But this is compensated by the fact that it also cools down over a long period of time. The advantage of such batteries is that they heat the room using the thermal convection method, as well as by radiation. A cast iron radiator transfers heat to all neighboring objects. One section of the cast iron structure produces power from 100 to 160 watts.

Room heating process

As for bimetallic batteries, their heat transfer rates are also high. They heat up almost instantly, but also cool down just as quickly. The heat transfer power of one section of a bimetallic radiator is higher than that shown by cast iron devices. It is 150-200 watts.

Therefore, in order to choose the right radiator, you must first take into account the characteristics of the room in which you plan to install it. If there are no problems with the supply of coolant in the house, the process is carried out stably without interruptions, then it is advisable to install bimetallic batteries.

Heat transfer of cast iron radiators

Now let's talk about the heat transfer of cast iron radiators. While waiting for them to heat up, you can turn into ice, but they also take a long time to cool down, which in turn is good if the heating is suddenly turned off. Unlike cast iron, bimetallic batteries heat up quite quickly. Although, just as they heat up quickly, they cool down instantly. Although the heating of rooms in which bimetallic batteries are installed is much faster.

If the water treatment of the boiler room has not been carried out, the pressure in the heating system is unstable. Boiler house workers turn on the pumps abruptly, which leads to water hammer, causing radiators to burst. Therefore, you need to choose radiators that have large pressure reserves.

A significant disadvantage of the heating system is the unknown composition of the coolant. The water supplied to the batteries is not clean and also has an unknown composition. There are small pebbles and sand in it, which exerts its influence on the walls of the batteries.

Cast iron is not afraid of either alkalis or acids that may be in hot water. After draining the water at the end of the heating season, the batteries are not afraid of rust. The same cannot be said about bimetallic batteries. They have the same resistance to the chemical composition of water as cast iron ones, but after draining the water, the steel rod may rust. Thus, in this regard, bimetal is inferior to cast iron.

Durability, ability to withstand high pressure and withstand pressure changes

The pressure in most central heating systems of multi-storey buildings is traditionally not stable. This is often influenced by the technical condition, and sometimes by the negligence of workers. According to the rules, the taps of circulation pumps must open slowly and smoothly. Many people neglect this and abruptly turn off the water supply. This can cause water hammer to occur. As a result, batteries installed in apartments burst due to an immediate increase in pressure. In this regard, it is necessary to choose devices that can withstand heavy loads.

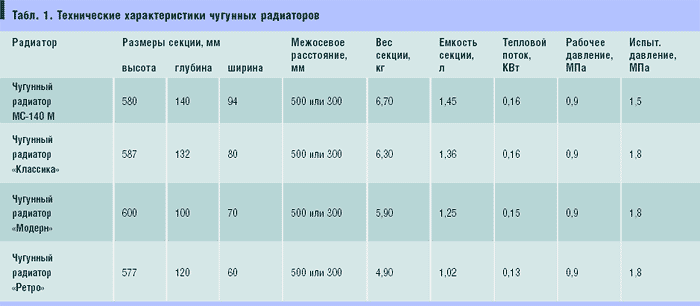

Cast iron is a strong material, but at the same time non-ductile and brittle. Therefore, with a sharp increase in load, it may burst. With stable pressure, cast iron products can withstand 9-12 atmospheres without problems.

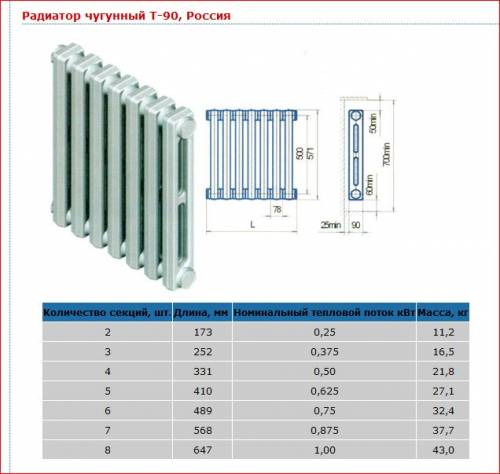

Technical characteristics of cast iron radiators.

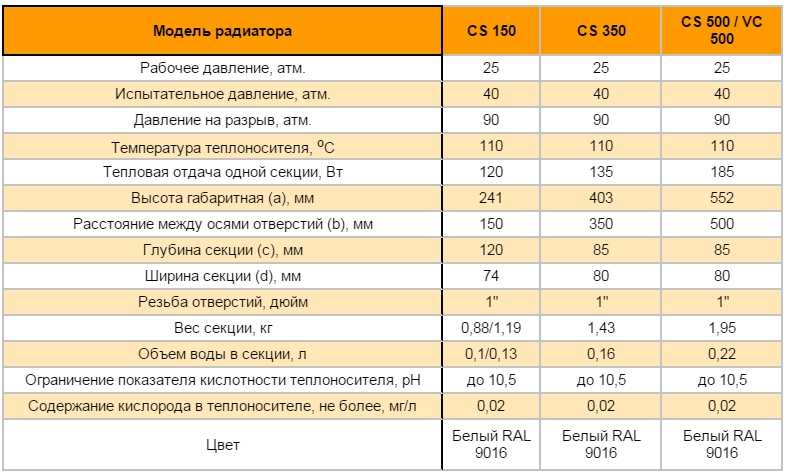

Bimetallic radiators have significantly higher performance. Sectional devices, according to manufacturers, can withstand pressure from 25 to 50 atmospheres, depending on the model. This allows them to withstand high-power water hammer without losing their characteristics. Monolithic bimetallic radiators have even more impressive performance. The non-separable design and steel inner core give the product enormous strength. For such devices, a pressure of 100 atmospheres does not create any problems.

Technical characteristics of bimetallic batteries

Taking into account the described facts, we can conclude that bimetal is much better in this regard.

Distinctive characteristics

Let's start with the simplest thing, with the shape of the product.

The appearance of modern aluminum batteries is extremely successful from an aesthetic point of view.

Diagram of technical characteristics of a cast iron radiator.

They fit well into the interior of rooms of different styles and designs. Unlike cast iron batteries, they have a very flat and smooth surface and invisible section transitions. As for threaded connections, cast iron batteries lose in that:

- Cast iron threads are more fragile. As a result, it is more brittle than steel fittings for aluminum batteries.

- Cast iron radiators have two thread directions (left and right), which in itself can be confusing and lead to thread breakage or destruction of the threaded entry.

- On aluminum batteries, fittings have finer threads than cast iron plugs and do not require additional sealing of the connection.

- Cast iron batteries do not have the most reliable and easy-to-install system for connecting individual sections.

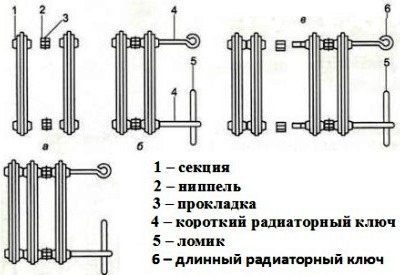

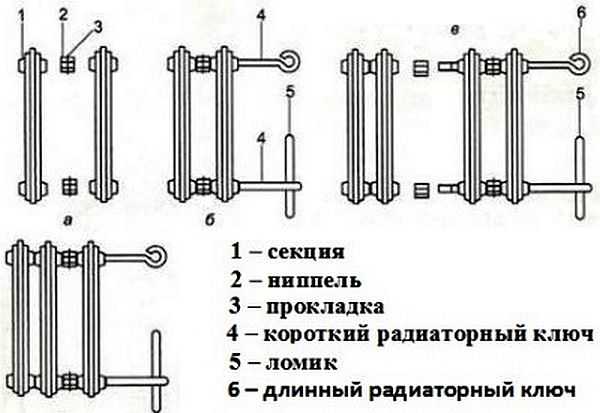

Technology for unscrewing and assembling cast iron batteries: a – nipples capture the threads of sections (2-3 threads); b – tighten the nipples, join the sections; c – install the third section; d – two radiators are grouped.

Modern cast iron radiators, like several years ago, are equipped with Mayevsky taps, which have already outlived their usefulness as an engineering solution. Aluminum, on the contrary, have a more progressive air exhaust system, and an automatic system. This system is based on the action of a membrane-type check valve, which can only release air, but not let it in.

The battery installation technology is almost the same. Holders must be installed under both aluminum and cast iron. But it’s still easier to put the battery in place with an aluminum one. Largely due to the weight, which is significantly less compared to cast iron products.

To install aluminum or cast iron batteries, you will need:

- taps;

- fitting;

- roulette;

- marker,

- level;

- square;

- a set of keys, including an adjustable one;

- clamps;

- pliers;

- drill;

- dowels, screws;

- brackets.

Aluminum radiator design.

When comparing the materials from which batteries are made, it should be noted that in terms of mechanical properties, cast iron is much stronger, but aluminum is softer. That is, aluminum radiators do not have the fragility that is inherent in high-carbon alloys.

The principle of operation of batteries is, of course, the same, but the trick is that the nature of their functioning is very different. A high-quality, good aluminum battery heats up very quickly (this is definitely a plus). It also cools down quickly, giving off maximum heat per unit of time (this is also a plus). At the same time, it contains a smaller amount of coolant (this is another plus).

All three advantages together give one significant disadvantage - the exhausting rhythm of operation of the boiler and boiler equipment. Cast iron batteries take longer to heat up and reluctantly give off heat, but they are able to maintain the accumulated temperature for a long time and release it to the surrounding space.

Difficulty of installation

Bimetallic batteries are lighter than similar cast iron products. Accordingly, moving them to the desired location and installing them yourself will not be difficult. They can be mounted on any wall. Both concrete and drywall can easily withstand the low weight of bimetallic batteries.

Difficulty installing cast iron batteries

Cast iron radiators are quite heavy. It is very difficult to wear them yourself, and with large sizes it is impossible to do without an assistant. As for installation, the option with drywall should be discarded immediately. They are mounted only on strong walls using special brackets that can withstand the enormous weight of cast iron.

If you purchased the cheapest version of the radiator, you will still need to do painting and broaching.

Assembly (broaching) of cast iron heating radiators

The conclusion is obvious. In terms of ease of installation, bimetallic devices are much better.

Reaction to bad coolant

Cast iron performs better in terms of endurance and resistance to the effects of low-quality coolant. It is a neutral metal and does not react with the liquid flowing through the pipes.

Debris and dirt in the radiator

The presence of small pebbles, rust, chemical elements and scale in the coolant causes slight damage to the internal walls of the batteries. Under their influence, the radiators slowly wear out in the middle. But this happens so slowly and insignificantly that it is not a problem for thick radiator walls.

Bimetallic batteries also react calmly to the composition of water. A more detrimental effect is exerted by the air that enters the products after the heating season ends and the liquid is drained from the system. Steel cores are susceptible to corrosion.

Corrosion inside bimetallic radiators

Design, principle of operation of aluminum radiators

Aluminum radiators are a complex-shaped structure based on aluminum tubes through which coolant flows from the heating system. Heat transfer plates are attached to the tubes. The shape allows the thermal energy received from the system to be radiated and heat to be transferred by air convection between the radiator plates.

Calling home heating batteries aluminum is not entirely correct; they are made not of pure metal, but of an alloy with a number of substances. The most common component is silicon.

Batteries for apartment and house heating systems made of aluminum alloy are made in two ways:

- Casting is a complex, labor-intensive method. Batteries are more expensive, but of better quality. The service life of the system is at least 15 years.

- Extrusion. The method is reminiscent of squeezing cream from a culinary cone into a mold. It is technologically simpler and therefore is used by manufacturers from Far Eastern countries. Heating batteries are quite cheap and look little different from injection molded ones. The downside is the poor quality of the walls and seams. The service life of batteries as part of the heating system does not exceed 10 years. They often fail after 2-3 heating seasons.

Some manufacturers apply electrochemical anodizing to the inner walls of radiators. Radiators are less susceptible to corrosion, the amount of hydrogen released from water is reduced (the anti-air vent cannot be excluded from the battery piping).

The number of sections made of aluminum alloys is usually even. They are connected by nipple adapters and integrated into the heating system using threaded connections. The flow of water is somewhat difficult. There are completely cast non-dismountable battery models. The number of sections cannot be changed. They are distinguished by a smooth inner surface, which simplifies the flow of coolant from the apartment or home heating system (often anodized).

Home heating battery made of aluminum alloys FONDITAL CALIDOR 500-100 B4

Maximum coolant temperature

Which radiators withstand temperature changes in unstable domestic heating systems better? Both types of devices are almost equally good here. They are able to withstand critical indicators without problems. Of course, if the liquid in the heating system heats up to a temperature of 110 degrees or more, then it is better to install bimetallic batteries, because this is precisely the indicator that cast iron devices have.

Heat transfer table for heating radiators

Bimetal is able to operate uninterruptedly when exposed to coolant heated to 130 degrees. The only caveat is that under the influence of high temperatures, the steel cores expand and put pressure on the aluminum elements. As a result, a slight crackling sound may be heard from the radiator. But this does not affect the operation, integrity and service life in any way.

Main advantages

The temperature of the water in the batteries is also not always stable, sometimes it’s barely warm, sometimes it’s very hot, so if you hold the battery you can get burned. Cast iron batteries can withstand up to 110 degrees, while bimetallic ones are rated up to 130 degrees. Therefore, both types of radiators tolerate temperature fluctuations well.

The service life of cast iron radiators is significantly longer than bimetallic ones. They will last more than 50 years. At that time, bimetallic batteries will last no more than 20 years. In this regard, cast iron takes precedence among radiators.

In installation, bimetallic batteries win. Still, the weight of cast iron radiators is very large, a plasterboard wall will not support it, and reinforced fastenings are needed. Working with bimetallic radiators is a pleasure. They are lightweight and can be installed by even one person. Therefore, in ease of installation, bimetal takes the lead.

Prices for cast iron batteries differ significantly from bimetallic ones. Cast iron is much cheaper than bimetal. However, if the model is made in retro style, then the price for such radiators will be high.

Now we can decide which batteries you need, cast iron or bimetallic. Cast iron radiators are well suited for five-story buildings, since the pressure in such houses is not very high. However, if possible, it is better to install bimetal. Residents of high-rise buildings are better off installing bimetallic batteries due to the high pressure in the heating system. In any case, bimetal is more efficient than cast iron.

Conclusions and recommendations of experts

After comparing cast iron and bimetallic heating radiators, you will still have to make a choice directly. When purchasing a radiator, you need to take into account the characteristics of the device, the assessment of the room and other aspects. The correctness of the choice will determine how well and how long the heating system will work.

Cast iron heating radiators

By many criteria, bimetallic radiators win. But if you want to save money, make sure that there are no water hammers in the house and feel free to buy cast iron devices. They can be installed in apartment buildings that have no more than five floors. If the number of floors exceeds 5, then it is not recommended to take risks. Devices made of bimetal should be installed.