Today there are many types of heating systems, each has its own advantages and disadvantages, features and connection principles, but all have one requirement - high-quality work. The quality and efficiency of the heating system plays an important role for every home. During the development of the system, one should also take into account which heating batteries will be used in it.

For example, owners of private houses with economical autonomous heating today are increasingly choosing inexpensive German-made KERMI steel panel radiators. And in order to reduce the cost of organizing a heating system, homeowners often install radiators themselves.

Connecting heating batteries without the help of specialists is the most common method to save money. Modern heating equipment comes complete with detailed instructions, following which you can quickly and efficiently connect the devices yourself. Most often, even those who have never encountered installing radiators can easily cope with the job. In this article we will look at the most popular methods of connecting steel radiators.

Principles for connecting steel batteries

Lateral connection.

The most popular is the classic lateral connection, passing through the following path: the supply pipe is connected to the upper branch pipe, the pipe through which the “return” passes is connected to the lower branch pipe. Both pipes are parallel to each other on one side.

This principle allows you to achieve maximum effect from the operation of the heat supply system. Maximum heat transfer is the main advantage of this method.

Steel radiators with a side connection type have prices slightly lower than models with similar technical characteristics with bottom connections.

Advantages of Kermi steel radiators

Despite the fact that a cast iron radiator has a much larger mass, the thermal capacity and inertia of a Kermi steel radiator are better. Comparisons of these characteristics were carried out under the conditions of a modern heating pipeline, the coolant of which has far from the most stable performance and not the most constant chemical composition.

The device must respond as quickly as possible to changes in the thermal characteristics of a two-pipe heating system, which means it must gain temperature very quickly and not have excess heat loss when the coolant supply stops. Kermi radiators whose technical characteristics are very flexible, and in this regard confirm their convincingness.

Bottom connection of radiators.

If you plan to organize a system with bottom wiring, in which pipes pass under the floor or baseboards. It is believed that this method is the most aesthetic, since it allows you to hide from

from prying eyes all pipes leading to heating devices.

For a system with such wiring, it is necessary to buy radiators with a bottom connection type, in which the pipes are routed from the bottom of the structure. The cost of such models depends on the power and manufacturer; the German manufacturer of heating equipment offers high-quality steel radiators KERMI FKV (FTV) with a bottom connection that are affordable for most Russians.

This connection principle is becoming increasingly popular today due to its aesthetics. However, considering it from the point of view of practicality, it can be emphasized that in comparison with the classical method there is a decrease in heat transfer rates.

Types of steel radiators

Based on the type of execution, they are divided into several varieties.

Panel type

The body of such a radiator contains several panels (from one to three), each of which is a pair of plates welded along the contour. This principle of the device allows you to assemble heating radiators of any size and power according to the size of the room and the thermal resistance of walls, doors and windows.

Panel batteries are sensitive to water hammer and are designed for low operating pressure, therefore they are recommended for installation in private or low-rise buildings.

The popularity is due to its affordable cost, impressive design (many models are equipped with decorative elements) and low inertia, which allows you to quickly adjust the room temperature when installing a thermostatic head.

Tubular

Tubular heating radiators

The heating device is a set of thin steel tubes welded together.

There are no hard-to-reach places in this radiator, so it is easier than others to maintain in a perfectly clean condition.

This feature makes the tubular radiator most suitable for medical institutions, as well as rooms with large crowds of people.

Devices of this type are designed for medium-range operating pressures.

Sectional type

The most durable type of steel radiators. They are able to withstand maximum operating pressure.

According to the principle of the device and in appearance, they are very similar to ordinary cast-iron batteries, which are installed in most Soviet-built houses.

Not only the sections themselves are characterized by high strength, but also their joints, since spot welding is used in the production of radiators.

Call a specialist to install radiators in Moscow inexpensively

Naturally, no homeowner without experience in this matter can do the work of organizing a home heating system better than a professional. Therefore, many immediately decide to transfer the issue of organizing the system, purchasing heating devices and connecting them to a specialist who knows a lot about this and has considerable experience behind him.

The question of how much it costs to install radiators is of interest to many homeowners; on the Internet there are many advertisements of private craftsmen offering the service quite cheaply, but you should not trust the task to the first person you meet. Firstly, the master may not be qualified enough, and secondly, you can fall for scammers and lose money.

Therefore, it is better to call a plumber working in a specialized company, for example, our online store offers related services: delivery and installation of radiators. Our specialists have been working in this field for a long time, have experience, certificates confirming their qualifications, and also provide a guarantee for the work performed.

The installation of radiators is carried out by a specialist on a day convenient for you; the specialist brings all the necessary tools with him, so you do not need to look for or rent a drill and other tools necessary to connect the batteries.

The cost of installation depends on the number of radiators and the complexity of the work, in general it is inexpensive, the visit of a specialist is included in the price.

Volume of Kermi radiators

For centralized heating, in principle, the volume of the radiator is not decisive, unlike systems for autonomous or private heating of an individual house. But in this case, the cast iron 12-section battery 2KP60 has a heat output of 1444 W, and an internal volume of 13 liters. The cast iron heating battery MC140 has a heat output of 1925 W with a volume of 18 liters. The technical characteristics of the Kermi battery show that with a volume of 6.3 liters, one section has an effective heat transfer of at least 2100 W, as stated in the passport. As we see, in this regard, Kermi steel batteries have a double advantage.

A larger volume of coolant in the system leads to large heat losses both in the pipeline and in other elements of the system, and this is inevitable unless you carefully insulate the entire system and use modern pipe materials. Also, an increase in the volume of the heating system affects the pumping equipment, which operates under high load, naturally, with a shorter resource and less productivity, which decreases as the system is used. When using a Kermi steel radiator, to obtain the same amount of heat as a cast iron system, three times more coolant must be passed through the pipes. Another benefit provided by the technical characteristics of Kermi steel radiators.

Design Features

The design of Kermi FTV 22 steel radiators includes two panels with U-shaped fins between them. The installation depth is 100 mm.

For the manufacture of all elements of the heating device, high-quality steel with an anti-corrosion coating is used. To prevent the accumulation of contaminants, the inner surface is subjected to special treatment. High strength of the coating is achieved through the use of high-temperature heating.

This model of panel radiators provides a bottom connection. Pipes supplying energy can be hidden in the floor, baseboard or wall, which makes the design of the heating system more aesthetically pleasing.

The panels are made of profiled sheet steel and the channels are fastened using electric arc spot welding. The perimeter of the structure is connected with a continuous or roller seam. The use of this technology allows us to achieve a high level of strength and tightness of the seam. The quality of the welded joint is controlled by testing under a certain load under conditions corresponding to pressure testing of the heating system.

Review of Kermi Type 22 radiators

To create warmth and comfort in their home, many choose Kermi brand radiators. This is a German company that has been producing various models of steel panel heating radiators for more than half a century. Despite their compactness, they have excellent heat transfer performance. And the attractive appearance allows the batteries to fit into any modern interior.

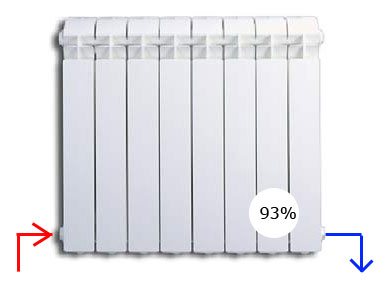

The most popular model is Kermi 22 500 500 . The device consists of two steel panels, between them there are two convectors, which are made in the form of a U-shaped fin. A distinctive feature is the use of the unique Kermi Therm x2 technology in the manufacture of batteries. Thanks to the special design, the coolant first enters the front panel, so that the air in the room is heated first. The back panel heats up later and acts as a screen.

By the way, before the introduction of the Therm x2 innovation, Kermi radiators with bottom connections had the abbreviation FKV, but they have already been discontinued.

Technical characteristics of Kermi 22 type :

- The maximum coolant temperature is 110 degrees Celsius.

- Power depends on size. With a temperature range of 90/70/20 and dimensions of 500x500, the power of Kermi 22 radiators is 965 W.

- Working pressure – 10 atmospheres.

- The maximum testing pressure is 13 atmospheres.

- Thickness – 100 mm.

- Height – from 200 to 900 mm.

- Width – from 400 to 3,000 mm.

- Center distance - for FKO you need to subtract 54 mm from the height, for example for the Kermi 22 500 500 Radiator this value will be 500 mm - 54 mm = 446 mm; for FTV the distance between the tubes is 50 mm.

- Standard color – white Kermi RAL 9016

Depending on the type of connection, there are two options.

1. Radiators

Kermi FKO 22 .

These are models with side connections; pipes are connected to the left or right. 2. Radiators Kermi FTV 22 . Batteries with bottom connection. The advantage over FKO 22 is the ability to hide pipes in the floor or under the baseboard. Due to the increased complexity of manufacturing these devices, as well as their high aesthetic qualities, the cost of Kermi FTV is higher.

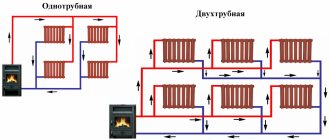

Regardless of the connection type, the Kermi Type 22 steel radiator is recommended for installation in closed heating systems. In this case, circulation can be natural or forced, the system is one- or two-pipe.

The purchase package of the device includes a plug, a Mayevsky valve - a valve for bleeding air, and a set of wall mountings. radiators with bottom connection have a built-in thermostatic valve, which allows you to install equipment to regulate the air temperature in the room.

Kermi panel radiators have an advantage over their analogues - they are coated with iron phosphate and two layers of varnish. This treatment significantly increases the service life!

Externally, the radiator looks modern and stylish. It will not only warm your home, but will also become a stylish part of the interior. A perfectly white surface is a varnish coating that, when heated, does not release toxic substances into the air. The radiator is covered with solid panels on the sides and a grille on top.

Manufacturers

The entire company specializes in the production of steel panel-type radiators and other equipment for heating systems.

Kermi (Germany)

Company `s logo

In their design, Kermi panel batteries are almost no different from conventional ones: their panels consist of two connected plates with a cavity between them, through which the coolant circulates.

But, despite the apparent simplicity of the device, in terms of heat transfer they are 10% - 40% ahead of similar products from competitors.

The superiority is due to Kermi's own development - Therm X2 technology.

Devices of this brand are intended for use in small closed-type heating systems with forced circulation of coolant (learn more). They are universal: they allow connection to both a single-pipe circuit and a two-pipe circuit.

To protect against corrosion, the component parts of the panels are coated with a double layer of varnish.

All Kermi radiators are divided into two types: FKO (modification with bottom connection) and FKV (with side connection). Depending on the area of the heated room, you can choose a model from one of five available sizes.

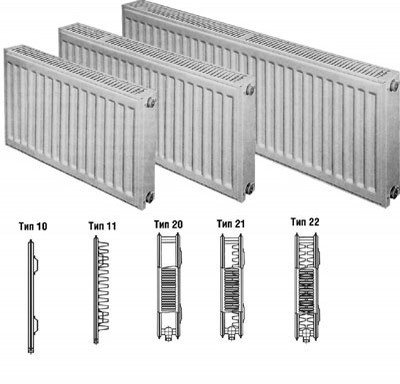

Each standard size differs from the others in depth and number of panels:

- sizes 10, 11 and 12 consist of one panel and one layer of grid;

- size 22 – made of two panels and two layers of lattice;

- standard size 33 – three panels and grilles.

As the standard size increases, the heat transfer power also changes:

- from 300 W - for the smallest;

- up to several kilowatts - for larger ones.

Kermi Products:

Korado (Czech Republic)

Company `s logo

This successful company also relied on the production of well-proven steel panel batteries .

For the production of products, steel with a thickness of 1.25 mm is used.

The devices can be installed in one- and two-pipe heating circuits with forced (closed type) and natural (open type) coolant circulation.

Korado products are presented in four series:

Radik Hygiene

Radik Klasik

Radik Plan

Radik Ventel Kompakt

A characteristic feature of each series is the method of connecting the radiators included in it:

- models of the Radik Klasik and Radik Hygiene series are connected from the side;

- models of the Radik Ventel Kompakt series – from below;

- models of the Radik Plan and Ventel Kompakt series – from below and from the side.

Within each series, the models differ in the design of the outer surface (flat or embossed) and standard size.

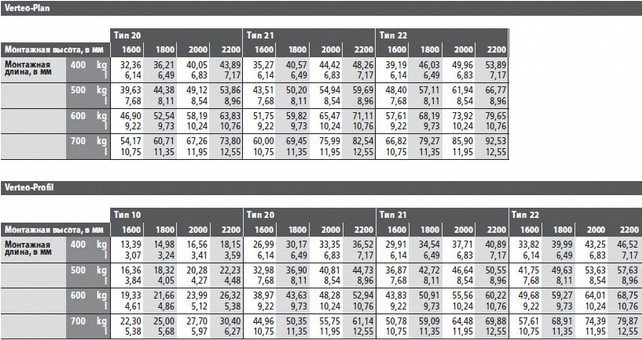

The standard size implies the number of panels, the depth of the radiator and its heat transfer power:

- on models with standard sizes 10 and 11, one heat exchanger is installed;

- on models with standard sizes 20, 21 and 22 – two heat exchangers;

- on the most powerful models with size 33, three panels are installed.

In terms of their structure, devices from the Radik Klasik and Radik Hygiene series are almost the same, but the latter are designed so as not to have places that are difficult to clean. This modification was developed for use in medical institutions and public buildings.

Purmo (Finland)

Company `s logo

For the manufacture of most Finnish panel-type models, cold-rolled 1.25 mm steel is used, but in some varieties material 2 mm thick is used.

As anti-corrosion protection, radiators are painted by cataphoresis followed by application of epoxy paint (RAL 9016). Despite this, it is not recommended to install the devices in rooms with high humidity and connect them to open heating systems without additional corrosion protection.

The design of all Purmo radiators allows connection to both a single-pipe Leningrad and a two-pipe heating system.

Purmo products are presented in five variations:

Ventil Hygiene PV

Compact C

Hygiene P

Planora Plan DF

Ventil Compact VKO

- pPurmo Compact C is designed for lateral connection.

- Purmo Ventil Compact VKO is designed for side or bottom connection and is equipped with a thermostatic regulator.

- Purmo Hygiene P is connected from the side and is characterized by the absence of convection elements.

- Purmo Ventil Hygiene PV also does not have convection elements, but is equipped with a thermostatic regulator and can be connected both from the side and from the bottom.

- Purmo Planora Plan DF has side and bottom connections and features a smooth radiator screen, which is a better design solution.

The geometric parameters of various models vary over a wide range.

When operating heating systems with Purmo radiators, it is necessary to ensure that coolant losses do not exceed 10% of the volume . Complete emptying of the radiator is also not allowed.

Before repairs, the coolant is drained only from the area of the system where work is planned. The remainder of the outline should remain filled.