Classic chimneys are gradually losing their popularity and fading into the background; their place is rightfully occupied by ceramic chimneys, which perfectly combine all the main advantages and capabilities of all channels. Particular attention is paid to ceramic chimneys when it is necessary to remove high-temperature gases, for example, for classic solid fuel boilers. Next, we will analyze in detail not only the features of the installation, but also the significant positive aspects of smoke exhaust devices.

Application of ceramic chimneys

Chimneys made of ceramics have found their field of application, which requires not only resistance to high temperatures, but also anti-corrosion resistance to chemicals. So, the main areas of use for:

- Kaminov.

- Furnaces.

- Boilers (coal, wood, gas).

- Liquid fuel boilers.

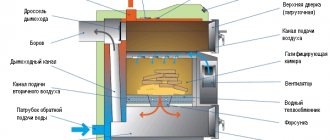

In addition to pipes that are designed to exhaust gases with temperatures above 300 degrees, there is also a separate group of channels where the maximum temperature does not exceed 200. These are the so-called low-temperature boilers, where the installation of ceramics is allowed with a temperature threshold of no more than 200 degrees.

Ceramic chimney after installation is completed

OFFEN O-BLOCK systems

The OFFEN O-BLOCK system consists of components of the HART MKR, HART KLR, HART AT systems + non-flammable thermal insulation + outer shell made of YTONG aerated concrete of various modifications. The distance between the ceramic chimney and the outer shell is filled with a layer of thermal insulation made of high-density basalt fiber, which forms continuous protection from the temperature of load-bearing structures and ceilings, including those made of combustible materials. Thus, we obtain a significant reduction in the distance - only 50 mm, to combustible materials, even under very difficult operating conditions, such as soot fire and constant condensation formation. The use of various components allows you to create universal systems. Arrangement of chimneys for one, two or even three heat sources is not a problem! Need ventilation ducts - easy!

More about OFFEN O-BLOCK

Advantages and disadvantages

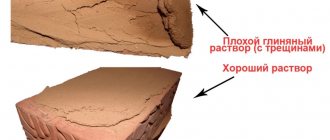

A ceramic chimney is made from specially treated clay, so-called refractory. It meets the following characteristics. So, the positive aspects:

- Resistant to changes and high temperatures.

- Low susceptibility to corrosion.

- Durable, the density is such that it simply does not allow exhaust gases, even some time after work, to enter the room.

- Thermal conductivity.

- An extremely low threshold for the formation of growths and deposits of soot and soot, due to which less attention is required to cleaning the channels.

- Easy to install.

- High wear resistance.

As for the negative aspects, only three factors can be mentioned:

- Of course there is a cost.

- Ceramic chimneys are quite heavy, which will therefore require a reliable foundation.

- Installation is carried out only vertically.

Installation procedure

In order to find out the nuances of installing a chimney from ceramic pipes, the process needs to be considered in detail.

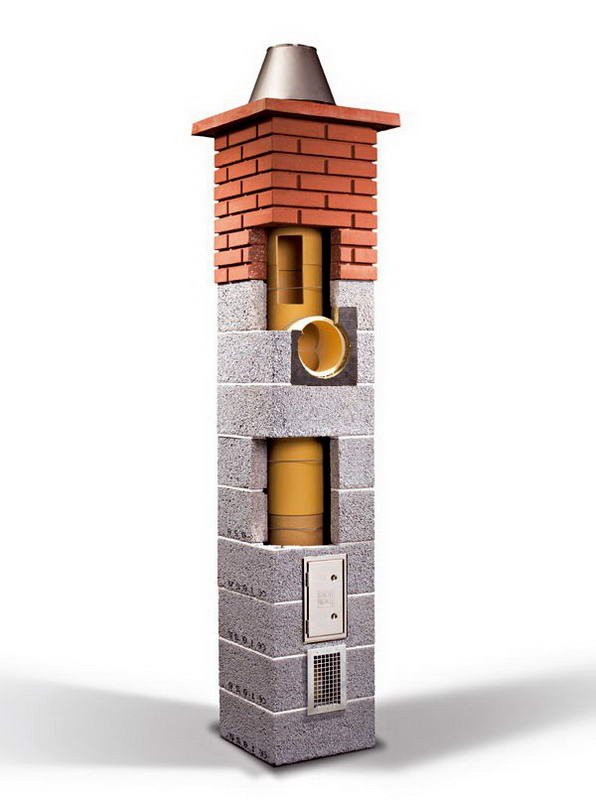

- First, the base is prepared. Here it is necessary to emphasize that due to the impressive weight of the entire structure, its installation will require its own foundation. To do this, the floor at the installation site is dismantled, and the place needed to install the chimney is filled with cement mixture and leveled. For greater strength, the screed is reinforced with metal reinforcement.

- After the foundation has hardened, it must be covered with a layer of waterproofing.

- Then the main expanded clay concrete block is installed, into which containers are installed so that the condensate formed during the operation of the chimney flows inside without destroying the structural elements.

- The first elements of a ceramic pipe are installed inside the block, equipped with special inspection holes to allow maintenance of the chimney.

- Between the outer surface of the ceramic pipe and the inner surface of the blocks, a layer of basalt wool is laid, which will be used to ensure thermal insulation of the chimney.

- Then, all subsequent blocks and parts of the pipe are laid in a similar manner. The blocks are connected to each other using cement mortar, and the pipe elements are sealed with heat-resistant sealant.

- Where the chimney passes through the roof surface, additional waterproofing must be done.

- At the end of the work, the part of the chimney protruding above the roof plane must be equipped with a special protective casing. On its part, a protective umbrella is additionally mounted to it, protecting the chimney from mechanical contamination and precipitation.

At this point, the main work on installing a chimney made of ceramic pipes can be considered completed. As can be seen from the material presented above, the implementation of the plan is not an easy task, but with proper preparation and the presence of certain experience, it is fully possible for independent implementation.

Requirements for ceramic chimneys

A ceramic chimney pipe must comply with certain operating rules, which are prescribed in the building codes for the use of such material. Attention to these rules and regulations must be paid, otherwise, due to non-compliance with certain points, the system of operation and outflow of gases may be disrupted, which will lead to the destruction of the seams and the release of exhaust gases into the room. Everyone understands perfectly well what such problems threaten. Therefore, we list the basic requirements for expanded clay concrete blocks:

- They must be raised above the roof (flat) by at least 1.20 - 1.25 cm.

- The elevation above the parapet, ridge, is at least 50 cm.

- It is prohibited to install the pipe below the ridge mark.

- It is prohibited to place below the ridge and at an angle of more than 10 degrees.

- The minimum height calculated for such a pipe should be 5 meters; the section from the grate to the top is taken into account.

In addition, do not forget about the most important rule prescribed in SNiPs. Namely, the diameter, the cross-section of the pipe itself cannot be larger or smaller than the outlet of the pipe.

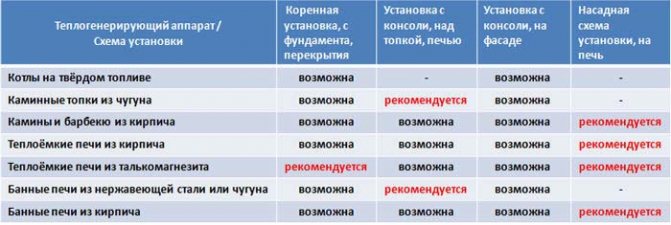

Scope of application and installation diagrams of ceramic chimneys

Design

The ceramic chimney is a three-layer structure. The ceramic pipe is assembled from individual circular cross-section elements inside expanded clay concrete hollow blocks. External blocks have a square cross-section.

The external blocks have holes for laying reinforcing reinforcement. The blocks of the outer sections are held together with ordinary mortar.

The space between the outer and inner sections is filled with special fireproof insulation. Typically basalt based insulation is used.

- Ceramic chimneys for fireplaces, unlike their metal counterparts, can only be used if the location of the fireplace does not imply the presence of load-bearing beams above it .

- Chimneys for ceramic stoves can be installed both inside and outside the building. The height of the chimney should not be less than 4 meters.

Installation features

Installation of a ceramic chimney involves several important features. So, keep in mind that you will need to prepare a solid foundation. The “pillow” should be perfectly horizontal and level, without tilting or anything else.

Next, the main work plan:

- The required amount of solution is laid out on the finished “cushion”; in each individual case, calculate it yourself based on the weight of the structure and the diameter of the chimney. So, a module is installed on the solution, which can combine not only a connection pipe to the boiler, but also a special condensate receiver. By the way, do not forget to install a hatch for preventive cleaning with a “cesspool”.

- We are preparing a special solution on which the chimney will “sit.” Keep in mind that it must be resistant to acids. It is necessary to dilute the solution according to the manufacturer’s recommendations, but often rely on a similar calculation: 1 part water to 7 parts powder. In addition, remember that mixing must be done at a temperature not lower than 17-20 degrees, and the solution must be used within 1.5 hours.

- Install the tee module, be sure to coat the area with the solution.

- Install the remaining sections of pipe, but do not forget to put plenty of mortar and level it after shrinkage. By the way, be sure to remove excess mixture from the inner walls.

Assembled ceramic chimney

Important advice: do not place the joints of two different sections in areas of overlap. As you can see, the features of a ceramic pipe are quite acceptable for constructing such a structure yourself. It is important to pay attention to the rules and recommendations given above.

Advantages

Ceramic chimneys of a three-layer design were first used in France in the 1980s; a decade later they covered the American construction market, and came to Russia only in the early 2000s. Russian experts greeted the new product with caution, but after an in-depth study of its performance qualities and testing in winter cold, they came to the conclusion that a ceramic chimney pipe has the following advantages:

- Versatility. Due to high thermal stability and changes in wall thickness, ceramic pipes can withstand temperatures of up to 1000 degrees. Therefore, they are used for stoves, fireplaces and boilers operating on any type of fuel. Especially for low-temperature boilers, pipes with thin walls are produced in which there is no reduction in draft.

- Fire safety. The fireproof qualities of ceramics and the use of insulating material reduce the risk of fire.

- Energy efficiency. Due to the high thermal insulation qualities of ceramics, the pipe does not cool down during operation, thereby maintaining a normal level of draft and saving fuel.

- Durability. The service life of ceramic chimneys declared by manufacturers is 50 years or more. Resistance to corrosion, mold and mildew makes this type of pipe the most durable and easiest to maintain.

- Fast warm-up. Even after a long period of inactivity, with the help of a ceramic chimney you can light a fire and heat the house in a matter of hours.

Assembled ceramic chimney

Assortment of elements for assembling a ceramic chimney

Important! A significant disadvantage of ceramic chimney pipes is their high price. Russian-made models are cheaper than their foreign counterparts, but are not inferior to them in quality. Domestic manufacturers, playing catch-up in this niche of the construction market, focus on adapting products to the conditions of the Russian winter. To do this, they provided additional fasteners for external thermal insulation, increased the length of additional elements, reduced weight and increased the diameter of the pipes.

OFFEN S-BLOCK systems

The OFFEN S-BLOCK system consists of components of the HART MKR, HART KLR, HART AT systems + non-flammable thermal insulation + outer shell made of expanded clay concrete of various modifications. The distance between the ceramic chimney and the outer shell is filled with a layer of thermal insulation made of high-density basalt fiber, which forms continuous protection from the temperature of load-bearing structures and ceilings, including those made of combustible materials. Thus, we obtain a significant reduction in the distance - only 50 mm, to combustible materials, even under very difficult operating conditions, such as soot fire and constant condensation formation. The use of various components allows you to create universal systems. Arrangement of chimneys for one, two or even three heat sources is not a problem! Need ventilation ducts - easy!

More about OFFEN S-BLOCK