Characteristics of corrugated sheets

- Low price of material.

- Simple and quick installation and dismantling process.

- No waste.

- The maximum sheet length is 12 meters.

- Light weight structure. 1 sq. meter weighs 5-8 kg, which allows installation work to be done alone.

- High corrosion resistance due to polymer coating. However, if the protective layer is damaged, this property is lost.

- Durability and safety.

Despite the large number of advantages, there are also disadvantages that reduce the options for using metal profiles.

- There are many color options for corrugated sheeting, but it has a fairly uniform appearance.

- Poor sound insulation. When it rains, there will be a loud sound in the house from falling drops, so additional insulation will be required.

Video instructions will help you choose the right corrugated sheeting and not overpay for it:

Care

- It is most convenient to store a metal profile for a facade on a stand made of boards more than 20 cm thick, which are laid in increments of 50 cm.

- If scratches appear on the surface of the facade, then you need to paint over this area locally using spray paint. Although the galvanized layer will protect the material from rust, with paint it will last much longer.

- If the facade becomes dirty, you can wash it with any detergent, powder, or soap.

Preparation for sheathing

First of all, it is necessary to measure the area that will need to be sheathed.

Finishing of facades with metal profiles occurs using corrugated sheets of the PS-8, PS-10 and PS-20 brands. These types do not have condensate grooves, so they can be used without waste.

PS-20 corrugated sheet for walls

When calculating the amount of material, it is necessary to take into account the installation direction: vertical, horizontal or diagonal. You also need to buy additional elements: corners for doors, window openings, corners of the house, drains for the roof, strips for the plinth, and self-tapping screws.

How to lay corrugated sheets

The finishing of the facade using corrugated sheets is carried out as follows:

Wall corrugated sheeting is often used in the construction of private houses and large industrial buildings. This type of material is used both for external and internal wall decoration.

- First, horizontal waterproofing is performed along the entire perimeter of the foundation. For this, it is convenient to use rolled materials; inexpensive mineral wool is perfect;

- then the guide profile is fixed to the foundation using special anchor bolts;

- vertical posts are mounted into the guide profile, this creates a wall frame;

- then we move on to the installation of vapor barrier, insulation material, and wind protection;

- sheathing with corrugated sheets is carried out in stages, the sheets are attached to the frame posts. This is done using self-tapping screws specially designed for this purpose, equipped with colored heads and rubber gaskets. Such additions protect the sheets from scratches and damage.

In order to properly design all openings (both window and door), corners and drains are used, which must be matched to the color of the corrugated sheeting. Wall sheets can be positioned in different directions: vertical, horizontal, and sometimes they can be arranged diagonally. You can enhance the attractiveness and expressiveness of the facade with the help of additional corner elements.

Due to the light weight of the building material, it is possible to use corrugated sheets on any frames. Self-tapping screws used to attach corrugated sheets to slats must be polymer or galvanized, with rubber gaskets. You should not skimp on them: reliable fastenings are the basis for the durability of the structure.

Installation of a ventilated facade

Finishing the facade with a metal profile is often accompanied by its insulation. In this case, ventilated facade technology is used. Its structure provides a technological gap between the wall and the insulation, which will provide protection from moisture and condensation.

Air circulation will prevent the formation of mold, which will increase the durability and insulating properties of the cladding.

The metal profile facade will consist of several layers:

- Vapor barrier;

- Insulation;

- Wind barrier;

- Frame made of bars or metal profiles;

- Cladding layer.

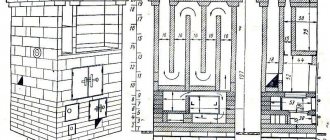

Schematic photo of a facade made of corrugated sheets

Production and sale of corrugated sheets for facade and wall cladding

| The KRONA company is a representative of the plant (production) and sells corrugated sheeting for walls and facades, both galvanized and with a polymer coating of any color, from metal from Russia and Europe from well-known manufacturers: METALLPROFIL (Lobnya), GRAND LINE (GRAND LINE, Obninsk), PROMINTEKH ( Lyubertsy), STEENERZHI (Protvino). In our company you can order and buy corrugated wall, façade, and fence sheeting from a good quality manufacturer wholesale and retail with high trade discounts. The sale of façade corrugated sheets in bulk is carried out by direct shipment from the factory with the possibility of free delivery throughout Moscow and the Moscow region for both private customers and wholesalers, subject to fulfilling factory conditions. Production time in production is 2-3 days, cutting of corrugated sheets is carried out in any lengths required by the buyer from 0.5 m to 12 m. This factory service is free. |

| Warehouse items - galvanized wall corrugated sheets and color-coated polyester of the popular C8 brand in three colors - RAL 8017 (brown), RAL 3005 (burgundy), RAL 6005 (dark green) in sheet lengths of 2 m. The current price of wall corrugated sheets for storage and cutting (ordering) in the production of any other profile is indicated in the price list on the “Prices” page. The full cost of ordering a façade made of corrugated sheets, including self-tapping screws and component strips, can be calculated independently or you can send us a “Calculation Request” |

Our company has its own bending mill and also produces any metal components for roofs, facades and fences - ebbs, slopes, caps, parapets, chimneys, metal strips of any configuration. All these elements can be made of either simple galvanization or metal with a polymer coating of any color. All products manufactured and sold by our Company have quality certificates and written warranty cards issued by the manufacturer.

Photo Types and sizes Colors Accessories

Profiled sheet C8For walls, facade, fence

| Profiled sheet C10For walls, facade, fence

| Profiled sheet S20, MP20For roofing, ceilings, load-bearing

|

Profiled sheet C21For roofing, walls, facade, fence

| Profiled sheet MP35For roofing, walls, facade, fence

| Profiled sheeting NS35For roofing, ceilings, load-bearing

|

Profiled sheet C44For roof, facade, walls

| Profiled sheeting NS44For roofing, ceilings, load-bearing

|

Installation

- Frame diagram for a ventilated facade

Installation work begins with the installation of a frame made of bars or profiles. If you use wooden blocks, be sure to treat them with antiseptics. To create a metal frame, L-, Z-, T-shaped profiles are used, as well as KKU brackets.

- First, brackets are fixed to the wall, and U-shaped profiles are attached to them. Their installation must be carried out level, and care must be taken to maintain an even position vertically and horizontally.

- An auxiliary Z-shaped profile allows air to circulate between the insulation and the cladding. Its pitch depends on the size and load on the wall, as well as the size of the insulation, but it cannot be more than 1 meter.

- When the sheathing is assembled, the installation process continues with the installation of insulation and vapor barrier.

- The insulation sheets are attached to the wall using plastic dowels with a large cap at the end.

To do this, a hole is made through the insulation and concrete. It will be enough to recess the dowel 4 cm into the concrete wall. The dowel is inserted into the hole and a plastic or metal wedge is driven into it with a rubber hammer. Facade dowel - After this, a windproof film is attached to the façade insulation.

- Then the corrugated sheeting is installed. It needs to be screwed onto the profile with self-tapping screws in increments of 30-40 cm.

Advice! We recommend using galvanized self-tapping screws with a rubber gasket to completely prevent moisture from penetrating into the hole. To create a hole, use only a drill with a metal drill bit, no nails or punches!

- To give the house the final look, install additional elements and plinth strips around the perimeter of the corners of the building, windows, doors.

Installation locations for component strips

- If there is no base, the corrugated sheeting can reach the foundation, but in this case it must be perfectly level.

- By the same principle, corrugated sheeting is used for facades and finishing the pediment of a building.

Pediment made of corrugated board

Advice! If necessary, the facade metal profile can be cut using tin scissors, a small hacksaw or a circular saw. Do not use any abrasive tools for cutting.

Profiled sheeting for hangars

In addition to cladding ordinary buildings, corrugated sheets are often used to create hangars. This is simply an ideal material for this, due to the high speed of sheathing.

Such structures are often used as garages, warehouses and production facilities.

Prefabricated hangar

Various types of hangars are created from corrugated sheets:

- Straight-walled;

- Arched;

- Tent.

For cladding, sheets up to 1.2 millimeters thick, coated with a colored polymer coating, are used.

The hangar structure consists of a foundation, supporting frame and cladding. If you need to make a warm room, façade sandwich panels with insulation are used for cladding.

Facade corrugated sheeting: price, characteristics, quality

Wall corrugated sheeting for the facade is made either from simple galvanization (galvanized without a color coating), or in any monochromatic color scheme according to the RAL palette and in colors like wood and stone (wall corrugated board like wood). The service life of profiled sheets for walls, as well as manufacturers’ warranties, depend on many factors and range from 3 to 30 years.

The cost of a façade profiled sheet can vary significantly and depends on a number of values:

- Galvanizing of metal used for manufacturing and rolling. This value is relevant both for galvanized façade corrugated sheets and for profiles with colored polymer coating. Today on the market there is wall corrugated sheeting with low galvanization of 100 and 80 g/m2 - a super economy class product. However, cheap profiles with low galvanization are products for temporary use (usually temporary fences and fences) and are not intended for long-term use. A layer of zinc of a certain density (galvanizing) and a top polymer coating protect the steel sheet from corrosion (rust). Standard galvanizing should not be lower than 140 g/m2, and for some manufacturers it reaches 275 g/m2. The price per sheet and, accordingly, the cost per m2 of wall corrugated sheet with low galvanization is cheaper than rolled metal with standard galvanization, but the service life of metal with low galvanization is much shorter than with standard galvanization.

- • Thickness of the metal from which the corrugated sheet is made. The production of corrugated wall sheets is possible from galvanized metal coils of different thicknesses from 0.35 mm to 0.8 mm. Thin, inexpensive, economy-class facade corrugated sheeting - 0.35 and 0.4 mm, followed by a possible thickness of 0.45 mm, then strictly 0.5 mm, and then 0.55 mm; large thicknesses for facades and walls are used extremely rarely. The thinner the metal, the cheaper any brand of corrugated sheeting.

- Profile height and dimensions. The heights of the wall profile trapezoids play a big role in determining the price, since rolling of higher grades requires more sheet metal per m2. The higher the profile, the more expensive the price per sheet and per square meter. Facade profiled sheet of the C8 brand has the lowest profile (only 8 mm) and is the cheapest option for cladding facades and walls.

- The type and quality of the colored polymer coating directly affects the properties of corrugated sheeting (durability, mechanical stability, color fastness) - polyester, polyurethane, plastisol. A regular galvanized profile for a facade will last less than a profiled sheet with a colored polymer coating. Accordingly, the price of simple galvanization is less than that of polymer products. You can buy wall corrugated sheeting at the best price in the simplest colored polymer coating, polyester; other coatings are not popular for façade cladding, as they have a higher cost.

| Corrugated wall sheeting | Price | Service life |

| Galvanized wall corrugated sheeting | Price from 195 rubles per m2 | from 1 to 15 years |

| Wall corrugated sheeting with painted coating | Price from 211 rubles per m2 | from 5 to 25 years |