It has the largest radiation area; the warm surface is constantly in contact with the inhabitants.

There are no warmer or colder areas in the room; heating is evenly distributed throughout the entire volume. At the same time, a warm floor has its own characteristics - it is a system in which all the constituent elements play an important role. The most important function is performed by the floor covering; it is the surface that directly transfers heat into the atmosphere of the home.

In this respect, the requirements for the coating become exactly the opposite of those for conventional floors, where thermal insulation and thickness are important. Therefore, when choosing this type of heating, you have to make some efforts to organize the correct mode of operation of the system, combining the usual requirements for the coating with those that the heated floor puts forward for itself.

general information

A warm floor is a system of several layers responsible for heating, radiation and cutting off heat loss.

The floor covering, as a surface that releases thermal energy, must be best suited for this task.

This raises a problem: the types of coatings most suitable for heat transfer are only good when the heater is running.

Thus, ceramic tiles, when the heating is turned off, become cold and unpleasant to walk on barefoot. The heated floor system cannot be used constantly; there is no need for it in the warm season. Therefore, a choice of coating is required so that it can be used comfortably throughout the year. In this regard, carpet or rug is the most comfortable covering and has a number of advantages.

The structure of the carpet is a dense base on which the fleecy part (strand) is located. In this case, the decisive factor for determining the suitability of the coating for use on a heated floor is the type of base. For a more unhindered passage of heat, the best choice would be a jute or felt type of base; synthetic or rubber bases are much less suitable for these purposes.

Tile

The coating allows you to add attractive design solutions, of which there are quite a lot, to the comfort and warmth that have already been created. In general, the choice of floor coverings does not cause any particular difficulties, since absolutely any material can be laid on the screed. Porcelain tiles are most often popular in bathrooms, kitchens and hallways. Such a coating for a water-heated floor will be excellent, because it has the best characteristics and has an attractive price and aesthetic properties, so you can choose it if it suits the type of room.

Bathroom tiles

A very high value of a certain indicator is not good, since the cold gets inside the premises very quickly.

All types of ceramic tiles significantly reduce the load on the heating system as a result of overheating of elements without adequate heat transfer. In addition, calories are saved while heat flow is used efficiently. If the load allows, you can use thinner elements, since the thickness of the tile will determine the speed at which it warms up. If we talk about sanitary standards, then there are more flexible indicators for them, in contrast to residential premises.

Related article: Glazing of a balcony in Khrushchev: tips and recommendations

Premises

Carpet is an excellent choice for a child's room. It is soft and reduces the risk of bruises and other injuries that small children are susceptible to. In addition, carpet will create a cozy and comfortable environment in the bedroom or living room. It is not recommended to lay the material in the hallway, kitchen, bathroom or toilet - in all rooms where there is a risk of contamination or wetting of the material.

Reviews and price issue

Most people like to have a soft surface under their feet that they can walk on comfortably barefoot. Therefore, reviews of heated floors are purely positive. Moreover, there is one important detail: floor heating is contraindicated for people with vascular diseases. But carpet, unlike other finishing materials, does not heat up too much, so a person will not experience high temperatures. So with such coverage, sick people do not have to fear exacerbations of their ailments.

You can buy heated floors at any construction supermarket or order them directly from the manufacturer’s dealers. In any case, you need to take only certified products that meet the requirements of GOST. This guarantees the high quality of the product and its compliance with safety standards.

The cost of materials will depend on the manufacturer. In general, the price of heated floors under carpet is approximately 15-17 thousand rubles per room. The cost estimate includes all necessary consumables. But in difficult situations, when additional preparation is required, or the room size is much larger than standard, costs can increase up to 30 thousand rubles.

Laying a warm floor under a carpet with your own hands is not a difficult task. All you need is desire and free time. This approach will save a large amount of money, which can be spent on other repair needs. And doing the work yourself will bring much more pleasure while using the floors. After all, no one will put as much effort into upgrading a home as the owner.

Kinds

Both types of heated floors are suitable for use under carpet.:

- Water.

- Electric.

The design of both types has significant differences, the main of which is the presence of a coolant in water-based structures and self-heating in electric ones.

Water floors are a pipeline with hot water evenly distributed over the floor area. For the normal functioning of water systems, it is necessary to have a connection to communications - central heating or hot water supply systems.

If this is not possible, it is necessary to install a boiler (for example, gas or electric) that heats the water to operating temperature. This means a lot of expense (in addition to the boiler itself, a large number of control devices, wiring, etc. will be required), but it puts the heating system into autonomous mode, which is important.

Electric heated floors are heaters in themselves; they only need to be connected to the power supply system. This greatly simplifies the installation and operation of the system, but problems may arise in the event of a sudden power outage. In winter, this situation means no heating.

Mermen

Water floors can have the following installation types:

- Pouring into a concrete screed. This option ensures smooth and uniform heating; the system has high inertia, which allows it to be turned off for a while without affecting the indoor climate. The disadvantages include the great complexity of repair work - you have to break the entire screed, which is not always possible. It is used on concrete subfloors (slabs) that have sufficient power to bear the additional load from the weight of the screed.

- Laying pipelines on a wooden subfloor without screed (“dry” method). Used on wooden subfloors that are not suitable for excess load. Pipelines are laid either directly on the floor in grooves formed by strips of the same thickness as the pipes (rack system), or in ready-made modules. It is also possible to lay pipes in grooves cut into a layer of expanded polystyrene (EPS), which also serves as additional insulation to prevent unnecessary heating of the subfloor.

Electrical

Electric heated floors have two types of design:

- Cable systems. They are a heating cable laid on a mounting tape or fiberglass mesh with position fixation. It can be a separate cable, or in the form of cable mats - a cable pre-strengthened with a “snake” on a fiberglass mesh, rolled into a roll. This design greatly simplifies installation, since you only need to spread the mats over the required area. The cable system consumes a large amount of electricity, this must be taken into account when planning heating. They can be installed either in a screed or in a “dry” way.

- Infrared systems. The principle of their operation is heating the coating using infrared radiation. There are two types of infrared heaters - the rod type and the more modern film type. Rod systems are ending their use due to the fragility of the structure, causing rapid failure. Film ones are easy to install, effective and reliable, but installation is only possible using a dry method.

Installation of warm film flooring under carpet.

Here are detailed step-by-step instructions for self-installation of a warm film floor under a carpet.

To carry out installation you will need the following materials:

- Film heated floors

- Heat-reflecting material that does not conduct electric current.

- Thermostat.

- A set of additional materials.

- You will also need: pliers, a knife, a soldering iron.

Step one. Preparation.

Carefully level the floor surface. There should be no irregularities protruding more than 3 millimeters per square meter. Then thoroughly clean the surface from dirt and dust.

Step two. Thermal insulation

In order for your floor to retain heat, you need thermal insulation. To do this, take a material based on a cork or foil surface. Be careful that it is not an electrical conductor. Carefully measure it for laying over the entire surface of the room, then cut it and lay it, fastening all the parts together with tape.

Step three. Laying the heating surface.

The infrared film is not placed over the entire area of the heated room. It should be remembered that the film should not be placed in places where bulky furniture without the required ventilation pockets is expected to be installed. You should also maintain ten-centimeter distances from the walls. After laying the film taking into account all the above requirements, cut it in places where there is no graphite coating, and if this is not possible, simply stick insulating tape on all cut points.

Step four. Connection.

At this point, you should install the thermostat. In this case, you should remember a few basic rules. The maximum area on which the thermostat is installed is 15 square meters. The thermostat should be located directly near the wiring. There are two types of thermostat installation: internal and external. The internal type of installation will require you to pre-drill the wall for laying wiring and installing the regulator. The external method will require the installation of a plastic box.

Connect the wires using pliers parallel to the film and secure the copper clamps to the copper conductors of the film. Carefully insulate all connections. For more reliable insulation, fill all joints with silicone sealant. Place the temperature sensor in a pre-made recess under the film. Now it’s worth checking that the connection is correct; to do this, turn on the thermostat for a few minutes. And if everything is done correctly, all parts of your floor will heat up evenly. Check all connections again with a tester. Ground your heated floor using foil tape. To do this, run it diagonally along the entire length of the infrared film, and connect one end to the wire.

Step five. Installation of protective material.

Before actually laying the carpet, you should lay down a layer of protective material. Foamed polyethylene is best suited for these purposes. Lay it in an even layer over the surface of the film, remembering to ensure that no unevenness occurs.

Step six. Carpet installation

Carpet can be laid in a variety of ways. The most suitable would be to use special glue or tape. The gripper strip may damage the thermal film. Before laying the carpet, spread it over the entire area of the room and leave it for a day. The temperature in the room should not fall below 18C, the humidity in the aisles should be 10-65%. Apply tape or glue and lay down the carpet. Limit any movement around the room during the day. Furniture should not be placed less than 24 hours after installation of the carpet.

Your warm infrared floor is ready.

Attention! Strictly prohibited!

- Carry out installation in conditions of high humidity.

- Carry out installation at temperatures below 0°C.

- In a 5 cm area, bend the film at an angle of 90 degrees.

- Place large furniture on film.

- Use nails to secure the film.

- Make holes in the film.

- Use heated floors without grounding.

- Use lengths longer than 15 meters.

- Use sections with a consumption of more than 10 amperes.

- Install heated floors next to stoves, fireplaces, and other similar heating elements.

If you have any questions related to the installation of warm film under carpet, contact us in the most convenient way for you, and we will definitely answer all questions.

Video instructions for installing heated film floors

Device

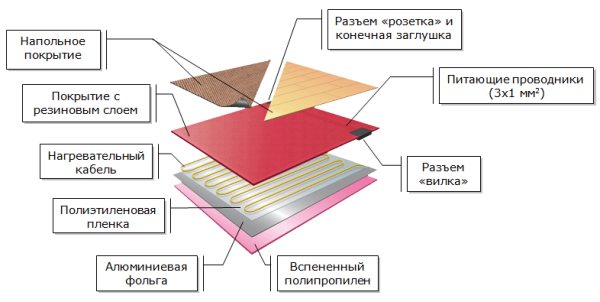

A heated floor system is a multi-layer cake that performs several tasks simultaneously:

- cutting off the subfloor from the heater to eliminate wasteful consumption of thermal energy;

- floor heating;

- protection of the heater from mechanical damage (especially important for water pipelines);

- floor covering that directly transfers heat into the atmosphere of the home.

For water floors

For water heated floors, the usual composition of the cake is as follows.

On a concrete subfloor:

- Concrete floor.

- Waterproofing layer.

- Insulation layer (EPS).

- MAK mesh (or a similar mesh to equalize the load on the pipes).

- Water heated floor pipes.

- Concrete screed.

- Carpet.

On a wooden subfloor:

- Heated floor pipes (or, as an option, modules or polystyrene foam with laid heated floor pipes).

- A protective layer of plywood, chipboard or similar rigid sheet materials.

- Carpet.

For electric

Pie composition for electrical systems.

For concrete floors:

- Concrete subfloor.

- Waterproofing, insulation layer.

- Heating cable (mats).

- Screed layer.

- Carpet.

Attention! For electrical cable systems, the layer of screed may be thinner - sometimes only to level the surface, since there is no danger of rupture of pipes under pressure.

For wooden floors:

- The cable (mats) or film emitter is laid directly on the subfloor.

- A protective layer of sheet materials is laid on top - chipboard, plywood, etc. (this is not necessary for film systems).

- Carpet.

To eliminate wasteful heat consumption, it is recommended to place a layer of foil film between the heater and the subfloor, which reflects infrared rays upward and prevents unnecessary heating of the subfloor.

How to use

A film resistive electric heater, or mobile heated floor, is designed to provide a warm floor surface in any room by installing it under carpet, laminate, carpet, and other floor coverings.

The design consists of several strips of electrical film with heating properties - film thickness 0.6 mm, width 0.5 m, which are fastened together with an electrical cable with mandatory grounding.

The mobile heated floor has its own temperature controller, which is attached to the wall, and from it the device is connected to the network via a regular 220 V socket.

The installation of such a floor consists of simply rolling it out on the floor in the right place and covering it with a carpet or other covering.

After turning on the mobile mat, its temperature begins to rise and is limited by the thermostat settings. The large area of the mobile floor allows you to quickly and efficiently heat a fairly large room.

The thermostat provides smooth temperature control with a threshold of 1° C and saves energy.

The average power of a mobile heated floor is 250 W/m². This value suggests that if you cover only 25-30% of the floor in the middle of the room with such a rug, this will be enough to fully heat the room.

That is, there is no need for complex arrangement of water heated floors, insulation of the existing floor or major repairs of the floor with its subsequent adaptation to existing “warm floor” systems.

Installation

The system is installed in a strictly defined sequence.

Mermen

Concrete base:

- The ceiling is waterproofed with a layer of hot bitumen and roofing felt.

- Laying the heat insulator. The slabs are laid tightly, without gaps. All gaps are immediately filled with polyurethane foam. After hardening, it is cut off with a knife.

- Laying the MAC mounting mesh to fix pipelines in the desired position.

- According to the chosen pattern (“snake” or spiral), the heated floor pipes are laid and attached to the mesh.

- The pipes are fully connected to the power system.

- Pressure testing, test run of the heated floor system, elimination of detected deficiencies.

- Pouring a layer of concrete screed. The pipes must be under operating pressure at this time.

- Allow the screed to harden and lay the carpet.

Attention! If the screed is thick or the room is large, it is recommended to untie the screed from the walls. To do this, a damper tape is attached along the perimeter of the walls before pouring to the height of the screed, which will subsequently take on all the loads from shrinkage of the walls, compensate for floor movements, etc.

Dry method:

- Lath slats (or modules, polystyrene boards with grooves) are installed on the subfloor.

- The pipeline system is being laid.

- The system is connected and fully tested - pressure testing, test run, elimination of deficiencies.

- Laying protective flooring made of chipboard, plywood, etc.

- Carpet laying.

The process of installing a water heated floor is discussed in more detail in this article.

Electrical

Concrete base:

- Waterproofing concrete floors.

- Laying the heat insulator.

- Filling the protective screed (2-4 cm).

- Laying cables (mats).

- Full connection, performance check, resistance measurement of all test points.

- Filling the screed.

- Carpet laying.

Wooden base:

- Preparing the subfloor.

- Laying cable mats (laying infrared film).

- Laying a protective layer of chipboard or plywood.

- Carpet laying.

Attention! For the installation of infrared heaters, the presence of protective coatings made of chipboard or similar materials is not necessary. To avoid unnecessary heat loss, it is recommended to place a foil reflector under the infrared film.

Types of heated floors

A person always strives to furnish his home with the maximum level of comfort, and so that the finishing will last for as long a period as possible. Therefore, you need to use only the highest quality materials. Film heated floors under carpet will last a very long time if they are laid using the correct technology. There is nothing complicated about this, the main thing is to follow the recommendations of professionals and everything will work out.

The material goes well with any type of heating elements. An infrared heated floor will serve perfectly and will not cause the slightest harm to the coating itself. This has been proven by many years of experience in using this combination. Infrared heating, in general, is considered one of the most effective methods, so the possibility of its use gives carpet good advantages over other finishing materials.

Can be installed under carpet and electric heated floors. They will also work effectively and are not dangerous to the material. According to statistics, this type is the most common. Users are attracted by the ease of installation, the relative cheapness of components and the possibility of flexible settings thanks to advanced thermostats with programmable functions.

Water heated floors are used less often. Installation of this type of heating is the most labor-intensive, as it requires preliminary installation and adjustment of the boiler. Unnecessary manipulations scare off many users who prefer simpler methods of floor heating. But it’s not for nothing that water heating is used as the main heating system in any room, so it would be a big mistake to write off water-heated floors. They do their job very well.

Advantages and disadvantages

Advantages of heated floors under carpet:

- The presence of a soft and comfortable floor covering, convenient for children and adults.

- Possibility of comfortable use both with the heated floor system connected and disconnected.

- Good sound insulation.

- Easy to install.

- Wide selection of types and colors of material, pile length, base.

The disadvantages include the following points:

- The coating can only be used in dry and clean rooms.

- Frequent cleaning to remove dust and dirt is required.

- Allergy sufferers may have problems.

- If there are animals in the house, the use of such coatings is undesirable.

- Carpeting is an excellent heat insulator, which makes it much more difficult to use on heated floors.

Other types of floor coverings for heated floors discussed on our website: under tiles (selection and installation), under laminate (is installation possible), under linoleum (is installation process possible), under parquet boards.

Warm water floor and carpet. We are looking for a way out of this situation

Today, consumers have a large selection of materials at their disposal for floor finishing. Fiberboard and parquet are considered rarities today. Linoleum continues to be in demand as a technical floor covering. However, nowadays we prefer ceramic tiles, laminate and carpet. These materials are very convenient, practical and technologically advanced. For the heating system “warm water floors”, tiles, linoleum and laminate are quite suitable, characterized by acceptable technological parameters and good thermal conductivity.

Note: for heated floors, use linoleum without a synthetic backing or insulation. Otherwise, your floor will transfer heat poorly, and the material itself will begin to deform over time, losing its physical and aesthetic qualities.

Compatibility between carpet and underfloor heating is questionable, despite the fact that such a coating has attractive performance properties. A warm floor under a carpet has the right to life if everything is done correctly, taking into account the characteristics of the heating system and the technological parameters of the finishing coating.

A warm floor can be a full-fledged heating system for the entire house or is an auxiliary heating equipment. For example, heated floors are often installed in children's rooms or in the living room, in those rooms where the most comfortable temperature in the floor area is required. When the floor surface is warm and beautiful - this is one thing, but when it is also soft and pleasant to the touch, it is a completely different matter.

Which carpet is right for you in this case? How to choose the right brand of underfloor heating?

Currently, there is a huge selection of products on the market, each of which has certain qualities and characteristics. Carpets are distinguished by the density and height of the pile, and have a variety of colors. Don't worry about the thickness of the carpet. Let's note one thing right away. The thinner the carpet base, the better the material will work with your underfloor heating system. A good material is tufted carpet, which is similar in properties to laminate.

If we talk specifically about what a carpet floor covering for heated floors should be, the following factors should be taken into account:

- what is the basis of the material (foam rubber, natural or synthetic);

- what is the length of the pile (there are short-pile, medium-pile and long-pile products);

- what material is used for manufacturing (nylon, polyester, polypropylene, wool);

- what is the method of processing the material (“texture”, “saxoni” or plush).

Each of these factors affects the thermal conductivity of the carpet and its behavior during operation together with a heated floor.

Pile length can be a key aspect affecting the thermal conductivity of a carpet. It is best to use short pile products. The air cushion in such coatings is smaller, so heat is better distributed in the surrounding space.

Note: here you should pay attention to the fact that synthetic coatings, despite their visual appeal and durability, are not environmentally friendly. Natural materials, wool and felt are much safer. In addition, such carpets do not contribute to the development of an allergic reaction in the inhabitants of the house.

As for pile treatment, it is preferable to use textured carpets for a children's room. This type of carpet is easy to clean, less susceptible to abrasion and durable. It is usually placed in the children's room, living room or hallway.

Typically, manufacturers indicate on their products information about whether the carpet is suitable for combination with heated floors.

conclusions

The use of carpet (carpets) on a warm floor is a completely possible option, subject to the restrictions on the material. It is necessary to choose a coating with a porous base made from natural materials; such a coating is less likely to interfere with the passage of heat. In this case, you will have to constantly clean and vacuum the carpet to eliminate the possibility of dust mites and other insects. Nevertheless, a warm floor under a carpet is in some sense more profitable than others, due to the possibility of use at any time of the year without loss of comfort.

Wood coverings

The coating for a warm water floor should have qualities such as strength and durability, so you need to choose it wisely. Wooden coatings are the most sensitive and capricious to heating and cooling cycles. In order to operate such materials for a longer time, it is necessary to maintain constant thermal and humidity conditions.

If there is high humidity, then the parquet floor may take on the appearance of waves, and if there is low humidity, then changes in the form of gaps will occur. Such material is not and does not have any economic benefits.

Wooden flooring for heated floors in the bathroom

It is worth noting that in any case, the choice of material is solely a matter of your taste and wallet size, however, before you start building a heated floor, you need to thoroughly familiarize yourself with the features of its installation, as well as study technologies that will help extend its life.

Warm water floors, which have the best reviews, must be installed correctly, observing all the technologies, subtleties, and features.

Related article: How to make water supply in a country house: choose pipes, diagram, installation method

Parquet for warm water floors is used less frequently, and this is caused by some shortcomings of the presented material. In order to ensure long-term operation, parquet floors must comply with the necessary humidity and heat conditions.

If there are high humidity levels, then the parquet may be subject to deformation, and if these levels are low, then changes may occur.

Wooden flooring for heated floors in the bathroom

If you decide to choose a wooden flooring, then it is best to choose parquet boards or cork. If you are installing a heated floor, you need to know that for this base you should not increase the temperature by more than 27 degrees. In order to avoid installation errors, it is necessary to analyze the room for heat loss before the installation process, so that the obtained data can then be verified.

With the right choice of material, you will receive comfort and maximum convenience, and will also feel much better, so get ready for a change.