Speaker manufacturer information

The Baltic Gas Company (BaltGaz Group) has been operating since 1995. Today the concern is the Russian market leader in the development, production and sale of gas water heaters and boilers.

The group includes two large plants: St. Petersburg Gazapparat and Armavir Gas Plant. equipment." The concern sells finished equipment and spare parts wholesale and retail to household and industrial consumers. Sales points are open in more than 1,500 settlements in the Russian Federation and neighboring countries. The number of authorized service centers is more than 400.

BaltGaz Group products combine Russian engineering experience and advanced European technologies. Gas water heaters are produced under the Neva and Neva Lux brands (NEVA and NEVA LUX). The quality of their workmanship and the level of environmental safety meet international standards, and the price is lower than that of foreign analogues.

Installation

The installation is safe.

All systems are turned off in the following cases:

- Gas turned off

- The water was turned off

- The pilot burner has gone out

- The water has heated above 90 degrees

- The draft in the chimney is broken.

Advantages of the water heater "Neva" 4511

- Small dimensions

- Design

- Loyal price

- Downtime operation

- Silent

- Simple on/off system design

- Temperature and power indicator

- Safety system

- Adjusting water and temperature

- Possibility of repair, low prices for spare parts

Minuses

- Low efficiency

- There is no control over the degree of water heating, but only adjustment

- Low bandwidth. You can only use water from one point, if you open a second tap you can get burned

- If the water quality is poor, it quickly becomes clogged.

- Installation is only possible on a dry wall with good thermal insulation

- Batteries must be replaced periodically.

Types of faults and their elimination

As you know, a perpetual motion machine has not yet been invented, and even the most reliable and high-quality equipment may experience malfunctions.

Let's look at some of them.

The device turns off periodically

- Clean the chimney and check the entire system, as an option to strengthen the sealing

- Very high water temperature. Increase water supply, reduce gas supply level.

- Carbon deposits have formed. Just clean it.

The tap is turned on, but the water heater does not work

- The batteries are dead. Replace

- The inlet and outlet valves are not fully open.

- Not enough liquid. Adjust flow

- Poor pressure. Question with utilities

- The filter is clogged and scale has formed. Perform cleaning.

There is a spark, but the device does not start

- Check the gas supply valve, it may be closed

- There was air in the pipes. A problem with the first start-up or a problem that arose as a result of the dispenser being idle. Open the water supply tap for a few seconds (5-7). Close. Perform the manipulation several times.

- The spark does not reach the gas stream. The system is subject to adjustment.

Malfunctions of Neva geysers and ways to eliminate them.

Warning. This section is intended for specialists who have the appropriate clearance to repair gas equipment! If you carry out self-repairs during the warranty period, the warranty is void!

In this article we will talk about malfunctions of Neva speakers (models 4510, 4511, 4513, 4510M, 4513M, 4610, 5611). Many Chinese speakers, for example, Vecktor or Oasis, and not only Chinese ones, work on the same principle as the Neva, so the solutions below apply to them as well. But please be more careful, the photographs in the article show details specifically for the Neva speakers.

No spark discharge when opening hot water.

- Insufficient water pressure in the water supply network (with the tap fully open, less than 2 liters per minute). It is necessary to call the service to eliminate the causes of low pressure in the pipeline.

- Check the functionality or correct installation of the batteries in the battery compartment (if the polarity is correct). If the elements are discharged, they must be replaced.

- Check whether the hot water tap at the inlet in front of the column is open enough. If necessary, open it completely. Or the problem may be insufficient water flow when the water pressure adjustment knob is selected - switch it to the required mode.

- It is necessary to check the degree of contamination of the filter in front of the device. If necessary, replace the filter element or clean it.

- It is necessary to check the heat exchanger for the presence of scale on its walls. If necessary, remove it and wash it with Solita.

- Check the membrane of the water unit. Perhaps it has stretched out and does not respond to the pressure of water. More than half of the cases of column failures occur due to the unsuitability of the membrane, so you can safely keep this part in stock for such a case. The problem could also be with the microswitch. This part, like the membrane, is a “consumable” and is constantly subject to mechanical stress. The microswitch tongue often falls off over time, nothing surprising. It happens that the button on which the tongue presses also fails. In this case, it is necessary to ring the microswitch (it should ring when its tongue is depressed). If these elements are serviceable, then check the column control unit itself for serviceability.

- Electrical circuit break. It is necessary to find it and eliminate it.

- Check that the installation has been carried out correctly. Probably some requirements for it have been violated.

When you open a hot water tap, there is a spark discharge, but the column does not ignite.

- Check if the hot water tap in front of the column is open.

- There is no gas in the main gas pipeline. You need to call a service to fix the problem.

- Check the serviceability of the EMC. The connection contacts may be broken.

- Correct the spark plug; perhaps the discharge does not reach the flow of the gas-air mixture (about 5 mm from the end of the spark plug to the burner).

- When using a liquefied gas dispenser, you need to check the gas reserve in the container (cylinder).

- Weak spark from the spark plug electrode. It is necessary to clean the contacts of the battery compartment or completely replace the ignition elements (batteries).

The speaker will work for a while and turn off.

- Bad traction. Triggering of the traction sensor. It is necessary to clean the chimney or check the tightness of the exhaust pipe connection on the column pipe.

- Overheating of water (water temperature at the outlet is more than 90C, the limit temperature sensor is triggered). It is necessary to use the control knobs of the column to reduce gas consumption and increase water pressure.

- Replace the water unit membrane.

- There is no signal from the ionization sensor (flame presence sensor). In this case, the burner operates for no more than 7 seconds, and the spark discharges of the candle do not stop. It is necessary to restore contact with the sensor, correct its position (if it touches other elements of the burner) or replace it.

The display of the column does not show water temperature readings.

- The water temperature sensor is faulty. It needs to be replaced.

- Check the contacts connecting the display itself to the ignition unit. If there is no result, replace the display.

The water doesn't heat up well.

- Reduce water pressure.

- It is necessary to check the heat exchanger for the presence of scale on its walls. If necessary, remove it and wash it with Solita. It is also necessary to clean the column burner from dust and soot on its surfaces.

- Insufficient gas pressure in the main - call the service to eliminate the causes.

- The water unit needs to be repaired or replaced.

The column burner flame is yellow and weak, with smoky tongues.

1. It is necessary to clean the column burner from dust and soot on its nozzles and internal surfaces.

Model range of geysers Neva

The wide range of equipment offered can cause serious difficulties when choosing the appropriate option. We invite you to get acquainted with the most popular models, their distinctive features and technical characteristics.

Geyser Neva 4510

Affordable model with a flat body and an aluminum alloy heat exchanger. Has an efficiency of 84%. Power - 17 kW. The ignition is powered by batteries. The Neva 4510 geyser has a capacity of 10 l/min. Capable of heating water up to 77°C. Weighs 10.4 kg. It has small overall dimensions. Designed for a minimum pressure of 0.3 bar. Repairable. Spare parts are low cost. Power modulation is not provided. The disadvantages include the short service life of individual elements.

Neva 4510

Geyser Neva Lux 5514

Powerful unit with a capacity of 14 l/min. Neva Lux 5514 is equipped with a Unigar modeling burner, started by electric ignition. There is a gas control function, thanks to which, in the absence of a flame, a special sensor will turn off the gas supply.

The Neva Lux geyser can be used to service two water points. Allows you to heat water up to 90°C. When developing the model, the operating features of the Russian water supply system were taken into account. Positive reviews about the Neva Lux 5514 gas water heater and the price of 10,000–12,000 rubles make the model relevant for a wide group of consumers.

Neva 5514

Watch this video on YouTube

Geyser Neva 4511

A high-quality modern model with an ergonomic design, the capabilities of which have been tested by many consumers. The unit has a power of 21 kW. It can be used to heat water for two water intake points, as it has a capacity of 11 l/min. Equipped with a copper heat exchanger.

The operating mode is set on a digital display using an electronic control system. Electric ignition runs on batteries. Gas equipment is switched on automatically when the tap is opened. It has a modern security system, as indicated in the operating instructions. Reviews of the Neva 4511 gas water heater confirm the relevance of this model for private houses and apartments.

Neva 4511

Geyser Neva 4513

A reliable water heater with an attractive minimalist design that can withstand operation in harsh Russian conditions. The model has a gas control function, which provides a sufficient level of safety when the gas supply is interrupted. The presence of a two-stage power modulation function allows you to optimize the cost of heating water.

The Neva 4513 gas water heater with a capacity of 22 kW allows the use of liquefied and natural gas. The maximum productivity of the unit reaches 13 l/min at a water temperature of 25°C and 8 l/min at 40°C. Easy to use. Weighs 13 kg. Repairable. Automatic ignition.

Neva 4513

Geyser Neva 3208: technical characteristics and features

A reliable model with a simple design. Can last for many years. A suitable option for heating running water. Powered by natural gas. For water heated to 40°C, the productivity is 6.45 l/min.

The technical characteristics of the Neva 3208 gas water heater provide an efficiency of at least 80%. The unit is equipped with a copper heat exchanger. Weighs 20 kg. Piezo ignition.

Neva 3208

Geyser Neva transit VPG-10E

A budget flow-type model that can run on natural and liquefied gas. An open firebox imposes certain requirements for installation work. The productivity of the Neva Transit gas water heater is 10 l/min with a nominal thermal output of 21 kW. Allows you to heat water up to 60°C. Weighs 9.5 kg. A forced smoke removal function is provided.

Neva transit VPG-10E

Gas wall-mounted boiler NEVA LUX-8618

Wall-mounted gas boiler NEVA LUX-8618 is wall-mounted equipment with an open chamber for burning fuel. The device is equipped with a digital display for ease of use. You can buy a boiler for heating and hot water supply in apartment or country houses.

Peculiarities:

The NEVA LUX-8618 wall-mounted gas boiler is not similar to the previous generation appliances of this manufacturer. All innovations allow us to ensure reliable, high-quality operation and high safety:

• The combustion chamber is cooled with cold water, which only helps to extend the service life of the device.

• The heat exchanger for heating water is equipped with larger pipes than in previous models, which prevents rust from appearing inside the device and reduces the number of requests for warranty service.

• The lining of the device is made of metal-plastic, which has special protection against scale. First, the boiler is coated with a primer, then galvanized and additionally treated with a layer of enamel. Thus, the device can be used for decades.

• An innovative process control panel has been developed specifically for this model. Now you can set the necessary parameters and adjust them without having specific knowledge. The remote control simplifies the process. A sensor installed outdoors transmits environmental temperature data to the device so that it can operate as economically as possible. Connecting the boiler to a computer greatly simplifies troubleshooting. The electronic board used is fully adapted for using the device in Russian conditions.

The main advantages of the gas wall-mounted boiler NEVA LUX-8618 are as follows:

• 2 completely autonomous heat exchangers for space heating and hot water supply;

• the heat exchanger itself is made of stainless steel;

• open combustion chamber;

• flame level can be changed if necessary;

• a system thought out to the smallest detail to ensure safe operation;

• control of the device via electronics;

• in the event of any breakdown, the system itself will diagnose the faults that have arisen;

• the device is equipped with a thermostat for measuring temperature both inside and outside the device;

• convenient display;

• proper functioning even during pressure surges in the water and fuel supply;

• stylish design;

• all components are from European manufacturers.

Recommendations for carrying out repair work

Replacement of the membrane on the column of each model is carried out only with compatible parts. Products should be purchased strictly from official suppliers or certified dealers. In terms of material, the silicone diaphragm offers increased durability.

The regulators are removed from the body by moving them towards you. If the speaker is equipped with a display, you will need to disconnect the cables associated with it. The casing is removed by unscrewing the bolts or pulling forward and upward to loosen the latches. After this, you can disassemble the unit itself, which is responsible for replenishing the system with water. No special methods are needed to change batteries, but you should still know how to do it.

The flag holding the lid must be turned 90 degrees counterclockwise. When placing batteries vertically and securing them to flexible latches in the shape of the letter L, you need to move the parts to the side and remove the batteries. Immediately after this, new energy sources can be installed and secured in place with the same latches. Some versions use a retractable container that comes out when you press the middle part of the bottom until it clicks.

It is not difficult to disassemble a gas water heater; most often you have to do this to clean it. Cleaning must be carried out on both the water supply and gas circuits. The presence of dirt on the ignition elements threatens disaster, and clogging of the pipeline with scale sharply reduces energy efficiency. After removal, the unit receiving water is washed under the maximum possible pressure. The column radiator can also be cleaned only when removed.

It is worth taking into account that if scale has blocked the movement of the nuts, you should not demonstrate heroic perseverance or call for help from stronger people. It is more correct and safer to remove the blockage using WD-40 liquid, which allows you to not break anything. At home, a hot solution of citric acid or vinegar can replace the special liquid when flushing the heat exchanger. When returning the cleaned part to its place, it is necessary to replace each seal. In the gas burner itself, without the help of professionals, it is permissible to clean only the ignition (using a steel brush).

To learn how to troubleshoot Neva geysers, see the following video.

Water heater repair

To troubleshoot a Neva gas water heater yourself, you need to diagnose it correctly. Over the years of operation of a water heating device, one part of the parts wears out and requires replacement, the other requires periodic maintenance. In this case, various problems arise, characterized by certain symptoms. We propose to divide all emerging problems into groups according to the following criteria:

- The burner does not light when the DHW system tap is opened;

- After working for 5-10 seconds, the unit turns off;

- the flow-through heater starts up and functions properly, but does not heat the water well;

- other problems.

Device and principle of operation

In many cases, fixing a problem with automatic ignition or with other components of the device is quite easy, and you don’t even have to seek the help of professionals. However, in order to understand why the Neva geyser does not work well, it is worth studying its structure.

The system includes:

- housings (for wall-mounted models - supplemented with mounting loops);

- heat exchangers made of copper;

- water circulation units;

- burner complexes;

- concentrators of gaseous combustion products (diffusers);

- pipes for connection with the chimney;

- water supply tubes;

- igniter electrode;

- faucet regulating the passage of water;

- segment for batteries;

- a system that regulates heating power and fuel consumption;

- ionization fire indicator.

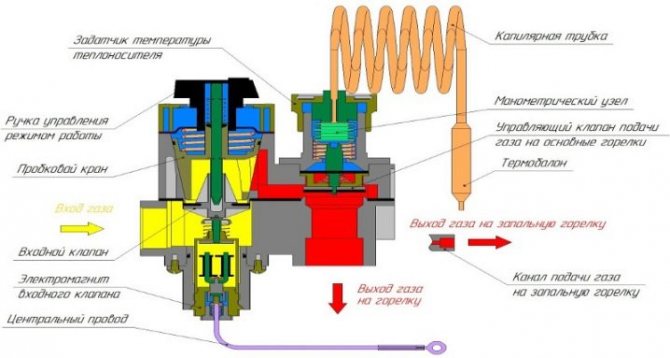

The typical method of operation of a gas burner is very simple. As soon as the water tap supplying hot water is opened, the pressure of the jet begins to act on the membrane of the control unit. Under its pressure, the rod moves, which opens the gas valve, and the contacts of the switching device close. Through the electrical circuit, current from the batteries begins to flow to the controller. The electronics sends two signals at once: one by one, the valve opens, allowing gas to pass through; the second, an electric spark appears on special electrodes.

As soon as the fire detector detects characteristic ionization, it sends a signal to the central automation. It stops initiating the spark. Heating is carried out in standard operating mode. The mixer valve is closed. The membrane immediately moves back, and the gas passage valve closes.

At this moment, the limit switch is activated, stopping the flow of current to the controller. Without power supply, the electromagnet remains. Since no gas enters the burner, it should go out immediately. The valve is connected to the same circuit as the draft meter. When this draft disappears or is weakened excessively, the heated sensor opens the circuit, thereby stopping the power supply to the electromagnet and the passage of gas to the burner.

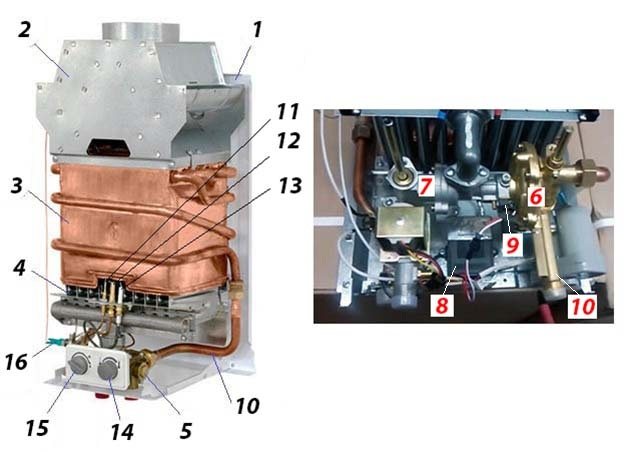

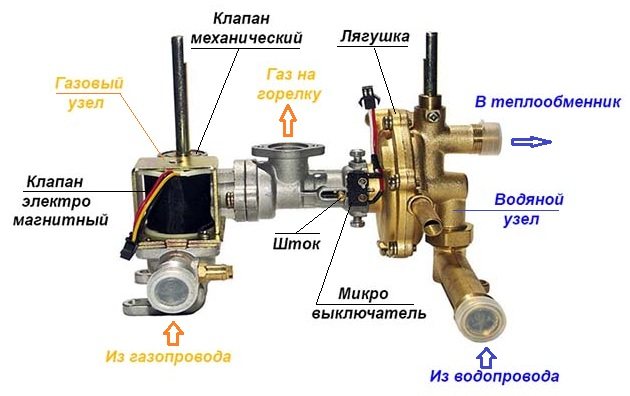

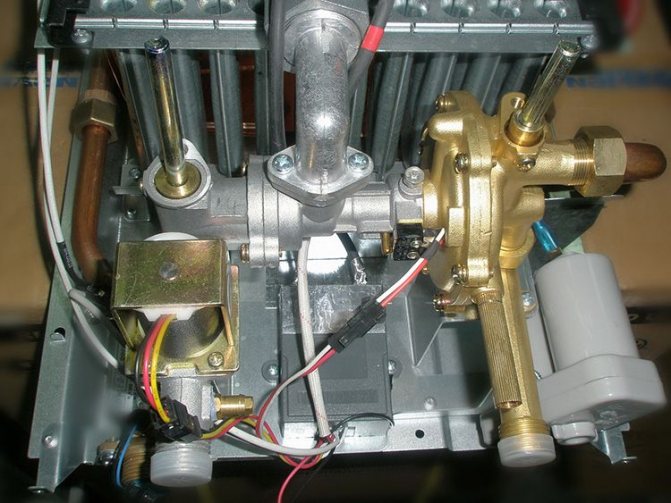

Design and principle of operation of the Neva 4511 model

It is impossible to repair a household appliance yourself without knowing how it functions and what it consists of. Unlike old-type water heaters, this series of geysers is equipped with a controller and electric ignition, which makes it possible to remove the constantly burning pilot light. Otherwise, the design remained quite simple and maintainable. It consists of the following main elements:

- Housing with hinges for wall mounting.

- Diffuser – a collection of combustion products with a chimney pipe.

- Copper heat exchanger.

- Gas burner device.

- Water node.

- Membrane actuator (so-called frog).

- Gas valve with an electromagnet connected by a common rod to the water unit.

- Controller.

- Microswitch for supplying power to the electronic unit.

- Water supply pipes.

- Ignition electrode.

- Flame sensor (ionization).

- Additional electrode for igniting the burner.

- The tap is a flow regulator.

- Adjustment of combustion intensity and heating temperature.

- Connecting a draft sensor installed inside the diffuser.

- Compartment for batteries (batteries).

The diagram above shows the structure of the Neva gas water heater with digital designations of parts corresponding to the list.

Automatic switching on and heating are controlled by the water unit together with the controller, and a solenoid valve connected to a draft sensor is responsible for the safe supply of gas. The operating algorithm of a water heating device looks like this:

- After opening the hot water tap, pressure arises at the inlet of the “frog”, acting on the rubber membrane of the unit. It moves the rod, which opens the gas valve and closes the microswitch contacts.

- When the electrical circuit is closed, power from the batteries is supplied to the controller. It gives 2 commands simultaneously: open the solenoid valve to allow gas to pass through and create a spark at the ignition electrodes. As a result, the burner ignites.

- The flame sensor detects the appearance of fire and transmits an impulse to the electronic unit, which interrupts sparking. The heater goes into operating mode.

- When the valve on the mixer is closed, the pressure in the network disappears and the spring pushes the “frog” membrane back, simultaneously closing the mechanical gas valve. The limit microswitch is triggered and the controller is deprived of power, and with it the electromagnet. The fuel supply stops and the burner goes out.

Fundamental point. The solenoid valve is connected in one circuit to the traction sensor (item 16 of the diagram). If for various reasons the draft in the chimney disappears or weakens, the sensor will heat up and open the circuit, de-energizing the electromagnet. The latter will return to the closed position and shut off the gas supply to the burner device.

To eliminate possible overheating of water in the heat exchanger, the manufacturer has implemented a simple technical solution: a temperature sensor connected to the controller is built into the pipeline. If the flow heats up to a critical level (about 90 °C), the gas supply will automatically stop and the burner will go out. The structure and operating principle of the Neva 4511 column is shown more clearly in the video:

Manufacturer – Germany

JUNKERS (Junkers) BOSCH (Bosch)

| BOSCH Neckar JSD20 ⁄ 26 – B23 | BOSCH Neckar JSD20 ⁄ 26 – B31 |

| Installation and operating instructions for the JUNKERS BOSCH WR gas water heater | ||||||||

| 10-2B | 13-2B | 15-2B | 10-2G | 13-2G | 15-2G | 10-2P | 13-2P | 15-2P |

| Instructions for installation and operation of the BOSCH Therm geyser | |

| 6000 S | 8000S |

VAILLANT

| Instructions for installation and operation of the geyser VAILLANT atmoMAG | ||

| 14-0/0 RXZ | 14-0/0 RXI | 14-0/0 GRX |

| Installation and operation instructions for the VAILLANT MAG geyser | ||||||

| pro 11-0/0 XZC+ | OE 19/2 XZ-C+ | remium SOE 19/2-24/2 XIP | premium SOE 19/2-24/2 XI | premium OE 19/2-24/2 XZ | premium OE 24/2 RXI | premium OE 24/2 RXZ |

| Instructions for installation and operation of the geyser VAILLANT GEYSER MAG | ||

| 275/12 XZ | 350/12 XZ | 440/12 XZ |

The general principle of operation of Neva geysers and their types

Any water heater includes a gas burner located under the heat exchanger. Combustion products are removed from the gas combustion zone through a special pipe located above the burner and heat exchanger. The operating principle of a geyser is based on heating water moving through a pipe located inside the heat exchanger. The heat generated during gas combustion ensures heating of the water unit of the gas water heater to a specified level. The maximum temperature depends on the design features of the particular unit.

The operating principle is dictated by the design features

The manufacturer offers various types of units that differ in power, type of ignition, and design features of the combustion chamber.

Related article:

Description of the NEVA 4510 model with reviews

This compact and lightweight water heater is one of the popular economy class options. Its characteristics:

- power - 17 kW;

- productivity - 10 l/min;

- ignition - automatic;

- body colors - white or grey.

The front panel of the water heater is equipped with a digital liquid crystal display. It indicates the current water temperature. There is flame control: if for some reason the fire goes out, the supply of blue fuel stops. According to the manufacturer, the unit was created taking into account Russian realities, so it works even at low water pressure (0.10 Bar).

Numerous buyers did not agree on this Neva gas water heater. Some people praise the budget heater because it fully justifies its cost. Other consumers criticize for technical mistakes and frequent breakdowns. Some users note that the unit does not work if the water pressure is poor.

Problems with the water unit

Often, the NEVA 3208 column refuses to light up when the water pressure in the system is not high enough or the water unit of the unit is faulty. And if in the first case we can only put up with the poor performance of public utilities, then in the second, repairing the NEVA 3208 geyser with our own hands can be done immediately and with minimal losses to the wallet.

How to identify a faulty water unit? Compare the pressure of cold water and the pressure coming from the column. If the second is significantly less intense than the first, then the problem is a clogged strainer. Don't be surprised if the problem suddenly appears, as this often happens when the water supply is turned off and then restored. To clean the filter, you need to unscrew the union nut in the place where the water is supplied, remove and rinse the mesh along with the calibration hole.

If you were unable to visually determine changes in the intensity of water supply, it makes sense to evaluate the condition of the rubber membrane in the unit. To do this, unscrew the union nuts and fixing screws. Then disassemble the structure by unscrewing the 8 screws. The rubber membrane we need is located between the two halves of the water unit. If you find deformation of the membrane (in ideal condition it should be flat), then the cause of the malfunction has been identified.

It would also be a good idea to rinse the cavities of the water unit and the filter mesh. It is better to replace the standard membrane with a silicone one, as it is durable. After replacement, you can assemble the water unit by tightening all the fixing elements until they stop. To ensure that the membrane is clamped evenly, it is recommended to tighten the screws diagonally.

Results

We looked at how to repair a NEVA 3208 geyser with your own hands, using the example of the most common breakdowns. But you need to understand that the design of the unit is simple enough so that you do not limit your capabilities to the recommendations described above. If you wish, you can study repair skills in more detail in order to independently perform a wide range of service operations, such as:

- Elimination of leaks in connections;

- Replacing the copper water supply pipe;

- Cleaning the igniter;

- Removing scale from the heat exchanger;

- Checking the thermal fuse;

- And much more.

The above tips will help you fix most of the problems yourself without turning to specialists for help.

Design and principle of operation of the Neva 4511 model

It is impossible to repair a household appliance yourself without knowing how it functions and what it consists of. Unlike old-type water heaters, this series of geysers is equipped with a controller and electric ignition, which makes it possible to remove the constantly burning pilot light. Otherwise, the design remained quite simple and maintainable. It consists of the following main elements:

- Housing with hinges for wall mounting.

- Diffuser – a collection of combustion products with a chimney pipe.

- Copper heat exchanger.

- Gas burner device.

- Water node.

- Membrane actuator (so-called frog).

- Gas valve with an electromagnet connected by a common rod to the water unit.

- Controller.

- Microswitch for supplying power to the electronic unit.

- Water supply pipes.

- Ignition electrode.

- Flame sensor (ionization).

- Additional electrode for igniting the burner.

- The tap is a flow regulator.

- Adjustment of combustion intensity and heating temperature.

- Connecting a draft sensor installed inside the diffuser.

- Compartment for batteries (batteries).

The diagram above shows the structure of the Neva gas water heater with digital designations of parts corresponding to the list.

Automatic switching on and heating are controlled by the water unit together with the controller, and a solenoid valve connected to a draft sensor is responsible for the safe supply of gas. The operating algorithm of a water heating device looks like this:

- After opening the hot water tap, pressure arises at the inlet of the “frog”, acting on the rubber membrane of the unit. It moves the rod, which opens the gas valve and closes the microswitch contacts.

- When the electrical circuit is closed, power from the batteries is supplied to the controller. It gives 2 commands simultaneously: open the solenoid valve to allow gas to pass through and create a spark at the ignition electrodes. As a result, the burner ignites.

- The flame sensor detects the appearance of fire and transmits an impulse to the electronic unit, which interrupts sparking. The heater goes into operating mode.

- When the valve on the mixer is closed, the pressure in the network disappears and the spring pushes the “frog” membrane back, simultaneously closing the mechanical gas valve. The limit microswitch is triggered and the controller is deprived of power, and with it the electromagnet. The fuel supply stops and the burner goes out.

Fundamental point. The solenoid valve is connected in one circuit to the traction sensor (item 16 of the diagram). If for various reasons the draft in the chimney disappears or weakens, the sensor will heat up and open the circuit, de-energizing the electromagnet. The latter will return to the closed position and shut off the gas supply to the burner device.

To eliminate possible overheating of water in the heat exchanger, the manufacturer has implemented a simple technical solution: a temperature sensor connected to the controller is built into the pipeline. If the flow heats up to a critical level (about 90 °C), the gas supply will automatically stop and the burner will go out. The structure and operating principle of the Neva 4511 column is shown more clearly in the video:

Technical characteristics of Neva-4511

- Capacity 11 l/min. (+25 degrees)

- Energy resource consumption: natural 2.2 m3/h, liquefied 1.66 m3/h

- Camera - open type

- Power 21 kW

- Ignition type – electronic

- Chimney diameter 11-12.5 cm

- Efficiency – 87%

The unit has a classic shape, a simple design and small dimensions of 55.6 * 22.1 * 29 cm. Its weight is 10 kg. On the front panel there are rivers/relays for adjusting the water supply and the amount of gas, as well as an electronic display that shows to what temperature the water in the tap has heated up.

The heat exchanger is two-tier. Manufacturing material is copper. Its pipes are deliberately made of a larger diameter - this significantly reduces the amount of scale.

The device starts automatically when the “hot” tap is opened. The spark is automatic electronic and runs on batteries. Directed towards the incoming gas stream.

Malfunctions of Neva geysers and ways to eliminate them: 10 comments

the wick burns very strongly during the night, it heats up the tubes of water when the water is opened, after a few seconds there is boiling water, killing the daughter-in-law of the children, when they wash their hands, the water tubes are plastic, how to reduce the sewing of the wick

Hello, can you tell me the model of the speaker?

remove the front cover and on the gearbox you will see a yellow bronze screw for a screwdriver. Turn it smoothly while the wick is running.

WHY WHEN THE WATER REGULATOR INCREASES IT GOES OUT

Nikolay, to open the gas valve you need a certain water pressure in the water valve. As the water flow increases, you reduce this pressure and the gas valve closes.

The situation is as follows: when you open a hot water tap, the flame does not light up for 4 seconds, and then there is a strong bang. The flame ionization sensor does not work. Previously, when there was no flame for three seconds, the gas supply to the burner stopped. This rarely happens. Neva 4501

Hello Dmitry. The ionization sensor has nothing to do with it. There are several probable reasons: 1. Check the batteries (replace if necessary) 2. Check the spark plug, its location relative to the burner (5mm gap) 3. Poor draft is possible (gases accumulate and therefore popping noise occurs) 4. Clean the burner itself from soot 5. It is unlikely, but still, the control unit itself requires replacement.

Hello. Column Neva. There is a slight leak in the microswitch area. What do you recommend doing?

Cleaning the heat exchanger, descaling

One of the common malfunctions of geysers is insufficient water heating

. As a rule, the reason for this is the formation of a layer of scale inside the heat exchanger tube, which prevents the water from warming up to the set temperature and reduces the water pressure at the outlet, which ultimately leads to increased gas consumption by the geyser. Scale is a poor conductor of heat and, covering the heat exchanger tube from the inside, forms a kind of thermal insulation. The gas is open to full speed, but the water does not warm up.

Scale forms when tap water is more hard. You can easily find out what kind of water you have in your tap water by looking into the electric kettle. If the bottom of the electric kettle is covered with a white coating, it means that the water in the water supply is hard, and the heat exchanger is also covered with scale from the inside. Therefore, it is necessary to periodically remove scale from the heat exchanger.

There are special devices on sale for removing scale and rust in hot water systems, for example, Cillit KalkEx Mobile and flushing fluids. But they are very expensive and are not available for home use. The operating principle of the purifiers is simple. There is a container in which a pump is mounted, like in a washing machine, to pump water out of the tank. Two tubes from the descaling device are connected to the tubes of the geyser heat exchanger. The flushing agent is heated and pumped through the heat exchanger tube, even without removing it. The scale dissolves in the reagent and the heat exchanger tubes are removed with it.

To clean the heat exchanger from scale without using automation equipment, you need to remove it and blow out the tube so that no water remains in it. Anti-scale agent, ordinary vinegar or citric acid can serve as a cleaning reagent (100 grams of citric acid powder is dissolved in 500 ml of hot water). The heat exchanger is placed in a container with water. It is enough that only a third of it is immersed in water. Using a funnel or thin tube, completely fill the heat exchanger tube with the reagent. You need to pour it into the heat exchanger tube from the end that leads to the bottom turn so that the reagent displaces all the air.

Place the container on the gas stove and bring the water to a boil, boil for ten minutes, turn off the gas and let the water cool. Next, the heat exchanger is installed in the gas water heater and connected only to the water supply pipe. A hose is put on the outlet pipe of the heat exchanger, and its second end is lowered into the sewer or any container. The water supply tap to the column opens; the water will displace the reagent with the scale dissolved in it. If there is no large container for boiling, then you can simply pour the heated reagent into the heat exchanger and let it sit for several hours. If there is a thick layer of scale, the cleaning operation may need to be repeated several times to completely remove it.

This modification of geysers from the Baltgaz company appeared in 2020, old Neva geysers bought in St. Petersburg with brass water units, gas valve blocks have sunk into oblivion, the design of geysers has been simplified and made cheaper. These columns have a simple gas solenoid valve, a plastic water unit developed by the Baltgaz company, what did they come up with, and let’s compare the Neva gas columns:

Neva 4510

The heat exchanger of the Neva 4510 geyser is made in the form of a cassette, it is called cassette, the heat exchanger jacket is made of steel sheets with inserts of non-flammable heat-retaining material.

The water unit became plastic, the cold water tube from the water unit to the heat exchanger became a bellows made of stainless steel, the nuts were made of composite material (plastic).

The hot water tube from the heat exchanger is the same bellows type, the fitting into which the temperature sensor is screwed is made of the same plastic as the nuts. Otherwise, the design has changed slightly, the electromagnetic gas valve remained the same, only it was turned 180 degrees and it became difficult to access, otherwise it almost never broke. The control unit is located on the rear panel.

Neva 4510M

Neva 45101M, one of the cardinal differences from the 4510 is, of course, the heat exchanger, it is made entirely of copper with a jacket, the plates surrounding the combustion chamber with inserts have disappeared. The cold water pipe from the water unit to the heat exchanger remained the same, bellows type with plastic nuts. The fitting into which the temperature sensor is screwed is made of brass and built into a copper tube; this design is more reliable and durable. Otherwise, 4510 and 4510m are absolutely the same, the power of the speaker remains the same 17.9 kW, and the dimensions are 290 * 565 * 221 (w * h * d).

Neva 4510 m

Neva 4511

Neva 4511 is distinguished by its larger heat exchanger dimensions and an enlarged ramp with nozzles and burner; accordingly, the power of this gas water heater has changed, it is 21 kW with the same dimensions 290 * 565 * 221 (w * h * d).

Neva 4513M and Neva 5514 (14L)

They are distinguished by the absence of a DHW temperature sensor in the 5514, as well as, consequently, the absence of a screen on the 5514; otherwise, they have interchangeable heat exchangers, similar burners, but different ramps and the internal arrangement of the water and gas unit; the battery compartment on the 5514 is moved to the left for convenience part. The power is also different: 26 kW for 4513M and 28 kW for 5514, however, their dimensions are the same 350*650*239 (w*h*d).

Time will tell how long and how the updated Gas Heaters Neva from Baltgaz will serve, but the fact that the company can give a 5-year guarantee on its equipment already deserves respect. Neva 4513M Neva 5514