You can decorate the floor and make the room warm with the help of a modern carbon heated floor

Insulating your home is a responsible task, especially in latitudes with moderate and cold climatic conditions. Carbon heated floors allow you to insulate your home using innovative and safe technologies. Warm floors can be considered, if not universal, then additional heating. The infrared heater works using graphite-silver rods connected to each other by a cable that has increased security.

Benefits of carbon flooring

Carbon flooring runs on resistive heating elements that resemble carbon cable, carbon paste, or carbon fiber. This is an electric floor that runs on mains power. The resistive heating element operates under voltage. It is converted into warm energy by electrical resistance.

The resistor transfers the resulting heat to the entire floor surface, distributing this heat evenly throughout the floor.

The carbon floor can be used as both main heating and additional heating. If the carbon floor is an additional source of heat, you can cover a certain area of the floor in the room. If the floor is the main one, then the covering area should be at least 70% of the total area of the room.

The main advantage of carbon heated floors is that it is an economical source of heating

Advantages of carbon floor:

- Comfortable heating source;

- Floors are not overloaded;

- Quite economical;

- It can be turned off in winter;

- High efficiency;

- Resistance to corrosion processes.

The floor can be installed in any type of room. In this case, you can cover both large and small areas. Carbon fiber flooring can be installed in an apartment, country house, on a balcony or loggia, in a hotel, hotel and industrial premises.

Design features of carbon rods

A material based on polyester and polyethylene is used as a protective insulating shell for carbon rods.

Inside, the heating elements are filled with a carbon-polymer composite material. To connect them, a heat-resistant stranded copper wire 2.5 mm thick is used, which is additionally protected by a 3 mm sheath.

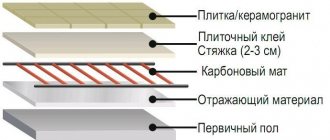

Schematic structure of a carbon heated floor

Those who have tried the innovative heating system from personal experience claim that there is currently no alternative to it. A room with such heating is always dry and warm, while the natural humidity of the air is not disturbed. Such conditions are provided by a technically unique intelligent system, implemented on completely new principles for the design of heating elements. Carbon heated floors are also an economical way to heat a room, which is extremely important especially recently.

Why install underfloor heating: carbon mat

The carbon mat is an advanced, innovative technology that allows the use of infrared waves to heat a room. Carbon is a highly durable material; when exposed to electricity, it produces heat, which is based on the long-wave infrared range. The rods have a parallel connection, which allows you to be confident in the uninterrupted operation of the floor.

Thanks to the high thermal coefficient of heat transfer, the level and amount of heat produced by the floor can be adjusted.

The innovative components from which the rods are made ensure a long and trouble-free service life for the system. The floor can regulate itself, which allows significant savings in thermal energy. That is why the cost of purchasing and installing such a floor pays off very quickly.

Many people prefer to install a warm carbon floor because it can independently regulate the temperature in the room

Why should you install such a floor:

- The smart floor itself regulates the temperature in the room. It reacts to the slightest fluctuations and changes in temperature and stabilizes it.

- When installing or rearranging furniture, the carbon floor itself stops working in the area where the furniture was placed, since heat transfer there has deteriorated.

- The floor feels the slightest fluctuations in heat transfer thanks to the finely dispersed graphite, which is its composite material.

- This floor reduces heating costs by at least 30%.

- The carbon floor ionizes the air, which has a positive effect on the body.

- The floor is reliable. It cannot overheat, since the rod mat has increased strength and resistance to external influences.

The mat can be easily installed in a room of any size and characteristics. Before purchasing, you just need to correctly calculate the amount of material needed. The floor can be installed in a screed, as well as in tile adhesive.

Carbon heated floor - rod and film (solid) in the photo

New products on the market of underfloor heating systems appear with enviable regularity, and the user who decides to install one of them has to study a variety of information, from technical characteristics to installation nuances.

Rod carbon heated floor

Carbon heated floor - what is it?

Let's consider one of the new electric infrared heating systems - carbon heated floors (carbon, carbon fiber). This is a progressive floor heating system, the operation of which is based on the use of far-wave infrared radiation. A distinctive feature of this range is the absence of electromagnetic radiation and “live” heating of the room. Infrared radiation is harmless to human health, and in medicine it is generally used for medicinal purposes.

Carbon and carbon underfloor heating - what is the difference?

Carbon is the international name for all composite materials, the basis of which is a carbon nanostructure and various binding components. Thus, what is known to domestic consumers as carbon and carbon are one and the same substance. Those. film carbon floor and film carbon floor are the same system.

Manufacturers offer two types of carbon floor systems:

There are two more types of carbon floors on the market:

111

Bimetallic heated floor

Bimetallic heated floor Heating system based on bimetallic film. A distinctive characteristic of carbon film is a patented two-layer compound (the top layer is an alloy of copper and additives, and the bottom is an alloy of aluminum with additives). Heating plates emit waves in the infrared range. Such a warm floor should only be laid “dry”; it is prohibited to lay it in a screed or in tile adhesive.

Amorphous heated floor (ANT)

Amorphous heated floor (ANT)The Israeli company Advanced Heating Technologies (AHT) Ltd has developed a new technology - a heated floor based on an amorphous metal strip. The main feature is fire safety, because floors do not heat up above 35 °C (for example, cable floors can heat up to 60-70 °C). Made in the form of thin heating mats. The heating element is made of amorphous metal (ultra-thin tape, 30 microns thick). Warm floors on amorphous tape can be installed under all floor coverings (tiles, parquet, laminate, linoleum and carpet).

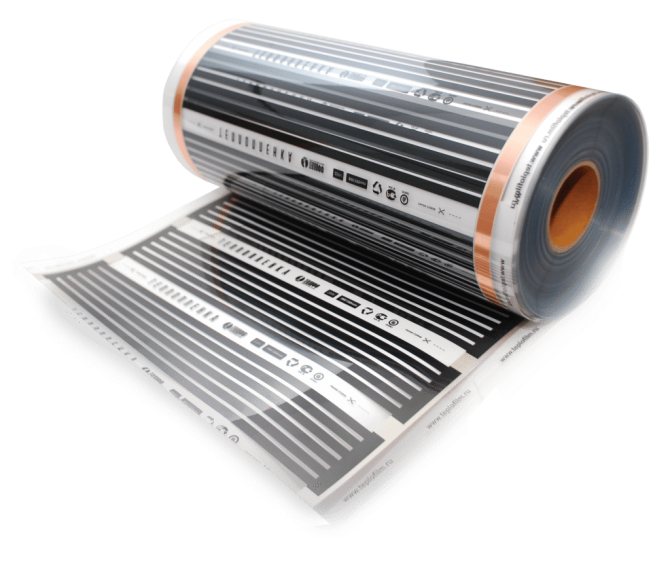

Film carbon heated floor

Film carbon electric heated floors get their name from their appearance – the film. Although in fact the heating element is a carbon-graphite mixture, which is located between two layers of dense polymer. The polymer film can withstand temperatures up to 120 °C, which means reliable protection of the heating element. Thus, the three-layer film structure provides good heating and ease of installation. And for the safety of operation, 5 protective layers applied on each side of the film are responsible.

Heating carbon film for underfloor heating

Film carbon heated floor

The peculiarity of a film carbon floor is that it does not require a screed. To install the system, it is enough to lay the film under the finished floor covering.

Note. The film floor is mounted on a prepared base, directly under the finished floor covering. When installing the system, the use of foil insulation is prohibited.

Scope of use of carbon film flooring

A solid carbon film heated floor can be laid under any floor covering. The exceptions are:

A wooden floor can be laid on film, but with some restrictions due to the specifics of the wood itself (its ability to dry out). Therefore, the temperature of the heating element should not exceed 28 °C. The same conditions must be observed when laying the film under the laminate.

Please note that we are talking about the temperature of the heating element itself, and not the front surface of the floor. After all, part of the heat is spent on heating the floor covering.

Film carbon heated floor - pros and cons

Advantages

Flaws:

Technical characteristics of carbon floor

Characteristics and properties depend on the manufacturer. Analysis of several systems will provide average data:

The best manufacturers of carbon (film) flooring:

Reviews about these manufacturers are mostly positive. Users confirm that carbon floors work without problems for at least five years, and note the absence of extraneous sounds during operation (crackling, etc.) and odor.

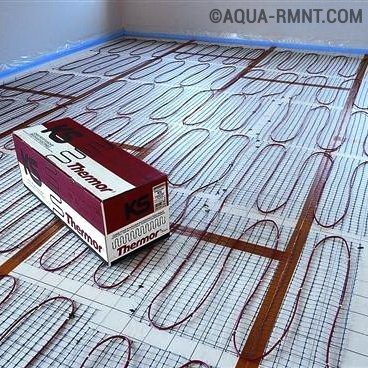

Rod carbon heated floor

Today, rod floors (infrared mats) are the newest and most progressive type of heated floors. Due to the system’s ability to self-regulate, it is often called a “smart floor” system. The design of a carbon rod floor is more complex compared to a film floor. Despite the fact that carbon also acts as a heating element here, it has a different configuration.

Rod carbon heated floor

Installed core heated floor

The heating element of a rod carbon floor is a rod filled with carbon-polymer filler. The rods are connected using stranded copper wire (2.5 mm thick) with an additional protective insulating sheath made of polyester and polyethylene.

Scope of use of rod floor

Due to its increased performance characteristics, the rod floor can be used in a living room, in a bathroom, on a loggia, in a room, in a winter garden, in a gym, in office buildings, warehouses, as an element of an anti-icing system.

The core floor can be laid on any type of covering, without exception. It goes perfectly with such fastidious materials as natural wood, parquet or laminated boards. And due to the fact that a rod carbon floor is mounted on a thin layer of screed, such an electric floor heating system is the only one suitable for installation under tiles or porcelain stoneware. In addition to the possibility of installation, the rod system allows you to save on work if you use an adhesive solution instead of a screed and directly lay the tiles.

Rod carbon heated floor - pros and cons

Advantages:

If you look at it, when purchasing a rod infrared carbon floor, the user buys a floor heating system, which is significantly superior in its characteristics to systems of a similar purpose.

Flaws:

Technical characteristics of rod heated floors

General characteristics differ slightly depending on the manufacturer, but analysis of different systems makes it possible to provide average data:

The best manufacturers of rod heated floors

Conclusion

Reviews from those users who have already installed an infrared carbon heated floor system suggest that this is a worthy alternative to existing systems, both in terms of operational properties and in terms of heating efficiency. Installing a core floor allows you to reduce the cost of heating a room by up to 50%.

You may also like

Photo wallpaper for the nursery

04/05/2018 Anastasia Prozheva

Storage Ideas for the Bathroom and Any Space

04/04/2018 Anastasia Prozheva

How to choose an instantaneous water heater?

04/11/2018 Anastasia Prozheva

Add a comment Cancel reply

Carbon rod heated floor

A carbon floor can independently regulate the air temperature in the room - that is why it is called intelligent. The heating elements work thanks to the composite composition. As the room temperature decreases, the temperature of the heating element increases - the material is subject to expansion.

Increasing the distance between the graphite grains leads to the fact that the resistance in the system becomes greater, and the power, therefore, decreases.

Carbon rods react to temperature changes in different areas of the floor covering, which leads to a decrease in heating in warm places and an increase in cold areas. This is why the floor is considered safe. Its owners should not be afraid of overheating of the system or furniture.

It is quite possible to install a rod heated floor with your own hands, the main thing is to prepare the tools and materials for the work

How to install a heated floor:

- Check if all necessary materials are available.

- Measure the surface area and determine its configuration.

- Clean the surface before proceeding to the main stage of work.

- Start installing the temperature sensor.

- Evenly distribute and connect the strips of carbon mat over the area for which heating is needed.

- Secure the thermal mat using masking tape.

- Install the thermostat.

The thermostat must be connected to the floor heat sensor using a special corrugated tube. The final stage is connecting the floors to the electrical network. All work can be done independently - it is completely safe for life.

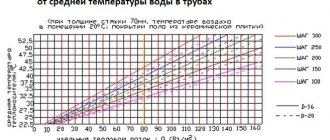

Electricity consumption for infrared heated floors

Warm carbon floors are classified as electric heating devices. The floor covering is heated by infrared radiation. The range of operating waves is 5 – 20 microns.

This process in the system occurs due to its design, which consists of heating strips or rods filled with a carbon mixture. Each element is connected by copper conductors through which an electrical charge is supplied.

All wires and heating parts are covered in a protective polypropylene sheath. Therefore, carbon heating equipment is not afraid of moisture. Due to the parallel type of connection, the IR heating system is able to function even if its individual sections are damaged.

READ MORE: How and which carpet to choose - reviews and which one is better

Infrared radiation, which is emitted by an electric carbon device, allows you to evenly heat the entire area of the floor covering. In this case, heat spreads to surrounding objects. Thanks to these properties, the air in the room does not dry out and a favorable microclimate is created.

Carbon heated film floor

The coolant in IR floors is a two-layer film with emitters sealed between the two layers.

They are connected in a parallel circuit, so if one emitter fails, the device continues to work properly. The main advantages of this method of additional heating of the room include the following:

- Uniform heating.

- More efficient use of electricity and associated resource savings.

- Hypothermia or overheating of the heating system and the room is excluded.

- The dust content of the atmosphere is reduced.

- There is no need for operational maintenance.

- There is no burnout of air oxygen.

- Heaters do not affect the humidity in the room.

- Easy to install.

Devices of this kind are increasingly used both in industrial premises and in residential construction for a variety of purposes. This can be heating equipment or containers with liquids, additional heating in extreme situations, or heating the floor to create comfortable living conditions.

The thermostat will turn on the heaters when the temperature drops by 1 degree. It will take 12 to 15 minutes for the heating system to restore the set temperature. Consequently, when the thermal film is on, 10 square meters will remain on for approximately 3 hours a day. This is true if, when building a house, all SNiP requirements for wall insulation and thermal insulation of windows and doors were taken into account.

Under these conditions, 0.275 kW/hour of electricity will be consumed, which in terms of a day will amount to 6.6 kilowatts subject to payment.

It must be taken into account that the heat received from the floor surface will reduce the temperature in the main heating circuits, reducing its costs.

It is impossible to keep track of all the nuances of the heating regime. It makes sense to invest in a system of operational programmable heating mode, which will automatically take into account both weather factors and the dynamics of temperature fluctuations in the home.

Let's figure out in what cases unusual IR technology is used. The heated floor is equipped with a two-layer film between two layers of emitters. They are connected in parallel, and even if one of the emitters fails, the device works.

Installation of film material is simple

The structures are used both for various organizations and in private construction. This material is used not only in living rooms, but also for swimming pools, bathrooms or saunas. This option is also suitable for residents of apartment buildings, since on high floors the pipes can be colder. The radiation is considered completely safe, which allows it to be used in living rooms.

Film construction is often used as an addition to the main heating

The emitters are produced in the form of rolls, which is convenient for using any coating. The thermostat is a mandatory component of the system, which is included if you buy a warm infrared film floor. This device records sensor readings, which allows you to adjust the desired heating.

Film system connection diagram

Among the technical characteristics of heated floors, it is worth noting the following indicators:

- power depends on the specific film and varies between 150÷400 W/sq.m;

- slight release of electromagnetic field;

- the material is refractory;

- radiation length indicator – 7÷20 µm.

The table shows comparative characteristics with similar designs

Infrared carbon heated floor

Carbon film flooring differs from rod flooring in that its installation is even easier. The film is simply laid over the floor covering. The film floor can be covered with any type of material, except carpet and tiles.

Film infrared carbon floor consists of carbon strips, which are connected to each other using copper busbars. The stripes are covered with special polyester.

When the floor is connected to the network, it gains temperature and then goes into economy mode. This flooring is highly durable, reliable and has a long service life. It is also environmentally friendly and safe to use.

Infrared carbon fiber flooring, which can easily be installed indoors, is popular and in demand.

Advantages of film flooring:

- Fast and even heating. Maintains temperature for a long time, creating coziness and comfort.

- Continuous operation. It regulates the temperature itself.

- Not afraid of corrosion and mechanical damage. It is not damaged when rearranging furniture.

- If damaged, the floor continues to work, even if some sections remain out of order.

The floor is specially laminated, so it is not afraid of moisture and steam. The film is resistant to fire and begins to melt only at a temperature of 120 degrees. The floor is very mobile; when moving, you can easily remove it, fold it and take it with you.

Pros and cons of carbon floors

Compared to other types of underfloor heating, carbon systems have a number of advantages:

- they are light, so the load on the floors is minimal;

- use energy sparingly;

- ideal for installation over large areas and in rooms with complex configurations;

- compatible with any type of floor covering;

- have a long service life;

- fully function when individual elements burn out;

- there is no risk of system fire;

- heating elements do not emit electromagnetic radiation;

- can be installed in rooms with high humidity;

- the floor heats up quickly and evenly.

If the carbon rod is damaged, only this one rod fails, and the entire system continues to work, whereas if the cable is damaged, the entire system stops working

In addition, if it suddenly becomes necessary to turn off the system and the room is temporarily not heated, this will not affect the performance properties of the carbon floor. Carbon tolerates low temperatures well, so there is no need to worry about freezing. The advantages of such systems also include the ease of installation and mobility of the film floor, which can be mounted not only on horizontal, but also on vertical surfaces.

Carbon floors also have disadvantages:

- high cost (especially rod systems);

- Film floors have low resistance to mechanical stress;

- rod floors are mounted only in a screed or adhesive layer, which deprives the system of mobility and complicates repairs in the event of replacing the structure.

In terms of quality, the products of K-Technologies, produced under the Unimat and Caleo brands, are considered the best.

Self-regulating film heated floor kit

These systems are highly reliable, and today they are widely used not only in residential but also in commercial areas - hotel complexes, shopping centers, offices. Unimat are self-regulating rod floors, Caleo are film floors.

Warm floors Unimat

Characteristics of UNIMAT

Carbon heated floors for laminate

The carbon floor will not yield superiority to any heating analogue. This is the best material that could be invented for laminate. Carbon fiber ensures uniform heating of the floor, which makes its operation completely safe. The floor is easy to install; even novice craftsmen who have not previously dealt with similar heating systems can handle its installation.

To install a heating system under the laminate, you need to prepare a heating carbon film, connecting clips, tape and thermostats.

After installing the floor, it is important to pay attention to the temperature sensor. It should be noted that the laminate should not heat above 27 degrees. Therefore, you need to take care of setting the correct temperature in advance.

The carbon floor, which is installed under the laminate, allows you to pre-adjust the heating temperature

Advantages of carbon floors under laminate:

- The heating temperature can be set in advance.

- The system itself regulates the heating temperature.

- The floors are completely safe, they do not burn or melt.

Reviews about these heating systems can be found on the Internet. Many argue that carbon floors are very economical, although you will need to spend money on their installation. However, soon all the expenses will pay off, since the “smart” system knows when to lower the temperature and when to increase it. When choosing a covering, it is important to ask the seller whether it is possible to install a carbon fiber floor under it.

Specifications

Carbon cable diameter from 1.8 – 5 mm, others on order; Test voltage 4500 V; Leakage current 0.05 mA/m; Insulation resistance : ?0.5 MOhm; conductor: 33 Ohm/m; Power : 25 W/m; Heating temperature : 180°C; Rated voltage : up to 400 V; Infrared waves : 8 – 18 microns; Minimum cable length : 10m. Silicone braid color : black, white, red; others on order.

Characteristics of carbon heated floors (video)

Innovative carbon heating systems not only allow you to completely heat your home, but also significantly save energy. Carbon coatings are suitable for installation in all types of premises: office and residential. When choosing a coating, it is important to consider the area that needs to be covered, as well as decide on the future finish of the floor. Carbon fiber floors are of high quality, elasticity, and strength. Reliability, safety and environmental friendliness. You can install the floors yourself from start to finish.