Purpose of gas boiler houses:

Automated gas boiler systems are widely in demand as the most economical and environmentally friendly heat sources.

As a result of gas combustion, the least amount of carbon dioxide is released per unit of heat produced compared to other popular types of boiler fuel. Also, the gas does not contain solid particles of sulfur compounds, which makes it easier to utilize waste heat. Gas boiler plants are manufactured to operate on natural gas, liquefied hydrocarbon fuel and associated petroleum gases.

Industrial gas boiler houses, depending on the purpose of their use, are divided into steam and heating boiler houses.

The convenience of autonomous gas boiler houses is due to the fact that they are not tied to outdated communications and produce the strictly required amount of heat. In Russian practice, the cost of heat when using an autonomous gas boiler house is several times lower than in centralized heating systems.

Modern boiler houses using gas fuel have the highest efficiency with the smallest dimensions.

order and turnkey gas boiler houses by calling: +7 (8452) 744-329.

The price of a gas boiler room is determined after filling out the questionnaire.

Gas boiler installation standards

To avoid any troubles when putting the gas boiler into operation, it is necessary to select the installation location in accordance with current standards. The installation of a gas boiler in a private house (single-apartment or semi-detached) is regulated by SNiP 02/31/2001, and the installation rules in apartment buildings are prescribed in SNiP 2.08.01.

For private houses

According to the standards, a gas boiler can be installed in a ventilated room, which is located:

- on the first floor of the house;

- in the basement or basement;

- in the attic:

- gas boilers with a power of up to 35 kW (according to MDS 41.2-2000 up to 60 kW) can be installed in the kitchen.

There are currently two standards in force regarding the installation of boilers in the kitchen. According to one document, heating devices with a power of no more than 35 kW can be placed, according to another - no more than 60 kW. And we are talking only about heating devices. Gas stoves or other appliances using gas are not taken into account.

What to do? You need to find out what standards your GorGaz adheres to. After all, it is their representatives who will accept the equipment into operation. Actually, the designer should tell you all the details, but it is also advisable to know this - you will need to prepare the room for installation.

Where to put

Now let’s talk about where and how gas equipment of different capacities can be located. We will talk about gas boilers and water heaters, their power is summed up:

- with a power of up to 150 kW inclusive - in a separate room on any floor, including the basement and basement;

- from 151 kW to 350 kW inclusive - in a separate room on the first, basement or ground floor, as well as in a separate attached room.

More powerful installations are not used in private homes.

Requirements for kitchens in which a gas boiler is installed

When placing a flow-through gas water heater or a gas heating boiler with a power of up to 60 kW in the kitchen, the room must meet the following standards:

- The volume of the room must be at least 15 cubic meters, plus 1 cubic meter for each kilowatt of gas boiler power.

- Ceiling height - at least 2.5 m.

- Availability of ventilation: exhaust hood with a capacity of at least three times the volume of the room;

- the inflow is the same, plus combustion air.

There is one more thing that is not specified in the standards, but which exists: installing a gas boiler is allowed only in a room with doors. In light of the latest trends - removing partitions and making arches instead of doors - this can be a problem. Without a door, the permit will not be signed. The solution is to install sliding (sliding) or folding doors. Another option is glass doors. They do not “load” the interior, but they are perceived exactly as doors.

All these requirements must be met. If there are violations, they simply won’t sign the acceptance certificate for you.

Requirements for individual premises

The requirements for individual boiler rooms are similar, but there are some differences:

- Ceiling height - at least 2.5 m;

- The volume and area of the room are determined by ease of maintenance, but should not be less than 15 m3.

- Walls leading to adjacent rooms must have a fire resistance limit of 0.75 hours and zero limit for the spread of fire through the structure (brick, concrete, building blocks).

- An exhaust hood with the same requirements: for outflow - three times exchange, for inflow in the same volume, plus air for combustion.

- The room must have a window. The glass area is at least 0.03 m2 per cubic meter of volume.

If equipment is installed with a power of 150 kW or more, one of the prerequisites is the presence of access to the street. A second exit can be equipped - to a utility room (not residential). This could be a storage room or a hallway. Doors must be fireproof.

Please note that when calculating windows, the glass area is considered, not the size of the window opening. Moreover, in some cases they require at least one glass with an area of at least 0.8 square meters. If enlarging the windows is problematic, you can make a similar window in the door (the regulations do not say that it must be in the wall).

How to attach boiler rooms

Sometimes it is not possible to allocate a separate room in the house. In this case, the boiler room is added. The standards for ceiling height, volume, glazing and ventilation remain the same as for individual rooms, only specific standards are added:

- The boiler room is attached to a solid wall. There should be at least a meter to the nearest window or door.

- The walls must be non-flammable. This means they must provide 0.75 hours before ignition (45 minutes). Such materials are brick, concrete, shell rock, cinder block, foam and gas concrete.

- The walls of the extension should not be combined with the main building. That is, the foundation is made separate, incoherent, and all four walls are built.

Please note that the extension must be registered. No one will give you gas without official documents. And one more thing: when designing it, lay down all the standards without deviations, otherwise they won’t accept it. If the installation of a gas boiler is planned in an existing room, they may turn a blind eye to some deviations or offer some compensation (if there is a missing volume or height of the ceilings, they may be asked to increase the glazing area). For newly constructed buildings (and extensions too) there are no such discounts: they must include all standards.

Combined kitchens

Today it has become fashionable to have studio apartments or combine the kitchen with the living room. It turns out to be a single large space in which it is easy to implement design ideas. But the gas service regards such premises as residential and prohibits the installation of gas equipment.

It will not be possible to solve the problem with a studio apartment, but with a combined apartment there is a solution. If you are just planning to combine the kitchen and living room, when preparing the documents, call the resulting room kitchen-dining room. This premises is not residential, so there will be no restrictions. If the papers have already been completed, you can try to redo them or go the other way - install a sliding partition. True, in this case, the documents will need to be redone.

Gas boiler fuel

Gas for boiler houses is divided into natural and artificial and is a mixture of flammable and non-flammable gases and water vapor. The amount of gas fuel is measured in cubic meters under normal conditions (760 mm Hg and 0 ° C), the composition is measured as a percentage of the total volume.

Natural gas is most often used. It is characterized by a high calorific value (from 33 to 40 MJ/m3). Natural gas mainly consists of methane - its share in the total volume ranges from 76.7% to 98%. The content of other gaseous hydrocarbon compounds in its composition does not exceed 4.5%.

It is possible to install an automatic gas boiler room to operate on liquefied gas obtained from oil refining and consisting mainly of butane and propane. Density of liquefied gas 2.6 kg/m³, calorific value from 110 to 120 MJ/m³, explosion limit: 1.5% - 9.5% of the room volume, flash point: 750°C - 850°C. The winter mixture of liquefied gas for boiler houses is prepared in the proportion propane: 75%; butane: 25%. Summer – propane: 25%; butane: 75%.

Place for installing a gas boiler

If we talk specifically about apartments, then gas boilers are installed in them, mostly in the kitchens. There are all the necessary communications: running water, gas, a window and an exhaust hood. All that remains is to determine a suitable location for the boiler. For this installation, wall-mounted (mounted) boilers are used. They are installed on several hooks fixed to the walls (usually included in the kit).

As for installation in other areas of the apartment or house, as a rule, none of them meet the requirements. For example, in the bathroom there is no window with natural light, the corridor is usually not suitable in size - there is not enough tolerance from the corners or to the opposite wall, there is usually no ventilation at all or it is insufficient. The problem with storage rooms is the same - there is no ventilation and windows, there is not enough volume.

If there is a staircase in the house to the second floor, the owners often want to place the boiler under the stairs or in this room. In terms of volume, it usually passes, but in terms of ventilation it will have to be very powerful - the volume is considered to be at two levels and it is necessary to ensure its threefold exchange. This will require several pipes (three or more) of a very large cross-section (at least 200 mm).

Once you have decided on the location for installing the gas boiler, all that remains is to find a place for it. It is selected based on the type of boiler (wall-mounted or floor-standing) and the manufacturer’s requirements. The technical data sheet usually specifies in detail the distances from the wall on the right/left, the installation height relative to the floor and ceiling, as well as the distance from the front surface to the opposite wall. These may vary from manufacturer to manufacturer, so it is worth reading the manual carefully.

Installation standards according to SNiP

In the absence of such recommendations in the equipment passport, the installation of a gas boiler can be carried out according to the recommendations of SNiP 42-101-2003 p 6.23. It says:

- Gas boilers can be installed on fireproof walls at a distance of at least 2 cm from it.

- If the wall is fire-resistant or combustible (wooden, frame, etc.), it must be protected with fireproof material. This can be a three-millimeter sheet of asbestos, on top of which a sheet of metal is fixed. Plastering with a layer of at least 3 cm is also considered as protection. In this case, the boiler must be hung at a distance of 3 cm. The dimensions of the fireproof material must exceed the dimensions of the boiler by 10 cm from the sides and bottom, and from the top must be 70 cm larger.

Questions may arise regarding asbestos sheet: today it is recognized as a material hazardous to health. It can be replaced with a layer of mineral wool cardboard. And also keep in mind that ceramic tiles are also considered a fireproof base, even if they are laid on wooden walls: a layer of glue and ceramics provide the required fire resistance.

The installation of a gas boiler relative to the side walls is also regulated. If the wall is non-flammable, the distance cannot be less than 10 cm. For flammable and non-combustible walls, this distance is 25 cm (without additional protection).

If a floor-standing gas boiler is installed, the base must be non-flammable. A non-flammable stand is made on the wooden floor. It must provide a fire resistance rating of 0.75 hours (45 minutes). These are either bricks laid on spoons (1/4 brick size) or thick ceramic floor tiles laid on top of an asbestos sheet fixed to a metal sheet. The dimensions of the non-combustible base are 10 cm larger than the dimensions of the installed boiler.

Automation systems for gas boiler plants

The developed instrumentation and control systems for gas boiler houses allow you to regulate the operation of the system in automatic mode or in remote manual mode from a PC.

Automation systems manage temperature schedules taking into account the ambient temperature. The required coolant pressure is also maintained, the pump group operates in a resource-saving mode, and fuel and coolant consumption is taken into account. The heating output of a gas fuel boiler room is also regulated automatically.

If emergency situations occur, such as a fire or gas contamination, the automation system turns off the power, controls the gas shut-off valve, and automatically stops the boiler room.

produces gas block-modular boiler houses and stationary boiler houses. The cost of a gas boiler room is calculated based on the Customer’s technical specifications.

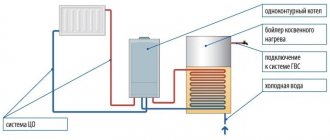

Boiler room arrangement diagram

The volume of the room must be at least 7.5 m3, and in a new private house - more than 15 m3;

Room area for gas equipment – from 4 m2;

The height of the boiler room is not less than 2 m;

The width of the doorway is from 0.8 m, and at the bottom near the floor there should be a gap (2.5-3 cm) for ventilation;

A prerequisite in the furnace room is a window with a glazing area of 0.3 m2/1 m3 of room volume.

The walls of the boiler room must be plastered and finished with non-combustible materials. Lay ceramic tiles, porcelain tiles on the floor, and pour a concrete screed.

Important! Don’t forget to install a gas meter along with the boiler or water heater.

The window in the boiler room must open and have a window. The productivity of the boiler depends on how much oxygen gets into the combustion chamber.

Technical characteristics of the gas boiler room:

| Options | ||||||||||||||

| Maximum thermal power, kW | ||||||||||||||

| Type of fuel | ||||||||||||||

| Service life, years | ||||||||||||||

| Number and unit power of boilers, pcs. x kW | ||||||||||||||

| Efficiency, % | ||||||||||||||

| Heated area, thousand m² | ||||||||||||||

| Heated volume of the room, thousand m³ | ||||||||||||||

| Type of coolant | ||||||||||||||

| Fuel inlet pressure | ||||||||||||||

| Inlet coolant pressure | ||||||||||||||

| Nominal fuel consumption, l/hour | ||||||||||||||

| Maximum operating water temperature, °C | ||||||||||||||

| Maximum working pressure MPa | ||||||||||||||

| Available pressure, MPa | ||||||||||||||

| Electrical power, kW (installed / consumed) | ||||||||||||||

| Excess air ratio | ||||||||||||||

| Temperature of flue gases at nominal capacity, °C | ||||||||||||||

| CO content in flue gases, mg/m³ | ||||||||||||||

| Nox content in flue gases, mg/m³ | ||||||||||||||

| Overall dimensions of the container, mm | ||||||||||||||

| Length | ||||||||||||||

| Width | ||||||||||||||

| Height | ||||||||||||||

| Weight, t | ||||||||||||||

| Boiler room operating mode | ||||||||||||||

Premises requirements

Construction regulations, which are approved by the state regarding the installation of gas equipment in a residential building, determine the requirements for the room where the boiler will be located. This must be taken into account when installing the system. Failure to follow these recommendations may create a fire or explosion hazard.

Important! Installation of boilers must be carried out in a room that is designated in the technical passport for a private house as a boiler room or furnace room. This room must have sufficient area and volume. In this case, the monitoring services will not have any complaints against you, because all conditions have been created for the normal operation of the equipment.

Gas boilers must be installed in the basement, basement or in a separate room on the ground floor if its power exceeds 150 kW. At lower rates, heating equipment can be installed in the kitchen. In this case, it is easy to connect to the pipelines and use a gas water heater to heat water. If the boiler room is located in the basement or on the ground floor, provide a separate exit from it.

The combustion chamber must have optimal dimensions. Please note that for 1 kW of heating system power there should be 0.2 m3 of room volume.

Installing a boiler in the kitchen - the best scheme

A double-circuit gas water heater, which not only heats an apartment or private residential building, but also heats water for household needs, should be installed in the kitchen, where there is access to a gas stove.

In this case, it is allowed to install boilers in a wooden residential building with your own hands, not forgetting about all the standards and rules:

Place the wall-mounted heater at a distance of 200 mm from the stove;

Apply 3-4 mm thick non-flammable material to the wall;

The room must have a window with a window;

A gas meter must be connected to a double-circuit boiler, water heater or stove;

Lay a sheet of durable material on the wooden floor under the column;

It is prohibited to place any objects under the wall-mounted double-circuit boiler;

The minimum distance from the column to the ceiling is 500 mm, and to the floor - 800 mm.