Differences between gas boilers by the number of circuits

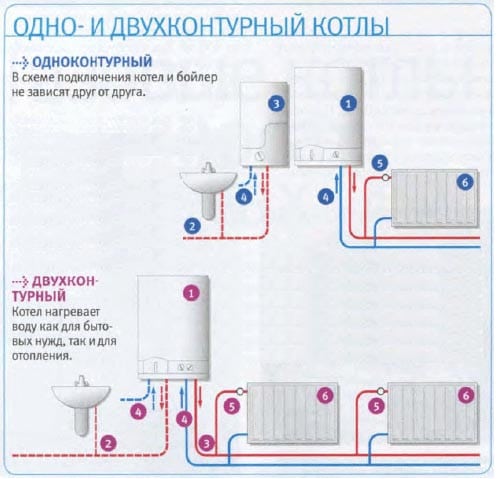

Gas units are divided into 2 types according to their functional purpose:

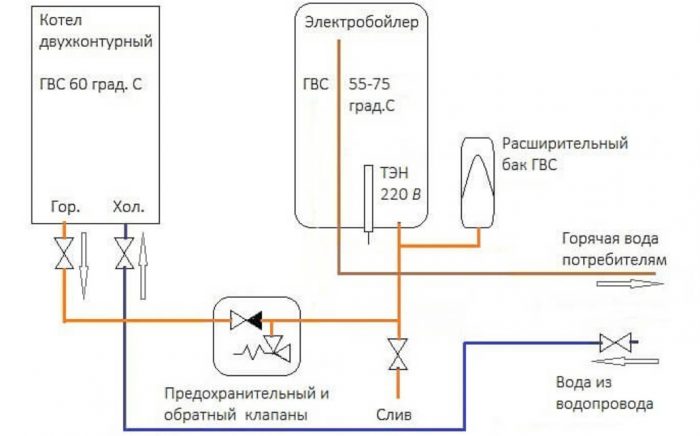

- Single-circuit. They are used only for space heating, and the heat exchanger of the device is a single structure. To organize a hot water supply system, you will need to purchase an indirect heating boiler.

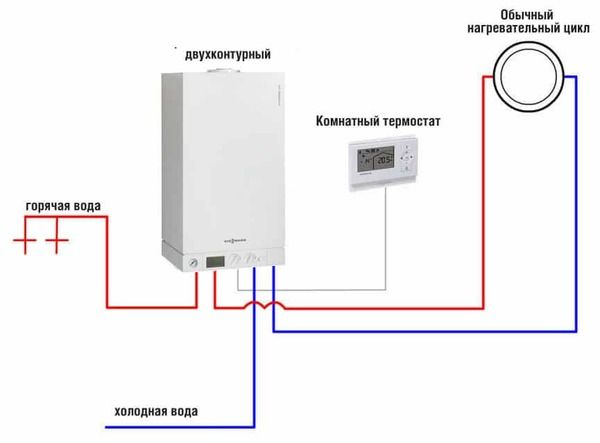

- Dual-circuit. In addition to heating the house, water is heated in the water supply system.

Benefits and Choices

To make a final decision, you need to take into account the needs of a particular family, as well as the operating conditions of the equipment.

Factors influencing model selection

As a rule, several criteria are considered before choosing a particular unit.

- Life time. Simpler devices that perform only one function are among the favorites in this case. However, not everything is so certain. The service life is affected by operating conditions, the power of the models, and the loads they experience. Water quality often becomes the main factor: “bad” liquid quickly damages heat exchangers, regardless of their number and circuits in the device.

- Comfort. In this case, the advantage is entirely on the side of double-circuit boilers, which make it possible to do without the installation of additional water heating equipment. Single-circuit models “alone” are convenient only where you only need to heat the premises. But such a “one-sided” requirement is presented to them quite rarely.

- Dimensions. Dimensions do not play a big role if we consider boilers of the same model line. Yes, wall-mounted models are more practical due to their compactness, but here, in most cases, the size depends on the performance and power of the equipment.

- Price. It also depends on the model and its power. However, if we take approximately identical units, then there is only one winner in this case: it is a single-circuit boiler. But since more often they also purchase a boiler for it, victory becomes defeat.

- Additional functions. More “advanced” dual-circuit units have a larger number of them. Features include remote monitoring and control, programming, connecting an external (room thermostat), etc.

Another important factor is the heating area, but this indicator does not depend on the number of circuits. Here the main role is played by the power of the unit. To heat 10 m2, 1 kW is required.

Help from other equipment

Future owners need to pay attention to one more point - the addition to the “face” of the boiler (gas water heater). For a single-circuit unit, this assistance is often the rule rather than the exception. However, a double-circuit boiler may also require a water heater.

There may be several such situations. The first example is a young family who did not have problems with hot water supply and heating until the child was born. In this case, much more water will be required, and a “double-action” unit will no longer cope with such a task.

The main advantages of a double-circuit boiler are small dimensions, lower cost and the ability to perform two functions at once. A single-circuit device with a boiler addition will require you to pay a large sum, and such a kit will take up more space.

Possible conclusions, but not the "real truth"

The difference between a single-circuit and a double-circuit boiler has now become more or less clear, but what to choose if the future owners cannot yet give their sympathies to one of the rivals? It all depends on the size of the house and the family living in it.

- A single-circuit boiler with a boiler can be considered ideal for a large house and the same number of residents. In this case, finding and allocating the necessary area for a boiler room will not be a huge problem. But the family will be guaranteed a stable supply of water to several consumers at the same time. For example, there will be no difficulty if one person takes a shower and the other washes dishes in the kitchen.

- A dual-circuit device is optimal for small buildings, where it is not so easy to allocate space for large equipment. However, in this case, the owners run the risk of encountering an unstable temperature of the supplied water, so there may be inconvenience when using it at the same time. But this drawback can be tolerated, and it is not significant for small families, especially those without small children.

For families of 2-3 people, in a house with one bathroom, compact double-circuit units are usually recommended. If 4-5 people permanently live in a building and it has 2-3 bathrooms, then it makes sense to think about buying a single-circuit boiler and an indirect heating boiler.

The difference between a single-circuit and double-circuit boiler is only in the circuits, but the comfort of using the units depends on them. What to choose - maximum comfort or lower costs? In this case, any advice is meaningless. The issue is resolved by the owners, who have different ideas about what convenience is, as well as the size of the house and the desire (or unwillingness) to part with a larger amount.

Leaders of user likes

If we talk about practicality, then in this category a single-circuit boiler with a connected boiler unconditionally wins over the opponent, since the owners will have a supply of truly hot water even if some kind of breakdown suddenly occurs. Double-circuit equipment, on the contrary, will not give owners such a chance, and taking an ordinary shower can become an almost unforgettable adventure.

In any case, the decision remains with the owners, and to find out what experts think about the choice, it is better to watch the following popular video:

Number of heat exchangers

The double-circuit gas boiler is produced in two versions:

- With one heat exchanger. In this version, the coolant is supplied through a special valve. When the water taps are closed, the coolant is supplied to the heating circuit, and when they are opened, the water in the DHW circuit is heated.

- With two heat exchangers. The liquid for the heating circuit and water supply is heated simultaneously. This option is more convenient and common.

Design features

The structure of a single-circuit boiler is very simple:

- Gas-burner.

- Automation that controls the burner.

- Special gas ignition device.

- A pipe that is placed above the burner and through which the coolant flows.

Because of this design, a single-circuit gas boiler can heat water only for the heating system. It can also be used for domestic hot water, but for this you need to buy an indirect heating boiler.

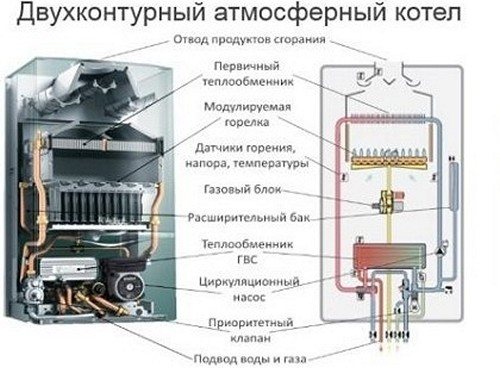

The difference between the design of a double-circuit boiler and a single-circuit boiler is the presence of:

- Three way valve.

- A small heat exchanger.

- Expansion tank.

- Security groups.

- Pump.

The rest is the same. Among these additional nodes, the first two elements are of primary importance. The rest are necessary for the safe operation of the device and the entire heating system.

A three-way valve is capable of changing the direction of movement of the heated coolant . It releases heated water into the heating network. If one of the residents of the house opens a hot water tap, the flow sensor is triggered, and on his command, the valve closes the hole that supplies water to the heating system of a private house and opens the hole through which the coolant enters the small-sized heat exchanger.

The heat exchanger is a container with a spiral pipe. Inside the container there is running water, and a hot coolant moves in a spiral, which heats the flowing substance for hot water supply . The coolant will be directed to the heat exchanger as long as the hot water tap remains open. The heating system of the house at this time remains without a heat source.

The design of a double-circuit gas boiler allows you to heat the house and have hot water in the kitchen. This is one of the reasons why people want to choose it.

Advantages and disadvantages of single-circuit gas boilers

Single-circuit units have the following advantages:

- Large thermal power.

- High reliability due to simplicity of design.

- In combination with an indirect heating boiler, they allow you to get comfortable control of the water temperature, regardless of pressure and pressure.

When using heating devices with one circuit, the following disadvantages arise:

- To organize hot water supply, you must additionally purchase a storage boiler.

- A more complex process of installing all equipment.

Single-circuit heating boilers

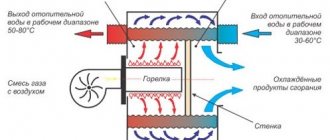

The task of the unit, which has one circuit, is only to heat the rooms and create a comfortable temperature in them. To provide hot water supply, another equipment is connected to it - an indirect heating boiler. From the name it is clear that there is only one circuit in the device, therefore the principle of its operation is quite simple. Thanks to the fuel entering the combustion chamber, the coolant circulating through the pipes inside the device is heated. Its movement is ensured either by a circulation pump (gas, electrical equipment) or by a temperature difference (natural circulation in non-volatile boilers). To guarantee high-quality heating, water must circulate in the circuit constantly.

To organize hot water supply, an additional circuit must be connected to a single-circuit unit. As a rule, a boiler plays this role. Connecting does not cause any difficulties, but such a “tandem” has disadvantages. Connecting an additional circuit causes unstable operation of the boiler. The reason is the different amount of heat required to heat water: greater consumption occurs in the morning and evening. Firstly, the boiler will have to be reconfigured to supply more fuel. After the period of maximum water intake ends, the device will begin to work again only for heating, which inevitably leads to excessive fuel consumption.

Components of single-circuit equipment

Such structures include:

- fan;

- gas block;

- chimney;

- Control block;

- gas burner and heat exchanger combined with it;

- housing, control board with self-diagnosis sensors;

- thermostat, temperature sensor;

- three-way valve;

- circulation pump.

Non-volatile models do not contain devices powered from the mains. Their design is as simple as possible, but such devices are designed for areas where there is no power supply, so they get the job done.

Types of designs

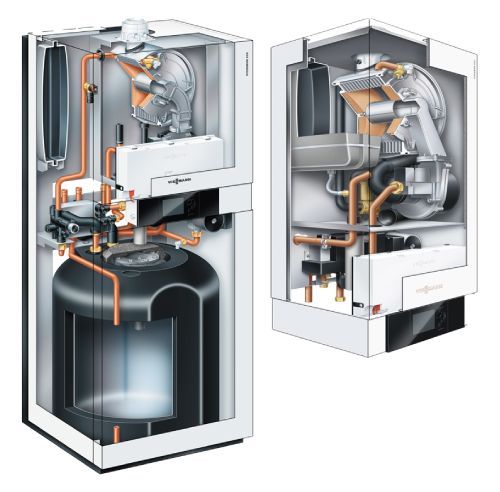

Based on the installation location, single-circuit boilers are divided into floor-mounted and wall-mounted.

- Floor-standing units installed either directly on the floor or on a stand. They are distinguished by their heavy weight and high power. Many models are equipped with the most efficient devices - cast iron heat exchangers, the price for which is greater weight of the structures. There are boilers that allow you to create a cascade connection, but they are intended for large buildings.

- Wall structures. These are compact devices that are usually attached to load-bearing walls. Since the weight of such models is very limited, wall-mounted boilers often do not have high power.

Single-circuit units are also classified according to the type of combustion chamber. It can be open or closed.

- Atmospheric - open. In this case, the air comes directly from the room in which an efficient ventilation system must be installed. Smoke removal is ensured by natural draft in the chimney.

- Turbocharged ones are closed. In such models, air is taken in using a fan that blows air from outside. The same device creates the pressure necessary to remove combustion products.

Models of single-circuit boilers may have other, additional functions. These include programming the operating mode, the possibility of remote control, allowing you to include the equipment in the “smart home” system, etc.

Advantages and disadvantages of simple devices

The only function can be considered a minus, but single-circuit equipment has advantages.

- Equipped with an automatic security system. It makes it possible to choose the optimal operating mode, which means it can reduce fuel consumption.

- Variability. Single-circuit boilers allow you to create completely different heating distribution systems for rooms, which can significantly increase the service life of the unit.

- Modern models include air temperature sensors outside the home. Depending on their readings, the fuel supply is regulated, the temperature in the pipeline decreases or increases.

Simplicity, reliability of the design, high power and the absence of its losses during heat transfer, ease of control and adjustment of the unit - these are the advantages that become decisive for many. If water heating is not required for the needs of the family, then the lower price of single-circuit models is added to the list of advantages.

Such models have one serious drawback: limited functionality. It makes the device unsuitable for those homes where there is no hot water supply. Buying additional equipment - a water heater - is a solution, but the costs in this case will increase significantly.

Pros and cons of double-circuit gas boilers

Double-circuit models have the following number of advantages:

- No installation of additional equipment required.

- The price of boilers with two circuits is equivalent to single-circuit units.

- Due to the absence of a boiler, space is saved in the room.

The disadvantages of using a dual-circuit device are:

- Changes in liquid temperature when opening the second tap, changes in pressure and pressure.

- Greater load on the heat exchanger and components, which can subsequently lead to breakdown.

Double-circuit universal boilers

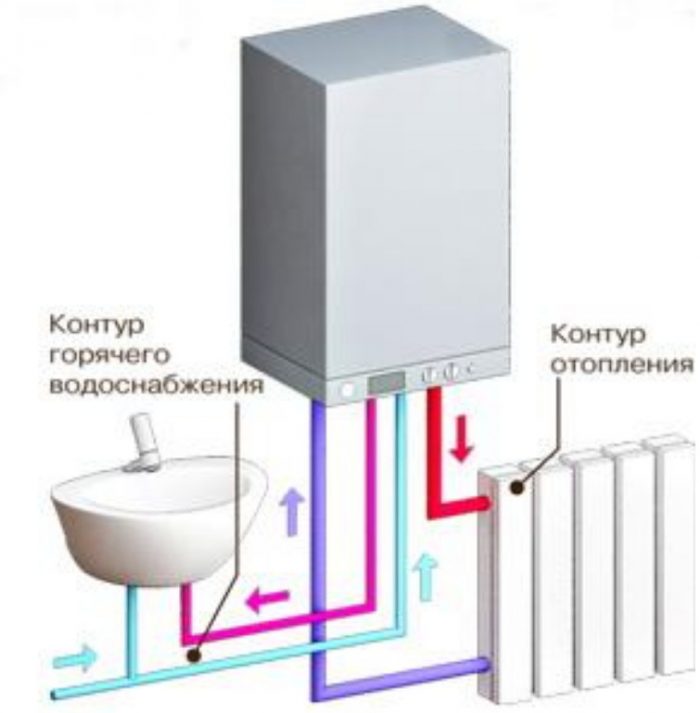

The difference between a single-circuit and a double-circuit boiler is the presence in the second equipment of a second circuit (and a heat exchanger), which is intended for arranging a hot water supply system. Powerful models make it possible to organize water supply to two water intake points at once. To prevent the water from cooling along the way, the boiler is placed as close to them as possible.

Circuits and heat exchangers

Since the cold water heating function is additional, it is guaranteed by the transfer of part of the energy from the hot coolant coming from the main heat exchanger to the secondary plate heat exchanger. This element heats water in flow mode, so such work creates restrictions for consumers, especially if there are quite a lot of them. The more intense the water intake, the worse the liquid heats up. There are models that provide priority settings for one of the circuits.

The problem of inefficient heat distribution between two circuits was solved. For this purpose, bithermic, combined heat exchangers were created. These are coils made of coaxial type pipes. Hot water circulates in their internal volume, while the external volume is occupied by coolant. Due to the simultaneous heating of liquids, inventors had a chance to get rid of the disadvantages of conventional units and prevent loss of thermal energy. Such devices are as effective as possible, but are not perfect, as they have another drawback. This is the rapid formation of limescale, which is difficult, almost impossible, to remove, and replacing the “super heat exchanger” will cost a large amount.

There are two types of double-circuit boilers: units with one heat exchanger (for example, bithermic), and partitions with two conventional elements. Firstly, the coolant used for heating needs passes through the heat exchanger. If there is a need for hot water, the coolant supply is shut off and it is replaced by cold liquid, which the equipment begins to heat. In the winter season, such a system with one element will create some inconvenience.

Boilers equipped with two heat exchangers do not have this drawback, which is why they are more in demand and popular. In them, both “devices within a device” operate independently of each other. In one heat exchanger, water is heated for the heating system, in the other, the liquid necessary for hot water supply is heated. Modern models of double-circuit boilers are equipped with steel heating elements, so heating of the coolant and cold water occurs very quickly.

Types of units

Since both types of equipment are primarily designed to heat the coolant, the difference between a single-circuit and double-circuit boiler is not so great if we consider the types of boilers with two circuits. According to installation methods, they are also divided into two types - floor and wall. The combustion chambers in these units are similar - either atmospheric or turbocharged.

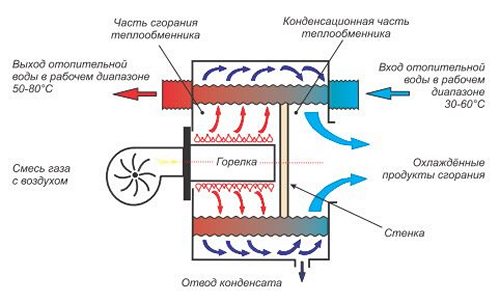

Based on the method of heat transfer, structures are divided into convection and condensation.

- Convection. In this case, the operating principle is based on the natural movement of air masses having different temperatures and densities. This is normal heating with a burner flame.

- Condensation. This is the so-called two-stage heating. First, preheating occurs due to thermal energy generated by condensation of moisture present in the flue gases. This is followed by conventional heating with a gas burner.

The second option is preferable, because preliminary preparation of the coolant allows you to save gas, change (lower) the temperature regime, but ensure a similar result in the operation of the equipment.

Another difference between dual-circuit models is the type of heat exchanger. Om can be separate and combined. The first units have two separately operating elements - a primary one, which heats the coolant, and a secondary one, which prepares water for hot water supply. Combined, or bithermic “imperfect perfections” have already been discussed above.

Pros and cons of two circuits

In addition to the main advantage, double-circuit boilers have several more advantages over their simpler competitors. This:

- lower price of equipment when compared with the cost of a set - a single-circuit device and an indirect heating boiler;

- the absence of a storage tank in which it is necessary to maintain a constant water temperature, this provides a chance to reduce heat loss and reduce costs;

- practicality - cost-effectiveness, efficiency, the ability to temporarily turn off the hot water supply.

Power, along with compactness, as well as a relatively low price, make dual-circuit devices optimal for many owners. Disadvantages - limited volume of hot water, complete dependence of the temperature in the heating system on water consumption by consumers.

What nuances should you pay attention to?

Also important points to consider when purchasing are:

- Dimensions. Double-circuit models are more compact and allow installation even in small spaces.

- Installation location. While the installation of a single-circuit boiler is carried out in a separate room, the installation of a double-circuit device differs in some nuances. Thus, the use of a double-circuit gas appliance is possible only in a building where water points are located at a short distance from each other. And the heating device itself must be placed at an equal distance from the main water sampling points.

- Power. To select the correct parameter, you need to calculate in advance the expected hot water consumption, heat loss of the building, and also take into account the maximum temperature in winter.

Disadvantages of units with one circuit

- To connect the heating system at home, you need to purchase a safety group, an expansion tank and a pump.

- Large sizes of floor-standing boiler models, as well as the need for space for the above-mentioned additional elements. This means that it won’t be possible to place it in the kitchen; additional space is needed.

- Difficult to install. It is also enhanced by the fact that it is necessary to additionally connect an indirect heating boiler and create a more complex DHW piping system. Additional pipes are needed for constant circulation of warm water through the hot water supply. It cannot circulate on its own, that is, it needs a pump.

- The cost of the boiler together with the boiler is higher than the price of a double-circuit boiler.

- Since the water in the hot water supply gradually cools down, it needs to be heated from time to time. Additional heating requires more gas. The bad thing is that this heating occurs at a time when hot water is not needed.

These disadvantages can be minimized. You can avoid difficulties with lack of space and installation by purchasing a kit with wall-mounted options for the boiler apparatus and indirect boiler. Both units are small in size and therefore can be installed in the kitchen. You will have to limit the volume of the boiler, which is why there will not always be hot water.

Where can I get advice on choosing a gas boiler?

Progreem LLC employs qualified employees who will select heating equipment with maximum precision to suit your needs, with the necessary functionality and at an affordable price. In our online store you can buy single-circuit and double-circuit gas boilers from different manufacturers, with an official guarantee and free delivery throughout Minsk and Belarus. Contact us, we will answer all your questions!

Two different heat exchangers

A heating device, each of whose two circuits has its own heat exchanger, requires a lot of space in the room. This is precisely its main drawback. However, it is compensated by at least two advantages.

- In such heat exchangers, salt deposition occurs less intensively, and therefore they can last much longer.

- The circuits are independent of each other; such models are often equipped with their own burners, so there is no need to stop the heating system when hot water is required.

By and large, a 2-circuit boiler with a pair of heat exchangers is a heating device and a gas water heater enclosed in a single housing. But this is a smarter choice than purchasing two boilers.

Which boiler is best for a private home?

Let's try to compare types of boilers with different numbers of circuits and determine which one is better suited for your home. A 2-circuit model with a single heat exchanger will be very useful when the heated building is not large in size. When almost every cubic millimeter counts, it is important to use devices that will not take up much space in the room. But if there is no need to save space, it is better to give preference to a 2-circuit device equipped with a pair of heat exchangers.

As for a 1-circuit boiler, it is advisable to install it when there is no need to organize hot water supply. Otherwise, you will need to connect a boiler. But this procedure is not cheap, and the boiler will take up a lot of space. In general, purchasing a single-circuit boiler and boiler will cost more than purchasing a boiler with two circuits (of course, if we are talking about devices with similar parameters).

However, like any heater, a boiler designed for connection to a 1-circuit boiler has some advantages over a water heater, which is an integral component of a 2-circuit device. In particular, the temperature of the water in the boiler remains constant, regardless of how much is used. The temperature will not change even if several consumers are working at once. However, you must remember that it takes time to heat the water. Therefore, it is important before purchasing to determine exactly what volume will be optimal in specific conditions.

Classification of gas boilers

By location:

- floor - placed on the floor or a special platform;

- wall-mounted - placed on the wall or in a special frame. In addition, wall-mounted boilers are low-power, but more compact.

By type of traction:

Diagram of a wall-mounted gas boiler.

- with natural draft, in which air is taken from the room where the boiler is located, and combustion products exit due to natural draft. An example of such a room would be a boiler room;

- with forced draft, in which both air intake and exhaust occur from the street. Such boilers do not require a specially equipped room.

By type of ignition:

- with piezo ignition - such boilers are turned on manually using a button and are very convenient to use if there are power outages;

- with electronic ignition - they start themselves, automatically.

By completeness of fuel use:

- convection - they use only the lowest combustion temperature;

- condensing - use the highest heat of combustion using an economizer device.

And finally, based on functionality they distinguish:

- single-circuit boilers;

- double-circuit boilers.

A single-circuit boiler is a boiler that is capable of providing only space heating if it is not equipped with an additional boiler, while a double-circuit boiler is a unit that is capable of providing both space heating and water heating for consumer needs.

Advantages and disadvantages of Zhukovsky plant products

The advantages of gas boilers are as follows:

- simplicity and ease of use;

- possibility of working in a system with forced circulation of coolant;

- affordable price;

- independence from power supply;

- service availability;

- ease of installation;

- economical gas consumption;

- long service life.

The disadvantages of Zhukovsky heating units include:

- weak automation;

- difficult to find spare parts;

- low efficiency = 80-86%;

- outdated appearance.

Standing out from the crowd are floor-standing gas boilers AOGV (gas water heating unit) with a round cylindrical shape. All products of the Zhukovsky plant are certified and adapted to domestic conditions. The presented units are not inferior in quality to foreign analogues, but are much cheaper. The manufacturer is confident in the reliability of its products and provides a 2-year warranty.

Gas boilers AOGV Zhukovsky: Comfort, Universal, Economy Plus

Gas boilers AOGV Zhukovsky have been produced by the ZhMZ enterprise for more than 50 years and heat thousands of private houses throughout the former USSR. Single-circuit and double-circuit floor-standing units have firmly taken leading positions in the market of Russian heating boilers.

The company is constantly improving its products, modernizing gas heating devices, making them more economical, installing Italian and German automatic equipment on them. Let us consider in detail the floor-standing Zhukovsky gas boilers AOGV and AKGV, taking as a basis the operating instructions (passport) of the device, customer reviews and criticism from specialists.

Let’s compare the models of the “Economy” and “Economy Plus”, “Comfort” and “Universal” series, the differences between the automation and its correct settings. Let's analyze the device and technical characteristics, compare the advantages and disadvantages of Zhukovsky

boilers for heating.

Model range, types and features

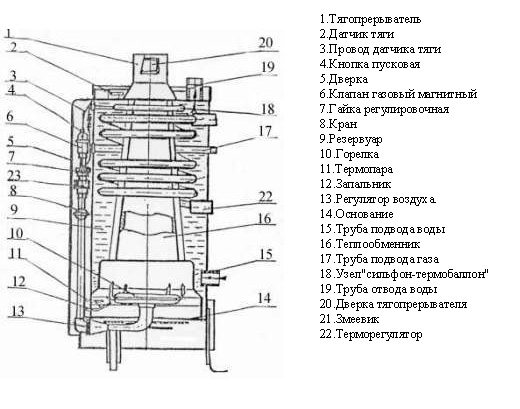

The floor-standing gas boiler AOGV Zhukovsky consists of several main elements:

— steel body; — tank for heating heating water; — main and pilot gas burners; — automation unit; — doors (on the “Economy” series); — a coil for heating running water (in double-circuit modifications AKGV); — traction breaker; — thermometer (on the “Comfort” and “Universal” series).

Floor-standing gas boilers AOGV Zhukovsky: Universal and Comfort

Heating devices are presented on the domestic market in different types and series. From the simplest and inexpensive device with still “Soviet” automation, to a modern, convenient and economical unit with piezo ignition with Italian “ SIT ” or German “ Mertik Maxitrol ” automatics.

The Zhukovsky Machine-Building Plant enterprise currently produces two types of floor heaters:

— single-circuit gas boilers AOGV; — double-circuit gas boilers AKGV.

Single-circuit units are only capable of heating a private house with a total area of 30 to 300 m2. The coolant, entering the boiler, begins to heat up in a special container due to the operation of the gas burner. Coolant temperature

at the boiler outlet it should be 50-90 °C.

Double-circuit boilers not only heat the rooms in which they are installed, but also provide the consumer with hot water, thanks to the heat exchanger coil built into the device. The water in this coil is heated to a temperature of 60 °C due to the heated coolant in the boiler, without mixing with each other.

In addition, Zhukovsky boilers are produced with different rated power: 11, 17, 23 and 29 kW. This parameter is also designated in the name of the floor-standing devices:

Gas boiler AOGV Zhukovsky Economy

— AOGV (AKGV) 11.6-3; — AOGV (AKGV) 17.4-3; — AOGV (AKGV) 23.2-3; — AOGV (AKGV) 29-2.

If a few years ago the ZhMZ enterprise was limited only to the production of devices with its own “proprietary” automation, now the company has significantly expanded the range of gas boilers and offers customers single-circuit and double-circuit AOGV (AKGV) units with installed imported automation.

Automation of gas boilers AOGV Zhukovsky: settings, operating features

Let's start with the most “ancient” automation, which the ZhMZ enterprise has been installing on its heating devices for several decades. Gas boilers with this type of automatic gas burner device are now produced under the “Economy” series, both single-circuit and double-circuit.

It contains its main elements, familiar to all of us: - thermostat; — thermocouple; — bellows-thermal cylinder; - solenoid valve with button; — nut for manual gas supply adjustment; - gas tap.

Diagram of the automation device on the AOGV boiler of the Economy series:

Boiler automation series Economy

1 — union nut from the boiler thermocouple; 2 — solenoid valve button for starting; 3 — union nut from the draft sensor; 4 — washer; 5 — pusher rod; 6 — nut for temperature adjustment; 7, 8 and 9 - bushing, nut and screw.

The automation unit is a system of levers with an electromagnetic valve, a bellows-thermocylinder installed inside the boiler tank. Using the adjusting nut, you can set the temperature of the coolant in the range from 50 to 90 °C. After the temperature of the coolant in the boiler reaches the set values, the “low fire” mode is turned on and the gas supply to the main burner of the device is reduced.

The gas supply automatically increases when the water temperature in the heating circuit drops by 15 °C or when using the hot water circuit. When the water temperature in the heating circuit reaches 90 °C, the gas supply to the main burner automatically stops.

The draft sensor is triggered when there is insufficient draft in the chimney or its complete absence. It is a bimetallic plate installed on the boiler lid, connected to the solenoid valve using a special cable.

The pilot burner is ignited as follows. It is necessary to press and hold the solenoid valve button for about 40 seconds and light the igniter with a match. After the flame appears, release the button after 1 minute. The main burner is ignited after opening the gas tap on the gas boiler.

Features of gas boilers AOGV (AKGV) Zhukovsky Comfort (N)

AOGV Zhukovsky Comfort series

The gas boiler AKGV and AOGV Zhukovsky Comfort consists of a cylindrical steel body, on the front side of which there is a gas burner and a Mertik Maxitrol automatic control unit under a special chute. On the front side of the gutter there is a thermometer, on the side there is a fitting for connecting the gas supply, and on the top there are knobs for boiler automation controls.

Adjustment knobs perform different functions:

— the right one performs piezo ignition of the boiler burner; — the left one is intended for setting and adjusting the temperature of the coolant.

The purpose of the automation of gas boilers AOGV (AKGV) of the “Comfort” series:

— supplies gas to the igniter and burner; — stops its supply when the pilot light goes out and there is no normal draft in the chimney; — turns off the boiler when the coolant temperature is above 90 °C; — the burner is ignited using a piezoelectric element; — automatically maintains the set water temperature in the heating circuit.

German automatic equipment “Mertik Maxitrol” is installed on all single-circuit and double-circuit devices of the “Comfort” series:

— AOGV-11.6-3; 17.4-3; 23.2-3; 29-3 “Comfort” (N); — AKGV-11.6-3; 17.4-3; 23.2-3; 29-3 "Comfort" (N).

Setting up automation and igniting the burner on AOGV Zhukovsky “Comfort” boilers

Automation on the Comfort series boiler

Turn the right handle all the way to the left, press it and hold it for 40 seconds. Without releasing the knob, turn it further to the left until it clicks - the igniter should light up. If this does not happen, make several clicks with the handle until the igniter lights up.

Hold the knob for another 30-40 seconds while the thermocouple heats up, move it to the “On” position - the main burner of the gas boiler will light up. In this case, it is necessary to ensure that the flame on the igniter does not go out.

Using the temperature control knob, you can set the temperature from 45 to 90 °C and control it using a thermometer. When the temperature drops by 15 °C, the main burner automatically ignites.

Features of gas boilers AOGV (AKGV) Zhukovsky Universal

Boilers of the “Universal” series are not much different in appearance from the devices of the “Comfort” series. The same chute covering the gas burner device and automation, a thermometer and a gas connection, a draft breaker with an inspection door.

Boiler AOGV Zhukovsky Universal

Their only difference is the type of automation used for devices in this series. On single- and double-circuit Zhukovsky gas boilers of the “Universal” series, Italian “SIT” automatic equipment is installed:

— AOGV-11.6-3; 17.4-3; 23.2-3; 29-3 "Universal"; — AKGV-11.6-3; 17.4-3; 23.2-3; 29-3 "Universal".

Unlike German automatics, Italian ones have only one adjustment knob and a separate piezo ignition button for the device. Designed to supply gas to the ignition and main burners, and it turns off when the water temperature in the heat exchanger exceeds 90 °C. Automatically maintains the set coolant temperature.

Ignition and adjustment of the “SIT” automation on the AOGV Zhukovsky “Universal”

Turn the adjuster knob to the “asterisk” (*) position, push it in all the way and do not let go for 40 seconds. Light the igniter by holding the handle and pressing the piezo ignition button several times. Check that the flame burns steadily; it should not go out.

Italian automatic “SIT” boiler series Universal

In order to light the main burner, you need to set the regulator knob to position “2 or “3”. When the burner is turned on, a characteristic flame noise will be heard. To turn it off, move the knob to the “asterisk” (*) position.

Zhukovsky gas boilers of the Economy Plus series

This type of floor heating units is available with a power of 11 and 17 kW:

— single-circuit AOGV-11.6-3 Economy Plus (01); — double-circuit AKGV-17.4-3 Economy Plus (01).

Like the “Comfort” series boilers, they have German “Mertik Maxitrol” automatic equipment. It is located in the lower part of the device; it does not have a protective groove or a thermometer.

Technical characteristics of Zhukovsky gas boilers

Technical characteristics of boilers AOGV (AKGV)-11.6-3

Advantages of the gas boiler AOGV Zhukovsky:

— wide selection of models; — most boilers are equipped with imported automatic equipment with piezo ignition; — the possibility of using non-freezing liquid in single-circuit devices; — operation on natural or liquefied gas (when replacing injectors); — availability of spare parts in stores; - time-tested devices.

Disadvantages of gas boilers AOGV Zhukovsky:

— outdated design; — low efficiency 86%; — high price for boilers; — Russian assembly.

We examined in detail the gas boilers Zhukovsky AOGV - single-circuit and AKGV - double-circuit. We disassembled the devices of the “Economy” and “Economy Plus”, “Comfort” and “Universal” series. Their differences, technical characteristics, advantages and disadvantages. We described the SIT and Mertik Maxitrol automation systems, their settings, piezo ignition and device features. Let's watch the video review.