Why does a gas water heater need a hood?

A geyser is a convenient device that allows you to provide residents of your home with hot water at any time of the year. Modern devices are equipped with temperature regulators, sensors for the operation of the water point and other convenient functions. But even the most modern unit will not protect against carbon monoxide if the chimneys in the house are not cleaned.

In addition, household gas is explosive, and if leaked, in a certain proportion with oxygen, it can provoke a disaster.

A hood will help solve the issue of removing combustion products and providing sufficiently high draft. It should be installed strictly in accordance with the requirements of regulatory documents.

The chimney of the column should not be confused with devices for other kitchen appliances that run on gas.

Column burner type without chimney

Burners in flueless gas equipment can be variable (automatic power control) and constant (stepped power).

Diagram of a column burner without a chimney.

Models with stepped power burners allow the user to independently set the required flame power to ensure the desired water temperature. However, it is not a fact that it will remain constant during further operation of the device. The temperature of the received water can be greatly influenced by changes in gas pressure, the temperature of the inlet water (for example, if the column was adjusted while relatively warm water was coming from the riser, and then colder water came from the street), changes in air pressure. After setting the required power, the water temperature can be adjusted by unscrewing and screwing the tap. There is no need to turn the tap on too tightly, trying to get very hot water: the column may simply turn off, and you will get the exact opposite of the intended effect. In units with manual power control, it is not recommended to obtain the required temperature by mixing cold tap water with hot water from the boiler.

Speakers with flame modulation (automatic power control) are free of all these disadvantages - after setting the required temperature, it will be maintained automatically, regardless of external factors.

Requirements for chimneys for geysers (SNIP)

Requirements for chimneys are set out in the following documents:

- SNiP 41-01-2003 in a new edition (SP 60.13330.2012);

- NPB 252-98 (fire safety standards);

- SP 42-101-2003;

- VDPO (rules for the production of pipe and furnace works).

The main provisions regarding the direct removal of smoke from household water heaters are collected in the following paragraphs:

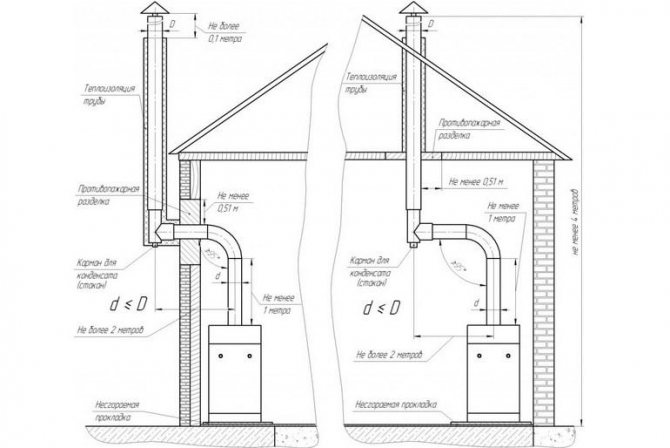

- The cross-sectional area of the chimney pipe must be greater than or equal to the cross-section of the outlet pipe of the column;

- Laying gas pipes through living rooms is prohibited;

- The chimney system must be completely sealed, resistant to corrosion and temperatures up to 200°C;

- The vertical section of the chimney at the outlet of the column should not be shorter than 500mm. Only in some cases this figure is reduced to 250mm;

- The length of connecting pipes should not be more than 3 m in designed houses and no more than 6 m in existing ones;

- The design allows for no more than 3 turns with a radius of at least the pipe diameter;

- If the wall of the building is made of non-combustible materials, the distance from it to the exhaust pipe must be at least 5 cm, if the wall material is flammable - at least 25 cm. If the fire protection requirements of SP 42-101-2003 are met, the distance can be reduced to 10 cm;

- If the connecting pipe passes through an unheated room, it must be protected with thermal insulation;

- The slope of the exhaust pipe towards the column must be more than 0.01;

- You cannot use one hood for a gas water heater and a gas stove;

- The ceiling height in the room with a water heater and chimney should not be less than 2 m. Area – at least 7.5 m for one device, at least 13.5 for 2 devices.

Method of igniting a chimneyless gas water heater

The column ignition system is, first of all, not only the ease of use of the device, but also the safety of its use. Modern chimneyless gas water heaters are represented by 3 types of ignition: electronic ignition, piezo ignition and hydraulic turbine ignition.

Water consumption table for a chimneyless geyser

The peculiarity of models with electronic ignition is that they do not need a constantly burning igniter, and the charge for the spark is created by two AA batteries. The ignition process is quite simple and is carried out by opening the water tap.

Piezo ignition is based on the piezoelectric effect, when mechanical forces are converted into a spark (electric charge). The inconvenience of using such a gas water heater is the need for constant burning of the igniter, which ignites the burner of the device.

Ignition from a microturbine (hydrodynamic generator) is a modern way of generating electricity necessary to ensure the operation of a gas water heater. Some manufacturers install real miniature hydroelectric power plants in their equipment. A miniature generator is installed in the gas water heater pipeline, generating electricity from flowing water that passes through the turbine blades. As a result, such geysers have all the advantages of models with electric ignition and do not require any sources of electricity (batteries, network, etc.).

Related article: Improved double-glazed windows for the balcony: how to choose and install

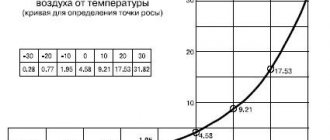

Calculation of hood parameters

Before starting work on installing a chimney for a geyser in an apartment or private house, it is necessary to calculate the parameters of the exhaust channel. These parameters determine the required amount of air removed from the room.

When calculating, the following indicators should be taken into account:

- power of heating devices;

- volume of exhaust gases;

- difference in temperatures of outside air and combustion products;

- the height of the chimney pipe (for gas installations at least 2 m).

There are many types of pipelines for geysers, of different diameters, shapes, and lengths. Standard chimney diameters are 110-130 mm. For dispenser power up to 19 kW, a pipe with a diameter of 11 cm is used, above – 13 cm.

Heat exchanger repair procedure

If traces of leaks are found inside the structure, then the problem is much more serious. A leak can form from a copper radiator in a household gas water heater, which can be caused by deformation of the tubes. It can also appear due to malfunctions in the operation of the water unit, which is typical for automatic geysers. Such a violation indicates a malfunction of the gearbox, which can cause the column to completely fail.

Hard water from the city water supply, improper connection (grounding), and frequent overheating of the column contribute to the fact that scale begins to form on the walls of the heat exchanger pipes. The material of the radiators is not particularly durable, so fistulas quickly appear on the surface of the pipeline and heat exchanger.

Owners of modern geysers very often encounter this problem. This is due to the fact that such devices use thin copper, often of low quality. To correct the problem, you can perform ordinary soldering at the site of the fistula.

Stage #1 - draining water from the radiator

It is worth noting that you cannot immediately proceed to soldering. First, you should make sure that the dispenser is disconnected from the gas and electricity supplies.

It must also be disconnected from the water supply and the heat exchanger, which contains a sufficient amount of coolant, must be completely emptied. If this simple precaution is neglected, the incoming heat will be constantly removed due to the liquid.

It is not possible to remove all the liquid from the heat exchanger using a tap. Therefore, you should unscrew the nut that is placed on the pipeline. Now all that remains is to get rid of the leftovers. For this purpose, you can use an ordinary vacuum cleaner or compressor, or you can also manually circulate air using a garden hose.

Stage #2 - soldering copper pipes

When the heat exchanger has been completely emptied, you can begin soldering. But how to properly solder a heat exchanger in a gas water heater in places where fistulas form? This is quite easy to do, since the whole process is well established. If you have never done this, we recommend that you read the instructions for soldering copper tubes.

First, you should take a fine-grain emery cloth and work it over the required area. Cleaning the fistula should be carried out until there are no oxides left. It is not difficult to determine their location, since such copper has a greenish tint.

After cleaning is completed, rub the desired area with a cloth soaked in cleaning agent. Now you can proceed directly to tinning. To do this, everyone individually selects solders for themselves. You can also take the advice of professionals who recommend using POS-61. All that remains is to take a soldering iron with a power of 0.1 kW and rosin as a flux.

If rosin is not available, you can use aspirin. It is sold at the pharmacy. It will be effective in situations where it is necessary to work with a problem area that cannot be completely cleaned.

When soldering is done on the heat exchanger of the gas column in the required place, evenly distributing the layer of solder over the area, it is necessary to increase the thickness of the homogeneous mass to 2-3 mm. Thus, the fistula will completely close and will not appear again.

What kind of corrugation is used for chimneys

Combustion products in an apartment building are discharged into the ventilation duct, in a private apartment - to the street. Depending on where the gases are discharged, the pipes are divided as follows:

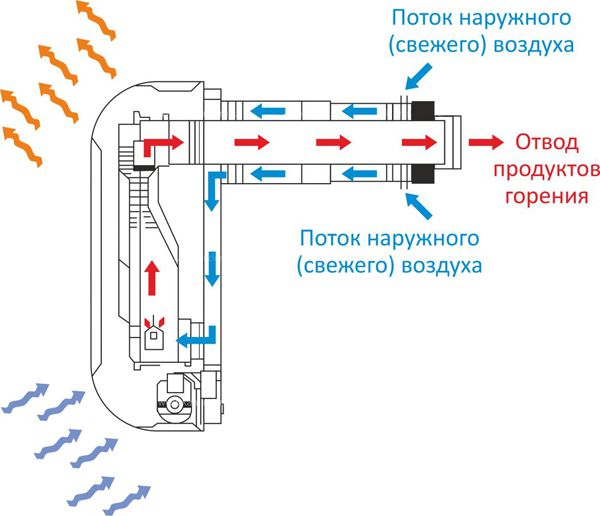

- Coaxial - the pipe exits through the wall or roof of the house to the street;

It is a structure of two pipes, the larger of which is put on the smaller one. Oxygen from the street is supplied to the fire through the free space between the pipes.

- Chimney - with connection to the ventilation duct.

Chimney pipes, in turn, can be smooth steel or corrugated.

- Smooth steel pipelines. Covered with white heat-resistant enamel or galvanized. Maximum length -1.5m. Made from sheet steel with a minimum thickness of 0.6mm. Due to temperature differences, condensation forms in the pipes and freezes in winter. Therefore, the structure must be carefully insulated.

- Flexible corrugated air ducts. Corrugated pipes are the best choice for removing waste gases from the column. They are convenient, reliable, and inexpensive. Due to their low weight and flexibility, they are easy to install.

The standard diameter of corrugated pipes is 11 and 13 cm. Maximum length – up to 3m. If you need to mount a longer section, the parts are connected with metallized tape. It can also be used when repairing corrugation.

When choosing a pipe for exhaust, it is necessary to take into account the temperature of the exhaust gases. Usually in the column it reaches 200-300°C, so the operating temperature of the corrugation should be at least 350°C.

Corrugated chimneys are made from stainless steel or aluminum.

In the case of gases venting through the wall, a special hole is prepared in it with an installed passage pipe, isolating the wall and the pipe from each other.

Let's look at the features of each material.

Stainless steel chimney:

- Withstands heating up to 900°C.

- Stainless steel is a durable and corrosion-resistant material;

- The corrugation bends in any direction and does not require additional fittings.

Aluminum:

- The multilayer structure made of aluminum foil and reinforcing wire is not inferior in flexibility to stainless corrugation;

- The temperature of the exhaust gases should not exceed 400° C;

- Aluminum is lighter than stainless steel and has better stretchability;

- These products are inferior to their stainless steel counterparts in strength.

The use of aluminum pipes is not prohibited, but, as practice shows, inspectors in most cases require replacing aluminum with another material.

In any case, you should purchase only certified products.

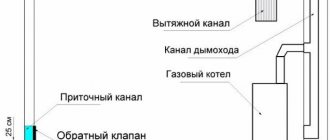

Flue gas removal system for a column without a chimney

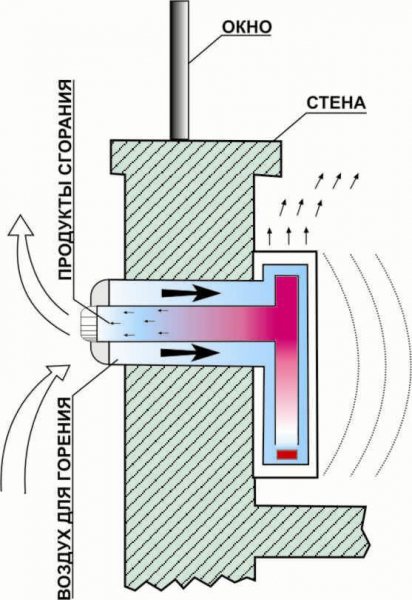

Scheme for removing flue gases from a column without a chimney.

Geysers without a chimney use a closed combustion chamber. Exhaust gases are removed and air is supplied using a coaxial chimney (the so-called pipe in a pipe), leaving the room through the wall.

A chimneyless geyser is perfect for rooms that do not have a traditional chimney. In this case, combustion products are removed through a special coaxial chimney, for which it is enough to simply make a hole in the wall. The use of a chimneyless gas water heater will allow the use of various modifications of chimneys when designing. The gas exhaust system can be designed as a horizontal chimney or as a vertical chimney.

The purpose of the column hood and its types

The main purpose of the hood is to remove gas combustion products in the column burners. Carbon dioxide and water vapor themselves do not pose a danger to humans, but their excess reduces the amount of free oxygen. But that's the best case scenario. The exhaust gases contain a considerable amount of products of incomplete combustion, including the most dangerous component - carbon monoxide. Carbon monoxide poisoning is most common when operating boilers and furnaces using solid, liquid or gaseous fuels.

The second purpose of the hood is forced air circulation in the room where gas-powered appliances are to be installed.

Based on their types, hoods are divided into two categories:

- Built into standard chimney ducts;

- Individual exhaust devices.

Hoods in a private home usually belong to the second type.

Hoods can also be divided into:

- rigid, the installation work of which involves the use of straight short sections connected by special corners with sealing of the joints using special metal tape;

- flexible, made of corrugated pipe, allowing it to be bent in the desired direction.

Rigid and flexible hoods for geysers

All versions are made of metal, which must have high corrosion resistance to combustion products. This:

- Stainless steel;

- Enameled steel;

- Aluminum.

Enameled pipes have the greatest resistance to corrosion and low resistance to the movement of gases, but they have increased weight and allow installation only of straight sections.

Corrugated hoods are preferred in most applications. Even the fact that the corrugated surface has increased resistance to the movement of gases, the absence of sharp kinks and smooth transitions fully compensates for this fact.

Advantages and disadvantages

The column is also called an instantaneous water heater. This device, due to the combustion of gaseous fuel in burners, increases the temperature of the water passing through the heat exchanger. Gas can be supplied centrally through a common pipeline or come from a gas cylinder. In city apartments, in the vast majority of cases it is of natural origin.

In old houses it is impossible to install electric boilers, since the wiring will not withstand the load. Therefore, a gas water heater is the only option.

The burner in old appliances is lit by a match. The degree of heating is regulated by the speed of water flow. The new speakers use auto-ignition controlled by an electronic control system. The electronics also take care of temperature regulation.

In this video you will learn how to install a gas water heater:

The advantages of water heating columns include:

- fast water heating;

- small dimensions of the device;

- thanks to the direct-flow circuit, thermal energy losses are minimal;

- hot water begins to flow into the system immediately after turning on the device;

- low cost of operation.

It should be understood that the power of such a water heater cannot exceed the capabilities of the gas mains supplied to the house.

The disadvantages of the equipment include:

- high explosion and fire hazard;

- for effective operation of the device you need good traction;

- chimney installation required;

- Effective ventilation is required.

To reduce the risk of fire or gas explosion, strict rules have been developed for installing a gas water heater in an apartment. The installation itself can only be carried out after agreement with the relevant authorities. These rules indicate all the necessary parameters from the area of the room to the height at which the gas water heater should be hung.

Requirements for chimneys

The standards establish the following requirements for the installation of air ducts for geysers:

- the diameter of the exhaust pipes must exceed the size of the outlet pipe;

- to select the material, the maximum operating temperature is +2000C;

- laying smoke exhaust ducts inside residential premises is prohibited;

- the maximum permissible number of pipe turns is up to three;

- the minimum length of the section without joints is more than 3 m (in new buildings at least 6 m);

- the length of the outlet at the outlet of the device must be at least 0.5 m;

- the distance to walls made of fireproof material is more than 50 mm, non-flammable material is 250 mm or 100 mm if insulation has been installed;

- the slope of the pipe is from 0.01 away from the heating device (at least 300 per linear meter);

- Only one chimney can be connected to the device;

- The minimum distance between equipment is selected to be at least 0.75 m.

How we are working

Remember, according to the existing legislation of the Russian Federation, organizations that have received the appropriate approvals and permits have the right to perform work related to gas equipment and communications. You should not trust the work to dubious persons, even if their price for connecting a Bosch gas water heater is much lower. After all, people’s lives and health are at stake. In addition, if you connect yourself or involve persons without the appropriate license in the work, you will lose the manufacturer’s warranty and risk receiving a serious fine from regulatory authorities.

Do you need to connect Bosch geysers in Moscow in compliance with all standards and requirements? Contact . We have all the necessary permits and documents to carry out work with gas equipment and communications.

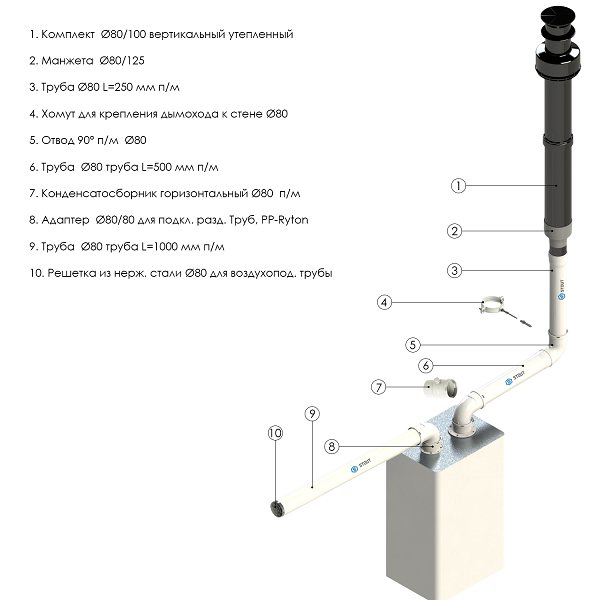

Types of exhaust pipes

Exhaust pipes can be of the following types:

- rigid, connected by fittings;

- flexible or corrugated;

- coaxial, which are a complex structure in which the outflow of combustion products is realized through one channel, and the influx of fresh air into the other.

Using corrugation is beneficial due to ease of installation, minimal number of connecting joints, and high level of tightness. Coaxial ones are the most expensive, but they do not require thermal insulation and are safe to use.

Corrugations for geysers are:

- stainless steel – resistant to corrosion, flexible, heat-resistant (up to +9000C), not exposed to acidic environments, and does not require the use of adapters for installation;

- aluminum - operated at temperatures up to +5000C, resistant to aggressive environments, corrosion, high humidity, the surface is easily scratched, deformed, high cost;

- enameled steel - heat-resistant, durable, have excellent aesthetic properties, the protective layer is not resistant to mechanical damage, it is necessary to monitor the integrity of the enamel;

- galvanized steel - do not require maintenance, are resistant to humidity, corrosion, and susceptible to mechanical damage.

Corrugated pipe for geyser

Types of chimney

The choice of a suitable pipe depends on the operating principle of the column. They are divided into two types:

- With an open combustion chamber (atmospheric). Combustion is supported by natural air pressure taken from the room. Therefore, ventilation is important here.

- With a closed camera. These are turbocharged models in which the air is forced by a fan.

Modern models are closed type. They are convenient to install both in apartments and private houses. Such a device can be called chimneyless, since it requires the connection of one type of channel - coaxial. The design includes two pipes that are inserted into one another.

The coaxial channel must be the same diameter as the output pipe of the column, no less. The same selection criteria exist for closed-type equipment, only in this case the choice of materials and designs is greater:

- Steel chimney . Consists of stainless pipes no more than 1.5 meters long. Used to organize drainage inside the house. Assumes no more than three bends during assembly;

- Double-loop sandwich . The design consists of two stainless pipes, which are located one inside the other. A layer of insulation is laid between them. Great for organizing in an unheated room when you need to avoid freezing. Also prevents the appearance of condensation;

- Brick, asbestos-cement, ceramic shafts , which are embedded in the inside of the wall;

- Corrugated leads made of aluminum foil or stainless steel - exhaust pipes for connection to the shaft.

Today on the market you can find steel structures that are coated with heat-resistant white enamel. This is an excellent solution for the internal arrangement of a chimney. It looks more aesthetically pleasing compared to galvanized.

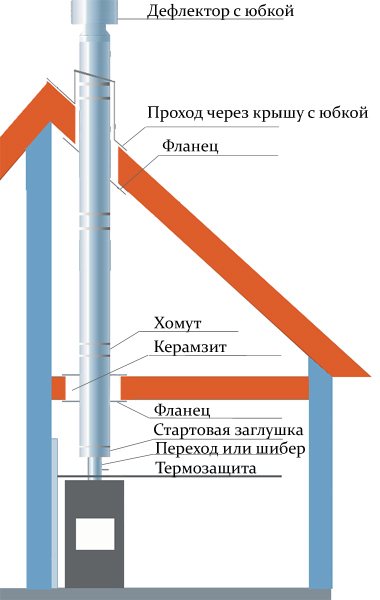

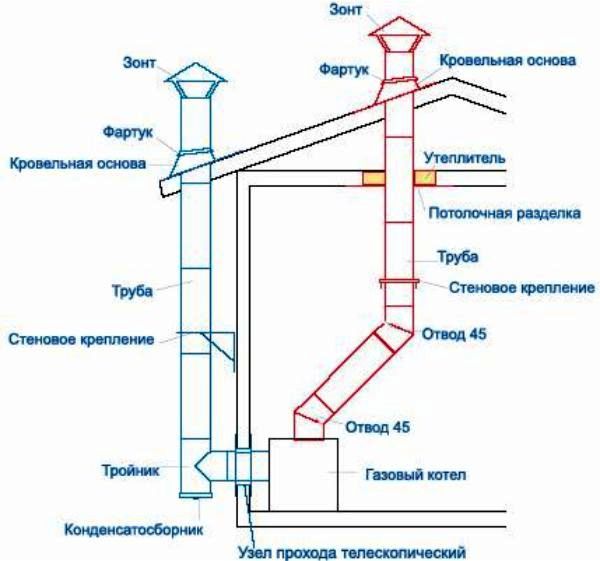

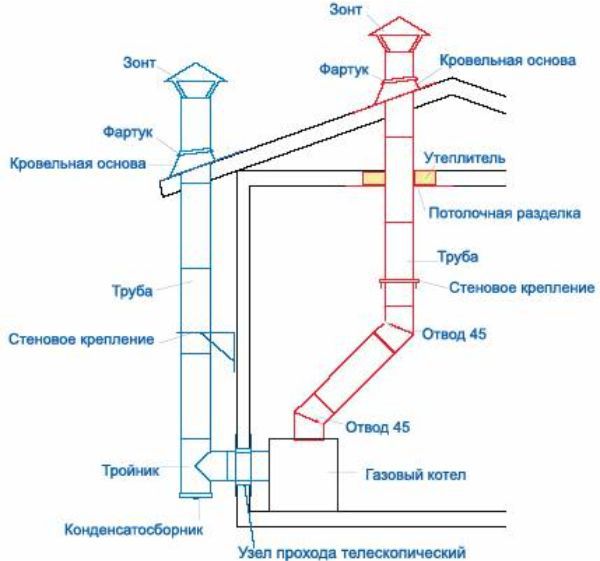

Chimney system design

Design components that you will need during installation:

- Umbrella - upper protection against foreign elements entering the hole;

- Chimney pipe;

- The pipe is an insulating element;

- Mounting brackets;

- Connecting elements - clamps;

- Tee - allows you to move from the column body to the hood;

- Monitoring window (hatch) - allows you to monitor the condition of the mine;

- Collection for condensate.

What is better to choose

Many apartment residents choose the cheapest option - corrugated aluminum pipe. They are easy to install and bend in any direction. At the same time, they are quite dangerous. Aluminum can burn out at any time, and carbon monoxide poisoning can be fatal.

Connecting a stainless steel outlet is safer. Purchase and assembly will cost more than corrugation, but you will sleep peacefully, because this design is reliable and durable.

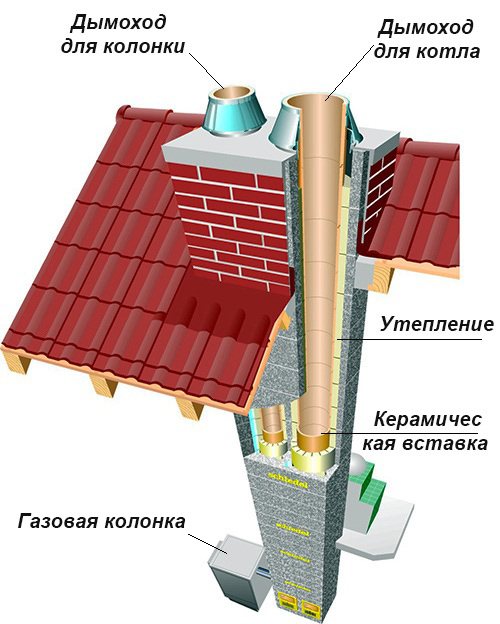

When building a private house, a chimney is immediately laid. The shaft is lined with bricks, and an asbestos pipe is installed inside to prevent condensation from accumulating. Moreover, separate smoke removal systems are provided for the column and boiler.

Another option for your home is an external steel chimney. It is insulated inside, easy to install and effective. If you bought a house without a hood and a solid shaft, then this will suit you.

The outer structure is equipped with a pocket with a steel tap for collecting condensate.

Things to consider:

- The height of the outlet channel must be at least 4.5 meters. It is important that the entire hole is of the same diameter, without narrowing, otherwise there will be poor traction;

- The standard diameter is 11–13 centimeters. Selected individually depending on the device model;

- Climatic conditions. The selection of designs and materials that will be resistant to cold and heat depends on this criterion;

- The chimney must rise above the roof of the house by at least 1 meter.

How to install a geyser

Now we have come to the actual installation of a gas water heater in the apartment. Once you have managed to register your activities in all inspections, install gas lines, receive a complete set of documentation and fulfill all technical conditions, setting up a gas water heater will not be difficult.

Main stages:

- Remove the front panel and use the markings of the fasteners to determine the location of the anchors. Checking the correctness of the markings is carried out using a building level. Drill holes, screw in dowels and anchors.

- Install the mounting plate (present in most models) and level with a building level.

- Place the column directly on the plate. A characteristic click will indicate the correctness of this action.

- Lay a corrugated pipe from the water heater outlet to the common chimney. Work through the wall with a hammer drill and insert a chimney there. The space between the wall and the chimney must be sealed with foam.

Choosing a location for installation

The standards for installing a geyser in an apartment require the correct placement of the equipment. First of all, they are based on the installation of the hood in accordance with all the rules, the convenience of the location of the water heater and the possibility of conducting communications.

The volume of the room must exceed 8m3.

The wall on which the unit is hung must be fireproof. Otherwise, galvanized metal sheet up to 1 mm thick is used. If we talk about at what height to hang a gas water heater, then everything is accurate here - from the side panel to the wall there is at least 15 cm and in front of the front panel there is at least 60 cm of free space.

In a living space, you can either place a new appliance in the kitchen or replace an old one in the bathroom. About how to install a gas water heater in a private house, we can say that the installation rules are the same as in an apartment building. These were the requirements for installing a gas water heater in an apartment or private residence. It can also be placed in non-residential specialized premises with the appropriate permits.

Preparation

If you need to replace the column, then first of all we dismantle the old device. Be sure to check the quality of the valve lock on the gas pipe to avoid gas leakage. All valves in the water supply must be closed.

Now disconnect all pipes and flexible hose with gas from the column. The chimney is also dismantled. The column is removed (after detaching the front panel).

Very often the wall needs cosmetic repairs. Old fasteners are removed and the holes are filled with a special solution.

During final installation, the wall is leveled. A special adapter is connected to the chimney to connect the corrugations. pipes.

Installation

You will need:

- drill (or hammer drill) with a set of drills (0.8-1 cm);

- a set of fastenings (screws, anchors), the type of fastening is selected depending on the speaker manufacturer;

- bubble, laser level.

To gain access to the water heater mounting, you need to remove the front panel. Next, according to the markings of these fastenings, mark on the wall the places where anchors or hooks are attached. The location of the marks must be checked by level. Using a drill, holes are drilled (2.4 pcs.), where anchors or dowels are then placed.

Most modern models have a plate that is primarily mounted on the wall. This greatly simplifies the installation of the gas water heater. The plate is applied to the wall, leveled and fastening locations are marked.

Drill a hole at the desired height and secure the plate, level it. Next, drill the remaining holes. This completes the installation.

All that remains is to secure the water heater. Place the front panel aside so as not to damage it (it is too early to attach it).

The chimney for the column is most often a corrugated flexible steel pipe. Go through the wall with a hammer drill, then insert the chimney. The remaining gap is either sealed with non-flammable insulation or simply filled with foam.

Gas connection

When installing equipment for the first time, a gas pipe is required. This work is performed exclusively by gas service specialists who have the appropriate permits. To do this, you will have to fill out an application and invite masters. They will work on inserting the tee into the pipe going to the slab. A pipe is connected to the tee and then moved to the installation site.

If you know exactly the model of the device, bring the tube to the joint to avoid the use of a flexible hose. Please note that there is a gas valve in front of the connection. First of all, the column is installed on the wall, and therefore a gas pipe is supplied to it.

An even simpler way is to bring the edge of the pipe up to a distance of 50 cm to the installation site and complete the path by connecting the gas valve. In this case, you will not have to focus on the work schedule of the gas service technicians, and carry out the installation at a convenient time.

Water connection

A pipe with cold water is directed to the device, and hot water is distributed throughout the house. It is better to connect to the water heater using an American connection (connection with a movable snap-on nut).

Be sure to place ball valves along the hot and cold water lines as shut-off valves.

The durability of the heat exchanger depends on the purity of the water. Therefore, it is advisable to install a filter.

There are two ways to lay pipes:

- At a distance of less than 30 cm, connect using a flexible hose or copper tube.

- Depending on the material of the main wiring, make a direct connection of metal-plastic, polypropylene, steel pipes.

Starting and setting up a gas water heater

Before starting, you should check for seams. Gas and water pipes must be sealed. To check if this is the case, there is a proven method:

clean all connections and fittings with soapy water;

- open the gas tap;

- check for bubbles on the connections;

- It is much easier to check water supply joints, just make sure they are dry.

The launch is carried out according to the instructions of the purchased device. Another important stage is setup. It is produced using a pressure gauge (the price of this device can vary greatly depending on the functionality). The gas pressure is set with an adjustment bolt, and the air supply is set with a wiper.

Selection principles

A corrugated pipe for a geyser is selected taking into account the following criteria:

- volume of exhaust gases;

- terms of Use;

- chimney height;

- temperature of combustion products;

- diameter of the gas equipment outlet pipe;

- the presence of aggressive or toxic elements;

- weight of the structure and load-bearing capacity of the walls.

Calculation of hood parameters

The exhaust power for geysers (m3/hour) is determined based on the formula:

, where S is the area of the room in which the equipment is located;

H - room height;

k is the number of air replacement cycles per hour, taken equal to 12, according to current standards.

The resulting value must be increased by 15–20%, since the equipment cannot constantly operate at maximum power. Gentle operating modes will extend the life of the column and increase the safety of its operation.

The volumetric flow rate of gas combustion products L is calculated as follows:

, where Qt is the selected power of the dispenser, kW.

Based on the volume flow, the diameter of the outlet pipe is determined. If there is no suitable model, then the closest one with higher performance is selected.

Average prices per set

A steel gas pipe with a diameter of 115 mm or more will cost approximately 17 thousand rubles, depending on the length, type of insulation, and the number of additional elements. A similar stainless steel set will cost from 19 thousand rubles. The cost of enameled steel structures starts from 65 thousand rubles, and aluminum ones - from 90 thousand rubles.

The price varies depending on the diameter of the chimney, configuration, and manufacturer.

The best gas water heater, semi-automatic

The Bosch Therm 2000

- The classic shape, small parameters and soft shades allow the device to be used in any design.

- An electric type of burner that is powered by standard batteries.

- The presence of a copper heat exchanger significantly improves operation and performance properties.

- To use liquefied gas, manufacturers offer the use of an additional kit with a burner.

- The device operates at a minimum fluid pressure of 0.15 bar.

Pros:

- The presence of two separate handles for adjusting water pressure and power.

- The water heater has high performance and heats more than 10 liters of liquid per minute.

- The minimum diameter of the device's chimney is 11 cm.

- The use of European components, which significantly affects the service life.

Minuses:

- Availability of Chinese components, which often fail.

- Automatic ignition is too loud.

- Expensive spare parts made in Europe.

Gas boiler hoods: design, features

Gas heating boilers with a power of up to 30 kW are usually placed in a kitchen with an area of 15 square meters. Requirements for the window are an area of 0.3 square meters, a ceiling height of more than 2.2 m. In this case, the presence of a window in the room is mandatory.

Higher power equipment requires a special boiler room. In any case, a high-quality hood for a gas boiler is the most important condition for its efficient and safe operation.

The main elements of a reliable hood for a gas boiler:

- passage box;

- pipeline outlet;

- adapter for securing the inlet and outlet pipes;

- crimp clamps with brackets for fastening to walls and ceilings;

- telescopic pipes;

- a tee equipped with a condensate drain;

- special bends;

- cone tip.

Materials for exhaust structures

The temperature of gas combustion products is within 400...450 degrees. Therefore, hoods for gas boilers and modern water heaters are made of heat-resistant materials. Due to insufficient tightness and reliability brickwork , previously widely used for chimneys, is now used as a decorative element for metal pipes.

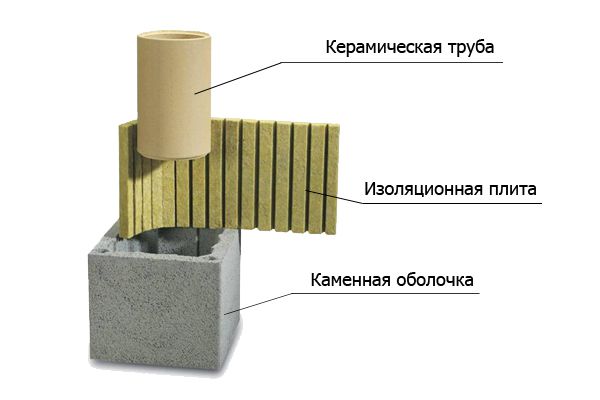

Ceramic exhaust pipes, wrapped with insulation in an expanded clay box, are used relatively rarely due to their high cost. The key advantage of ceramic routes is durability.

Metal pipes with a thickness of about 0.6 mm are mainly used . Lightweight aluminum is easy to install and reduces the risk of condensation. Aluminum foil is also used to make corrugated pipes, which are popular for hoods, easy to install, and condensate-resistant. Strong, reliable steel pipes are made of stainless steel or protected with an enamel heat-resistant coating.

A highly effective solution is to use coaxial pipes. Flue gases are vented outside through the internal pipeline, and air is sucked in between the pipes. By heating the air, the efficiency and efficiency of equipment is improved and gas consumption is reduced.

It is mandatory to use a coaxial pipe to exhaust a gas boiler and a closed-type column.

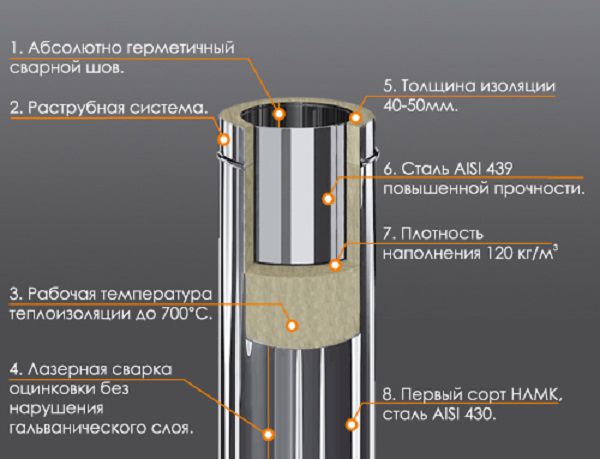

Thermal insulation requirements

Thermal insulation must be used to eliminate condensation. Often, hoods for geysers are made from double-circuit chimneys with an internal stainless pipe, an external galvanized pipe and thermal insulation between them.

Heat-resistant materials are used as thermal insulation - usually mineral fibers. Galvanized pipes are used only for the external coating of heat-insulated channels, since overheating of zinc above 419.5 degrees leads to its melting.

DIY boiler

From the geyser

To heat a small room, for example, for a garage or a sauna, if you have the “right hands,” you can make a heating boiler from a gas water heater by making some changes in it. How to make such a gas boiler and what drawings are needed for this modification? The column has a fairly high output, which is not needed for heating, and consumes a large amount of gas.

To reduce gas consumption, you can install two Chinese gas burners, drilling out the jets by 1 mm. For the expansion tank, you can use a gas cylinder or a plastic container. The expansion tank should be installed on the supply line so that no vacuum is created during pump operation.

You can buy a pump, or you can use a used one, for example, from a washing machine. If there is a timer in the automatic dispenser unit, it will periodically turn off your mini-boiler. The control unit should be replaced with a new one, without a timer. Such a device can also operate on bottled gas.

From a gas stove

Actually, making a boiler from a gas stove is problematic; you can make something like a boiler with your own hands using a gas stove. This device is used during the off-season, when the central heating is not yet turned on, and the apartment is already quite cool, since given the low power, it will not be possible to fully heat the home in severe frosts.

A metal container with water is placed on one of the heating burners. Pipes leading to a plastic pipeline are connected at the top of the tank, and the return line is connected to the side, at the bottom of the tank. A pump is installed that supplies liquid to the batteries.

In case of a power outage, you can connect an uninterruptible power supply from your computer. To ensure safe operation of such a heating device, an expansion tank should be connected; an unused small gas cylinder is suitable for it,

or a plastic container. It would also be useful to install a safety valve that will work in such a unit if you forget to turn on the circulation pump, or there are problems with the power supply to it.

From a cylinder

A gas cylinder is used for production; the boiler operates on the principle of a pyrolysis boiler, in which the coolant is heated by gas combustion. In order to make such a device yourself, you will need:

- gas cylinder of 50 liters (enough to heat a room up to 70 sq.m.;

- welder;

- electrodes;

- grinder or gas cutter;

- Metal sheet.

You can cut out the side door for loading fuel, or you can load it from above. The top of the cylinder is cut off, the cut part, after minor modifications and the installation of handles on it, is used as a lid. A piston with a lower nozzle is immersed into the cylinder. The nozzle consists of a hollow pipe through which combustion air enters. A “pancake” of slightly smaller diameter than the diameter of the cylinder is welded to the bottom of the piston.

Arc-shaped blades (can be cut from a cylinder) are welded to it to create a vortex flow over the smoldering fuel. A metal circle of smaller diameter than the “pancake” itself welded to the blades in the lower part will prevent the appearance of an open fire. This design ensures a slow smoldering of the fire, and the gas, rising, will burn in the upper part.

A hole for the chimney is cut out on the side of the cylinder, a drain pipe is welded and taken out. The chimney pipe is made of pipes of two diameters, the side bend is 0.15 m, the vertical bend is 0.2 m. The difference in diameters will create a two-stage draft, more passive than in a pipe of the same size, which ensures long-term combustion, up to 10 hours.

The water jacket for heating can be made in different ways - around the body of the cylinder or around the chimney. A unit with coolant around the chimney is more economical, as it uses heat that usually evaporates outside. Heating pipes are connected to the jacket, and an expansion tank is mounted on the upper supply pipe, which can be made from a small-capacity cylinder. A pump is installed to provide forced circulation.

From a solid fuel boiler

When connecting a gas main to their home, owners of solid fuel boilers begin to think about how to make a gas boiler out of solid fuel. If you simply insert a gas burner into the lower part, there will be no savings. Solid fuel boilers are not suitable for operation on gas and in this situation most of the heat will escape through the chimney.

It is possible to obtain a modernized device with high efficiency by significantly changing the design of the solid fuel unit. But with such a change in the heat generator, it will no longer be possible to use it in the future as a solid fuel one. The modification consists of welding one-inch metal pipes above the burner of the unit.

In this case, the burner flame will not go into the chimney pipe, but will give off thermal energy to the water circulating in these pipes. First, the boiler is dismantled and the casing is removed. Before starting remodeling work, there are several points to consider:

- pipes are placed at a height of 30 mm from the burner;

- to avoid stagnation of liquid in the pipes and its boiling, they are placed at an angle;

- the pipes are arranged in a checkerboard pattern in three tiers, the distance from one pipe to another should be 1.5-2.0 cm.

From the outside of the boiler, using a grinder, a hole is cut out in the water jacket with a small margin for ease of welding.

To drill holes in metal for pipes, you will need a crown with bits made of Pobedit. The diameter of the crown should be several millimeters larger than the diameter of the pipes to allow the pipe to be positioned at an angle.

Water the drilling area with soapy water from time to time to prevent the pobedite bits from flying off due to overheating. It is best to weld pipes with a gas torch. After all the pipes have been welded, it is necessary to seal the water jacket. Weld a reinforcement pin in the center, which will subsequently prevent the boiler from swelling.

Then weld a hole in the water jacket around the perimeter. Before installing the boiler, pour water into it and check for leaks. If detected, the window is cut out again and the leak site is welded.

Features of the chimney device

The ventilation system for removing waste combustion products and ensuring air flow in the room has the same device, whether it is a corrugated hood for a gas water heater or a solid brick chimney. The chimney must consist of the following parts:

- Feedthrough pipe.

- Pipe for removing combustion products.

- Adapter for connecting previous parts to each other.

- Crimp clamps and mounting brackets.

- Telescopic tubes.

- Tee with a hole in the region to remove condensate.

- Bends.

- Cone tip.

All parts can be attached one by one independently, without violating safety precautions, using special non-flammable materials. But it is better to turn to professionals.

How do chimneys differ from each other? The material from which the parts are made, the choice of pipe installation method and the geometry of the ventilation shafts.

How to choose material for the hood?

For these purposes, brick, galvanized and stainless steel and ceramics can be used. Let's take a closer look at each of them, and also study what other options the market and engineering offer.

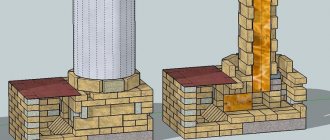

Brickwork hood

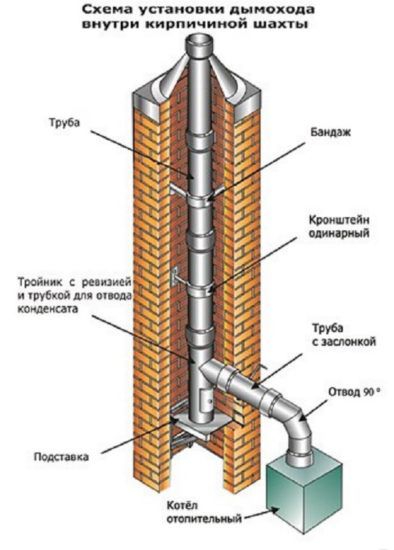

Although brick is used by builders when arranging ventilation, its properties do not allow them to save on other materials. Firstly, brickwork is not durable. The most comfortable conditions for her are constant contact with hot gases. Otherwise, condensation will form, which leads to its rapid destruction. Secondly, a brick chimney is labor-intensive to install, has a complex design and is unreasonably high in cost. Therefore, if you are faced with the task of arranging a chimney for a gas boiler, it is better to pay attention to other options. In this situation, a shaft is made of bricks. This same option can be chosen if for some reason heating the house with gas is currently impossible, but in the future it is planned to use it.

If brickwork is chosen as the material for the shaft, then the chimney itself is assembled from single-circuit galvanized pipes. The thickness of their walls is selected taking into account the temperature of the outlet gases.

Components of a chimney inside a brick shaft

Steel hood

In this situation, steel pipes are very convenient. They are easy to install when compared, for example, with brickwork. The wall thickness is selected depending on the heating. Gas boilers produce quite hot exhaust gas, about 400-450˚C, so the thickness of the walls should be 0.5-0.6 mm. However, there are pitfalls here too. Of course, steel is resistant to the negative effects of condensation. But on average, its wear resistance is much lower than, for example, the wear resistance of ceramic products. In addition, thin-walled pipes burn out quickly if used with solid fuel devices, so this option is not optimal when using different types of heating elements for different periods of time. Steel choose:

- during reconstruction;

- if there is no space for a ceramic hood.

Since steel ventilation ducts often spoil the exterior of a private house, they are covered with brickwork or other finishing materials.

Steel pipes are marketed in two variations - single-circuit and double-circuit. The second option is called a “sandwich” in slang. It consists of two pipes nested one inside the other, the gap between which is filled with fire-resistant basalt wool. The thickness of the inner pipe is determined by the temperature of the outlet gases (recall that this value is 0.5-0.6 mm for the devices discussed in the article).

Installation of a steel double-circuit chimney

“Sandwiches” are considered more economical among all steel hood options. This conclusion suggests itself if we take into account good thermal insulation, which increases the efficiency of the heating device.

Double-circuit steel chimneys are made of stainless and galvanized steel. Both metals are combined in “sandwiches”, since using only stainless steel is not economically feasible. The difference between galvanized and stainless steel is the latter’s higher resistance to condensation, which negatively affects its price. Otherwise, the properties of these two materials are not inferior to each other.

It is critically important that the internal part of the double-circuit structure is made of stainless steel; the material of the external part does not play a special role. This is due to the properties of zinc. Its heating above 419.5°C is dangerous. In this situation, the metal oxidizes, and further chemical reaction leads to the release of toxic fumes. Everything becomes even worse with high humidity, which cannot be avoided when commissioning a gas boiler. Therefore, when purchasing a sandwich structure, pay attention to this.

In principle, you can make a double-circuit chimney yourself without any special skills. To do this, wrap the stainless steel pipe in fire-resistant heat-insulating material. When choosing the latter, you can pay attention to basalt fiber, expanded clay or polyurethane. Then place everything together in a galvanized pipe of larger diameter.

Installation diagram of a steel hood

Features of installing a steel ventilation column:

- The segments are assembled using the “pipe to pipe” method in order, starting from the bottom;

- For the convenience of subsequent cleaning of the post, provide a sufficient number of inspection wells;

- For stability, wall brackets are attached in approximately 150 cm increments;

- When designing, pay attention to the horizontal segments - they cannot be more than 1 meter long unless forced draft is provided.

Stainless steel ventilation duct

Ceramic hood

This type of hood is the most versatile, so it is an ideal option if you plan to switch from or to gas fuel. They are easy to clean, resistant to dirt, due to their high gas density, and to aggressive chemical compounds, so you don’t have to worry about toxic substances getting into your living rooms. And, of course, ceramics are durable.

But there are also disadvantages. Ceramic pipes have high moisture absorption. If you choose them, you will have to provide good external ventilation and equip the structure with condensate drains, otherwise the invested effort and money will not be worth it.

Ceramic alone is not used in chimneys. To make the most of its positive properties, it is combined with mineral wool and stone. Simply put, the ceramic pipe is wrapped in insulating material and then placed in an expanded clay concrete shell.

Structure of a ceramic chimney

Ceramic hood design

Coaxial ventilation structure

When designing ventilation for gas boilers, pay attention to the compact “pipe-in-pipe” design, or, in other words, a coaxial chimney.

Operating principle of a coaxial ventilation system

Components of a coaxial chimney

Coaxial systems, due to their characteristics, are suitable for heat generators with a closed combustion chamber (which is a gas boiler). Oxygen necessary for combustion enters through the outer pipe, and exhaust gases are removed through the inner pipe. This design has its advantages:

- safety (exhaust gases are cooled by cold air circulating in the outer pipe);

- the incoming air heats up and increases the efficiency of the boiler;

- high efficiency means that the coaxial design is more environmentally friendly than others;

- can be used with the appliance in the kitchen (it is located outside the room and does not affect the comfort in it).

Features of installing a coaxial chimney

- You cannot use a horizontal coaxial chimney if you do not plan to install forced draft;

- try to get by with no more than two knees;

- if there are several boilers, create a separate chimney for each; combining them is undesirable.

Requirements for smoke exhaust structure

The basic rules of SNiP 42-01-2002 and 2.04.08-87 approve the following requirements for installing gas boilers and connecting them to the hood:

- The ceiling in the boiler room must be at least 2.5 meters high.

- The area of the room for one piece of equipment must be at least 4 square meters.

- It is necessary to have a window with a window of at least 0.3 square meters in area. Otherwise, additional ventilation is required.

- The walls in the boiler room must be made of non-combustible materials.

- There must be an inspection window in the chimney system; such a device is installed at a distance of 0.25 meters from the chimney opening.

- You cannot connect several gas-powered appliances to the same ventilation system.

- The gas stove must be placed in another room, separate from the boiler at a distance of at least 6 meters. If these conditions are met, it becomes possible to cancel the previous comment.

Step-by-step instructions for constructing a smoke exhaust system

When commissioning the equipment, room ventilation must be taken into account. In the absence of air exchange, forced turbo exhaust must be installed. Without it, putting a gas boiler into operation is impossible. We will look at how to install a hood for a gas boiler in a private house using the example of a coaxial chimney. The length of the pipe from the boiler room to the street for this type of hood cannot be more than two meters.

- When starting work, make sure that the installation of the gas boiler complies with the rules and regulations approved by inspection organizations in order to avoid reworking the entire power unit.

- Select the appropriate material for the hood, taking into account the parameters of the gas outlet: gas boiler inlet = pipe diameter.

- Calculating the power of the fans and their number, taking into account how long the hood is, the number of bends in its structure, and the position in space relative to the horizon, at what height the exhaust pipe is located in the room.

- Do not forget about the features of budget equipment indicated in the technical passport.

- All materials used in the work must be fireproof and not susceptible to corrosion.

- After making sure that all parts are intact, we proceed to assembly. We connect the chimney elbow to the gas boiler pipe using a tee.

- To extend the coaxial pipe and connect all its parts, special crimp clamps and fire-resistant sealants are used.

- Turbo exhaust is used if there are more than two elbows in the pipeline geometry. This helps maintain the efficiency of the gas boiler . The fan and all sensors are installed after installing the supply pipe.

- Installing a coaxial pipe outside a building is no different from installing a conventional sandwich chimney.

Outside the building

Having laid the line for the exhaust device in the house, the design of the hood for the gas boiler goes outside.

- As soon as the pipe has been brought outside through a hole in the wall, it must be closed with special metal plates. The remaining space between the pipe and the wall is filled with mineral wool.

- Now we install the tee. The lower hole is closed with a plug with an inspection for cleaning the pipe.

- We increase the chimney to the required length by connecting the parts using a special sealant and clamps with gaskets. As the pipe grows, we attach it to special brackets.

- We install a protective cone at the top of the chimney and additionally attach it to guy wires in those places.

- If the chimney structure was not coated with special paint at the factory, this can be done at home. This is done to protect the metal from environmental influences.

When ordering an outdoor chimney system, it is important to consider where the forced exhaust starts from the gas boiler or from the room where the turbo elements are installed.

Inside the house

Inside the house, the installation of a coaxial chimney was described in detail, with comments, above. The only step you have left to do is to connect two pipes, street and indoor, using the extension method. For additional insulation, it is recommended to use special metal tape.

I would like to note an important advantage of a coaxial chimney - the absence of additional holes in the roof or wall of your home.

Connecting the geyser to the water supply

You can supply water to the column either from the main riser or from the nearest distribution section. However, if the throughput of the intra-apartment pipeline is low or the pressure is low, the second option is undesirable. Such a connection scheme can lead to the fact that the performance of the device will decrease every time someone in the household opens another tap or flushes the toilet. The burner may even go out, and this is quite unpleasant if someone is taking a shower at that moment. It is also necessary to install a separate tap on this branch so that you can turn off the water in case of repair of the column.

The liner is usually made with pipes made of PVC, polypropylene or metal-plastic. The first two options are more reliable, but require a special welding machine and the ability to use it. At the same time, the installation of metal-plastic pipes can be carried out using tools that can be found in almost every home: a set of keys, a hacksaw for metal and a drill. The weak point of such a water supply system is the compression connection. Even securely tightened nuts become loose over time, which can lead to small leaks. Therefore, they are usually tightened for prophylaxis after 4–6 months.

The supply pipe can be connected directly to the column inlet using the appropriate fitting. Many manufacturers install a coaxial hose at the hot water outlet. This is done to avoid unwanted mechanical loads that occur in the pipes and heater components due to thermal linear expansion. So even if the hose is not supplied with the column, it is better to use just such a one.