Home / Solid fuel boilers

Back

Published: 05/23/2019

Reading time: 6 min

2

1287

Heat supply to private houses, industries and administrative premises from solid fuel boiler houses is very common in areas where there is no possibility of connecting to a gas main or in the far north. The fuel for such boiler houses is coal, firewood, pellets and briquettes. The general disadvantage of this type of heating is that the firebox has to be regularly supplied with fuel. However, there is a type of solid fuel equipment that does not have this drawback - a pyrolysis boiler.

- 1 What is pyrolysis

- 2 Operating principle of a pyrolysis boiler

- 3 Design of a long-burning pyrolysis boiler

- 4 Pros and cons of a pyrolysis boiler

- 5 How economical is a pyrolysis boiler?

- 6 Is it worth doing it yourself?

- 7 Popular models

- 8 Installation

Rating of the TOP 15 best long-burning solid fuel boilers

| Place | Model | Price |

| The best long-burning models with a water circuit | ||

| #1 | Stropuva Mini S8 | |

| #2 | Teplodar Cooper Expert-15 | |

| #3 | ZOTA Topol-32VK | |

| #4 | Stropuva S40P | |

| #5 | Stropuva Mini S8U | |

| #6 | NMK Magnum KDG 15 TE | |

| The best classic models | ||

| #1 | Lemax Forward-12.5 | |

| #2 | Lemax Forward-20 | |

| #3 | ZOTA Topol M 20 | |

| #4 | Teplodar Cooper Praktik 14 | |

| #5 | Teplodar Cooper Praktik 8 | |

| #6 | ZOTA Yenisei 18 | |

| The best pyrolysis models | ||

| #1 | Bourgeois-K MODERN-12 | |

| #2 | Vesuvius Elbrus-10 | |

| #3 | Bourgeois-K MODERN-24-2K | |

Page navigation:

What is a solid fuel boiler?

For your information! This is a unit for heating coolant in a heating circuit, generating thermal energy by burning fuels such as coal, firewood, peat, etc.

Solid fuel boilers have found their application in private homes and in production. They are distinguished by their high efficiency and have a high safety class.

More expensive models are equipped with automatic control systems, while cheaper designs are controlled manually.

Main disadvantages

When consumers consider the equipment described in the article, they note that it also has certain disadvantages, which are expressed in:

- impressive mass;

- the need to control work;

- uneven heating of the coolant;

- the need to prepare firewood;

- fairly high fuel consumption.

A number of consumers refuse to purchase such installations for the reason that, made of cast iron and steel, they are characterized by a rather impressive weight. In addition, their work requires control. The boiler should not be left unattended for long periods of time. Every 4 hours you will need to add firewood.

Some consumers are also put off by the uneven heating of the coolant, as well as the impressive fuel consumption, which sometimes does not allow achieving the desired effect, because wood emits a rather small amount of thermal energy during combustion. And the preparation of firewood is a rather lengthy and labor-intensive process.

What parameters should you pay attention to when choosing?

When choosing such a device, you need to pay attention to a number of important factors:

- type of fuel loading. Manual loading through the loading door or automatic using a special mechanism is common;

- heat exchanger material. The latter are made of steel (strong, with good resistance to thermal shock, heat up quickly, but cool quickly) or cast iron (resistant to corrosion, excellent heat retention, but have an impressive weight and are vulnerable to temperature changes);

- type of fuel used. These are firewood with not the highest efficiency, coal with the longest burning time, pellets and briquettes made from various materials with certain pros and cons. Many boilers operate on mixed fuel; these models are the most versatile;

- method of fuel combustion. There are boilers with natural (work on the principle of a conventional stove) and additional draft (equipped with a fan that additionally supplies air to the firebox). There are also pyrolysis devices equipped with a complex combustion mechanism, in which the fuel in the primary chamber burns in a low-oxygen environment and at the same time releases a flammable gas that ignites in the secondary chamber;

- long burning boilers. This is a separate category of devices where combustion occurs longer and more evenly due to a number of engineering and technical solutions;

- thermal power. The heating device should be selected with a power reserve, since in addition to heating, it will heat the water in the system.

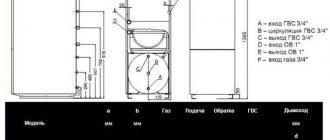

When choosing a boiler , you should not discount the volume of the loading chamber, the features of connecting the device to the chimney and the heating system circuit, the presence or absence of automation, automatic fuel loading, and a hob.

Note! Additional options increase the cost of the equipment, but provide greater comfort and ease of use of the boiler.

Electric heating

Electric heating has a number of positive and negative aspects. Let's look at some of the advantages of this heating system:

- Changing the heating system and quick redevelopment;

- Absence of any noise during operation;

- Easy to install;

- Electrical energy is converted into heat without a coolant. Therefore, the equipment has a high level of efficiency;

- Good indicators of hygiene and environmental friendliness;

- Small dimensions of heating equipment;

- Independent thermostat system. With its help, it is possible to regulate the heat supply to different rooms;

- Heats the room quickly enough.

Let's look at the disadvantages of electric heating:

- Power fluctuations;

- High installation cost;

- Problems with power supply.

In order to provide normal electric heating in the house, you can use a heater. Such equipment does not require the installation of pipelines, coolant, pumps and other elements of the heating system.

The cost of a heating boiler ranges from approximately 25 to 35 thousand rubles.

Electric heating is easy and quick to install. You can also quickly switch to another type of heating system.

The best manufacturers of solid fuel boilers

Today the Russian market is dominated by boilers from domestic manufacturers:

- Teplodar - produces and sells small-sized equipment with a well-thought-out design for heating private houses and other premises;

- Stropuva is a Lithuanian manufacturer, the oldest brand producing long-burning solid fuel boilers;

- ZOTA - a full range of boilers with a capacity from 3 to 400 kilowatts;

- NMK is a metalworking company that produces solid fuel boilers Siberia, Atum, Magnum, Hephaestus, Sunfire;

- Lemax - advanced technologies that meet international quality and safety standards;

- TeploGarant is a leading manufacturer of boiler equipment in Russia, such as Burzhuy-K boilers;

- Vesuvius was the first in Russia to produce cast iron stoves; the products are easy to use and do not require special maintenance skills.

A certain niche is occupied by boilers from foreign companies - Buderus, Bosch, Ferroli, SIME, VIADRUS, Protherm.

The best long-burning models with a water circuit

Heating boilers with a water circuit allow you to quickly and evenly heat the room. They are a great option for a year-round home.

Stay up to date! Among the features of such devices are high efficiency, stable savings in fuel materials and low heat loss.

The higher cost of long-burning boilers compared to other models is justified by the presence of a number of technical advantages.

Rating of the TOP 6 long-burning models with a water circuit in terms of price and quality ratio.

Stropuva Mini S8

The unique design of Stropuva Mini S8 allows you to use solid wood fuel as efficiently as possible and maintain the temperature in the room without overspending.

The single-circuit model Stropuva Mini S8 maintains long-term combustion without additional fuel, providing heat to medium-sized rooms.

The boiler does not require electricity to operate; the process is supported by natural draft.

The power is enough to heat the house even in severe frosts.

Specifications:

- thermal power - 8 kW;

- recommended heating area - 80 sq. m;

- Efficiency - 85%;

- type of fuel - firewood, wood briquettes;

- coolant temperature - 60–95 °C;

- water pressure in the circuit (max) - 1.5 bar.

Advantages

- compact dimensions (barrel-shaped body);

- sold completely assembled;

- strong, reliable handles on the doors prevent inadvertent opening;

- no power required;

- economical with high efficiency (up to 20 hours on wood).

Flaws

- heavy;

- the lining above the door becomes covered with soot, which is difficult to clean;

- Not very convenient to load fuel.

Teplodar Cooper Expert-15

The Cooper Expert-15 model is distinguished by its high combustion duration, which is facilitated by the well-thought-out design of the heat exchanger and three-zone air supply.

The boiler is a long-burning device with a water circuit; it is excellent for heating medium and large rooms.

Firewood, briquettes and coal can be used as fuel. The boiler supports four operating modes.

A block of heating elements of sufficient power is used as a unit for maintaining heat. If desired, the user can install a burner.

Key parameters:

- power - 15 kW;

- recommended heating area - 150 sq. m;

- Efficiency - 80%;

- type of fuel - coal, firewood;

- Heating element for maintaining temperature - 6 kW;

- coolant temperature - 50–95 °C;

- water pressure in the circuit (max) - 3 bar.

Advantages

- high-quality heating of the room with the ability to adjust the combustion intensity;

- burning duration on one load of coal is up to 24 hours;

- versatility, you can use both firewood and coal;

- safety;

- high efficiency.

Flaws

- complex installation and connection;

- a separate room is required for installation;

- Designed for short lengths of firewood.

ZOTA Topol-32VK

According to the manufacturer, the ZOTA Topol-32VK boiler has the highest efficiency among similar solid fuel and combined budget models.

A single-circuit boiler released in 2020 is suitable for large areas.

It uses an improved adjustable ash door blower damper.

Adjustment is made using a screw in manual mode.

The design provides for the installation of a block of heating elements with an external control panel.

Key parameters:

- power - 10–32 kW;

- recommended heating area - 320 sq. m;

- Efficiency - 75%;

- type of fuel - coal, coal briquettes, firewood, wood briquettes;

- coolant temperature (max) - 95 °C;

- water pressure in the circuit (max) - 3 bar.

Advantages

- wide range of fuels used;

- Fuel loading is possible both in vertical and horizontal planes;

- there is a removable damper (convenient to clean the heat exchanger);

- installation of heating elements with external control is provided;

- installation of a gas burner is possible.

Flaws

- no automation;

- no built-in circulation pump;

- There is no built-in expansion tank.

Stropuva S40P

The Stropuva S40P boiler has a unique design that allows the most efficient and economical use of the volume of fuel with its gradual combustion.

The single-circuit model is ideal for heating large rooms; it maintains excellent temperature balance without wasting energy.

Stropuva S40P maintains combustion for up to 72 hours when using firewood or fuel briquettes.

The boiler does not require an electrical connection; combustion is supported by natural draft. The maximum power of the device is 40 kW.

Specifications:

- power - 40 kW;

- recommended heating area - 400 sq. m;

- Efficiency - 85%;

- type of fuel - pellets, firewood, wood briquettes;

- blower fan;

- coolant temperature - 60–95 °C;

- water pressure in the circuit (max) - 1.5 bar.

Advantages

- power;

- ease of use;

- long burning time;

- availability of fuel (works on any type of firewood and briquettes);

- efficiency - fuel is consumed gradually;

- safety - the integral steel structure is equipped with a safety valve that relieves pressure during a sudden surge.

Flaws

- mechanical control;

- The blower fan is noisy.

Stropuva Mini S8U

Due to the rising cost of gas for consumers, the Stropuva Mini S8U model can effectively compete even with the most economical gas boilers.

This single-circuit coal boiler of medium power is suitable for heating small and medium-sized premises.

In addition to coal, it can use other alternative energy sources.

Depending on the heat loss of the building, external temperature and fuel quality, the maximum burning time of one bookmark is: coal - 120 hours, pellets - 72 hours, briquettes - 48 hours, firewood - 30 hours.

Key parameters:

- power - 8 kW;

- recommended heating area - 80 sq. m;

- Efficiency - 85%;

- type of fuel - coal, pellets, firewood, wood briquettes;

- blower fan;

- coolant temperature - 60–95 °C;

- water pressure in the circuit (max) - 1.5 bar.

Advantages

- high efficiency;

- reliability and safety;

- long service life - 5 years, including annual maintenance;

- ergonomic design;

- aesthetic appearance.

Flaws

- no expansion tank provided;

- no circulation pump;

- low power.

NMK Magnum KDG 15 TE

This single-circuit model has established itself as one of the best solutions for heating country houses and other medium-sized premises.

Magnum KDG 15 TE is one of the representatives of solid fuel heating devices in the line of long-burning boilers.

The model is designed for heating with coal and coal briquettes.

The designers have implemented the option of installing heating elements to maintain a comfortable temperature in the room at night and in the off-season.

The block of heating elements can be used when burning fuel in the boiler and independently. Magnum KDG 15 TE is distinguished by a long time of uninterrupted operation during the heating season.

Key parameters:

- power - 15 kW;

- The recommended heating area is 120 square meters. m;

- Efficiency - 75%;

- type of fuel - coal, coal briquettes;

- coolant temperature - 45–85 °C;

- water pressure in the circuit (max) - 2 bar.

Advantages

- high efficiency;

- convenient coal filling;

- it is possible to remove ash without stopping the operation of the boiler;

- if necessary, can be equipped with heating elements;

- ergonomics - all elements are located as conveniently as possible.

Flaws

- difficulties may arise during assembly;

- imperfect door seals;

- not the most economical unit.

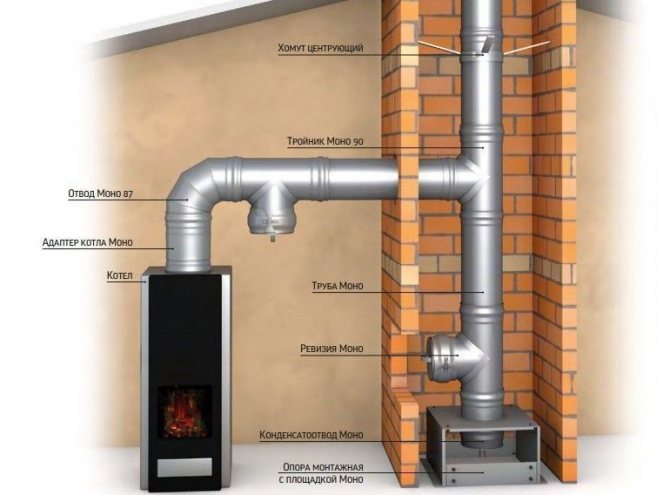

Differences from the rear chimney

The exhaust gas exhaust system of a horizontal (coaxial) configuration is mounted on boilers with a closed combustion compartment. Straight chimneys are combined with a fan unit and a forced-operation pressure pump. The main difference from the upper analogues is the horizontal placement of the outlet end on the street. Such structures are mounted on a heating boiler using an elbow, and are led out through the wall ceiling or roof to the side.

The upper chimney consists of a pair of round elements located inside each other, characterized by internal and external diameters.

Smoke is removed through a smaller cross-section pipe, and the outer part serves to suck in fresh air masses with further entry into the boiler.

The best classic models

Reference! Traditional solid fuel boilers are distinguished by their simple design, basic operation and simple maintenance.

Classic models were among the first to be developed. These devices are available, inexpensive and at the same time effective.

They do not have automation and there is no need to connect to the mains. Such boilers operate from 6 to 12 hours on one charge .

Review of the best 6 models according to customer reviews and ratings.

Lemax Forward-12.5

The heart of Lemax Forward-12.5 is a firebox made of durable boiler steel from the Magnitogorsk Iron and Steel Works, coated with a layer of inhibitory composition.

Single-circuit Forward-12.5 is designed for heating residential and non-residential premises of medium size. It runs on several types of solid fuel.

Other key features include: vertical fuel loading option, non-volatile design, heat-resistant coating of the heat exchanger, the ability to connect a boiler and draft regulator.

Specifications:

- power - 13 kW;

- The recommended heating area is 100 square meters. m;

- Efficiency - 75%;

- type of fuel - coal, firewood, coke;

- coolant temperature (max) - 95 °C;

- water pressure in the circuit (max) - 2 bar.

Advantages

- affordable price;

- compactness;

- fast heating;

- high-quality assembly;

- no noise;

- reliable hard case.

Flaws

- vertical loading is poorly thought out;

- The boiler is inconvenient to clean.

Lemax Forward-20

The Lemax Forward-20 boiler is a completely energy-independent design with the ability to heat rooms not connected to the electrical network.

The single-circuit model operates on different types of solid fuel.

It has high efficiency, which contributes to economical consumption.

The undoubted convenience of the Lemax Forward-20 is the possibility of top loading of fuel: there is no classic front door here, firewood, coal or coke are loaded through the top of the equipment.

Temperature control in the heating circuit is provided; for this purpose, the boiler is equipped with a thermometer.

Key parameters:

- power - 20 kW;

- recommended heating area - 180 sq. m;

- Efficiency - 75%;

- type of fuel - coal, firewood, coke;

- coolant temperature (max) - 95 °C;

- water pressure in the circuit (max) - 2 bar.

Advantages

- ease of maintenance (cleaning, preventative maintenance);

- the cost is lower than that of similar models;

- universal in terms of fuel;

- works in tandem with a water heating system with natural circulation;

- aesthetic appearance.

Flaws

- combustion products enter the room;

- when the boiler itself is very hot, the temperature of the batteries is noticeably lower;

- no expansion tank.

ZOTA Topol M 20

The powerful but compact ZOTA Topol M 20 boiler is designed using modern developments in the field of alternative heat sources.

The housing of the single-circuit device is gas-tight and thermally insulated.

The water jacket under the decorative cladding is covered with basalt, which significantly reduces heat loss.

The doors can open both horizontally and vertically, and they are additionally equipped with locks.

The blower damper is adjusted manually using a special screw. This makes it possible to significantly increase the fuel combustion cycle per load.

Key parameters:

- power - 20 kW;

- The recommended heating area is 180 square meters. m;

- Efficiency - 75%;

- type of fuel - coal, firewood;

- coolant temperature (max) - 95 °C;

- water pressure in the circuit (max) - 3 bar.

Advantages

- reliable, well-thought-out design of the boiler body;

- conveniently opening and closing doors and ash drawer;

- high pressure in the heating circuit;

- If desired, you can install an automatic traction control.

Flaws

- small size of the ash drawer;

- small firebox size (for short firewood);

- The kit does not include a brush for cleaning the heat exchanger pipes.

Teplodar Cooper Praktik 14

Cooper Praktik 14 will be an ideal choice for installation in country houses of medium and large area; this boiler will serve faithfully for many years.

The boiler is equipped with a powerful cast-iron grate, but the single-circuit device is very compact and does not take up much space.

The deep sloping firebox allows the use of firewood up to 40 cm long.

Built-in electric heaters make it possible to maintain warmth at night.

In order to increase the burning time and reduce firewood consumption, mechanical draft adjustment is provided.

Key parameters:

- power - 14 kW;

- recommended heating area - 140 sq. m;

- Efficiency - 80%;

- type of fuel - coal, firewood, peat briquettes;

- Heating element for maintaining temperature - 6 kW;

- coolant temperature - 50–95 °C;

- water pressure in the circuit (max) - 1 bar.

Advantages

- compactness;

- affordable price;

- quick heating of the coolant;

- duration of burning of one stack of firewood;

- laying firewood up to 40 cm long.

Flaws

- does not produce the declared power;

- thin metal body.

Teplodar Cooper Praktik 8

Teplodar Kupper Praktik 8 is one of the best representatives of the economical line of solid fuel boilers from a domestic manufacturer.

This universal single-circuit device can operate in closed and open heating systems with forced or natural coolant circulation.

It is equipped with a perforated convector casing for additional heating of the room where the boiler is installed; a cast-iron damper prevents spillage of burning coals.

The firebox is inclined - this increases the convenience of fuel distribution and promotes uniform burning.

Key parameters:

- power - 8 kW;

- recommended heating area - 80 sq. m;

- Efficiency - 75%;

- type of fuel - coal, firewood, peat briquettes;

- Heating element for maintaining temperature - 6 kW;

- coolant temperature - 50–95 °C;

- water pressure in the circuit (max) - 1 bar.

Advantages

- compactness;

- it is possible to connect automation to regulate the temperature;

- the presence of a block of heating elements to maintain temperature;

- small weight;

- convenience and ease of use.

Flaws

- The efficiency in reality is lower than stated;

- small heated area;

- mechanical control.

ZOTA Yenisei 18

Zota Yenisei 18 is an ultra-economical single-circuit solid fuel boiler for heating a room and a stove for cooking in one.

Other features of the model include a deep firebox that allows you to use firewood up to 60 cm, an angled firebox door (for easy loading), and gas-tight doors that prevent air from entering through the cracks.

The water jacket is installed along the entire contour of the boiler, including the ash area.

This was done to cool the ash box to avoid deformation, provide additional heat removal and improved coolant circulation when heating.

Key parameters:

- power - 6.5–18 kW;

- recommended heating area - up to 180 sq. m;

- Efficiency - 70%;

- type of fuel - coal, coal briquettes, firewood, wood briquettes;

- coolant temperature (max) - 95 °C;

- water pressure in the circuit (max) - 3 bar.

Advantages

- high efficiency with small size;

- the deep firebox allows you to load firewood up to 60 cm long;

- gas-tight loading and ash doors eliminate the possibility of air leaks;

- There is an auxiliary heat source powered by electricity.

Flaws

- poor design of the stove; in order to cook, you need to heat it up a lot;

- no traction control.

How profitable is using an oil-fuel boiler?

Many manufacturers of liquid boilers for home heating simply do not indicate the consumption of their units. Thus, if you buy too powerful equipment, you may encounter a large “appetite” for it, which will make its use unprofitable. Therefore, you should know how to independently calculate the approximate fuel consumption of a particular unit.

At maximum operating mode, the burner usually consumes 1/10 of the diesel fuel of the specified power. Thus, if the burner has a power of 20 kW, then this indicates the consumption of two liters of diesel fuel per hour or 48 during continuous operation per day. This power is quite enough to heat a house of 200 m2 in a very harsh climate. There is no need to talk about the price of fuel, since it varies depending on the region and calculating costs in this case is not difficult.

Advantages and disadvantages

The advantages of such systems include:

1. High efficiency.

2. Good automation.

3. Autonomous operation.

The disadvantages are as follows:

1. Quite high operating costs.

2. Loud noise produced by fan burners. Their work can be clearly heard even through the wall.

3. The need to store fuel, for which a special room should be equipped that will be protected from low temperatures. It is advisable that the unit itself be located in a place remote from residential premises, due to the unpleasant smell of diesel.

The best pyrolysis models

The design of such boilers implies the presence of an additional chamber for the combustion of pyrolysis gas generated during fuel combustion. It is located at the top of the device.

Keep in mind! Pyrolysis boilers additionally require electricity to power a fan, which draws in the air necessary to maintain the combustion process.

The prices for such models are higher compared to the cost of traditional boilers, but the costs are recouped by the reduction in heat loss and high efficiency.

Bourgeois-K MODERN-12

Bourgeois-K MODERN-12 is an improved model of a solid fuel boiler with increased safety, ease of use and burning time.

The single-circuit pyrolysis device is distinguished by a high efficiency, which exceeds 90%.

Compared to an electric or solid fuel boiler, it is the most economical option.

In the upper part of the combustion space there is a layer of fireclay bricks, which collectively improves all thermal indicators.

The boiler is recommended for use in medium and large areas.

Key parameters:

- power - 12 kW;

- recommended heating area - 120 sq. m;

- Efficiency - 92%;

- type of fuel - coal, pellets, firewood, wood briquettes, peat;

- coolant temperature (max) - 95 °C;

- water pressure in the circuit (max) - 4.5 bar.

Advantages

- long battery life;

- unpretentiousness to firewood;

- burning rate regulation;

- high efficiency;

- efficiency.

Flaws

- quickly becomes contaminated with soot and ash;

- high price.

Vesuvius Elbrus-10

Vesuvius Elbrus-10 is the most profitable option for heating a small country house equipped with a water heating system with natural or forced circulation.

A single-circuit boiler can operate in both open and closed heating systems.

It is suitable for use in temperate and cold climate zones. Elbrus-10 runs on different types of solid fuel.

The boiler provides the possibility of installing a block of electric heating elements. The set includes a poker and a scoop.

Key parameters:

- power - 10 kW;

- The recommended heating area is 100 square meters. m;

- Efficiency - 85%;

- type of fuel - coal, firewood;

- coolant temperature (max) - 95 °C;

- water pressure in the circuit (max) - 3 bar.

Advantages

- good tightness of cast iron doors;

- thoughtful design of the heat exchanger with convenient access to internal surfaces for cleaning;

- universal connection to the heating system (on the left or right side);

- basalt thermal insulation of the water circuit;

- 8 hours of burning on one fill of fuel.

Flaws

- there is no heating element unit (installation is optional);

- power may not be enough for the square meters declared by the manufacturer.

Bourgeois-K MODERN-24-2K

The double-circuit boiler Burzhuy-K MODERN-24-2K uses a special fireclay stone, which reduces heat loss while burning fuel more efficiently.

The model is also distinguished by a reinforced internal structure using fire-resistant materials and heat-resistant stainless steel.

The lining elements are easily removable, allowing easy access for cleaning and replacing parts as they naturally wear out.

If necessary, the boiler can be equipped with hot water supply and thermal relief circuits.

Key parameters:

- power - 24 kW;

- recommended heating area - 250 sq. m;

- Efficiency - 92%;

- type of fuel - coal, pellets, firewood, wood briquettes, peat;

- coolant temperature (max) - 95 °C;

- water pressure in the circuit (max) - 4.5 bar.

Advantages

- long burning time for a full load (up to 12 hours);

- the presence of an emergency unloading circuit in case of overheating;

- automated power control system;

- possibility of using wet firewood (up to 50%);

- easy maintenance and operation.

Flaws

- high price;

- no DHW circuit:

- there is no thermal relief circuit.

Upper chimney design

A simple vertical system for solid fuel boilers is assembled without stepped sections or horizons. In difficult cases, deviations and straight inlays no longer than 1 m, laid with a slight slope, are allowed.

In such configurations with branches, an accelerating segment is introduced to start the traction. In this case, the heating structure is connected vertically or horizontally.

Discharge pipes start from the boiler, length - at least 1 m, connect a direct adapter for input. Failure to comply with these recommendations causes a lack of traction. The deficiency is compensated by increasing the height of the entire structure.

Upper chimney installation.

conclusions

In conclusion, it is worth focusing on several points:

- a solid fuel boiler can be a way out when a private house is not connected to gas;

- when choosing a boiler, you need to pay attention to its power, type of loading and type of fuel used, chamber volume and a number of other technical parameters;

- Before purchasing, you should carefully study the characteristics and user reviews of a particular model.

Basic installation requirements

No separate permits or approvals will be required. There are some rules for installing solid fuel boilers, which we will consider.

- The solid fuel system should not be located in a residential area.

- The boiler room must have only one entrance, the total area is from 7 square meters, and the volume is 15 cubic meters.

- Lighting is required. An emergency system should also be installed.

- The walls of the room must be fire resistant.

- Avoid automatic locks. Door width – 80 cm.

- Gas-tightness of the boiler room is the main requirement.

- The ceiling height must be at least 2.5 m. An attic location is not allowed.

- Supply and exhaust ventilation independent of electricity is installed.

These requirements are just some of the general list. Before installing a solid-state boiler, you should familiarize yourself with the full list of rules.