Foam plastic is a modern construction insulation and insulator.

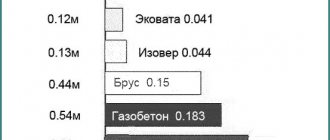

What is polystyrene waste, its processing and disposal

The used material is reused in production. The range of processing enterprises is gradually expanding. Research is being conducted into new ways to use recyclable materials.

Waste polystyrene (PS) that can be recycled are building materials and household items that change properties due to their long service life. Environmental factors also apply, such as:

- roll and tile finishing materials for ceilings, walls, floors;

- polymer film coverings for greenhouses and film for making packaging;

- cables, pipes, profile products;

- illiquid and defective goods;

- production waste – cuttings, sprues, trimming edges.

All material is studied under the influence of X-rays, ultrasound or spectroscopy. They use equipment for processing foam plastic. Polystyrene with poor physical properties is disposed of. Products that have passed the control are crushed and processed using one of the particle separation methods:

- deep cooling;

- separation in a liquid, gaseous environment or electric field;

- adding chemical reagents.

At the end of the process, the raw materials are calibrated. Suspended dry particles are added during the production of cement to fill recessed areas. Sometimes styrene is extracted from them using a catalytic method to re-produce the polymer. Disposal of polystyrene is combustion in special furnaces, where it decomposes into carbon and water.

The use of foam plastic in modern construction

In modern construction, more and more attention is paid to saving heat in winter, and for this purpose all kinds of insulation materials are used. And one of them is polystyrene foam. It has found the widest application for insulating all kinds of objects under construction, including residential buildings, garages, cottages, warehouses, hangars, and boxes. It is also used when performing routine and major repairs.

The use of polystyrene foam as insulation

Foam plastic is effectively used to insulate external walls, which are subsequently plastered and painted. Such walls not only make the building much warmer, but also give it a new look. It has proven itself well in the thermal insulation of pipelines, transport cars, vegetable stores, and roofs with an inclined surface. Foam plastic is also a leader in packaging various products to avoid damage during transportation.

Thermal insulating properties of polystyrene foam

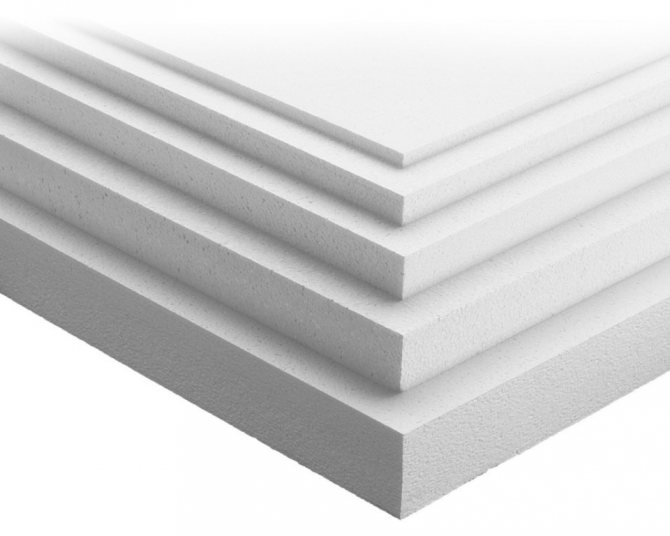

Why has polystyrene foam proven itself so well? First of all, because from an environmental point of view, it is one of the cleanest materials, consisting of foamed polystyrene and air. Polystyrene foam is durable in use, plays an excellent role as a heat insulator and at the same time is not afraid of fire, therefore it does not have such properties as flammability. Its service life ranges from 40 to 100 years. And most importantly, its prices are quite affordable, which is why it so easily conquers the construction market. The history of its use dates back to 1952, from the time of its invention by the BASF concern. It was then that its characteristics were revealed as a hermetic material, the dimensions of which do not change under any conditions. It is not subject to deformation, and is not afraid of the effects of cold, heat and moisture. And these qualities are not lost over time of its use. And not many building materials have such wonderful thermal conductivity. And these also include polystyrene foam. Its creation uses the principle of emptiness, which is filled with air, and it is the worst conductor of heat, which is why polystyrene foam is a high-quality heat insulator that has chemical and biological stability. It is not afraid of contact with salt, soap, acid, alkaline solutions, mineral oils, and is not exposed to fungi and microorganisms, so it can also be used in the food industry. It would take a very long time to list its uniqueness. Processing foam plastic does not require any special skills; it is easy to cut, but at the same time very durable, safe and practical. It is light in weight, so it is not difficult to unload and transport. Does not contain toxic elements. This material has also proven itself to be soundproof, moisture-resistant and windproof, having the most perfect thermal resistance. And it combines many more positive qualities.

Polystyrene foam is manufactured in accordance with the requirements of DSTU B.V. 2.7-8-94. There are different brands of foam with different densities and applications. Thus, PSB-S-15, which has a slab thickness of 20 to 100 mm, is used for insulation of containers, carriages, household premises, combined roofs, and roofs without attics. The most popular brand of this material is PSB-S-25, the thickness of the plates is from 30 mm to 100 mm. These slabs are used to insulate internal and external walls and external walls, floors, house facades, loggias, and roofs. Foamed polystyrene granules are also in demand, from which, with the help of cement and water, soundproofing and thermal plastic mass is made, used in leveling floors and roofs. Due to its high qualities, foam plastic has conquered the spheres of residential, administrative and industrial construction.

Foam waste, disposal and recycling

Polystyrene production technologies make it possible to enrich it with gas. The materials belong to a large group of foamed plastics. Recycling foam plastic and destroying it according to the rules is no different from recycling polystyrene. In practice, they are burned with the rest of the garbage in a landfill.

- small particles falling off during the production of children's and household goods;

- used products;

- debris during installation of slabs.

Foamed plastics are lightweight, which makes it easier to install tile products during construction. Used to make jewelry, toys, packaging, and marketing products.

Recycling and disposal of polystyrene foam

This is a PS copolymer, which is actively used in construction. It performs the function of heat and sound insulation of walls, floors, and ceilings. Waste is generated during the installation of slabs. To produce recyclable materials, used products and scraps are crushed into crumbs for subsequent addition to concrete.

The difficulty of processing expanded polystyrene lies in its large volumes and low mass. 98% of the material is air. The process of enrichment and destruction itself is identical to that described above.

Why recycle polystyrene foam?

Throwing used items into a landfill is a great way to dispose of household waste. But this inorganic material pollutes the Earth. It has been established that for 80 years at temperatures from -40 to +40 0 C it does not decompose. This means that polystyrene in general and plastics in particular:

- resistant to air and ultraviolet radiation;

- react with certain chemical elements.

Disposal of polystyrene foam using nitric acid is impossible, since PS is not affected by it. Styrene, acetone, benzene, chloride and aromatic hydrocarbons are polystyrene solvents. But the rules provide for special disposal for these substances, so they are not in the landfill.

Combustion of polystyrene provokes the release of harmful substances into the atmosphere: hydrocyanic acid, soot, carbon monoxide and carbon dioxide, hydrogen bromide, phosgene. Oversaturation with them is fatal for humans and animals, and nature suffers.

In fires, people often die not from fire, but from poisoning. Throwing away polystyrene along with household waste or burning it means causing harm to the environment and its inhabitants.

Where to recycle polystyrene foam

Enterprises in European countries and the USA are actively engaged in the manufacture of products from polystyrene and its derivatives. In Russia, interest in polystyrene foam recycling and disposal has been growing in recent years. But this is done by individuals and enterprises who are not indifferent to the state of the environment. Commercial interest is weak for a number of reasons:

- Polystyrene foam as a recyclable material is cheap, but it is difficult to find a consumer. It is necessary to organize waste collection, pay for the work of collectors, and due to the low price of the final product, this is difficult to do.

- The low density of waste raises questions about storage. Due to the large dimensions and low weight, volumetric areas are required.

- Requirements for the room: it must be dry. This is not always possible during periods of rain and frost.

But these problems are solved by entrepreneurs. Polystyrene foam recycling as a business is gaining popularity. Equipment for briquetting and pressing is purchased, and a search for sellers of used polystyrene is established via the Internet.

Polystyrene foam delivery process

The sale takes place in stages:

- Determining the type of polystyrene that needs to be handed over, finding the right organization. Collection points accept all polymers or certain types. The information needs to be clarified.

- Agreement between seller and buyer on delivery method and payment. Buyers may require waste samples to be provided upon the first transaction.

- Quality assessment at the collection point. To recycle polystyrene foam, you must meet the following conditions: the polymer must be dry, free of stickers, insulating panels, labels, staples, and food contaminants.

- Weighing.

- Making a deal.

Technical characteristics of polystyrene foam

Thermal conductivity

One of the main positive properties of polystyrene foam is its unique heat-insulating ability. This can be explained by the fact that the multifaceted cells of the foam are completely closed and, therefore, prevent air circulation, which prevents the cold from penetrating and retains heat.

Wind protection and sound insulation

The reason for the high degree of wind protection and sound insulation also lies in the cellular structure. The greater the thickness of the layer when installing the material, the better sound insulation can be achieved in the building.

Thanks to its structure, it is very difficult for wind to penetrate a layer of foam already 2-3 cm deep.

Low hygroscopicity

Of course, compared to other materials, foam has fairly low moisture absorption.

This is due to the fact that water penetrates only through individual gaps between the cells. However, with prolonged exposure to time and cold, this process can become destructive.

Strength and Durability

Depending on the thickness of the slab and the quality of the polystyrene foam, its durability will vary.

Even when exposed to negative factors, foam plastic will last about 10 years, which is a considerable period of time.

Withstands high pressure without deformation. It is even used in the construction of runways for aircraft.

Resistance to biological and chemical influences

It is very resistant to the effects of salts, lime, cement, paint, varnish, and various acids . Aggressive chemical compounds, such as solvents, acetone, turpentine, diesel fuel, diesel, fuel oil, kerosene, alcohol and substances containing animal and vegetable oils, will have a negative impact.

When exposed to them, the structure can completely collapse and dissolve. Polystyrene foam is not a suitable environment for the proliferation of microorganisms, but if it gets dirty, they can appear there.

Easy to install and easy to use

The material is extremely light in weight and therefore foam boards are easy to install and handle. You can cut it into the desired pieces without using special tools.

No protective equipment is needed when working with it, because polystyrene foam is a non-toxic material .

Fire safety

Although the manufacturers of this product claim that it is absolutely fireproof, this is not entirely true. Of course, compared to wood, the temperature at which it will ignite will be twice as high, and the temperature of combustion itself will be several times lower.

It ignites only upon direct contact with a fire source. When the impact wears off, combustion stops within a few seconds. These indicators characterize it as a relatively safe building material.

Where to put pieces of foam plastic (how to get rid of them)

Since large volumes are needed to dispose of polystyrene waste, ordinary citizens throw it in the trash. To prevent the dangerous consequences of the accumulation of harmful substances in a landfill, you can use one of the following techniques.

Method 1: How to Recycle Styrofoam

The method is to find a place to collect PS. These are businesses that display special containers, own websites on the topic, or accept products by mail. There are no such organizations in Russia yet, but it is possible to negotiate postal deliveries with foreign manufacturers. But there are institutions where you can take small amounts of polystyrene foam for recycling.

You can open your own collection point. This will require time and negotiation skills. The positive side of the coin is caring for the environment and meeting new people.

Method 2: Foam Alternatives

The substitutes are:

- foil;

- cardboard and paper;

- packaging materials based on soy and mushrooms.

These products are degradable or burn without releasing hazardous substances. They can replace those wrappers and seals based on polystyrene. Humanity has not yet come up with an alternative to construction raw materials.

Method 3: Reuse Styrofoam

In everyday life, the material is useful for the following purposes:

- Filling the insides of furniture. If the filling in a chair has become unusable, you can replace it with polystyrene foam.

- Making floats - polystyrene floats perfectly on the water.

- Creating crafts for children, decorative elements for the garden and home.

- Preparation of glue. To do this, you need to dissolve the waste in acetone. The chemical reaction itself is of interest. Suitable for gluing crafts, but nothing more.

With careful research, you can find an option on how you can use polystyrene waste in the household and for the development of imagination. But you shouldn’t insulate a house with used material. This is caused by the flammability of the raw material and loss of properties after use.

What is polystyrene foam?

Polystyrene foam is a special class of materials, which is a plastic mass with a foamed structure, white in color.

Structure

Most of the volume of polystyrene foam is gas . Its density is significantly lower than that of the material on which it is made – polymer. Heat passes only in individual cells, thanks to this it has good thermal insulation qualities .

High-quality noise reduction is due to the fact that thin cell partitions are a poor conductor for sound. Foams are made from almost all well-known polymers . The density and mechanical strength of polystyrene foam varies and depends on the production and processing technology and on the composition of the original raw materials.

What is it made of?

Usually in everyday life we most often come across pressless polystyrene foam. Styrofoam granules (PSV / EPS) are produced by polymerizing styrene and adding pentane, which forms pores. Expanded polystyrene is a very popular thermal insulation material, consisting of 98% gas contained in microscopic thin-walled polystyrene cells.

The polystyrene foaming procedure is performed several times and as a result, the density of the material becomes significantly less.

Then the resulting mass is dried to remove any remaining moisture. After drying, the granules are shaped into familiar slabs.

Pressing is done on special machines, after which the foam is processed with hot steam .

The thickness of the foam plates can be from twenty to a thousand mm. Below we will take a closer look at the technical characteristics of this material.

Interesting things about polystyrene foam

The American Alliance of Recyclers conducted research in 2004. The goal was to find out whether mold can grow on foamed plastics. Expanded polystyrene was taken as a sample. Pieces of material were placed underground, at a distance of 20 cm from groundwater. According to the results of the experiment, it turned out that neither mold nor fungi are adapted to life in such conditions. Even those blocks that were completely immersed in water were only 4% saturated with it. This is the best indicator for moisture resistance of building materials.

Polystyrene is widely used in everyday life. But the negative qualities of the material affect the environment. Disposing of polystyrene foam at home is dangerous to health and life. You can ensure proper disposal by contacting a waste recycling company.

Waste polystyrene and its copolymers are almost never recycled under natural conditions. Nature is not able to create a mechanism for the decomposition of substances created by man in a short period of time, so people, in order not to clutter the planet with garbage, must themselves take care of the disposal of industrial waste and unnecessary used products.

Advantages of a polystyrene foam house

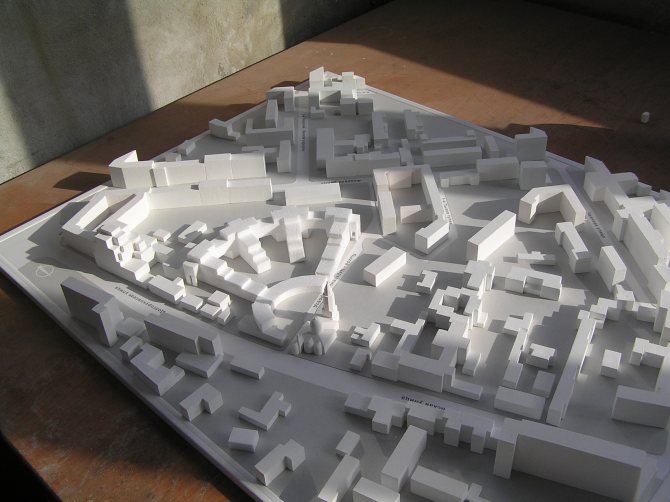

We build a house from polystyrene foam

To tell you about buildings made of foam plastic, it is worth highlighting a number of advantages that a building made of foam blocks can boast:

- Foam blocks help build a very warm structure

Such insulation, as it were, envelops reinforced concrete profiles on each side.

- A house made of foam blocks can serve as a “thermos”

Such a building can sufficiently retain warm air not only in the cold season, but also keep it cool on hot days.

- Available formwork

Formwork is not the familiar panels that need strengthening and installation. At their core, these are blocks of foam plastic, in the middle of which there is a cavity. According to some characteristics, this material is very similar to cinder block, but externally you can’t tell them apart from each other. When constructing a building from block foam, you fill its interior with concrete mass, installing reinforcement there in advance.

- Possibility to use permanent formwork

This formwork is presented as a complete material. The installation technology is the same: install the blocks, install the reinforcement and pour the concrete solution into it. In principle, such formwork can be presented in 3 varieties: as slabs, blocks or standard panel formwork, which is fixed together with specialized jumpers. Using panel formwork is the most affordable option from a financial point of view, but working according to such a scheme is not as easy as we would like.

The most suitable solution when doing construction work yourself is to use blocks that are so reminiscent of the long-familiar cinder block.

Also, foam plastic and concrete structures have some negative aspects, the most significant of which is considered to be the “thermos” effect. It can only be overcome by installing a high-quality forced ventilation system in the house, which makes the work performed more expensive.

Another, no less unpleasant point is the environmental friendliness of the structure, which, even if tightly sealed with plaster, is out of the question. It is also worth noting the possibility of the material igniting, after which toxic substances will be released during combustion, which can even kill a person.

As you can see, not everything is as rosy as it might seem at first glance.

What is polystyrene

Polystyrene is a product of the polymerization reaction of styrene. Chemical formula of styrene: C6H5CH=CH2.

Polystyrene is a hard, glass-like substance that transmits up to 90% of light. Polystyrene does not conduct electric current and heat, and is highly soluble in organic solvents such as ketones, aromatic hydrocarbons, aldehydes and ethers. Poorly soluble in alcohols, does not interact with acids and alkalis, and is passive in relation to water.

The so-called expanded polystyrene, obtained by heating polystyrene with gas-forming agents, has gained great popularity in construction. After cooling, the resulting material is a rigid structure with cells filled with air (only 2% by weight is polymer and 98% is air). The expanded cooled polystyrene is called expanded polystyrene (belongs to foam plastics - this is a whole class of foamed plastics).

Expanded polystyrene is a substance with low thermal conductivity, can be easily cut with a knife, is easy to install, and is not susceptible to radiation.

Polystyrene. What is it and what does it contain?

Polystyrene is a product of the polymerization of styrene (vinylbenzene) and belongs to the thermoplastic class of polymers.

It has a chemical formula of the form: -CH2-C (C6H5)H-n-

Phenyl groups prevent the ordered arrangement of macromolecules and the formation of crystalline formations. This is a hard, brittle, amorphous polymer with a high degree of optical light transmission, low mechanical strength, and is produced in the form of transparent cylindrical granules. Polystyrene has a low density (1060 kg/m3), thermal resistance (up to 105 C), excellent dielectric properties and good frost resistance (up to -40 C). It has low chemical resistance (except for diluted acids, alcohols and alkalis). To improve the properties of polystyrene, it is modified by mixing with various polymers - subjected to cross-linking, thus obtaining styrene copolymers.

The widespread use of polystyrene (PS) and plastics based on it is based on its low cost, ease of processing and a huge range of different brands. The most widely used (more than 60% of the production of polystyrene plastics) are impact-resistant polystyrenes, which are copolymers of styrene with butadiene and styrene-butadiene rubber. Currently, numerous other modifications of styrene copolymers have been created.

ApplicationThe main processing methods are extrusion, injection molding, the processing temperature range is 190-240 C. A wide range of products are produced from polystyrene, which are primarily used in the domestic sphere of human activity (disposable tableware, packaging, children's toys, etc. .), as well as the construction industry (thermal insulating boards, permanent formwork, sandwich panels), facing and decorative materials (ceiling baguette, decorative ceiling tiles, polystyrene sound-absorbing elements, adhesive bases, polymer concentrates), medical field (parts of blood transfusion systems, cups Petri, auxiliary disposable instruments). Expandable polystyrene after high-temperature treatment with water or steam can be used as a filter material (filter nozzle) in column filters for water treatment and wastewater treatment. The high electrical performance of polystyrene in the ultrahigh frequency range allows it to be used in the production of: dielectric antennas, coaxial cable supports. Thin films (up to 100 microns) can be obtained, and in a mixture with co-polymers (styrene-butadiene-styrene) up to 20 microns, which are also successfully used in the packaging and confectionery industries. Impact-resistant polystyrene and its modifications are widely used in the field of household appliances and electronics (casing elements of household appliances).

What is Polystyrene? Polystyrene is a colorless, hard glass-like substance that transmits up to 90% of the rays of the visible spectrum; density of polystyrene 1.05. The structure of the polystyrene chain is regular (of the “head-tail” type).

Polystyrene is highly resistant to water, acids (including hydrofluoric acid) and alkalis; polystyrene is soluble in aromatic hydrocarbons and esters. Polystyrene is insoluble in gasoline and alcohol. Due to its high dielectric properties, polystyrene is widely used in radio engineering and other branches of high-frequency technology. Polystyrene is aromatic in nature and quite easily undergoes substitution reactions in phenyl groups (nitration, sulfonation, etc.). These transformations of polystyrene are used in the production of ion exchange resins, polymer dyes, etc.

Polymerization of styrene is most often carried out in the presence of initiators using a radical mechanism. The molecular weight of the polymer, depending on the reaction conditions, ranges from 50-300 thousand. To process polystyrene into products, injection molding, pressing, extrusion, and blowing are used. In the production of lenses and electrical parts, mechanical processing of polystyrene blocks and plates is used.

Polystyrene fibers are transparent and elastic, which makes it possible to use polystyrene in fiber optics, electrical engineering, and the production of reinforced plastics.

Polystyrene is used to produce foam plastics and materials based on them. Polystyrene foam is produced by heating a mixture of polystyrene with a blowing agent (a substance that decomposes with the release of gas) above the softening temperature of the polymer (about 180-200 C). In this case, the blowing agent decomposes with the release of gases, which “inflate” the semi-liquid mass into foam plastic.

info-4all.ru

Why can't you just throw it away?

Do you have a collection of plastic cups at home that were used once, containers from household appliances brought from the store, egg cartons, etc.? Where should this waste go? How to where?! To the landfill! In Russia there are not, at least in the required number of collection points for polystyrene and polystyrene foam waste. What happens to garbage thrown into a landfill?

- Expanded polystyrene is not exposed to oxygen and ultraviolet radiation for a long time.

- It does not interact chemically with nearby garbage, since it dissolves in acetone, styrene itself, aromatic and chlorine-containing hydrocarbons, which, according to the rules, should not be in a household waste landfill.

- Tests have shown that at temperatures from –40 0 C to +40 0 C, polystyrene foam does not begin to decompose under the cyclic influence of water and ultraviolet radiation, corresponding to 80 years of being in a landfill (which is equivalent to the natural action of sunlight and precipitation).

Based on the above, it turns out that polystyrene and its derivatives are safe for nature? It is already clear that polystyrene waste, which has turned into crumbs and lies in a landfill for a long time, takes up useful land. In addition, if a fire occurs, the polymer will begin to decompose, releasing a bouquet of dangerous substances into the atmosphere: carbon monoxide and carbon monoxide, soot, hydrogen bromide, hydrocyanic acid, phosgene. Just three breaths of air saturated with phosgene kills a person.

Suffice it to recall the mass poisoning of guests of the Lame Horse club in Perm in 2009 by the combustion products of polystyrene, which was used to decorate the ceiling. At a temperature of 41 0 C and above, the process of self-decomposition slowly but surely begins in polystyrene, releasing styrene, toluene, ethylbenzene, formaldehyde, methanol and other unsafe substances into the air.

Polystyrene. What is it and what does it contain?

What is Polystyrene? Polystyrene is a colorless, solid glass-like substance that transmits up to 90% of the rays of the visible spectrum; density of polystyrene 1.05. The structure of the polystyrene chain is regular (of the “head-tail” type). Polystyrene is highly resistant to water, acids (including hydrofluoric acid) and alkalis; polystyrene is soluble in aromatic hydrocarbons and esters. Polystyrene does not dissolve in gasoline and alcohol. Due to its high dielectric properties, polystyrene is widely used in radio engineering and other branches of high-frequency technology. Polystyrene is aromatic in nature and quite easily undergoes substitution reactions in phenyl groups (nitration, sulfonation, etc.). These transformations of polystyrene are used in the production of ion exchange resins, polymer dyes, etc. Polymerization of styrene is most often carried out in the presence of initiators by a radical mechanism. The molecular weight of the polymer, depending on the reaction conditions, ranges from 50-300 thousand. To process polystyrene into products, injection molding, pressing, extrusion, and blowing are used. In the production of lenses and electrical parts, mechanical processing of polystyrene blocks and plates is used. Polystyrene fibers are transparent and elastic, which makes it possible to use polystyrene in fiber optics, electrical engineering, and the production of reinforced plastics. Polystyrene is used to produce foam plastics and materials based on them. Polystyrene foam is produced by heating a mixture of polystyrene with a blowing agent (a substance that decomposes with the release of gas) above the softening temperature of the polymer (about 180-200 ° C). In this case, the blowing agent decomposes with the release of gases, which “inflate” the semi-liquid mass into foam plastic.

Polystyrene is a product of the polymerization of styrene (vinylbenzene) and belongs to the thermoplastic class of polymers. It has a chemical formula of the form: [-CH2-C (C6H5)H-]n- Phenyl groups prevent the ordered arrangement of macromolecules and the formation of crystalline formations. This is a hard, brittle, amorphous polymer with a high degree of optical light transmission, low mechanical strength, and is produced in the form of transparent cylindrical granules. Polystyrene has a low density (1060 kg/m3), thermal resistance (up to 105 °C), excellent dielectric properties and good frost resistance (up to -40 °C). It has low chemical resistance (except for diluted acids, alcohols and alkalis). To improve the properties of polystyrene, it is modified by mixing with various polymers - subjected to cross-linking, thus obtaining styrene copolymers. The widespread use of polystyrene (PS) and plastics based on it is based on its low cost, ease of processing and a huge range of different brands. The most widely used (more than 60% of the production of polystyrene plastics) are impact-resistant polystyrenes, which are copolymers of styrene with butadiene and styrene-butadiene rubber. Currently, numerous other modifications of styrene copolymers have been created. Application The main processing methods are extrusion, injection molding, the processing temperature range is 190-240 °C. A wide range of products are produced from polystyrenes, which are primarily used in the domestic sphere of human activity (disposable tableware, packaging, children's toys, etc.), as well as the construction industry (thermal insulation boards, permanent formwork, sandwich panels), cladding and decorative materials (ceiling molding, ceiling decorative tiles, polystyrene sound-absorbing elements, adhesive bases, polymer concentrates), medical field (parts of blood transfusion systems, Petri dishes, auxiliary disposable instruments). Expandable polystyrene after high-temperature treatment with water or steam can be used as a filter material (filter nozzle) in column filters for water treatment and wastewater treatment. The high electrical performance of polystyrene in the ultrahigh frequency range allows it to be used in the production of: dielectric antennas, coaxial cable supports. Thin films (up to 100 microns) can be obtained, and in a mixture with co-polymers (styrene-butadiene-styrene) up to 20 microns, which are also successfully used in the packaging and confectionery industries. Impact-resistant polystyrene and its modifications are widely used in the field of household appliances and electronics (casing elements of household appliances).

Styrene polymer. Almost all transparent plastic products that you deal with in everyday life (pen cases, CD boxes...) are made of polystyrene, polystyrene foam is usually expanded polystyrene, and plastic dishes are also made from it. Along with polypropylene and polyethylene, it is one of the most widespread types of plastics. All plastic products that are marked with the letters PS are made of polystyrene

Styrene based polymer. Phenylethylene

touch.otvet.mail.ru

Disposal and recycling

PS waste is generated during the production of polystyrene plus these are obsolete products. Most polystyrene waste comes from foamed polymers, that is, foam plastics. Polystyrene-based waste can be reused in the following areas:

- Disposal of heavily contaminated industrial waste.

- Disposal of waste from the production of impact-resistant polystyrene

- Recycling of used products.

- Disposal of PS waste.

- Disposal of mixed waste.

Where to submit

Conservationists and simply people interested in order and cleanliness have most likely asked themselves the question: “Can polystyrene and polystyrene be recycled? If possible, then where?” In the USA and European countries, the acceptance of polystyrene foam for processing has been organized, which cannot be said about Russia. It is unprofitable to produce anything from polystyrene waste because:

- The products are cheap.

- It is difficult to organize waste collection from manufacturers and individuals, since you have to pay for recyclable materials, but due to the low cost of the final product, the payment will be meager.

- Styrofoam waste is lightweight but bulky and therefore requires significant storage space.

- Recycled foam must be stored in a dry place.

On a note! Despite the difficulties, small businesses are making progress in Russia. For example, manufacturers of furniture, toys and fishing products often search the Internet for polystyrene-based recyclable materials. Entrepreneurs are interested in uncontaminated heat and sound insulation, disposable tableware, egg trays, floats, components of life jackets, packaging, boxes from household and other appliances, foam waste from dismantling goods from wagons, ships, etc.

The problem of storing bulky products is solved by pressing and briquetting crushed foam and subsequently delivering the compacted foam to the manufacturer.

Disposal at home

It turns out that if you know the basics of chemistry, you can recycle polystyrene foam at home. To do this, uncontaminated strips of polystyrene foam should be crushed, placed in a jar and filled one-quarter full with acetone or benzene. As a result of the reaction and thickening of the mass, glue is obtained.

Styrofoam glue can also be obtained by spraying it with lemon peel extract (limonene). After processing, the volume of the foam will decrease by about 20 times, the mass will become sticky and sticky.

You can cut out a lot of useful things and decorations for your home from foam plastic. It can also be used to make DIY products from waste for children at school or kindergarten.

So, polystyrene and its derivatives are used in the human economy, but production waste and obsolete polymer products are not recycled in nature. However, waste can be used as handicraft recyclables and used as a business idea in a small business environment.

Waste foam made from polystyrene belongs to class 5 in terms of hazard level, according to FKKO. It follows from this that the disposal of this material does not require a special passport . However, recycling foam requires special attention. Since products made from this substance do not decompose in nature, soot and carbon monoxide are released during simple combustion or pyrolysis. This is unsafe for the environment and people.

Where can I recycle polystyrene foam?

The production of this material is so cheap that it is quite difficult to find interested parties in creating conditions for its processing. Still, although not as actively, there are organizations showing interest in collecting secondary waste of this kind.

World experience shows that the collection of polystyrene foam in landfills, landfills, dramatically increases the scale of these objects. This has become one of the main reasons pushing people to recycle polystyrene foam. In Europe and America there are special collection points. Moreover, in cities remote from factories involved in the recycling of cellular plastics, free shipment of this waste is organized.

Waste polystyrene foam in landfill

There is no such practice in Russia yet. However, entrepreneurs can organize a collection point on their own. Which happens periodically. Therefore, household users, corporate parties, and enterprises should monitor the Internet for advertisements where the authors are interested in recycled foam. Special offers from entrepreneurs are discussed later in this article.

What exactly do they hand over and what requirements do the acceptors have?

For reference, foam comes in a number of different forms that are used in different ways in practice. At the same time, the disposal of such waste has significant differences. Common types include:

- heat and sound insulators (although the admissibility of this fact is controversial among builders);

- disposable tableware (not excluding coffee cups, coolers);

- egg trays;

- floats, elements of life jackets;

- packaging material for transportation;

- products marked with a Mobius loop with a “6” inside.

More examples of foam plastic waste that are most often bought up: Production waste: cutting, sprues, defective products, surplus stock, fish boxes, office equipment boxes, polystyrene foam packaging, foam plastic waste from the dismantling of cars, ships and refrigerators, compacted foam plastic, pressed, the insides of household refrigerators , washing machine bodies, disposable polystyrene foam tableware, waste interior and picture frames, etc.

Regular waste collection points are in no hurry to accept these products. The reason is clear, the density of the material. It takes up large areas for collection, and it is necessary to provide protection from moisture. Since only dry and cleaned foam is accepted for processing. Contaminants include various types of labels, stickers, including tape, etc.

What is the correct name for polystyrene foam?

What are the types of foams (types of foam)

We've all seen foam plastic at least once. This material is used everywhere. However, what types of foams are there? You will get the answer to this question in this article.

What is polystyrene foam?

This is a finishing material (also called polystyrene foam), which is used to solve various problems in construction. Mainly for sound and heat insulation.

Polystyrene foam consists of 98% air enclosed in interconnected granules. Along with this, there are several technologies for manufacturing polystyrene foam, which determines its varieties.

Of course, each type of foam has its own properties and features. This also determines the scope of their application.

Today this material can be divided (conditionally) into the following types:

- Polystyrene;

- Polyurethane foams;

- Polyvinyl chloride;

- Polyethylene.

Here are the types of foams. Now, in order.

This type of foam can be produced in two ways: pressed and unpressed.

How to distinguish them? Very simple. Surely you have noticed how household appliances are packaged - refrigerators, televisions, audio systems. That's right - everything is packed in polystyrene - the kind that consists of small interlocking balls. It is somewhat reminiscent of a honeycomb. This is non-pressure foam. It crumbles and breaks very easily.

It will be more difficult to crumble with a press. This is due to the fact that this type of foam implies the presence of granules that are bonded much more firmly to each other. True, such foam has a more complex production technology. Therefore, it is used much less frequently than the pressless one.

There is also extruded foam, which is essentially the same as non-press foam.

It should be noted that pressless and pressed foam plastics have one significant drawback - water vapor can get into the smallest cavities that exist between the granules. And when exposed to negative temperatures, this steam condenses, which leads to an increase in humidity and a deterioration in thermal insulation properties.

As you know, when water freezes, it expands, which leads to the destruction of the foam. Of course, this process can be quite lengthy. But still…

Is there a way out? Yes. There is something called extruded foam on the market. It is homogeneous in structure and devoid of the above disadvantages. This type of foam is used for the production of food packaging and disposable tableware.

It should be noted that the quality (and therefore durability) of polystyrene foams greatly depends on the manufacturer. Therefore, even the same type of foam purchased in different places can differ significantly in thermal properties and more.

On average, the service life of pressless foam is about 15-40 years. But extrusion (with excellent manufacturing quality) can last much longer - 60, 70 years or more.

What other types of foams are there?

Surely you have seen foam rubber and know its properties very well. So this is a striking example of polyurethane foam. This material is highly elastic and characterized by an abundance of open pores. It allows air and steam to pass through perfectly.

The scope of application of such foam plastics is very wide - the production of furniture products, all kinds of household items, etc.

An important disadvantage of polyurethane foams is their fragility. They deteriorate very quickly when exposed to sunlight - they turn yellow and are gradually destroyed layer by layer.

They are also characterized by high flammability; when burned, they release toxic substances (more powerful than expanded polystyrene foams). The reason is the presence of a large amount of hydrocyanic acid.

The following types of foam...

The properties are similar to extruded polyethylene foam. They have high elasticity and do not contain highly toxic substances. At the same time, polyvinyl chloride foams are a self-extinguishing material.

And here it is very important: if polyvinyl chloride burns (in the case when it is completely surrounded by flame), it emits choking smoke. This must be taken into account when constructing all kinds of structures.

And the last type of foam -

You've probably met them quite often too. For example, such material is used to wrap breakable items and some equipment. This is the so-called film, which consists of air pimples.

This material is very elastic and does a good job of protecting things from damage.

Its thickness can vary - from a couple of millimeters to several centimeters. And usually this material is made in the form of flexible sheets (translucent).

Polyethylene foams are considered environmentally friendly materials and have high durability. However, such material is also flammable.

There are many varieties of this type of foam on the market with different brand names.

Now do you know what types of foams there are?

It should be noted that these are not all types of foam that are available today. However, we have listed exactly those varieties that are considered the most common.

Do-it-yourself insulation of walls with polystyrene foam

If you are thinking about insulating your home, then this material will be very useful to you. The easiest way to do this is to insulate the walls using polystyrene foam, and the technological process is so streamlined and uncomplicated that you can easily handle it yourself. Do-it-yourself insulation of walls with polystyrene foam can be done by anyone who knows how to work with simple construction tools.

Real proposals for the collection and processing of PP

Disposal of polystyrene foam in Moscow also takes place. Various forms are accepted, both by specialized points and by organizations using this material as a raw material.

For convenient storage, recycling of polystyrene foam allows for briquetting of these products. For this purpose, the plates are sent to compactors, where the material is crushed, pressed, and the output is briquettes of a standard size. Thus, they solve the pressing problem of polystyrene foam, reducing the area they occupy. In addition, experiencing an overabundance of this type of secondary raw material, briquettes are much more convenient to use for transportation to the place where the goods are required than waste collected in bags or other forms.

Foam crusher

Among the current proposals of organizations, it is recommended to pay attention to options for placing their own compactors in production areas where foam plastic waste is present in abundance. Such companies agree to buy cellular plastics in large volumes, with a tonnage of 40 or more. However, in reality, for mutual convenience, it turns out to be more practical to process the material on site and then transport it to the place of use.

Funny thing about polystyrene foam

As already mentioned, the crushed material is used to make children's toys. Moreover, even in this narrow area there are options for implementation.

This includes the following products:

- stuffed samples, inside of which small balls of foam are placed. They are interesting for children and adults (look for anti-stress toys in stores);

- objects made of solid foam. Mainly Christmas tree decorations (balls, airplanes, animal figurines).

Products of the first plan are easily transformed, returning to the original images under the influence of an elastic but resilient shell. To prepare the balls, grinders are used, which yield products of the desired shape and fraction.

Molded products are produced by casting. Special machines have been developed for this purpose. A sample blank (matrix) is used. A ready-made exhibit comes out of the machine, which only needs to be painted in a suitable color or covered with special stickers. Some products for fishing are obtained using the same method.

There is another option for making toys from foam plastic - cutting them out on a figure cutting machine, abbreviated as FRP. All that remains is to remind you of the need to make sure that the existing PP is non-toxic.

Snowflake made from recycled foam waste

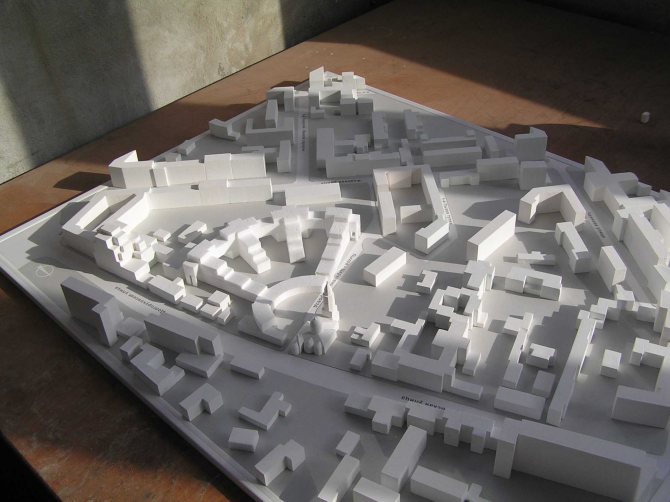

Model of an urban area made of foam plastic