Characteristics

Gas-electric boilers are cheaper due to the absence of two different fireboxes.

Gas-electric heating devices regulate the operating mode (on, off) automatically. In this way, the required temperature is maintained in the room, and resources are used as economically as possible.

Combined heating devices have the following characteristics:

- Small sizes. The design of such units includes oversized combustion chambers for burning gas and heat exchangers with a built-in heating element.

- Low level of electrical energy consumption. The boiler mainly operates on gas, and the electric heater starts up if necessary for prompt heating of water, as well as in the absence of a gas mixture supply.

- Reasonable price. It is formed due to the absence of a separate chamber (combustion chamber), since the heater is built into the heat exchanger. In equipment where there is no secondary circuit, an option is planned for the possible connection of a water heater.

- Heating elements with low power. Most models on sale only support the specified temperature value. Water heating heating elements begin to work when the electric operating mode is started.

Gas is considered an economical type of fuel, which cannot be said about electricity. In this regard, for heating houses in areas with a poorly developed gas supply, it is better to find a boiler option that runs on a different type of fuel.

An electric gas boiler costs on average 70-80% higher than a pure gas boiler. But since the installation of such a unit is cost-effective, its cost is fully recouped within 3-4 years.

Why are they needed and how are they used?

Undoubtedly, there are advantages of using a combined design:

- saving space in the boiler room, since the dimensions of a universal boiler are usually equal to the dimensions of a classic solid fuel boiler;

- the ability to use two types of fuel at any time, for example, electricity, until the planned gas main is installed near the house;

- in the presence of conditionally free electricity (solar panels, wind farms, etc.).

However, as we have already said, without special conditions, the purchase of an electric gas boiler is not justified either economically or practically.

Firstly , in absolutely all models of combined electric gas boilers, the gas burner must be purchased separately; the cost of an average burner is about 6-12 thousand rubles, which practically compares the cost of a full-fledged combination boiler with the cost of two separate budget boiler units.

Secondly , the efficiency and functionality of individual, even budget models, is always higher than one multi-fuel one. This is due to the structure of the combustion chamber, designed primarily for solid fuel, as well as fairly simple automation or its complete absence. The only exceptions are multi-fuel foreign models, but their cost starts from 290,000 rubles.

Thirdly , a small bonus of two single-fuel boilers is that if one breaks down, the second can be used as a backup. Moreover, even judging by the demand, this is a much more common scheme.

Design features

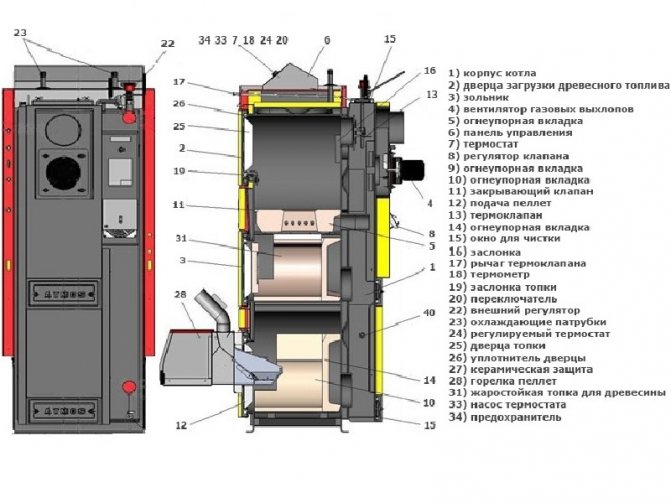

Multi-fuel units have several fireboxes for different types of fuel. Usually one is loaded with coal or firewood, the other is intended for liquid or gaseous fuel: gas or diesel fuel. Several fireboxes for different fuels are good because several separate independent circuits can be connected to them and the temperature in them can be different. For example, one serves the radiators, the second serves the heated floor. It is possible to divide by floor or according to some other principle. If you like this idea, when purchasing, pay attention to the fact that each firebox has a separate heat exchanger, which not all boilers have.

Combined heating boilers usually have several fireboxes for different types of fuel, and may also have several independent heat exchangers

If we talk about the developments of recent years, then almost all modern models also have built-in heating elements. It turns out that such equipment makes it possible to work on any currently available energy carrier.

Another interesting novelty: burners have been developed that can use gas or diesel fuel with equal success (at least, that’s what the manufacturers say). With such a spray unit there is no need for even two burners or chambers. The type of fuel used is changed by moving the switch to one of the positions.

For more economical and efficient heating of large areas and reducing the cost of heating, it is advisable to use heat accumulators. This is especially advisable when regularly using firewood and coal as one of the types of fuel. This is due to the peculiarity of multi-fuel boilers: when using solid fuel, the boiler power is not regulated and the room sometimes becomes too hot. If there is a heat accumulator, excess heat is transferred there and is “conserved” there, and if there is a lack of thermal energy, hot water from the heat accumulator is supplied to the system or used for hot water supply. Such a system allows you to fire the boiler much less often (how often depends on many factors, boiler power, heat loss at home, weather, calorific value of the fuel, etc.).

Design and principle of operation

In the design and operating principle of combined heating devices, there are various schemes that differ in their actions. Two types of heating system operate simultaneously and parallel to each other:

- in the first scheme, the electric heater is in the lead; gas equipment is connected only to increase the power and water temperature;

- in the other, on the contrary, gas equipment takes the leading position, and an electric heater is used as support.

We recommend: How do combined solid fuel heating boilers work?

Combined heating boilers for heating a house can be of several types:

- a device using gas as the dominant fuel. Such heating equipment is used to heat a room having a large area. In this device, an electric heater is used to increase the temperature in the system;

- Considering a combined electric boiler as a leader, you can understand that its operating principle is the same as that of electric boiler equipment. When the temperature drops in the system, the gas burner is automatically switched on. For example, during a power outage;

- Boiler equipment that has two heating elements operating simultaneously (gas and electricity) has a complex operating process. Such equipment is very economical and efficient.

When choosing a device, it is necessary to take into account its functions, architectural features of the building and area. If for some reason it is not possible to install the equipment yourself, then it is better to invite a specialist who will help install the device and use it without consequences.

Pros and cons of a combined heating system

Considering combined gas and electric heating boilers, their characteristics and capabilities, one cannot help but note some advantages of using the equipment:

- Equipment efficiency reaches 95%;

- Due to its small size, installation of the device is easier;

- minimum degree of contamination by emissions into the atmosphere;

- due to the possibility of combining types of heating, the consumption of both is reduced;

- boiler equipment can automatically switch between two types of heating, successfully combining different types;

- double-circuit boiler equipment. Has the ability to combine room heating and water heating;

- Over time, the cost of the equipment pays off.

We recommend: Do-it-yourself induction heating boiler: how to build a homemade unit

Cons:

- When connecting this type of boiler equipment with your own hands, you must coordinate your actions with the relevant authorities. Since the connection method is a three-phase network;

- cannot be used in apartments. Only on private property;

- if we compare gas heating, then this type of equipment costs 65% more;

- Constant supervision is required - tech. service and prof. work.

Combined heating boilers (gas, electricity)

Combined gas-solid fuel heating boilers

One of the most popular fuel combinations is solid fuel/gas. Many people are building houses in cottage villages where gas mains are planned. Therefore, buying and installing solid fuel equipment first, and then, after a few years, gas equipment, is not the most reasonable decision. So people are looking for boilers that can operate on both solid fuel and gas at the same time. In addition to the Finnish boilers described above, there is another offer - Polish combined heating boilers Zota. They can use solid, gaseous (natural or liquefied gas) or liquid fuel, but they belong to the class of replaceable boilers, i.e. To change fuel you need to install/remove the burner. If you are not going to frequently switch from one energy carrier to another, then this equipment is a good choice, since its price is low.

Combined heating boilers Zota

For those who will often change fuel, ECO CK Plus double-furnace combined boilers are much more attractive. Here the work scheme is different. If solid fuel is used as the main fuel, then after the end of combustion and the coolant temperature drops below the set one, the burner in the other firebox is automatically turned on. And it works on gas or liquid, which is set in the settings. A pellet or liquid fuel burner can also be installed in the solid fuel chamber. There is an option with and without hot water. A very interesting and truly multi-variant boiler. There are, of course, disadvantages: price and dimensions.

Combined double-furnace boilers ECO CK Plus

For those who are attracted by the combination of gas/solid fuel/electricity, the Finnish Jäspi Triplex and Swedish CTC described above are suitable. What stands out in this campaign is the CTC 2200 TRIO boiler, which can operate on all types of fuel - diesel/gas, wood, coal, electricity. Among the combined boilers, STS also produces the CTC 1200 Family 40, which can use gas/diesel and electricity, and several options using gas and diesel fuel. At the same time, it is suitable as solid fuel and briquetted (specify when purchasing regarding each modification).

Combination multi-fuel boiler CTC TRIO

Manufacturers, characteristics and design

Combined heating equipment on the Russian market is represented by products of domestic and foreign manufacturers. Some of the most popular are:

- Navien (Korea)

- CTC (Sweden)

- Hercules (Russia)

Let's start our consideration with Korean products. Gas-electric boilers from Navien are fully adapted for operation in Russian conditions. They easily cope with voltage drops in the network and do not react to a decrease in pressure in the gas main. The use of such technology allows you to save money on operation due to low gas consumption. They have a high degree of protection, and the circuits of electric-gas boilers make them completely safe to use. The operating modes of the device are set in software and can be selected independently.

The boilers of the Korean company have an optimal balance between price and quality. The presence of a special chip in the package that protects the device from voltage surges significantly extends the life of the device and also prevents its breakdown. The operation of this boiler is configured in such a way that it adapts to the conditions in a particular room, which saves fuel. The presence of a remote control allows you to control the operation of the device from a distance.

An electric-gas boiler from a Russian manufacturer under the Hercules brand can be used to heat rooms up to 300 m². The company's products are represented by a wide range of models. It includes samples with different configurations, depending on the energy carrier and functional features of the device. They have two circuits and are capable of not only heating the room, but also supplying residents with hot water, without connecting additional gas water heating burners. The DHW circuit in such boilers has a protective coating that increases its service life.

The device from the Swedish manufacturer has a power of 45 kW and is capable of heating rooms up to 500 m².

The gas-electric boiler STS is a model that can operate on any of the existing types of fuel. Its distinctive feature is that it is equipped with heating elements with a power of 15.75 kW. The presence of an internal automation system allows you to maintain the water temperature at a constant level. If necessary, boiler circuits can include programming devices that allow operation to be adjusted depending on the outside temperature.

The presence of a heat exchange unit in the configuration allows you to prepare up to 730 liters of water per hour.

The advantages of this device are:

- Easy access for cleaning smoke ducts

- Overtemperature control

- Possibility to turn off the pump and burner if necessary

Having considered the capabilities of three models of combination boilers from different manufacturers, you can make the right choice. It should be based on the size of the room, its thermal insulation properties and the availability of the required amount of funds.

What is the best way to switch to combined heating?

When a homeowner decides to install an automated local heating system in his home, traditional long-burning boilers used in private homes can be:

- improved;

- replaced by more modern combined models;

- supplemented with boilers with electrical connection;

- Each path has its own characteristics, requirements and conditions.

Not every old-style solid fuel boiler can be converted. Technical parameters do not always allow this to be done even in a workshop and using modern equipment. And in most cases, such re-equipment is unreasonably expensive, which makes it simply pointless.

Therefore, it will be easier to simply remove the outdated heat source and install a modern boiler in its place. The only limitation may be the correct choice of location for installing new equipment. There are certain requirements of fire and construction services that must be observed when installing a heating system in a house.

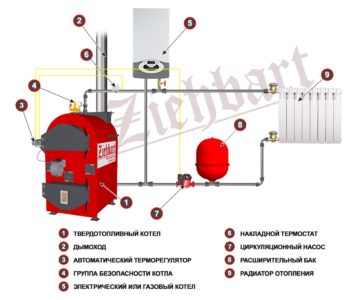

If the currently used boiler is quite satisfactory to the home owner and the time has not yet come to replace it, you can simply connect the electric boiler to a solid fuel boiler, having previously calculated all the technical parameters and made a diagram of the updated heating system. In this option, you will have to slightly modify the existing circuit, since the boiler piping must form a single whole. At the same time, the entire structure must work extremely clearly and efficiently, which can only be achieved by competent preliminary calculations and the highest quality performance of all work on the refurbishment of the heating system of the house.

The wiring diagram you need can be prepared by specialists who are closely involved in autonomous heating in the private sector. It will not be difficult for professionals to evaluate an existing system and select the most suitable equipment for specific conditions. As a result of such work, the efficiency of the heating system will significantly increase - economical wood-burning boilers, supplemented with electric heat sources, allow not only to effectively heat rooms, but also to significantly save on heating.

Features of the device and principle of operation

There are several types of gas-electric boilers for home heating:

- The main heating element is a gas burner. Equipment with a powerful gas burner can be used for heating large areas. An electric heater is used here for heating, which allows you to overclock the system at minimal cost.

- The operating principle of systems with a main electric drive is the same as that of electric boilers. Automatic connection of the gas burner occurs when the temperature drops, that is, at the moment when excess voltage is pumped into the electrical network.

- Designs where two heaters operate simultaneously are complex due to the rhythmic interaction of asynchronous heating. The units are efficient and constantly provide a stable temperature with minimal gas and electricity consumption.

Advice! The choice of a particular boiler design should be based on the required functions, area and architectural features of the building. If you have no experience in this area, it is better to seek help from professionals to draw up a heating system project.

We recommend: Soapstone stoves: features, principle of operation, do-it-yourself lining

How to choose

There is one important point that is worth knowing: the boiler will have different power for each type of fuel. How then to choose? According to the type of fuel that will be your main one. All the same, after all, you consider some fuel to be the best option for heating. And one more nuance that is worth considering when choosing: in imported boilers that are manufactured for sale within the Eurozone, the rated power is indicated, in boilers for Russia - the maximum. And this is a considerable difference in indicators. Sellers, by the way, announce the maximum power, which also needs to be kept in mind. Therefore, be careful.

Combination boilers for heating a home will have different outputs for each fuel

Types of boilers by number of circuits

Single-circuit devices are heating units designed only for heating network water. Double-circuit devices also additionally provide hot water supply. They are a good option for installation in country houses. At the same time, two important tasks are solved: high-quality operation of the heating system and the constant availability of hot water are guaranteed.

Single-circuit

Single-circuit boiler, a boiler is used for hot water supply

The power of such devices is quite sufficient for heating premises. But such a unit cannot provide hot water on a regular basis. For these purposes, you should additionally connect a capacitive water heater.

Dual-circuit

If staying without hot water is impossible, you need to immediately purchase a double-circuit gas-electric boiler. Unlike a single-circuit one, its design contains an additional heat exchanger that solves the problem of heating water. If power allows, you can increase the number of water points. To minimize the loss of water temperature, they should be located close to each other (boiler and tapping points).

All disadvantages of gas-electric units are determined by technical characteristics and depend on the manufacturer. When choosing a heating device, it is recommended to consult a specialist.

Repair of heating boilers of all types in Moscow!

heating boilers in Moscow, installation of gas, diesel, electric, solid fuel heating systems is carried out in a short time. The optimal time for work is the off-season. Installation of all types of heating heating systems. Problems are not always resolved according to plan, so it is important to act without delay. Remote points of Moscow and Moscow Region masters of the company DESIGN PRESTIGE LLC are ready to arrive in a short time. Having your own vehicle allows you to arrive at the site for repairs and installation of the heating system instantly.

Repairing boilers in the Moscow region is quite a difficult task. The accuracy of further operation depends on correct installation. More than a third of boiler failures are due to installation errors.

The employees of DESIGN PRESTIGE LLC cope with any models of boilers with high quality. To make sure that everything is working, it is important to carry out diagnostics. The equipment allows you to trace and identify the slightest installation inaccuracies. Heating boiler equipment is represented by a huge number of models and manufacturers. Each has a number of differences, positive and negative sides.

Heating repairs must be carried out taking into account the model features of the equipment. One important criterion for quality service is speed. To ensure maximum speed in carrying out complex tasks, DESIGN PRESTIGE LLC took care of the availability of a supply of components. Unlike most service services, when contacting the employees of DESIGN PRESTIGE LLC, you do not have to wait for a long time. Everything you need is always in stock, installation can be carried out in a short time. The cost of components will be below the market. Direct contracts with leading manufacturers allow us to offer DESIGN PRESTIGE LLC clients the best prices.

Minimum required power

For an average house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 100 m2, the minimum required power of heating equipment is 100/10 * 1.3 (30% reserve) = 13 kW. Boilers of this power are not found on the market, so we round up to the nearest higher value - 14 or 15 kW.

When choosing a double-circuit boiler, it is recommended to add another 10-15% to the result, since when heating hot water, the heating circuit is not heated.

Description and capabilities of double-circuit boilers

For houses and cottages located in the countryside, the ideal option would be double-circuit gas-electric boilers due to the following advantages:

- Less gas consumption;

- the cost of a double-circuit heat generator is higher than a single-circuit one, but lower when compared with the cost of equipment with a single circuit and an integrated boiler;

- simultaneous heating of hot water and coolant occurs;

- Less space is required for installation due to its compact size, which allows installation in the kitchen or in the furnace room, but subject to compliance with all norms and requirements.

But there are also disadvantages here:

- the consumption of gas, electricity and water must be balanced;

- if the flow of hot water decreases with unregulated gas, the temperature increases;

- It will be necessary to reconfigure the equipment if the pressure in the water supply network changes;

- periodic maintenance is necessary, since with hard water carbonate deposits quickly form on heat exchangers, which generally leads to decreased performance or breakdown;

- When you turn on the tap, cold water will flow for about 30 seconds.

Advice! It is worth understanding that all the disadvantages of double-circuit gas-electric boilers depend on the technical characteristics and manufacturer. When purchasing heating equipment, it is better to use the services of a specialist.

What are the installation requirements?

Connecting electric gas boilers must comply with certain standards and regulations, and you must also follow the attached instructions from the manufacturer. Depending on the design, installation can be floor or wall.

In any case, regardless of the device, the following requirements must be observed during installation work:

- according to fire safety conditions, the walls and floor of the room intended for the installation of a gas-electric heating boiler must be insulated, for example, with a sheet of metal;

- when working, you must be guided by the connection diagram issued by the gas service employees;

- when using several sources of thermal energy connected in parallel, free access to each must be ensured;

- the system must be connected to a protected electrical network (grounded and isolated);

- when installing a chimney, it is mandatory to maintain the distance from the walls; all requirements can be found in the technical data sheet;

- the circulation pump is selected taking into account the length of the utility network and the diameter of the pipes;

- Only threaded types of connections are allowed to be used;

- dual-circuit designs involve the use of filters for water purification for each circuit.

We recommend: How to choose the right insulation for heating pipes

If you follow the rules for connecting electric gas boilers, there will be no problems with performance, efficiency, fire safety, uninterrupted operation, and high efficiency is also guaranteed.

Installation and operation rules

Before connecting, you need to check the draft in the chimney

The combined heating system is installed by specialists from the gas service or a special organization according to a pre-approved plan.

Stages of work:

- Installation of supports that will provide the required level for the heating unit. As a rule, they are present in the latter's kit.

- Connecting the boiler to the gas supply.

- Electrical connection.

- Installation of special filters for water and gas.

- Leak testing and cleaning of the heating system.

- Connecting the boiler to the pipeline.

- Setting up the chimney.

- Test run of the heating system, troubleshooting problems.

- Final adjustment of the heating system.

Installation of a gas-electric boiler is permitted in a room where, in accordance with the rules and regulations, supply and exhaust ventilation is equipped.

Basic operating rules:

- During operation of the combined unit, acceptable traction is required. In this regard, the chimney must have a sufficient cross-section.

- The chimney used must be insulated to prevent the parts in contact with it from catching fire.

- During regular operation of the boiler, the ash pan should be periodically cleaned. The frequency of such procedures depends on the degree of gas combustion and the intensity of operation of the unit.

- There should be a steel sheet in front of the combustion chamber, which will provide the flooring with protection from sparks.

Electric gas heating boilers are considered the most technologically advanced and advanced.

The best known manufacturers and models: characteristics and prices

Teplodar Kupper OK 15

One of the best and most famous combined gas-electric boilers for heating a private home. The model is known for its simplicity and reliability at a low price. It is also distinguished by its successful inclined design of the firebox and its ease of cleaning. The power of the heating element block is 6 kW. The owners also note the stylish modern design and excellent build quality for a domestic manufacturer.

Despite the fact that the model is quite successful and in demand, there are also many disadvantages: a small loading hole and the firebox itself (wood up to 35 cm), a steel heat exchanger that is susceptible to corrosion, relatively low efficiency, and high soot formation.

Cost: 19,900-21,200 rubles.

Karakan 20 TEGV

Very compact domestic double-circuit combi boiler. In addition to its dimensions, it is distinguished by a simple and reliable design, omnivorous (you can use any fuel of any quality), and at the same time it has a large loading hole and the firebox itself. The heating element is pre-installed by the factory, but the gas burner, as in any other case, must be purchased separately.

The disadvantages are the same - a steel heat exchanger, efficiency is only 75%, and the maximum permissible operating pressure is 1 bar, which means it cannot be installed in a closed-type heating system, where the operating pressure is usually 1.5-2 bar. There have been no service complaints over more than 5 years of operation.

Cost: 22,500-25,000 rubles.

STS V25 FG

An expensive, high-tech, double-circuit multi-fuel heating boiler from a Swedish manufacturer. Works on almost all available types of fuel: natural and liquefied gas, electricity, diesel, fuel oil, firewood, coal, coke, anthracite, peat, pellets. The body itself is steel, but the firebox is cast iron: heavy and fragile, but extremely durable due to its resistance to corrosion (service life of 30 years). The power of the heating element is 6 kW.

The boiler is supplied from the factory with a remote electrical box with a power of 2×6 kW. When using a battery, you can achieve the highest combustion temperature, maximum efficiency, minimum amount of soot, flue gas purity and efficiency of more than 90%. There is also a built-in boiler for preparing hot water with a volume of 115 liters.

The disadvantages are the huge weight of 385 kg and dimensions (height more than 1.5 m).

Cost: 330,000-500,000 rubles.

Combination boiler power

In general, combination boilers were once developed in order to increase the time between fuel additions.

That is, if you put firewood in a regular wood-burning boiler, then you will have to do the next load in 3-4 hours.

In the case of a coal heat generator, this time increases to 6-8 hours, and sometimes, depending on the design of the boiler, up to 12 hours.

It seems to be good. But what if there is no good coal in your area or its supply is irregular?

All that remains is to use firewood or briquettes. And in this case, as already written above, you will have to go to the boiler every 3-4 hours.

Of course, there are options for long-burning solid fuel boilers, which are designed so that the fuel load burns from 12 to 24 hours. However, the cost of such thermal units starts from 70,000 rubles.

There is a much cheaper alternative - using a combi boiler to heat your private home. Which option is better to choose in this case is up to you to decide.

In terms of cost, a wood-electricity combination boiler is practically no different from a simple wood-burning boiler.

At the same time, when you calculate the power of a heating unit for your home, you can safely add up the thermal power of wood and the power of electricity. After all, you can heat the coolant with a heating element right in the process of burning wood.