Design

Using these devices in a bathhouse will cost much less than building a fireplace stove and maintaining its technical condition.

The fact is that the electric steam generator only needs to be secured in the right place and plugged into the electrical network. There are solid fuel options that run on wood (Perevalov’s steam generator), where water containers are directly exposed to flame. At the same time, in all options, no engines are used to supply steam, since water, being converted into steam, will come out on its own under high pressure.

To understand how to make a homemade steam generator, you need to understand what it consists of.

The classic electric version includes:

- channel for water inflow;

- a working unit where water will be boiled;

- evaporation module.

Of course, you can purchase ready-made models rather than making them yourself. However, the price of such options will be very significant. To assemble a homemade version, you can use some broken household appliances; they are available in almost every household and in this case they can get a second life.

Comments:

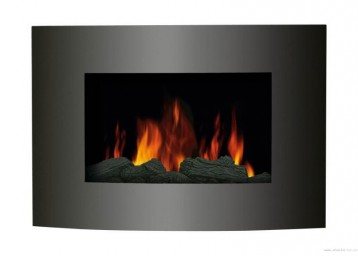

Sergeev

Of course, there is no benefit from such a steam generator, but the fire turns out to be so real that even my dog was afraid of it at first. I have Dimplex, the only thing I don’t like about this model is that the “fire” does not appear immediately, but only when the bulbs warm up enough for the steam to rise. Those. 3-4 minutes

Mikhalych

I agree with the author of the article, paying for something that you use 2-3 times to surprise guests, and then hide in the pantry is not entirely reasonable behavior. Even as a night light, this device does not work very well, because... pulls at least 100 watts.

Monet

Mikhalych, well, not everything can be measured in Watts and rubles? People hang pictures on the walls, collect coins, samovars. To each his own

Rinat

I ordered myself a dioramic hearth, maybe I’ll add a steam generator to it. And I don’t give a damn about energy consumption, the main thing is that there is comfort

Alexei

Well, as if the author also made a comparison akin to sellers. Regarding the steam generator. What does he propose to compare? Humidifier ASSEMBLY (with water container, fan, control and of course ultrasonic head) and one ultrasonic head (from the fireplace). The humidifier has exactly the same head! Accordingly, they produce steam equally. Unless the humidifier has two heads, which means the dimensions won’t be the same as in the picture...

Yana

This entire article, an anti-advertisement for the fireplace and praise for the humidifier, is an ordinary PR move, and nothing more. The author clearly does not understand what he is writing about :)))) I am especially curious about water that will stink... I got the impression that the author has not seen the fireplaces he is writing about here, otherwise how could such a funny thought about stinking water come into his head? I have been using a 3D fireplace for the fifth year now, there was a problem with the steam generator - alas, out of laziness, we filled it with regular tap water... and our fireplace worked on hard water for three years and in the end the steam generator had to be repaired. But, I believe, even this nuance adds a plus to the fireplace... after all, 3 years on tap water is impressive. In everything else there are only advantages, starting from aesthetic benefits: beautiful design of the portal, the effect of a living flame - it’s incredibly cozy! And there are psychological benefits: it’s nice to relax by the fireplace in the evening, the play of the flames is mesmerizing and calming. And there hasn’t been any stench from the water in all five years and there can’t be: the water doesn’t stagnate there - it evaporates quite quickly. Maybe for the stench you need to take water from the swamp... :))) As for the energy consumption, it’s also nonsense: if you don’t turn on the heating function, the energy consumption is minimal.

Leave a comment Cancel reply

Related Posts

Advantages and disadvantages of Dimplex electric fireplaces

Wall-mounted electric fireplace provides warmth and comfort

Photo selection of electric fireplaces in the living room

Panoramic electric fireplace - a budget option with enormous multimedia capabilities

Selection of capacity

It is best to use a broken or new pressure cooker as a working container where the water will be heated in the new steam generator.

The fact is that the effect of vaporization was already built into its design from the very beginning.

Such a device will fully comply with all the requirements in the context of creating a steam generator:

- it has a hermetically sealed lid;

- the strength of its body has the necessary indicators to withstand the pressure required to create steam;

- A valve is provided in the body of the pressure cooker to remove excess steam.

When the process of selecting a container is completed, it is necessary to determine how the water will be heated.

Selecting a heating element

When choosing a heating element, you need to start from the volume of the tank, its size and the required power.

To heat water, you can use a gas (electric) stove or an electric heating element.

The safest and most convenient way to heat water in the body of a pressure cooker is to place a heating element in it in the form of a heating element.

If you want to save on the heating element used, you can try to disassemble an old electric kettle or electric samovar, taking the heating elements that are used there.

Before you begin assembling the steam generator itself, it is necessary to carry out calculations to determine the optimal number of devices required to create steam. So, for a large amount of it, three or more similar heaters may be required.

Types of steam generators

Today you can find several main types of steam generators on sale, which differ in their design, purpose, technical characteristics and cost. By choosing the right model, it will be possible to significantly simplify the operation of the equipment in the future, and the device will be distinguished by functionality, versatility of use and excellent efficiency.

Ironing steam generating systems are multifunctional devices that include a special board with a special coating and a modified iron with a tank for generating steam. The main purpose of the device is to iron clothes and significantly simplify such work.

Steamers are designed for vertical processing of clothing. Such devices cope with smoothing various materials, perfectly steam curtains and make it easier to clean windows. They are equipped with powerful steam generators and are easy to operate.

A steam cleaner is a universal technique that generates steam, allowing you to easily remove old stains, clean carpets, disinfect and wash stone, wood and plastic surfaces. It is not used for smoothing clothes, but exclusively for removing stains.

The small steam mop is an easy-to-use device that makes it easy to clean windows, floors and tiles. The best models come with various attachments, which can significantly expand the capabilities of such equipment.

When choosing such a device, it is necessary to take into account how the equipment will be used in the future, which will allow you to select a high-quality steam generator. In this case, preference should be given to products from those manufacturers who specialize in the manufacture of such equipment, offering their customers reliable devices.

Build process

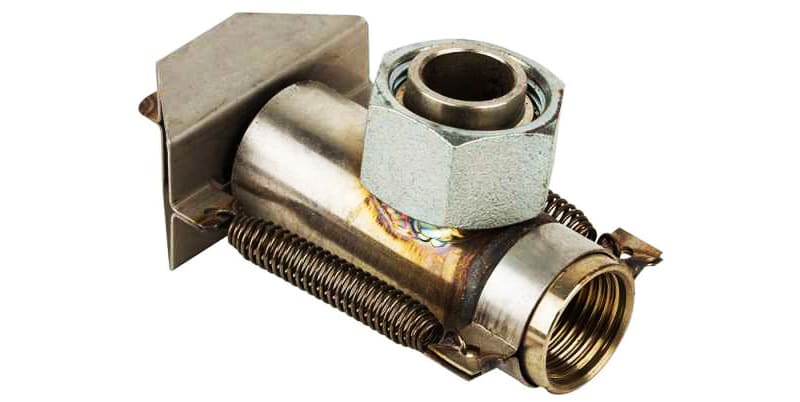

When choosing a method for attaching heating elements, you need to make sure that the tubes do not touch the bottom, much less the walls.

Therefore, it is necessary to drill a through hole of the appropriate size in the wall so that the heating element can be mounted there. At the same time, the distance of the heating elements from the surface should be approximately 1 cm. This will ensure proper heating without damaging the container itself.

It is best to use insulating washers, which should be installed both outside and inside the container. To seal the fasteners, silicone gaskets are used (it is important that these are heat-resistant options). They can be purchased at the store or made yourself.

Types of steam generators

With this device you can make your life much easier.

Steam generators perfectly disinfect and cleanse contaminants, help defrost pipes and a car engine in cold weather, and will also become an indispensable assistant for cleaning filters.

These devices operate differently, so it is customary to distinguish five types of design.

Steam generators are:

- Electric , powered from the network. Industrial models usually require connection to a regular 220 V outlet, while industrial models require a 380 V outlet.

- Oven steam generators use solid fuel (coal, wood) as heating.

- Electrode steam oven , which uses electrodes as the heating element.

- Induction steam generators, the operating principle of which is the transformation of an electromagnetic field.

- Ultrasonic steam generators evaporate steam using sound vibrations.

The easiest way to make an electric steam generator yourself is to use suitable elements. A steam generator for a car can be made from trash, which is easy to find in any home.

Firewood layouts

Regardless of the type of structure simulating a flame, a mock-up of firewood will always be needed. In this matter, the master’s flight of imagination is only welcome. Props can be purchased in the online store. They can send you components for fireplaces from China (we will use this fact in the future). In some cases, real firewood is used. With skillful lighting, a good result is obtained.

But if all searches are unsuccessful, then you will have to make a dummy yourself. But then it will be doubly pleasant to look at handmade work. The material used is corrugated cardboard, which can be found in boxes of household appliances. There it is often used as a filler between sheets.

Corrugated cardboard log

By making tubes from such cardboard and painting them brown, we will get a log, to which a knot made of the same material, only with a smaller diameter and length, is attached with tape. All that remains is to stack the wood in the fireplace; from a distance it looks like the real thing.

Good to know: What types of electric fireplaces are there, we consider all existing types

Design and principle of operation

The simplest products consist of:

- water tank;

- heating element

- supply tube.

Industrial units have many additional elements that provide expanded functionality of the device. For home use, such equipment will definitely come in handy, but the main disadvantage will be the high price. That is why you should pay attention to the possibility of making a steam generator for cars and other household needs with your own hands.

The essence of the steam generator:

- Water is supplied to the reservoir, preferably filtered and cleared of metal suspensions. This will increase the service life of the homemade device and help avoid frequent cleaning of the nozzle.

- When the heating element is turned on, the water begins to heat up and evaporate, entering the expansion tank, from where it exits through the pipeline through the nozzle.

The resulting steam can be directed to a contaminated surface, and can also be used for a sauna or Finnish bath.

Often, steam can remove oil stains or deeply ingrained dirt.

In most purchased models, you can adjust the temperature and intensity of evaporation. Despite the fact that home models do not have this advantage, they also cope well with their functions, and most importantly, they are affordable.

Main characteristics

When buying a particular steam generator model, you need to pay attention not only to its brand and price, but also to the capabilities with the main characteristics of a particular device. This is the only way to make the right choice by purchasing inexpensive and functional equipment at the same time.

The main characteristics include the following:

- Power indicators.

- Steam supply method.

- Availability of water tanks.

- Anti-scale protection.

- Basic operating modes.

- Additional functions.

On sale you can find a small household steam heater, the power of which ranges from 800 to 3100 Watts. For home use, it is best to purchase models whose power is in the range of 1600-2000 Watts. Such equipment will have an appropriate power reserve, which will allow it to cope even with old stains, providing high-quality cleaning and steaming of clothes.

You should not skimp on power indicators, since the simplest miniature paragenerator, which has this indicator of 800-1500 Watts, is unable to effectively cope with its work, which significantly complicates steaming and stain removal.

Buyers need to analyze the method of steam supply, which involves two main parameters. This is a pressure of 2-6 Bar and the intensity of the supply of heated air, the jet power of which can be 90-140 grams per minute. If the equipment is used as a steamer and for ironing clothes, then preference should be given to models with a thermal shock function. Such models provide a rich supply of steam with a jet of up to 200-250 grams per minute. The higher the steam supply, the better the specific model and the easier it is to work with.

Standard models of steam generators are equipped with an additional water boiler, the volume of which is 0.7–2.2 liters. In each specific case, the choice will be individual. If this technique is used as efficiently as possible, then preference should be given to models with a large tank volume. The best steam generators have such containers made of transparent plastic, which makes it much easier to control the volume of remaining liquid.

In the past, one of the problems with using such devices was the formation of scale, which quickly damaged the devices, forcing owners to carry out additional water treatment. Today, most steam generators have received additional protection against scale, which allows them to completely solve problems with the operation and maintenance of equipment. The formation of scale is prevented due to the presence of metal rods that trap particles suspended in water, accumulate them, and all that remains to be done is to carry out the simplest cleaning of the tank and the rods themselves.

DIY steam generator

Having decided on the main question - how the water will be heated, you can proceed directly to assembling the unit.

Selection of capacity

This parameter largely determines the performance and mobility of the equipment. To heat water, it is advisable to use a metal container with sufficient thermal insulation to reduce the risk of burns due to accidental contact during use. This could be a metal canister, a bucket, or even an old electric kettle. Depending on the required volume of steam and operating time, such a device requires periodic addition of water.

You can make a maximum power steam generator with your own hands from an old gas cylinder, after first cleaning it of possible residues and constructing a suitable pipeline for supplying steam.

It is on the example of using a gas cylinder (option - an old fire extinguisher) that our guide will be based.

Selection of heating elements

If you do not take into account the option of heating water using an electric, gas or wood stove, it is preferable to use heating elements of a suitable design. For the volume of the gas cylinder, this should be a heating element for the boiler. If the container is smaller in volume, heating elements from an old kettle will also work.

The main condition is that the heating source must be easy to change in case of failure.

The welded structure, of course, will behave more reliably when working under pressure, but if it overheats and requires replacement, you will have to almost completely disassemble the device.

How to make a steam generator for a bath from a gas cylinder with your own hands

This type of assembly is common among specialists. First of all, the cylinder itself is made of high-quality sheet iron. Finding something like this is quite difficult. The metal can withstand almost any temperature and is distinguished by its resistance to pressure surges.

What tools and materials are needed for the job?

Before starting assembly, you must prepare the following plumbing tools:

- electric drill and drill bits;

- roulette;

- elements for fixation;

- circular cutting machine;

- isolation;

- metal scissors;

- keys.

Tools for creating a steam generator PHOTO: oldoctober.com

In addition to the above tools, you will need a welding machine for the job. In addition, you will need indicators to measure the pressure and operating temperature range, as well as ball valves.

At home, they use low-power installations that can be made with your own hands from old household appliances or household items. For example, this can be a steam generator from a flask, an old kettle or a pressure cooker.

Steam generator from a teapot PHOTO: sc-master.ru

Selection and preparation of a container for a steam generator

The diameter of the base of the gas cylinder is universal and is suitable for selecting a heating element from an ordinary electric kettle. The heating element in such a situation will be the heating bottom, which will already be an innovative solution, since it will save money and time on installing any heating system.

Gas cylinder for steam generator PHOTO: vstroyka-solo.ru

The dimensions of the tank are selected directly from the planned volume of steam. When the manufactured device produces less than the required quantity, it will need to work without interruption, at the peak of its capabilities, which is why repairs are often required.

Before installation work begins, the cylinder should be emptied of liquid and dried. Welding work is carried out only when the user is fully convinced that there are no gas vapors. You need to sniff, there should be no smell of propane in the cylinder.

Installation of heating elements

Before installing the heating element yourself, you need to make a drawing of the steam generator. A heating element is installed at the top of the tank, which is fixedly mounted on a removable lid.

The heating element is installed so that if it burns out, it can be easily replaced. For this reason, it is not recommended to weld the heating element to the structure body.

When creating a device using solid fuel, special calculations and installation of heating elements are not performed. It is quite easy to assemble the device yourself; in addition, the costs for consumables will be minimal.

Installation of additional elements

To reliably fix cranes and automation, special fastening elements are used. They are located at the top of the steam generator. These are filling valves, pressure relief valves and ball valves.

Installation of auxiliary elements PHOTO: sc-master.ru

Each of these elements is selected carefully, since they will be responsible for the exchange processes in the cylinder. Violation of the assembly technology may result in the device not working.

Valve modifications

When using a gas cylinder, a brass valve can be used. It can be easily converted into a ball valve. For these purposes, the valve is disassembled, the pin is removed, the thread is cut, and the valve is screwed in. A similar design will be needed to select the steam flow.

Modification of valves PHOTO: sc-master.ru

Checking the safety of the steam generator

In the process of independently creating a steam generator for a bath and other needs, it is necessary to check the operation of the device. To do this, at the final stage of assembly, an automatic safety unit is installed, which consists of pressure gauges that make it possible to monitor temperature and pressure.

The safety unit functions in this way: when the pressure inside or operating temperature indicators reach maximum parameters, the heating automatically turns off. A magnetic starter must be included in the electrical circuit of the device. Once the operating values and safety auto-trigger have been verified, the product can be installed for further use.

Checking the safety of the steam generator PHOTO: sc-master.ru

Testing and Troubleshooting

After assembly, the homemade steam generator must be properly tested. The tightness of the container and installed fittings, the speed of heating the water and the operation of the sensors are checked.

To connect to the network, it is preferable to install an RCD ( residual current device ) and a grounding circuit. After this, you can check the heating rate and the volume of steam produced.

Possible operational problems are eliminated by adjusting the valves and debugging the automatic safety system.

Safety precautions

When operating a homemade steam generator, it is important to follow safety rules.

All heating elements used in creating such a device must be insulated and the circuit must be grounded.

To prevent generator failure when operating without water, you should rely on the readings of the cylinder filling control sensor.

Making a steam generator with your own hands is quite simple; the main thing is to have the necessary equipment at your disposal and know the basic principles of the device’s operation. Thanks to the useful recommendations in our article, you can assemble a simple device for household needs.

Video instructions for assembling the steam generator:

- Author of the material

- Other materials

Author Auto mechanic

For 15 years I have been repairing various types of cars, including brands such as VAZ, UAZ, Chevrolet, Mazda, Kia and many others. Everything related to the gearbox, engine or chassis. You can write me your question below in the comments and I will try to answer it in detail.

Hello, dear readers!

Quite a bit of time has passed since I shared with you interesting information about how to make gutters from plastic bottles. And, quite recently, my old friend and I realized an old idea - a steam generator for a bathhouse with our own hands! And, imagine, we succeeded!

From my own experience, I know that bringing an idea to life, no matter how complex it may seem, seems difficult only until you understand everything thoroughly and take action. And as soon as the activity begins, the process starts by itself.

This is exactly what happened with our hand-made phyto-barrel. By the way, you can read more about a real phyto-barrel here. Having mastered the principle of operation and the design of a steam generator in theory, we set about making it in practice, right at a friend’s dacha! It turned out that it is not difficult at all! Well, are you interested?! Then I begin my detailed story on the topic!

From this article you will learn:

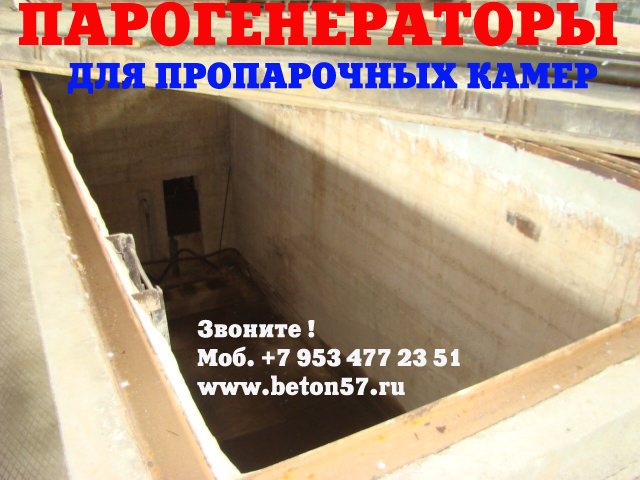

Do-it-yourself steam chamber for reinforced concrete products.

The design of the room for the steaming chamber can be very diverse, the main thing is to achieve tightness and a certain thermal insulation.

As practice shows, the most optimal option for a steaming chamber is the following solution. Photo on the left.

How to make a steaming chamber with your own hands?

1. A metal frame of the required dimensions is mounted. 2. Next, the frame is covered with thermal insulation panels. 3. The inside of the room is insulated with moisture-resistant material; polystyrene foam is best suited for this. 4. Additionally, the room is covered with a layer of waterproofing, for example liquid glass-PVC film with a temperature control system and steam supply. 5. It is necessary to provide a slope of 1 degree on the floor to remove condensation; 6. Provide protection against steam leakage at the inlet and outlet of the chamber. 7. To improve the quality of steaming, an exhaust pipe with a damper and outlet to the atmosphere is installed in the ceiling. Perforated steel pipes are used as steam pipelines for uniform steam supply, laid along the perimeter of the room or between rows of products. 8. Pipelines are installed at the bottom of the chamber. 9. The steam generator must have sufficient power to carry out the technological process, and also have an automation system for temperature and time control.

All products made from concrete cannot be used in construction until they acquire their technological strength. Enterprises producing reinforced concrete products have neither the time nor the space for this.

If, immediately after production, such building materials are folded to dry in the open air, they will become suitable for construction only after 28 days. Consequently, the company loses a significant part of its profit...

Therefore, special designs called steam chambers were invented

In the steaming chamber for concrete, the products are steamed and brought to tempering strength at high temperatures (+60-100°) and significant air humidity (about 90-100%).

Hardening essentially occurs in hot steam. The chamber creates the most favorable conditions to accelerate the hardening of the material at optimal humidity. The use of a steaming chamber for concrete allows you to make maximum use of production space and produce building materials from concrete in a short time.

Directly after the steaming process, the building material acquires 70% of its design strength and can be transported to the construction site, and there placed into the structure.

The hardening process will continue until it reaches 100%. For each material, its own mode of operation of the steaming chamber is selected, which is selected depending on the composition of the concrete, the quality and characteristics of the constituent components, the brand and characteristics of the cement, the configuration and dimensions of the product, the initial strength of the concrete and a number of other factors.

Industrial steaming chambers for concrete have different dimensions, power, capacity, duration of a full cycle, and power consumption.

They use different types of fuel and require different numbers of maintenance personnel.

Typically, 1-2 people are required to service the steaming chamber, and the duration of a full cycle is usually 24 hours.

How does the concrete steaming process work?

The peculiarities of steaming are that it occurs at a temperature of 80–90 degrees Celsius. The duration of this is 10–20 hours.

As a rule, the steaming process is preceded by preliminary exposure of concrete products at normal temperature. The time here varies depending on the type of concrete mixtures. Products made from harsher mixtures are aged for at least one to two hours. And especially harsh mixtures - no less than two to four hours. Steaming mode includes:

– preliminary exposure; – the process of gradually raising the temperature to the level of isothermia; – direct isothermia with maintaining a constant temperature; – cooling.

The temperature increases gradually, depending on the type of cement. And ranges from 20 degrees per hour to 30 degrees over the same period of time. Thermal heating is carried out at air humidity of 90–100%.

Features of the concrete steaming process.

Due to the specific nature of steaming concrete products, it is used in prefabricated structures. The duration of the process directly depends on the required tensile strength of concrete products. In summer this is no less than 70%, and in winter – 90%. These indicators will be optimal for concrete of one type or another. When some fillers are added to them (diamite, sishtof, travel and a number of others, including granulated blast furnace slag), the steaming time is reduced by 10%. In addition, the final strength of concrete structures increases almost one and a half times. Steaming of concrete can also be carried out using the so-called “thermos method”. It consists of gradually increasing the temperature to the maximum level. After this, the flow of steam stops. The products remain in the chamber until the temperature drops to 40 degrees Celsius.

Application options for steam chambers

Steaming chamber for concrete and reinforced concrete products.

In the production of concrete, reinforced concrete products, and expanded clay blocks, it is extremely effective to use steaming chambers to accelerate hardening; this solution speeds up the process up to 10 times compared to drying in the open air. In the chamber, the products are exposed to hot steam with temperatures up to 80-90°C and humidity up to 100%.

During steaming, hydration of the cement occurs: when water joins the cement, solid new formations (hydrates) are formed. Cement adhesive, which is initially in liquid or plastic form, turns into cement stone as a result of hydration.

Why do you need a steam generator?

Steam generators are widely used for the production and steaming of blocks because the steam in the steaming chamber maintains two parameters at once - temperature and humidity.

The use of steaming concrete structures reduces this figure by almost half. What makes this process undoubtedly more cost-effective.

Steam generators allow you to organize a steaming chamber for: reinforced concrete products and concrete blocks, as well as for steaming paving slabs and cinder blocks.

The use of a steam generator in the steaming chamber allows for complete automation of the technological process - automatic control of temperature, humidity, and time.

For steaming chambers, it is possible to use both electric steam generators and gas or diesel fuel models.

Our steam generators have a wide range of adjustments for power, pressure and temperature of the generated steam, which allows you to select a steam generator for the steaming chamber with the necessary parameters.

Knowing the volume of the steaming chamber and the type of product being processed, we can select the optimal power and steam generator options for the steaming chamber. To do this, contact us in a convenient way using the contacts listed at the end of the article.

Using steam generators for steaming concrete.

Under normal conditions, concrete structures reach specified strength values after a long time. The period for concrete to gain strength under normal conditions is about a month. When steam generators are used, this time is significantly reduced. It is 13–15 hours. And the required strength is achieved much faster.

Steaming concrete makes it possible to achieve the required structural strength of 65–70%. Moreover, all year round. Depending on the selected technological process, low or high pressure steam generators are used. Their power is selected based on the volume of industrial production.

The choice of a low pressure steam generator greatly simplifies its use.

The range of fuel used for steam generators is quite wide:

– gas; - diesel fuel; – solid fuel; - electricity.

What to do with all this?

The tens need to be strengthened in the canister, or rather, placed inside it. And to do this, holes of the appropriate diameter should be drilled in the canister body. From the inside of the canister (through the large lid) we insert a heating element into them, seal it and secure it well. In a word, we remember a boiler immersed in water and do it by analogy!

After the heating elements are inside, you need to connect their electrical terminals to the wire outside, and the contacts should be securely wrapped with electrical tape and protected from accidental touch. One stage of the work has been completed, congratulations, you did it!

And then?

We perforate a metal-plastic water pipe with a drill or screwdriver. The holes should be a maximum of 5 millimeters in diameter, and the distance between them should preferably be 5-8 cm. Then the plastic pipe must be rolled into a ring corresponding to a slightly smaller diameter than the diameter of the bottom of the wooden barrel. We place the pipe blank inside the barrel, on its bottom, with the holes facing up.

Almost everything! We have reached the final stage of work. Now you need to drill a hole inside the barrel that matches the diameter of the flexible metal hose. Thread the hose into this hole and connect it through a tee fitting to a metal-plastic water pipe. That's almost all, all that remains is to secure the thermometer inside the barrel and install the electronic thermometer display outside.

When can you start enjoying?

Patience! Very little left! Our design is 99% ready, all that remains is to pour water into the canister, plug in the plug, wait for the water to boil and steam to enter the barrel. Then climb inside, close it with a special shelf on top and a door on the side.

Now enjoy! Just remember to keep an eye on the thermometer so as not to overheat. And be sure to monitor the water level in the canister. Otherwise, there will be no luck! Let me note that this is the most basic way to make a homemade sauna steam generator, which can be done without straining.

This is the kind of country mini-hamam we got. And what? We can safely call the phyto-barrel that way. After all, steam baths, including the Turkish bath, are all built according to a similar principle - their design is based on a closed room and steam supply through a steam generator!

What about the sauna, is it not popular now?

Well why? To each his own! Some people prefer dry steam, others prefer wet steam. Most saunas are powered by an electric stove with an internal and external heating element - stones! And steam from such bath stones will only be produced if you use liquid for steam generation. Most often it is simple water with oils diluted in it. But such steam quickly evaporates due to the high temperatures in the steam room itself.

You can also use a more modernized bathhouse solution by installing a multifunctional installation in the steam room using a stove with a steam generator. Or you can buy a ready-made cool unit, but that’s a completely different story.

That's probably all. Until next time, dear readers. I hope you liked the article, and we will definitely meet again on the pages of this blog! If you rate this information positively, you can share it with your friends on social networks.

Comment, criticize, like. In a word, everything is as usual. Have a nice steam!

Wisdom Quote: Years teach many things that days do not know.

Description of the technique

A home steam generator is a heat exchanger that generates a large amount of water vapor used to clean fabrics, natural and artificial leather, various coatings and surfaces. This technique is functional and universal in use, it allows you to improve the quality of cleaning while simplifying the work performed. Currently, there are various types of steam generators, which differ in their operating principle and purpose.

The main functions of such household appliances include the following:

- Removing and cleaning stains from fabrics.

- Perfect smoothing with a powerful jet of steam.

- Removing stains from tiles and flooring.

The operating principle of such equipment is extremely simple. The device generates wet or dry steam at a temperature of 140−160 degrees. This high-temperature steam smoothes surfaces, removing various types of dirt from clothing, tiles, tiles, and carpets. You can choose both compact models, which are essentially reminiscent of improved irons, and powerful equipment, the main purpose of which is cleaning floor surfaces.

If previously steam generators for ironing clothes were bulky, high-cost designs and were available only to professional dry cleaners, today compact models that are universal in use and designed for domestic use are available for sale. The latter began to enjoy popularity among buyers who appreciated their functionality and ease of use.