Collector Features

Three parameters influence the quality of a product:

- dimensions;

- metal;

- finishing details.

Before starting work, you need to study the theory. A manifold made independently is noticeably different from one assembled at the factory. The device looks like a comb made by welding. For this reason it is called "comb". Usually this is a horizontal structure with bends. They can be directed in two directions or one, the direction determines the location of the boiler room. If the boiler is located on the ground floor, the pipes are located at the top. Above the boiler there are ventilation units, radiators, and a heated floor system.

Bottom connections are important for systems located below the boiler level. “Heating combs” are of a mixed type, supporting both options for the location of the pipes.

Self-made manifold

How to prepare for welding

The easiest way is to weld the device according to the finished drawing. There are many diagrams on the Internet, accompanied by instructions. The drawing is chosen individually; there is no universal welding method; each master provides his own diagrams with recommendations that he considers ideal. After selecting a drawing, the welder decides on the profile material. The following options are common:

- Stainless steel.

- Black steel - it is chosen for its reliability, availability and corrosion resistance.

- Polypropylene. It is an ambiguous material suitable for making a collector, but the finished products are not cheap and are often defective.

The selected material must withstand high temperatures and be resistant to rust. It is difficult to name the best material among those available, since the decisive role is played by the quality of welding and the specific conditions in which the product operates. The operation of the collector is clearly associated with extremely high temperatures; this fact must be kept in mind when purchasing a profile.

The location where the collector is located is studied before the device is manufactured. To make a high-quality collector, you will need to take into account some conditions - the location of the boiler, the distance of the walls from the installation, the power of the entire system. Based on these variables, the master understands what kind of finished product he will ultimately receive. If all parameters are taken into account correctly, the manifold, welded by hand, is made without defects. To improve the result of your work, first consult with a specialist. He will take measurements and tell you what technical nuances are important in this particular case.

Collector heating: first acquaintance

The heating system, called collector, is also known as radiant. It is increasingly being installed instead of conventional two-pipe heating, especially in two-story houses with a large number of rooms. In a two-pipe system, as is known, radiators are connected in parallel between two lines - supply and return.

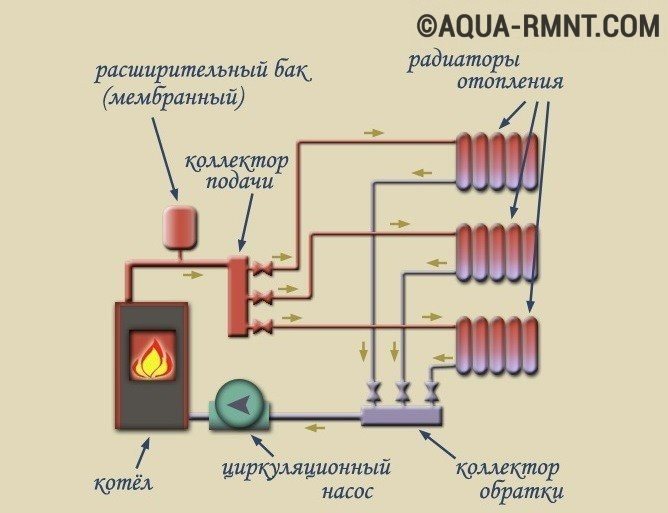

Collector heating is organized differently: the supply and return pipelines are connected to each radiator individually, and the collector plays the role of a central distributor in which all these pipes converge.

Operating principle of the heating manifold

Such a system, consisting of a single center and many rays extending from it, is said to be organized according to the principle of a star. The second name of the collector is the heating distribution manifold (distribution comb).

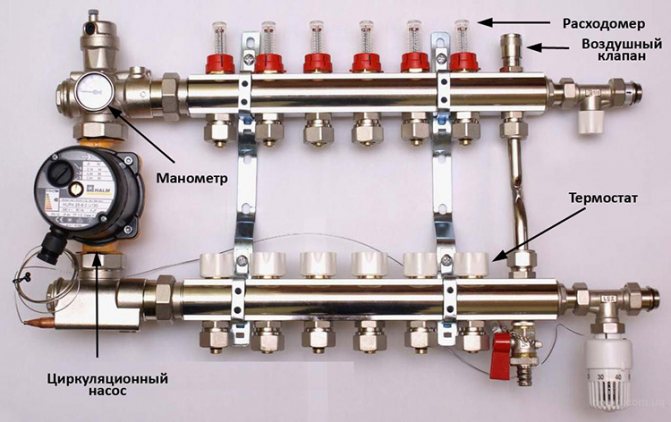

Its design is not particularly complex: it is a large-diameter pipe with several nozzles, which can be equipped with pipeline fittings, one or more pumps, an air vent and instrumentation. Through one group of pipes the hot coolant is directed to the consumer devices, and through another it returns in a cooled form. The collector itself is connected either directly to the boiler or to another collector.

The distribution comb with all the accompanying elements can be installed in an open form, but most often this device is placed in a special cabinet, which looks more neat.

Components that make up the manifold

The heating comb is a welded structure equipped with bends. The latter are distribution elements that transfer heat to radiators, boilers, etc. The speed of fluid movement through the heating circuits is determined by the circulation pump, and mixing is carried out in the collector itself. This process keeps the temperature in balance, which has a beneficial effect on maintaining the integrity of the entire heating system. Thanks to the manifold, the optimal pressure level is maintained. Without the pipes, the system would not function correctly.

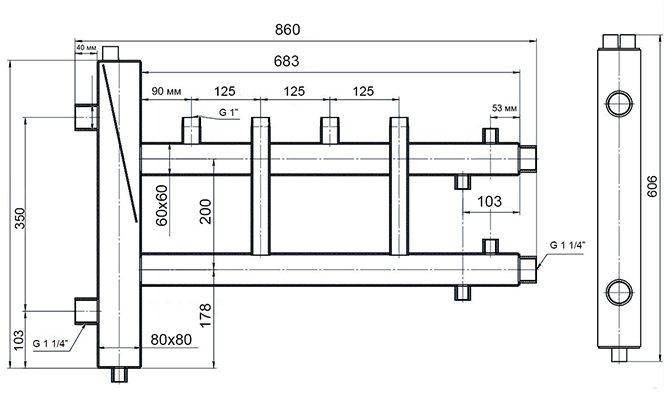

The second key parameter is the comb size. The distance between the collector axes affects the installation speed, and for proper operation it is important to maintain an equal distance between the nozzles.

Not least important is the collector inch and its outputs. All this depends on the fittings used to create the collector. The correct thread is not only welded, but also ground. For normal functioning, after grinding there is processing.

Before creating a product, make accurate calculations and strictly follow the diagram. An error of 1-2 millimeters will significantly complicate the process of installing the locking fittings or make it impossible. In this case, unnecessary expenses are inevitable, and to correct the mistake you will have to call in an outside person trained to work with such installations. Comprehensive preparation for welding will avoid troubles.

An example of a heating manifold drawing

DIY distribution manifold

If you have a small house, then it is quite possible that a factory manifold will suit you. But most often this does not happen, and many people do not know what to do about it. Having suffered and suffered, they hire a plumber who does everything directly from the boiler. And then they complain that there is no heat.

After drawing up an estimate for the collector, we purchase the material, prepare the tools and begin manufacturing the collector.

First, we clean the square pipe or pipe for the collector from rust. We make markings using a caliper, ruler and core.

We scald the pipes and threads and weld the fasteners.

Thus, it can be difficult or even impossible to select a factory distributor for your specific conditions, since the size of the manifold and the size of the manifold pipes are limited by the model range.

Let's look at drawing a collector circuit using the most common six-circuit collector model. First we draw the supply and return manifold itself.

The coplanar distribution manifold in one fell swoop solved the problem of the number and size of connections for boilers and heating circuits, the problem of piling up pipes was solved, and it became very quick and easy to monitor, maintain and repair boiler equipment.

The coplanar manifold has a fairly simple structure, so it will not be difficult to make even for beginners who have not previously attempted to assemble such devices.

Find out more about installing self-heating cables in water pipes.

The distribution manifold is a metal comb with many pipes, which are intended for connecting all heating devices in the premises for the purpose of centralized heating, the ability to regulate temperature, degree of coolant supply and pressure.

If the house has more than one floor, then the craftsmen install one distribution manifold per floor. This ensures high-quality heating in each room on the floor, and if repairs are necessary, you can turn off a certain room or floor, while other rooms or floors remain heated.

Now let's look at the principle of operation in several stages:

It is quite easy to find diagrams for self-assembly of distribution manifolds on the Internet, but at the same time there is not enough information about the specific actions required to assemble this device. Note that the reader who decides to assemble the wiring himself must first of all draw up a sketch, according to which further work will be carried out.

To draw an analogy, it is a centrally controlled system of conductors and connections for regulating heating.

We recommend watching the video, which tells you how to make water connections with your own hands:

Today, one of the most profitable and acceptable options for the most productive operation of a heating system is the use of a distribution manifold, which allows the heat flow of the medium to be evenly distributed over the entire surface. Taking into account the features of collectors, their properties and characteristics, this article will be devoted to these devices.

All working circuits will be connected to two devices - supply and return; this means that you, as a master, will have to assemble a simple coplanar manifold, the structure of which we described above. When the sketch is ready, all that remains is to assemble the collector.

The second wiring is necessary to adjust the water pressure and heating intensity - with its help you can set the required pressure level on each branch.

Welding the heating manifold

After choosing the metal and all the calculations, they begin to work. Welding of the device depends on the circuit and is carried out according to the following algorithm:

- Depending on the dimensions specified in the instructions, the master purchases a sufficient amount of materials.

- The pipes are connected according to the instructions from the diagram using welding equipment and connected to each other.

- The contact areas of the pipes are cleaned and treated with sealant.

- The heating comb is checked for leaks. To do this, only one pipe is left open. A correctly assembled collector, after supplying water, has no leaks in closed outlets.

- The finished structure is painted. After drying it is ready for installation.

The reliability of the collector, provided that the design is correctly implemented by the master, determines the quality of the drawing on which the assembly is based. They choose slowly, having studied all the details.

We offer you to watch a video on welding the collector:

Collector: device and principle of operation

The node is an element in the form of a comb, from which leads extend for connecting heating devices. The number of pins may vary. If necessary, the element can be expanded with additional bends. Drain and air outlet valves, as well as heat meters, can be installed on the collector. The terminals can be equipped with adjustment or shut-off valves, which makes it possible to regulate or turn off the coolant flow. The device is installed in the heating system in the form of a collector block, which includes a return and supply comb, equipped with outlet valves and corresponding taps.

The collector heating system operates quite simply. The coolant, heated by the boiler to the required temperature, enters the supply comb. Here it is distributed between heating devices. A pipeline is laid to each of them, through which the coolant is directed. In the radiator, having given up some of its heat, the liquid is partially cooled, and through another pipe it enters the return comb and from there to the boiler. This distribution contributes to uniform heating of the radiators, since each of them has a separate supply pipe.

The coolant heated in the boiler goes to the supply manifold, where it is distributed through pipes suitable for each radiator. The cooled liquid is sent back to the boiler through the return manifold.

Note! The distribution comb of the heating system, installed on each floor of the heated building, allows you to obtain floor-by-floor individual heating circuits with autonomous control. If the need arises, you can turn off the heating of the entire floor or just a few devices, which greatly facilitates the maintenance and repair of the system. This will not affect the functioning of the entire structure at all. The use of a collector increases the operating efficiency of the equipment, since devices that regulate the temperature and pressure of the coolant, as well as flow meters, can be installed on its terminals.