Will a car radiator work in the heating system?

While studying the issue of increasing the power of the heating system in the garage, my search led me to industrial fan heaters (hereinafter referred to as TV). Since there is already a hot water boiler, the type of TV was obvious, water.

But unfortunately, the price for such devices was equal to 48 sections of aluminum batteries from Leroy Merlin. Since my system already has 64 sections, I wanted TV. Not having the required budget, I began to look for an alternative.

By chance, the idea flashed into my head that the same industrial TV is in every car))) I started studying this question on the Internet, I didn’t find a sensible answer, but I had thoughts on this matter. And I started sculpting...

I took a couple of radiators from a Subaru, with fans, a power supply from a computer, a resistor from a VAZ, radiator pipes and clamps + mounting of aluminum radiators from Leroy.

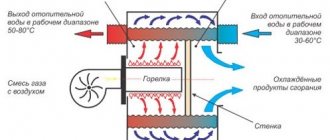

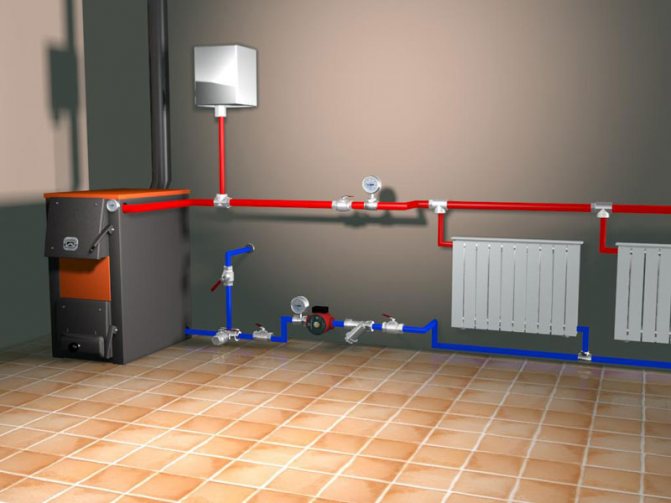

My current heating system is based on the Tichelmann system, where the coolant moves along the same path. The system is open, with a circulation pump, boiler 15 kW, power of aluminum radiators 8 kW. I decided to mount the TV at the very end of the system, already in front of the boiler, roughly speaking. This is what happened.

Will a car radiator work in the heating system?

While studying the issue of increasing the power of the heating system in the garage, my search led me to industrial fan heaters (hereinafter referred to as TV). Since there is already a hot water boiler, the type of TV was obvious, water.

But unfortunately, the price for such devices was equal to 48 sections of aluminum batteries from Leroy Merlin. Since my system already has 64 sections, I wanted TV. Not having the required budget, I began to look for an alternative.

By chance, the idea flashed into my head that the same industrial TV is in every car))) I started studying this question on the Internet, I didn’t find a sensible answer, but I had thoughts on this matter. And I started sculpting...

I took a couple of radiators from a Subaru, with fans, a power supply from a computer, a resistor from a VAZ, radiator pipes and clamps + mounting of aluminum radiators from Leroy.

My current heating system is based on the Tichelmann system, where the coolant moves along the same path. The system is open, with a circulation pump, boiler 15 kW, power of aluminum radiators 8 kW. I decided to mount the TV at the very end of the system, already in front of the boiler, roughly speaking. This is what happened.

Every car has one important detail that provides comfort - a heater, or simply put, a stove. Heat for heating the interior is taken from the engine using a heater radiator - read about this part, its purpose, design and operation, as well as malfunctions and repairs in this article.

The device of a car interior heater (stove)

The first cars offered their drivers a minimum of comfort - in those distant times, the very ability to move without the help of horses was a novelty, and there was no need to think about comfort. But over time, cars became more advanced, and engineers began to pay attention not only to the technical characteristics of vehicles, but also to the comfort of the driver and passengers. Therefore, at first the cars acquired closed bodies that protected them from bad weather, and later - heating devices that provided comfort when driving in the cold season.

It is no longer possible to imagine a modern car without a stove (heater), especially if the car is used in Russia. The presence of a heater has become standard; this feature is offered by default on most cars.

Today, cars and trucks, as well as small buses (PAZ, old LAZ and the like) use heaters that take heat from the engine, and it is these most common heaters that will be discussed further. In city buses with a rear engine, electric heaters are more often used to heat the interior - we won’t talk about them here.

Why a cooling radiator may be needed in the lubrication system

As the power of automobile engines increased, engineers were faced with the critical problem of removing the ever-increasing excess heat from the engine. The first step towards solving this problem was the appearance of additional cooling fins on the engine sump. However, fins could not radically solve the problem. On trucks, as well as on highly accelerated passenger car engines, the fins on the oil pan did not cope with the task. Overheated oil lost viscosity, the pressure in the system dropped, and the driver had to slow down to reduce the release of heat. Overheated oil prematurely lost its properties: additives disintegrated, and deposits formed on engine parts. It was possible to provide a long service life to a forced engine only through effective heat removal.

Air type oil cooler is easy to install as optional equipment

In modern cities, daily standing in traffic jams leads to a similar effect, which is why the design of many cars of the latest generations includes a radiator for cooling the engine oil.

The purpose of the heater radiator and its place in the interior heating system

A heater radiator is a conventional heat exchanger that transfers heat from the coolant to the surrounding air. This radiator is similar to the main radiator of the engine cooling system; it has the same connection diagram and operating principle.

For the heater to function, constant heating of the radiator is necessary - this is achieved by connecting it to the liquid cooling system of the engine. The heater radiator is connected to the system parallel to the main radiator; for this purpose, special fittings are provided in the engine outlet pipe or thermostat housing, as well as in the pump supply pipe - hoses for supplying and discharging coolant are connected to them.

It is important to note that the heater radiator is included in the first (small) circuit of the engine cooling system, while the main engine cooling radiator is located in the second (large) circuit. That is, when starting a cold engine, the coolant passes only through the engine water jacket and the heater radiator, but does not enter the main radiator. This connection makes it possible to heat the interior immediately after starting the engine.

Like the main radiator of the cooling system, the heater radiator has the ability to connect a steam pipe connected to the expansion tank. Through this tube, superheated water and steam are removed from the heater core in case of excessive temperature rise.

By the way, why can’t you heat the car’s interior with the heat generated by the main engine cooling radiator? After all, this heat is free, and it goes uselessly into the atmosphere, although it could be used for heating. The thing is that the air passing through the main radiator is contaminated with dust and various impurities, and its supply to the cabin will be harmful. The presence of a separate heater with its own radiator and fan allows you to use a filter to clean the air, as well as easily regulate the air temperature and the intensity of its heating. All this could be implemented on the basis of an engine cooling radiator, but such a heater would have a more complex design and lower operating efficiency.

How panel-type radiators work

The structures consist of stamped metal sheets welded together with symmetrical recesses. When the sheets are welded, the recesses coincide and form channels through which water circulates after installation and startup of the heating system. To increase the heat transfer of the device, metal ribs are attached to the inside of the structure. Individual panels can be combined into a common package and decorated with special strips. When choosing a radiator, you should focus on the size of the panels and the presence of fins; the power of the device and heat transfer by convection depend on this.

Panel radiator design

Types of heater radiators

All heater radiators can be divided into several types according to a number of characteristics.

Based on the material used, there are two types of radiators:

Copper radiators are a classic solution that is used less and less today. The fact is that a copper radiator has a much higher cost, and most modern cars are designed and manufactured based on considerations of achieving the minimum cost. However, copper radiators have two undeniable advantages - they have better heat transfer and are easy to repair (if a leak occurs, such a radiator can be soldered even at home).

Aluminum radiators have a much more affordable cost and are also lightweight. However, aluminum radiators are less resistant to mechanical damage and are extremely difficult to repair - it can only be restored using special tools and consumables. Therefore, sometimes it is easier to buy a new aluminum radiator than to repair an old one.

Oil Cooler Operation and Maintenance

In engines with liquid oil cooling, the radiator does not require any attention or maintenance. Sometimes the gaskets between its body and the engine block may leak. They need to be replaced without waiting for the oil to flow in a stream.

An oil cooler is often installed on “charged” versions of production cars. For example, there is an oil cooler on the BMW 335i E92 - a modification of the 3 Series in a two-door coupe body

If you find a dark coating on the inner walls of the expansion tank, and the liquid itself has turned into an emulsion, then a leaky oil cooler may be to blame. You cannot operate a car with such a malfunction, otherwise you will ruin the engine.

In an air-cooled oil system, the weak points are the pipes and, in fact, the radiator itself. From time to time it needs to be washed - fluff and small debris clog its honeycombs and impair heat transfer.

Oil leaks on the radiator indicate that it needs to be repaired or replaced. This cannot be ignored, because many cars do not have a safety valve, and if all the oil manages to “escape” faster than you notice, then serious repairs cannot be avoided. Also pay attention to the hoses. They must be elastic and free of surface cracks. It is better to replace “suspicious” hoses.

Design and operation of the heater radiator

The basis of the stove radiator is a heat exchanger - a system of parallel tubes connected by a series of transverse plates (or fins). The plates form a so-called honeycomb, which has a large surface area, which is necessary for more efficient heat removal. The number of tubes and plates, their relative position and density are selected in such a way as to ensure the most efficient heat transfer with minimal resistance to the air passing through this entire structure.

Three tanks are mounted to the right and left of the heat exchanger - inlet, outlet and return tank. The inlet reservoir is connected to the inlet pipe, hot coolant from the engine is supplied to it and distributed through the heat exchanger tubes. The outlet tank collects the liquid that has passed through all the tubes and discharges it into the outlet pipe. The return tank is necessary to reverse the flow of coolant passing through the first row of heat exchanger tubes and direct it to the second row of tubes.

Double row radiators have one inlet and one outlet reservoir, they are located on one side of the heat exchanger, as the coolant passes through the first row of tubes and returns through the second. There is only one return tank in this radiator; it is installed on the opposite side of the inlet and outlet tanks.

Three-row radiators also have one inlet and outlet tank, and two return tanks (since here the fluid flow changes its direction twice). In this case, the inlet and outlet tanks are located on opposite sides of the heat exchanger, and the return tanks are located next to them.

It is the location of the tanks and pipes that helps to quickly distinguish between two-row and three-row radiators:

• For double-row, the inlet and outlet pipes are located on one side of the heat exchanger; • For three-row units, the inlet and outlet pipes are located on opposite sides of the heat exchanger.

Radiators with round heat exchanger tubes have one more detail - turbulators (or swirlers), which improve heat exchange between the coolant and the walls of the tubes when the engine is idling. Turbulizers are plastic spirals inserted inside tubes (they are often called noodles due to their characteristic shape). Thanks to turbulators, turbulences (turbulent flows) are formed in the liquid flow, significantly increasing the volume of liquid in contact with the inner walls of the tubes. On average, swirlers increase the efficiency of the heater at engine idle by a third, but at higher speeds these parts practically do not improve the performance of the radiator.

The heater radiator is designed extremely simply, however, various malfunctions can occur in it.

The operating principle of heating radiators. Key Features

A radiator is the most common heating device, and it is extremely difficult to do without it in our climate. In order to wisely choose radiators suitable for a particular case, it is good to understand the principles underlying their operation.

The principle of operation of heating radiators is very simple and intuitively clear to everyone: the heated coolant (most often water) from the heating boiler flows through pipes directly into the heating radiators, which release the resulting heat to the air in this room. As you know from a physics course, the process of transferring thermal energy can be carried out in two ways - convection and radiation.

Convection is the type of heat transfer in which thermal energy is transferred in a non-directional continuous “flow”. During convection, we observe rapid heating of the air flow, freely flowing along the heating surface. Heating devices that emit heat in this way are called convectors. Heat transfer by convection can provide an accelerated heating process. That is why, in order to warm up the room as quickly as possible, it would be rational to use convectors. The main disadvantage of “clean” convectors is too much air movement. The air flows created by the convector intensively spread dust, and therefore they try to use convectors only where it is not possible to install conventional radiators due to their size. An example of a classic convector is thermal curtains installed in the entrance areas of retail and public premises.

The second type of heat transfer is radiation. A surface having a temperature higher than the ambient temperature will radiate heat to the external environment. Devices that give off heat primarily through thermal radiation are called radiators (in the classical sense of the word). In reality, all modern heating radiators transfer heat to the heated room in two named ways, that is, there is both radiation of heat and convective transfer of thermal energy. Moreover, on average, radiation accounts for about 60% of the total heat transfer, and convection accounts for approximately 40%. As a result of the operation of modern radiators, the room warms up quickly and evenly, while air movement is observed to a minimum.

The modern market offers an extremely wide range of heating radiators suitable for installation in apartments, private houses, office and other premises. There are sectional cast iron, aluminum and bimetallic sectional radiators, steel panel radiators. Each type of heating device mentioned has its own heat transfer characteristics, depending both on the design of the radiator and on the material from which it is made.

Aluminum radiators, so popular today, are characterized by the highest possible heat transfer capacity, which is explained precisely by the properties of the metal itself (high thermal conductivity is characteristic of aluminum). Aluminum batteries are characterized by high thermal power (about 180-200 Watt per section).

Bimetallic radiators are an excellent option that combines the benefits of both metals - steel and aluminum. The core of such a radiator is made of steel, and the outer fins are made of aluminum. The heat transfer power of a bimetallic sectional radiator is high and can reach 200 Watts per section.

Cast iron radiators are characterized by the highest heat capacity due to the physical characteristics of the metal from which they are made. They will warm up for a very long time, but will not cool down very quickly, gradually giving off heat by radiation. The heat transfer power of one section of a standard cast iron battery is approximately 150 Watts. The convection type of heat transfer in cast iron radiators is perhaps least pronounced.

Steel panel radiators are characterized by having a large heated surface area, which stimulates intense heat transfer by convection type. The amount of heat flow transferred due to convection reaches 75%. Additional fins are often welded on the back side of such radiators, which also serve to increase the contact area. Panel-type radiators provide very fast and uniform heating of the room. It is also known that steel panel radiators are more economical in terms of fuel costs (this is very important for autonomous heating systems). To get the same amount of heat, 7 times more coolant will have to be passed through a cast-iron radiator, and its temperature should be 20 degrees higher.