- We offer to buy cast iron radiators with delivery in the Tavago online store.

- Price for cast iron radiators from 2040 rubles.

- Read instructions and reviews about Cast iron radiators.

You can purchase high-quality cast iron radiators at affordable prices from Tavago. Here you will find a large selection of types and models of radiators, manufacturer-guaranteed quality and the fastest possible delivery of your order. The main thing is the right choice, and to make the task easier for you, we will consider the main characteristics, as well as all the positive and negative qualities of this type of heating system.

Alpine Air History 600

Main characteristics:

- cast iron floor radiator, multi-section, two-column;

- the strength of each section is designed for operating pressure up to 9 bar;

- maximum heating temperature of the coolant – 110 °C;

- overall height – 760 mm; center height – 600 mm; overall depth – 204 mm.

Model description

This model is used in water heating systems and is used to heat any premises, from apartments and offices to utility and warehouse premises. It all depends on the number of sections: the more of them installed in the radiator, the larger the heating area.

Alpine Air History 600 fully complies with all the requirements of EN442, GOST 8690-94 and SNiP 2.04.05-91, and is also equipped with quality certificates.

Thanks to the original design solution, this model will fit perfectly into any interior. The sections are covered with a colored print in the form of an elegant, unobtrusive floral pattern, but if necessary, you can repaint the radiator to match the interior colors.

Specifications

| Number of sections | Radiator width, mm | Volume, l | Weight, kg | Heat dissipation-delta 50°, W |

| 1 | 76 | 2,5 | 10,7 | 143 |

| 4 | 328 | 10,1 | 43,5 | 570 |

| 5 | 404 | 12,6 | 54,2 | 710 |

| 6 | 480 | 15,1 | 64,8 | 850 |

| 7 | 556 | 17,6 | 75,5 | 1000 |

| 8 | 632 | 20,2 | 86,1 | 1140 |

| 9 | 708 | 22,7 | 96,8 | 1280 |

| 10 | 784 | 25,2 | 107,4 | 1430 |

| 11 | 860 | 27,7 | 118,1 | 1570 |

| 12 | 936 | 30,2 | 128,7 | 1710 |

| 13 | 1012 | 32,8 | 139,4 | 1850 |

| 14 | 1088 | 35,3 | 150,0 | 2000 |

Main advantages

This model has an undeniable number of advantages that need special mention. The heating device does not require any special preparation; it can be used immediately. If necessary, the required number of additional sections can be quickly and easily installed.

Painting from the manufacturer

When painting radiators at the factory, a double coating is applied, which uses a special primer and high-quality varnish. This method allows surfaces to maintain an excellent appearance for a long time, without requiring constant touch-up.

Reliability and comfort

Each section of the radiator is tested for strength at the factory. It is tested at a hydraulic pressure of 15 bar, significantly higher than normal operating pressure. High-quality and corrosion-resistant cast iron will allow you to operate such a device for a long time without replacement.

Due to the thickness of the material, the circulation of water in the system is practically inaudible, and the simultaneous uniform heating of the sections will ensure constant and effective radiation of heat in the room.

MZOO MS-140M

Main characteristics:

- cast iron radiator, sectional, can be mounted on a wall or installed on the floor;

- maximum permissible coolant temperature - 130 °C;

- working pressure up to 9 bar;

- overall height - 300 or 500 mm, distance between nipple holes - 500 mm.

Model description

Radiators of this type are used for water heating of civil and industrial buildings of various heights. The material for manufacturing is gray cast iron with lamellar graphite, the nipples are made of cast iron with high malleability. The product consists of four or seven sections, which are assembled on nipples using rings made of high-quality rubber with increased heat resistance.

The device's technical characteristics are in no way inferior to popular European models, and has certificates of compliance with all requirements of state standards. The radiator can easily be adapted to any interior style; the surface of the device is well processed and ready for painting.

Technical characteristics for 1 section

The device has the following technical characteristics:

- volume - 1.45 l;

- weight - 6.7 kg;

- thermal power - 160 W;

- heat transfer area - 0.208 m².

Main advantages

Cast iron radiators MZOO MS-140M have many advantages both due to the manufacturer’s technical solutions and the thermal properties of cast iron. One of these advantages is the ability to adjust the number of sections. This allows you to adapt the device to specific conditions and achieve the most comfortable room temperature.

Reliability and durability

The high resistance of cast iron to corrosion ensures a long service life of the radiator (up to 40 years); it is also not afraid of active mechanical or chemical influences. The silicon film that appears on the surface of cast iron when casting a product makes the radiator undemanding to the quality of the coolant.

In the factory, all sections of the radiator are tested at one and a half times higher pressure, which completely eliminates the possibility of accidents or leaks.

Increased channel cross-section

Thanks to this improvement, the likelihood of blockages in the radiator is reduced and cleaning of the heating device is simplified, and the operating time of the radiator is increased without removing scale deposits in the channels.

Easy installation and repair

This model can be hung on the wall using simple brackets or installed on the floor on special stands. If any section fails, only the damaged element can be replaced.

Which cast iron radiators are better?

Not an easy question. Each person has their own requirements and evaluation criteria. They are worth focusing on.

If quality is the main thing for you, and price is secondary, you should choose from the range of European manufacturers. The Czech campaign Viadrus received very good reviews. They know how to work with cast iron: they make boilers and radiators. There are no problems with the quality of casting or painting: all technologies have been proven and tested over years of operation.

German campaigns are traditionally good. Germany has very strict regulations regarding the construction industry and building materials. And if a product has been tested in its homeland, then its quality is guaranteed.

Products from the German company Guratec

All of the above does not mean that others are worse. You need to carefully read the information provided by developers and sellers, compare and evaluate, look for consumer reviews and expert opinions.

If you want good quality, but your budget is not so wide, pay attention to Belarusian cast iron batteries from the Minsk Plant. There are also standard MS-140 and their restylings. Yes, they are not painted, but primed. But you can paint them yourself to match the walls (use heat-resistant paint).

Russian-made radiators also performed well. These are mainly four factories:

- radiator in Nizhny Tagil,

- OJSC "Santekhlit" in the Bryansk region,

- LLC "Descartes" in Novosibirsk,

- Cheboksary Aggregate Plant.

But geographic location also plays a role here. Whichever is closer will most likely be your choice.

There are Chinese cast iron radiators of good quality on the market. It is important to choose well-known brands that have been supplying products for years. No “new, but very good”, etc. Only those that already have a name and whose products are already known. Yes, they are not the cheapest. But it has long been known how many times you need to pay for cheap things. The “Chinese” Sti “Nova” and “Breeze”, Konner (Conner) have good reviews. With Conner, by the way, it is not clear whether the radiators are Italian, Russian or Chinese: the office is in Italy, the radiators are developed and exported by a company from St. Petersburg, and the plant is located in China. This is a difficult situation. However, the reviews are positive.

The company has a good reputation in the market

If you decide to install cast iron radiators, then we can please you: there are practically no cases of rapid failure of radiators due to poor quality.

There are casting defects: microfistulas, which, in theory, should be rejected at the stage of checking a section at the factory. But after installing any radiator, before connecting it to the system, it is pressure tested (tested at high pressure), so it is at this stage that defects are identified, which are usually changed without discussion. The percentage of defects is approximately 0.5-1% (this is among the “trusted” Chinese; among ours and Europeans, defects are extremely rare on the network). In all other cases, possible malfunctions are leaking gaskets or loose nipples.

Complete destruction of cast iron batteries is possible only with strong water hammer. But this is not a matter of quality, but of correctly selected parameters or an emergency situation. The second possible rupture option is defrosting the system. But these cases are the exception rather than the rule. In the entire practice of a plumber, this is one or two cases. So cast iron is the most reliable option.

Demir Dokum Retro 600

Main characteristics:

- cast iron radiator, floor-mounted, sectional;

- designed for a maximum pressure of 9 atm;

- operating coolant temperature - 110 °C;

- height - 768 mm, width - 498 mm, depth - 250 mm, height of legs - 107 mm.

Model description

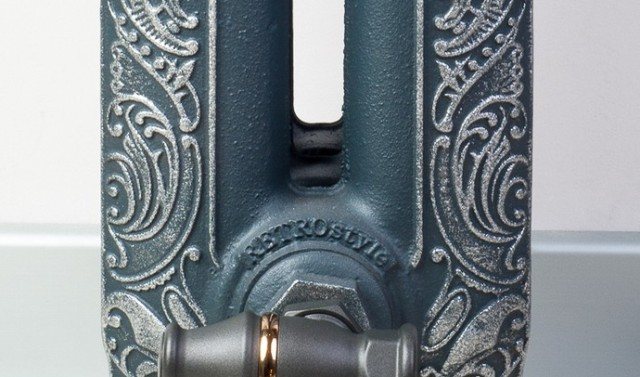

Radiators of this series are distinguished by the fact that the surface of each section is covered with cast iron, made in the palace style of the late 18th century. To connect to the system, control and shut-off valves (taps, plugs, valves) are also used, also in retro style.

The products are used for connection to a water or steam heating system and can heat large areas. The original elegant appearance will not only decorate the interior, but will become its highlight, giving the room charm and a finished look.

Specifications

Technical indicators are as follows:

- volume - 18.3 l;

- weight - 76.4 kg;

- heated area - 14.4 m²;

- heat output - 1440 W;

- crimping pressure - 12 atm.

Main advantages

The manufacturing company Demir has long won the love of Russian consumers with the quality of its products. The radiators produced have properties that allow them to be used in both autonomous and centralized heating systems. In addition, they have other positive qualities.

Great design

Radiators are available in an elegant gray cast iron color or coated with a high-quality primer, which allows you to paint them in any color, artificially age them, make the surface glossy or matte. Ornate patterns of cast iron decorate the device, and together with retro-style valves and taps, they turn it into a work of design art.

Material quality and design features

In the manufacture of devices, high-quality cast iron is used; it is practically not subject to corrosion, is resistant to mechanical stress, is not afraid of aggressive environments, and has a high heat capacity. The latter property allows you to avoid sudden changes in temperature in the room when the heating temperature of the coolant decreases.

A design feature of the device is the increased diameter of the internal passage holes. Therefore, Demir Dokum Retro 600 radiators are not afraid of water hammer, blockages due to poor-quality coolant, or clogging of holes as a result of scale deposits.

Advantages and disadvantages

Currently, a variety of materials are used for the production of heating radiators, but cast iron appliances have not lost their popularity. Let's list their strengths.

Ability to work with low-quality coolant

The working environment circulating in the heating circuit does not always treat pipes and radiators in a friendly manner.

This is especially true for large centralized heating systems. Here, the coolant is most often clogged with a large number of small solid particles, which, due to the force of the flow, act on the internal surfaces like an abrasive tool.

Thin-walled appliances made of steel or aluminum lend themselves to this “treatment” quite easily, but a massive cast-iron radiator cannot be quickly wiped to holes.

Often the coolant turns into an alkali solution. Under such conditions, many materials lose strength or begin to deteriorate due to chemical reactions. In this regard, cast iron demonstrates absolute stability and easily withstands the effects of both alkalis and acids.

No corrosion

It is not at all difficult to protect the outer part of heating parts from corrosion; to do this, it is enough to paint or varnish them.

But preventing its appearance on internal surfaces after draining the coolant is almost impossible.

The owner of a cast iron radiator should not worry about this problem, since even in damp conditions it will never become covered with rust.

For this reason, cast iron appliances are considered most suitable for open heating systems with natural (gravitational) circulation, the coolant of which is actively saturated with oxygen due to contact with air.

Heating radiators have a number of parameters by which their efficiency can be characterized. Heating batteries - which are better? Selecting a radiator according to technical parameters, as well as comparative characteristics of various types: cast iron, aluminum, copper, steel and others.

The characteristics of combination boilers using several types of fuel are given here. Features of design and operation.

Room volume and heat transfer are the main parameters for correctly calculating the number of heating radiator sections. In this article https://microklimat.pro/sistemy-otopleniya/raschet-sistem-otopleniya/kolichestva-sekcij-radiatorov.html you will learn how to make the calculation most correctly and accurately.

Ability to work in high pressure systems

Thanks to their massive construction, cast iron batteries can withstand not only high operating pressure (as already mentioned, it can reach 15 atm), but also significant water shocks.

Durability

This advantage is a consequence of all of the above. According to manufacturers, cast iron radiators can last from 30 to 50 years, but there are long-livers that remain operational even after a hundred years of operation. The main thing is not to forget to periodically wash the battery and change the gaskets between sections.

Affordable price

A cast iron heating radiator is a high-quality, reliable device, which, moreover, has a relatively low price. A modern bimetallic radiator with the same heat transfer power will cost several times more.

Cast iron radiator in the interior

GuRaTec Apollo 765

Main characteristics:

- cast iron radiator, floor-mounted, sectional;

- maximum operating pressure - 8 bar;

- highest coolant temperature - 110 °C;

- Available in three height sizes: 475 mm, 765 mm and 970 mm;

- width of 1 section - 76 mm.

Model description

Radiators GuRaTec Apollo 765 from a German manufacturer are decorated with cast iron in the form of an original floral pattern. They are available in thirteen different colors and shades. Lovers of the classics are offered strict white, gray and black tones in matte or glossy finishes. For those who like other styles, the colors of gold, silver, aged bronze and even mother-of-pearl are suitable.

For connection to a closed heating system, sets of shut-off and control valves made in the same style as radiators are offered. All together it represents a retro style with elements of luxury.

Thanks to their different heights, radiators can be used in small rooms with low window sills. For large heated areas it is possible to increase the number of sections to 15 pieces.

Specifications

The 768 mm high radiator has the following data:

| Number of sections | Length, mm | Depth, mm | Weight, kg | Volume, l | Power, W |

| 5 | 427 | 250 | 62 | 10,5 | 920 |

| 6 | 507 | 250 | 74 | 12,6 | 1104 |

| 7 | 587 | 250 | 86 | 14,7 | 1288 |

| 8 | 667 | 250 | 98 | 16,8 | 1472 |

| 9 | 747 | 250 | 110 | 18,9 | 1656 |

| 10 | 827 | 250 | 122 | 21 | 1840 |

| 11 | 907 | 250 | 134 | 23,1 | 2024 |

| 12 | 987 | 250 | 146 | 25,2 | 2208 |

| 13 | 1067 | 250 | 158 | 27,3 | 2392 |

| 14 | 1147 | 250 | 170 | 29,4 | 2576 |

| 15 | 1227 | 250 | 182 | 31,5 | 2760 |

Main advantages

Products manufactured by the German company GURATEC are in great demand in the heating equipment market. This is due to careful product quality control.

Thus, the factory test of radiators for strength involves increasing the pressure test to 10.8 bar, which significantly exceeds the working pressure. Such a load immediately reveals problematic sections and completely eliminates the presence of various defects inside other radiator elements.

Painting

Elements of heating devices undergo abrasive preparation in several stages before painting, then they are heated to displace moisture from the depths of the material, and they are primed. After this, they are placed in an electrostatic field and painted using powder coating. This multi-stage painting makes the surface of the radiators extremely resistant to mechanical damage.

Material of manufacture and connection method

Cast iron has high anti-corrosion properties, the service life of products reaches 40–50 years. The heat capacity of radiators allows you to maintain a comfortable temperature in rooms, and their high heat output allows you to heat large areas. The radiators of this series are full bore, as they have 4 side holes, which allows them to be installed in the system in various ways.

RETROstyle Windsor 500

Main characteristics:

- cast iron radiator, floor-mounted, sectional;

- coolant temperature - 110 °C;

- working pressure - 10 atm;

- height - 650 mm, depth - 195 mm, width of 1 section - 76 mm.

Model description

The surface of the RETROstyle Windsor 500 radiator is decorated with artistic cast iron. The original elegant ornament almost completely covers the outer parts of each section. For all its monumentality and heaviness, the radiator looks light and airy, thanks to subtle patterns and elegant stands.

The heating device is supplied with a high-quality primer coating, which allows you to paint it to suit any interior, organically fit into the most daring design idea and even make it the center of the composition. Complete with taps, valves and plugs made in the same style, the radiator looks stylish and very beautiful, looks like an independent element of the interior. Radiators are used in closed heating systems.

Technical characteristics for 1 section

The device has the following characteristics:

- volume - 2.3 l;

- weight - 11 kg;

- test pressure - 15 atm;

- thermal power - 119 W;

- two inner pipes;

- distance between axles - 500 mm;

- hole diameter 1 1/2´´.

Main advantages

Thanks to the high quality of products, radiators of the RETROstyle Windsor 500 model are well-deserved and in high demand. High-quality cast iron is not subject to corrosion, is resistant to internal damage due to poor-quality coolant, and is not afraid of chemical influences and mechanical damage.

All sections of the radiator undergo special treatment, acquiring a perfectly smooth surface, and then are covered with primer. Before being sent to the consumer, all radiators are subjected to strict technical acceptance at the factory and mandatory hydraulic tests at elevated pressure.

Power and installation method

Retro radiator from Demir Dokum

The power of the section should be found in the attached technical description. The higher this indicator, the better the heat will be transferred to the environment.

And, if, with equal dimensions, the thermal power of one radiator is 75 W, and the other is 120 W, then it is clear that the second will heat better. But the price of such a product will be higher.

There are only two installation methods:

- wall;

- floor.

If the wall on which you plan to install the radiator is not load-bearing, then there is only one option left: floor-mounted.

The fact is that to hang heavy cast iron structures you will need fasteners that will only be securely held in the load-bearing wall. In all other cases, it is worth using cast iron floor models with legs.

Sometimes they choose the floor installation method solely for decorative purposes: you don’t want to spoil the wall. In addition, batteries on legs, as a rule, look very beautiful (take the Turkish DemirDokum for example)

Konner Modern 500

Main characteristics:

- cast iron radiator, wall-mounted, sectional;

- height - 600 mm, depth - 96 mm, section width - 64 mm;

- permissible coolant temperature - 130 °C;

- maximum pressure in the system is 12 atm.

Model description

Radiators in this series are an example of modern and stylish heating devices. The outer surface of the sections does not have vertical protrusions; it is perfectly processed, completely flat, which allows it to fit more tightly to the wall. This radiator can easily be hidden behind curtains or a sofa.

At the same time, the design of the device allows it to be not the last element in interior decoration in the “classic” or “minimalism” styles. The products are similar in properties to steel radiators, but are an order of magnitude better in quality and durability.

Equipment and warranty

All devices in this series are supplied fully equipped, which includes 4 anchor brackets, 4 through-hole plugs and an air vent. The Konner Modern 500 model is provided with a long warranty by the manufacturer.

Technical characteristics for 1 section

Technical indicators are as follows:

- weight - 4.9 kg;

- volume - 0.9 l;

- distance between axles - 500 mm;

- thermal power - 0.15 kW;

- test pressure - 18 atm;

- inlet with a diameter of 1 1/4´´;

- adapter with a diameter of 3/4´´.

Main advantages

Radiators of the Konner Modern 500 series are modern, convenient and high-quality heating devices. Konner brand products undergo mandatory SanRos certification and fully comply with GOST 8690-94.

Versatility

Thanks to the enlarged passage openings, the products are used in systems with forced and natural circulation of coolant and are not subject to internal damage due to poor quality of water or steam used.

They can be installed in high-rise buildings, since radiators can easily withstand high pressure in the system.

Painting

The cast iron surface of the sections undergoes multi-stage processing to help achieve perfect evenness. The device is covered with a special super-resistant white enamel, which does not require updating for several years.

Flaws

Opponents of cast iron radiators point to a number of disadvantages, but only some of them can be considered indisputable. Let's start with them:

- Heavy weight: indeed, one radiator section weighs from 5 to 7 kg, which significantly complicates delivery and installation.

- Fragility: if radiators made of steel, aluminum and other plastic materials only become deformed during sudden impacts or temperature changes, while remaining sealed, then cast iron devices immediately crack.

- Weak design: modern cast iron radiators look quite decent, but still not as impressive as their competitors. This is explained by the fact that parts made of cast iron can only be made by casting, while parts made of steel, copper and aluminum can be given any shape by plastic deformation.

Now let's look at the dubious "cons".

Inertia

We agree: cast iron radiators take longer to heat up than others. But this drawback can only be felt when starting the heating system, which occurs only once a season.

In addition, it also has a downside: cast iron radiators accumulate a significant amount of heat and, in the event of an emergency heating shutdown, release it into the living space for a long time.

One more circumstance should be taken into account: a cast iron radiator emits almost a third of all thermal energy in the form of electromagnetic radiation, called infrared. Thanks to this, a “cast iron” can warm up the people and objects around it faster than, for example, aluminum and bimetallic radiators, in which the heated core is covered with a casing.

Large capacity

Indeed, a system consisting of cast iron radiators requires more coolant. Let's compare: the volume of one cast iron section is on average about 1 liter, while a steel or aluminum device of the same thermal power holds only 0.4 - 0.5 liters of coolant.

However, we should not forget that it is precisely because of the large diameter of the internal channels that cast iron batteries work perfectly in systems with natural circulation, which are still quite common in our country.

Fakora Dragon 730

Main characteristics:

- cast iron radiator, sectional, floor-mounted;

- height - 735 mm, depth - 224 mm, length of 1 section - 80 mm;

- maximum pressure in the system - 9 atm;

- permissible coolant temperature is 110 °C.

Model description

Radiators of this series are supplied in a strict and elegant black color; the seriousness of the design is diluted with artistic handmade forging. The two-layer varnish coating gives the black color sophistication and shine, and the patterns that stand out in relief on the surface soften the monumentality of the heating device, turning it into an exquisite piece of furniture.

There is no need to cover such devices with decorative grilles; on the contrary, they look like a luxurious work of art and can decorate a room in a classic style. Neat, graceful legs-stands lift the radiator and deprive it of excessive heaviness.

Specifications

| Number of sections | Length, mm | Weight, kg | Volume, l | Power, W |

| 4 | 405 | 67 | 13,2 | 740 |

| 5 | 485 | 83 | 16,5 | 925 |

| 6 | 566 | 98 | 19,8 | 1110 |

| 7 | 647 | 114 | 23,1 | 1295 |

| 8 | 728 | 129 | 26,4 | 1480 |

| 10 | 890 | 160 | 33 | 1850 |

| 12 | 1052 | 191 | 39,6 | 2220 |

Main advantages

Polish radiators of the Fakora Dragon 730 model are not only very beautiful and sophisticated, but also have excellent performance.

Heat capacity and heat transfer

The ability of cast iron to accumulate heat and retain it for a long time allows you to create comfortable living conditions in the room.

The temperature in the house will not depend on sudden jumps and changes in heating of the coolant; uniform heat transfer from the radiator will maintain the same temperature in the rooms for a long time.

Quality material and high strength

Made from high-quality cast iron that is not subject to corrosion, devices in this range will serve for a long time. They can be used in multi-storey buildings, since, unlike metal radiators, the devices can withstand high pressure and any hydraulic shocks of the system. When purging and pressure testing the system, the products can withstand pressures of up to 15 atm.

Pressure and other characteristics of aluminum batteries

If for some reason the boiler is turned off, be sure to drain the hot water from the radiator, otherwise the pipes may burst.

In multi-storey buildings with central heating and in individual heating systems of cottages and apartments, aluminum batteries are often used. They are designed for a pressure of 16-18 atmospheres. Aluminum radiators have a modern design, excellent thermal and strength parameters and are currently the most common.

Related article: Strengthening wooden floors - ways to strengthen the ceilings and beams of the second floor

They are made from die-cast aluminum. This manufacturing technology allows us to ensure high strength of finished products. Aluminum radiators are structures made of separate sections from which batteries of the required length are assembled. They come in sizes of 80 and 100 mm deep with a standard section width of 80 mm.

Aluminum has a thermal conductivity 3 times greater than that of steel or cast iron, so such batteries have a very high heat transfer rate. The high thermal power of radiators of this type is also achieved due to additional fins, which provide a large contact area between the air and the heated surface.

Aluminum radiators are designed for pressure from 6 to 20 atmospheres. Reinforced models of aluminum batteries are also produced, designed for the CIS countries - for apartment buildings with a central heating system with more severe operating conditions. Such batteries are made of durable high quality aluminum and have thicker walls.

Aluminum heating radiators are small-sized and lightweight, while they are characterized by high heat transfer. They have an attractive appearance. It is generally accepted that such batteries are optimal in conditions of autonomous heating (cottages, private houses, dachas, estates). However, the working pressure of aluminum radiators of 16 atmospheres allows them to be installed in apartments of multi-storey buildings.

DEMRAD Retro 600

Main characteristics:

- cast iron radiator, sectional, floor-mounted;

- maximum heating of the coolant - 110 °C;

- maximum permissible pressure in the system - 10 bar;

- height - 760 mm, depth - 203 mm, section width - 76 mm.

Model description

Radiators of this series have rightfully earned the name of a top-class product. Artistic cast-iron forging on the surface of the devices is reminiscent of forged decorations of rich mansions of the 18th century, but without bulkiness and pretentiousness.

Painted in noble colors of antique gold or blackened silver with a clear relief of intricate ornamentation, these devices create a mysterious atmosphere of palace chambers and noisy balls.

Technical characteristics of 1 section

Below are the main technical characteristics of the device:

- center distance - 600 mm;

- volume 2.6 l;

- weight 11.4 kg;

- heat output 126 W;

- inlet with a diameter of 1 1/4´´;

- test pressure 13 atm;

- shut-off valves are supplied included.

Main advantages

DEMRAD radiators have been in demand on the Russian market for several years. Along with their magnificent appearance, they also have other excellent properties.

Reliability and durability

The cast iron from which the devices are made is resistant to aggressive external influences, has an almost unlimited service life, does not rust, is not destroyed by poor-quality coolant, and can withstand high pressure.