Distinctive features

A stove assembled by yourself has a number of advantages:

- it saves fuel;

- if desired, you can design a stove of any size, which will be the most suitable option for a given room;

- easy to transport;

- ease of use;

- The oven dripper can be used for cooking. To do this, when constructing a stove, the pipe is placed on the side.

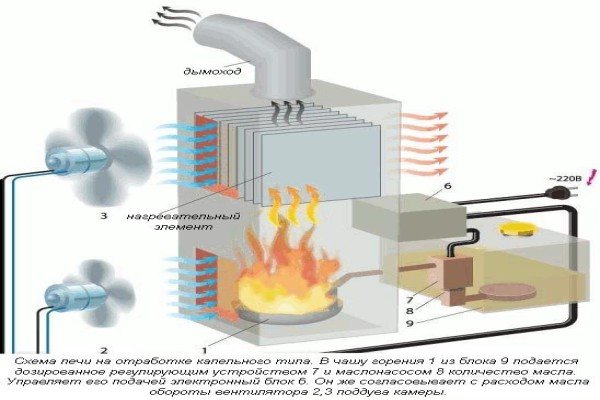

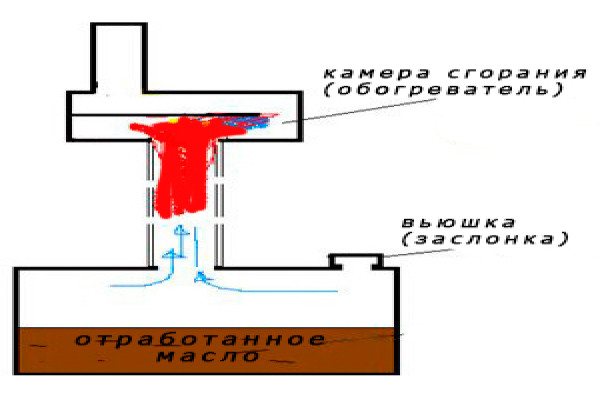

Diagram of a diesel-powered dropper stove. This is a very economical design. Complete combustion of compounds occurs in the furnace chamber

When making a drip stove with your own hands, you need to follow fire safety precautions:

- the device must be located in a draft-free room;

- flammable objects should be absent near the stove; it is advisable to have free space next to it (about half a meter);

- Do not use water to extinguish or cool the stove.

Materials needed to build the furnace:

- sheet metal;

- copper pipe;

- pipe branch;

- rubber hose;

- gas cylinder;

- screws;

- medical burner.

The main tools that will be useful for the job are a welding machine, a drill and a clamp.

A popular do-it-yourself device is a drip stove made from a gas cylinder

How the device works

In the lower tank, the fuel boils after five minutes of operation. The oil vapor enters the next compartment, which is called the burner. There, for better combustion, the steam is enriched with oxygen.

The principle of drip feeding of waste into a bowl (click on the picture to enlarge)

Then, combustion products enter the upper compartment, and from there into the chimney. The highest temperature is in the upper module of the drip furnace.

Tips for using a diesel stove

For the easiest and fastest removal of combustion products, the length of the chimney should be approximately 4 meters. The stove can also work during mining. In this case, cleaning must be carried out at least once every ten days to remove all accumulated waste. Make sure that the diesel fuel or used oil is of good quality.

Quick ignition can be achieved using a newspaper, which must be placed in the lower part of the stove, filled with diesel fuel and set on fire.

The combustion lasts about 10 minutes. During this time, the diesel fuel will completely burn out, and you will need to constantly add it to the tank. from a well-known company fittings Moscow, details on the website www.As-tim.Ru

Self-production

To do this, you will need a tank with a volume of at least 2 liters. There will be no smoke or soot during stove operation. During the process of igniting the stove, it will, so this process is recommended to be carried out outdoors.

Diesel from the fuel tank enters the wick cup. Using the dispenser, you can regulate the amount of incoming fuel. In the combustion cup, the fuel is heated until a gaseous mixture is formed, which then enters the combustion chamber. The spiral, which is located at the top of the chamber, is heated to a temperature of 800 °C. The smoke escapes through the chimney.

You can make your own apparatus weighing six kilograms. Diesel fuel is a fuel with a fairly high density, so its consumption is minimal. Overall, this stove is an efficient and easily transportable design.

Waste oil dripper stove

One type of cheap fuel is used oil. The stove can heat up to 800-900 °C. At the outlet the temperature will be 90 °C.

Pour a portion of oil and add 50-100 g of ignition agent (special fluid, heating oil, kerosene or diesel fuel). This is necessary to quickly ignite the stove. Wait until the combustion process stabilizes. Then you can pour in the next portion.

If there is any spilled oil, it must be removed immediately. Combustion occurs inside the pipe. This is a safe process. Fuel consumption is from 0.5 to 1.5 liters per hour. When the stove lights up, you can heat the water.

Waste oil dripper stove

Recommended for use: diesel oil, fuel oil, waste oil, heating oil. Do not use gasoline, acetone or other solvents. Avoid getting water into the fuel.

Special literature contains a large number of detailed instructions on how to make a drip stove with your own hands. Each of these designs is unique and has its own advantages and disadvantages. You can also use a store-bought version of the stove, but modify it at your own discretion.

Watch an overview video about the diesel drip stove:

The need for heating in a garage rarely causes controversy: motorists understand perfectly well how important it is to take care of the condition of the car, and they themselves do not want to freeze during inspections and repairs of equipment.

The main issue that needs to be resolved is the selection of the appropriate type of heating. A good option is a miracle diesel stove - the unit is easy to assemble and economical to operate. And these are important criteria for organizing garage heating.

Before you decide to assemble a stove, you need to understand its structure and operating principle, don’t you agree? In the article, we outlined the identified points in detail, and also provided several options for assembling a home-made unit. Step-by-step instructions will help you build a stove and organize efficient heating of your garage.

How it works

Launching a similar heater circuit from ZAZ is not so difficult. You need to perform several sequential procedures:

- the tap opens, the fan starts;

- the candle turns off, closes and turns on;

- after about 5-6 seconds, ignition occurs, the tap opens and the fan rotates for just a second;

- there is a noise from the flame and the fan turns on at full speed;

- when the stove reaches its full operating mode, the tap is turned to the minimum to ensure stable operation of the heater.

The important thing is that in such a conversion scheme, when the heating system is running on diesel fuel, the smell and signs of smoke will practically not be felt. But if you are concerned about the issue of smoke exhaust, you can use a piece of corrugated aluminum pipe, thereby removing all the exhaust outside. This depends on where and under what conditions the ZAZ stove operating on diesel fuel will be used.

There is also a slightly different option. Some organize the operation of the stove using a thick-walled corrugation, which is connected to the stove and supplies air through the corrugation inside the room or cabin, while the heater itself is located outside.

The advantages include the absence of pump modification in the considered scheme. Here the fuel is supplied by gravity, which saves the budget for modernization and consumes much less energy to operate the pump itself.

The scheme is working, although to implement it yourself requires certain skills, knowledge and preparation of a number of components. But it’s still cheaper than buying ready-made autonomous heaters.

Diesel fuel consumption in the case of a ZAZ stove will be noticeably reduced. According to some estimates, a standard gasoline stove requires about 500 ml of fuel per 1 hour of operation. If the heater has to be used frequently and for a long time, then there is no talk of any savings on gasoline. Diesel oil is much preferable in this regard. Hence the desire to modernize.

Also useful for repairs:

- Lilac leaves in autumn photo

- Mix for making blocks

- DIY bedside table

How should the heating be in the garage?

For many motorists, the garage is almost a second home. Here they delve into their hobby, take a break from the hustle and bustle and take care of the car. Therefore, first of all, you should think about the comfort of the person who spends hours indoors.

Heating is also necessary for the car, because... low temperatures negatively affect its technical condition and significantly reduce its service life.

To keep the garage dry, you should take care of good waterproofing and ensure the normal operation of the ventilation system. However, moisture still gets into the room on the wheels of the car. It evaporates and drops of water settle on surfaces.

If there is no heating, moisture accumulates, causing fungus, mold, and rust to appear. To prevent this from happening, heating is necessary.

Features of garage operation determine the requirements for heating systems:

- Efficiency . The oven must heat the air quickly and maintain the desired temperature for several hours.

- Easy to use . When coming to the garage, its owner should spend a minimum of time and effort heating the room.

- Ease of maintenance . The stove must be inspected, cleaned, and repaired in a timely manner, so its design must be simple and understandable, and its parts must be easily replaceable.

- Availability of energy source . When choosing a heating system, fuel availability is of fundamental importance. A stove using diesel fuel, diesel fuel or waste oil is well suited for a garage.

- Safety . There is always some amount of flammable substances in the garage. Since these premises often serve as workshops and sheds, flammable materials will often be found here. Therefore, heating must comply with all fire safety standards.

- Cheapness. The costs of servicing a car and arranging a garage are already high, so saving on heating without compromising its quality is a pressing issue.

A stove consisting of two containers

There is another way to make a diesel stove. It is based on connecting several containers to each other using a pipe with many holes. The lower container of this design serves as a compartment for fuel and at the same time as the firebox itself. Such a device can hold about 12 liters of diesel fuel. The body is made of metal sheets, the thickness of which reaches 5 mm. Then the walls of the stove will not burn out, and the heating device itself will last quite a long time.

It is necessary to make a hole in the upper container of such an oven, which must be closed with a lid. Then you can regulate its operation by supplying oxygen in the amount that is required at the moment in order to regulate the strength of fuel combustion.

The upper elements of the furnace and the connecting tube also serve as a heating device. If the stove is heated too much, their temperature can reach 800 degrees. This explains the fire safety requirements when operating such a stove design.

The pipe must be welded to the top of the stove. An exhaust pipe is attached to it. To make a hood you will need galvanization. When the stove is operating, the pipe can heat up to 250 degrees. If the stove will be used in a small room, then its top part should be removable to make it easier to clean.

About security

Even a “correct” homemade diesel stove does not exist from the point of view of fire safety rules - PPB directly prohibit the use of homemade heating devices using liquid and gaseous fuels. The very presence of such a unit in a household makes any insurance against fire, explosion and poisoning by volatile substances invalid, and its owner and, possibly, the manufacturer, guilty of all the consequences of any incident due to the stove. Therefore, the task of making a homemade diesel stove comes down to purely technical measures to ensure its safety; the formal side is entirely your risk.

Diesel fuel vapors should be mentioned in more detail. They're not just smelly, they're toxic, carcinogenic, and will even saturate old concrete. Therefore, for residential premises, food storage facilities, greenhouses, premises for keeping livestock and poultry, only an industrial diesel stove certified for these operating conditions is clearly suitable, and not a stationary one for temporary use.

Stationary liquid fuel heating devices for individual homes are produced and can be manufactured independently, taking into account - see above. But in this case they must be double-circuit, i.e. transfer heat from fuel combustion to the coolant, and be located in a fireproof extension with a separate, i.e. from the street, entrance.

Materials and tools

To make such a stove you will need:

- metal sheets;

- welding machine;

- gas cylinder;

- medical burner;

- copper pipe;

- hose;

- screws;

- drill;

- clamps;

- pipe branch.

Today you can find a lot of instructions that explain in detail the process of making a diesel stove. However, such devices can be of different types, so it is quite difficult for an ignorant person to choose the appropriate option, because each type of stove has both advantages and disadvantages. In addition, when choosing the type of diesel stove, it is also necessary to take into account the conditions in which it will be produced exploitation.

Which one should I do?

Keeping in mind safety requirements, a homemade diesel stove can, in principle, be built under one of the traces. schemes:

- Double-circuit gas-air;

- Wick;

- Drip.

A gun

A double-circuit gas-air heating stove is nothing more than a heat gun or auto stove, depending on the power. Its advantage is instant heating of the room; In this sense, the heat gun is the most wonderful of the miracle stoves. How it works and how to make a heat gun for a garage from parts and assemblies of unusable devices of the same kind, see the video:

Video: diesel/exhaust heater gun

In addition to technological complexity (you need turned, milled and stamped parts made of heat-resistant materials) and energy dependence (for supercharging and protective and control electronics, without which the heat gun does not work at all), a very serious flaw of heat guns is gluttony. The secondary coolant is air, its heat capacity and thermal conductivity are negligible, so the heat exchanger must be heated strongly and internal heat losses are large. Fuel consumption of the heat gun is approx. 1.15 l/hour per 10 kW thermal power. To warm up an ordinary garage, 3-5 liters of solarium are consumed. At current prices for diesel fuel, such heat is somehow not very comfortable. The only acceptable area of use for a heat gun in everyday life is to warm up an unheated garage before leaving, in order to have time to bring it back warm from recharging and install the battery.

Design examples

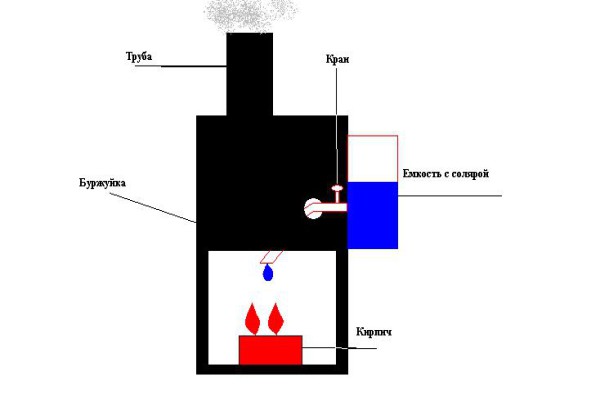

Potbelly stove

The easiest way is to convert a potbelly stove for diesel fuel. Thermal power will be up to 5-7 kW with a fuel consumption of 300-500 ml/hour. Fuel equipment of the same design can be used practically without changes in more powerful diesel heating boilers, as well as for starting with exhaust and kerosene.

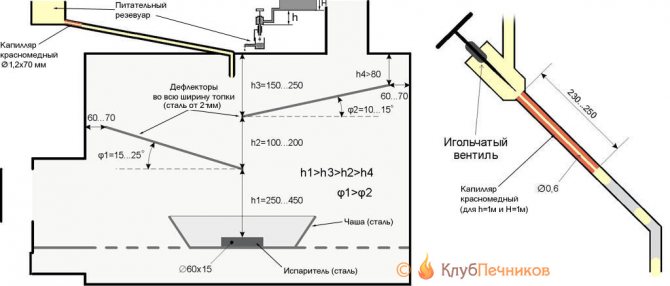

The scheme for modifying a potbelly stove for diesel fuel is shown in Fig. below. Deflectors prevent fuel vapors from cooling before they burn. By the way, deflectors increase the efficiency of the stove when running on wood and coal. The height of the side of the flame bowl is 60-80 mm; its capacity should not be less than the capacity of the feeding reservoir (see below). The operation of a liquid fuel stove, so to speak, is reversed: air enters the wide open door of the firebox; the vent is closed. Otherwise, the stove becomes voracious and quickly becomes coked (overgrown with soot).

How to convert a potbelly stove to liquid fuel

Power, starting and running

A diesel fuel dropper stove will be quite safe and will show all its advantages only if the fuel equipment is assembled and adjusted correctly. The drip furnace must be fed in a 2-stage manner, with a buffer feed reservoir. The reason is a rather strong dependence of the drop frequency on the outside temperature and pressure in the supply pipeline. The pressure, in turn, is determined by the level of fuel in the tank or the degree of its pressurization. It dripped less often - the evaporator cooled down, the stove went out, the bowl overflowed and fuel flowed out. It began to drip more often - the drops did not have time to evaporate, there was a smoky flame in the bowl, the stove wasted fuel. If there is no nutrient reservoir, it can lead to disaster: a flaming stream will flow from the stove. Therefore, manufacturing and launching liquid fuel stoves with single-stage power supply is an activity for rabid extreme sports enthusiasts or those who have nothing else to lose and really want to sleep.

Both capillaries (see figure) are made of red copper. The point here is the wettability of the metal with fuel: it either will not leak through a narrow tube made of another material, or the power system will not be able to be established. Setting up begins with selecting the length of the safety capillary dia. 1.5 mm. The volume of the nutrient reservoir is required 0.25-0.5 l; its height is 7-12 cm. The length of the safety capillary is adjusted so that when the nutrient reservoir is filled to the top, the drop frequency is 25-30 drops per 10 s.

Kerosene heaters

Kerosene is an oily, transparent, flammable liquid, colorless or with a yellowish tint, produced from petroleum. Without going into details of the physical characteristics, the potential of this substance can be judged at least by such areas of application as fuel (or its component) for rocket and gas turbine aircraft engines, as well as glass and porcelain firing furnaces.

In everyday life, kerosene is the most common energy carrier of all types of liquid fuel, as it is used in heating units operated in residential, utility, utility and industrial premises. The higher the purification class of this fuel, the less combustion products are released into the air when using the heater.

Several brands of aviation fuel (TS-1, T-1, T-2, T-1S) and lighting kerosene (KO-20, KO-22, KO-25, KO-30) are used to fill household heaters.

The main brands of kerosene used for household heaters

The characteristics of aviation fuel are high, but its price does not allow this composition to be classified as a combustible material widely available to consumers, so lighting kerosene is mainly used in home heaters.

Operating principle and design of household kerosene heaters

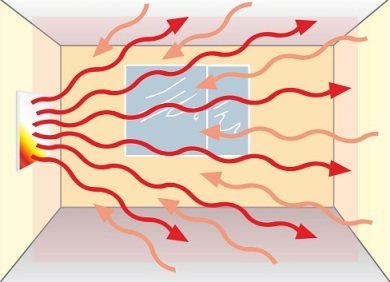

Kerosene heaters are heat generators that heat a room using infrared radiation. IR rays do not affect the transit medium - air, but when they encounter obstacles along the path of propagation, they increase the intensity of the movement of molecules on their surfaces, which causes an increase in the temperature of the upper layers of objects. The interior, which is heated in this way, then gives off heat to the air, initiating convective currents in it.

Operating principle of infrared radiation

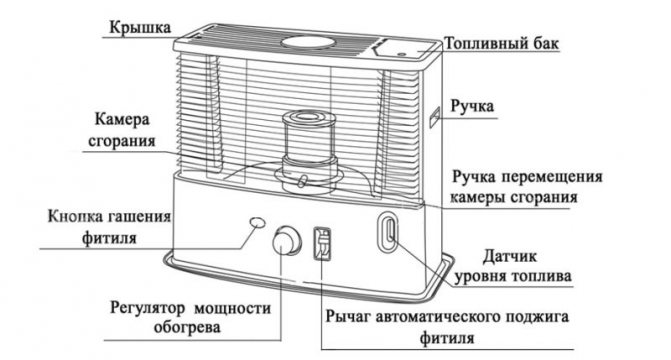

Conventionally, a kerosene heater consists of a housing in which the following components are located:

- fuel tank (removable or as part of the structure);

- electric ignition device (optional);

- wick with emitter and combustion intensity regulator;

- protective grille.

Kerosene from the fuel tank flows to the wick, where it burns and heats the metal mesh emitter. The intensity of combustion is regulated by a device that changes the length of the burning wick. To prevent burns from accidental contact, the infrared emitter is covered with a protective grille. There is a valve on the fuel tank lid for replacement air supply, and on the heater body there is a fuel level indicator and a unit shutdown device. For ease of movement, the heaters are equipped with folding handles or special grooves.

Depending on the design and performance class, heaters differ in functionality and, accordingly, price.

Types of kerosene heaters

Infrared kerosene heaters are manufactured in rectangular or cylindrical housings, the dimensions of which are directly proportional to their power.

Types of infrared heaters using kerosene

Rectangular devices, as a rule, are more powerful than cylindrical devices and are manufactured in the form of a unit, in the body of which, behind the emitter on one side, there is a reflective screen that concentrates IR radiation in the opposite direction. The heating direction of such units is adjusted manually by turning the heater in the desired direction.

The most powerful kerosene heaters with rectangular bodies are available in the form of a floor-mounted fireplace with a removable fuel tank and a battery-powered electric ignition function.

Kerosene infrared heaters in the form of fireplaces

Cylindrical heaters are produced in two types - directional and all-round heating. This line of kerosene heaters consists of units that are more compact due to the geometry of the housing. In addition, some models of cylindrical devices are used not only for heating, but also for lighting, reminiscent of the effect of performing this function as a gas lamp.

Cylindrical infrared liquid fuel heaters: on the left - with a built-in fan, universal (kerosene, diesel fuel), on the right - kerosene circular action

Let's look at the characteristics of kerosene heaters using the example of specific units.

Heater "Kerona" (Kerona WKH-3450)

Characteristics:

- power - 3.8 kW

- dimensions - 50.6 × 32.5 × 32.5 cm (height x width x depth);

- consumed fuel - aviation or lighting kerosene;

- energy consumption - 360 g/hour

- Fuel tank capacity - 4.8 l

- heating area - up to 20 m2

- electric ignition of the wick device;

- device for switching off the device when tipping over;

- unit weight - 12 kg;

- manufacturer - Republic of Korea.

The model is one of the most popular, due to its versatility - the ability to be used for heating both residential and warehouse, utility and utility rooms.

For use in residential premises, it is advisable to first light a kerosene heater outside the home, and let it work there for the first 5-7 minutes until soot formation stops, and then bring it into the room. However, ignition is also possible in the apartment - followed by 5-minute ventilation

Important! Fuel combustion in a heater occurs with the consumption of oxygen from the air in the room, so the heated room must be periodically ventilated - regardless of the degree of presence of the smell from burning kerosene in the home.

Operating principle of the heater:

- the fuel tank is equipped with a push-action valve at the bottom, which opens when the container is installed in its regular place in the housing;

- fuel from the tank is supplied to the base of the porous wick and impregnates it by capillary method;

- after ignition of the wick, the combustion chamber is heated, causing the subsequent evaporation of kerosene and combustion of its vapors;

- The mesh walls of the combustion chamber heat up to a high temperature and begin to generate infrared radiation.

Important! After heating the combustion chamber, manual adjustment of the wick operation is performed, which determines the calorific value of the heater, the intensity of consumption and the completeness of fuel combustion.

Advantages of infrared kerosene household fireplace heaters:

- mobility;

- autonomy (batteries);

- durability, including the wick;

- short duration of smoke formation (on/off);

- aesthetics.

Flaws:

- relatively high cost of heaters (from 9 thousand rubles);

- high cost of fuel;

- open fire factors (fire hazard, oxygen consumption from indoor air).

To get a more complete understanding of this kerosene heater, watch the video:

IR kerosene heater FUJIX M168

An economical portable device, a kind of “burner” for heating and cooking, with a body shape reminiscent of a kerosene lamp for outdoor lighting.

Characteristics:

- ignition type – electronic;

- automatic – standard adjustable thermostat;

- rollover shutdown system;

- body material – metal/glass;

- fuel/consumption – kerosene/≈ 0.25 l/hour;

- tank capacity – 2.5 l;

- calorific value – 2-2.5 kW;

- operating time on one gas station -10 -12 hours;

- dimensions - 33x33x44 cm; weight – 4.7 kg;

- country of origin: China.

This kerosene heater is compact, easy to move and therefore convenient for a garage, small greenhouse, country house. The device can be used as a heater for a tent, provided there is sufficient area and regular ventilation.

A video comparing Chinese and Korean products will help you better navigate your purchase:

Line of liquid fuel heaters:

- "KO - 1.8 Mini";

- “KO – 1.8 Caprice”;

- “Software – 2.5 Mini”;

- “Software – 2.5 Mini+”;

- "PO - 2.5 Savo".

The listed heat generators also belong to infrared heaters, and can run on kerosene or diesel fuel. The models differ from each other not only in power and fuel consumption, but also structurally - in the profile of the firebox, its material of manufacture, and the configuration of the reflector.

Let's look at their most popular modifications.

“KO – 1.8 Mini” is a miniature liquid fuel heater with the ability to cook food.

The firebox, located in a ceramic cylinder, is designed for heating on three sides and for placing dishes on top.

Characteristics of "KO - 1.8 Mini":

- calorific power on the burner - 1.8 kW;

- liquid fuel consumption - 0.2 l/hour;

- tank capacity - 2.5 l;

- operating time at one gas station - 18 hours;

- dimensions – 30x30x30 cm;

- weight - 4.3 kg.

In the line of Solarogaz heaters, the unit is distinguished by a steel cylinder around the hearth and a reflector surrounding the firebox on three sides. The upper part of the grid is designed to accommodate cooking utensils.

With dimensions of 37x42x32 cm, the device weighs 5.6 kg.

The calorific value of such a stove is 2.5 kW with an average fuel consumption of 0.2 l/h. The capacity of the fuel tank is 3.2 liters, which is enough for 14-18 hours of continuous operation of the heater.

The liquid fuel stove "PO - 2.5 Savo" is effective for heating apartments, small country houses and country houses, but the power of the units used in the buildings must correspond to the area of the heated premises, and the open fire of the furnace of the units requires periodic ventilation of the rooms. The device copes even better with heating a garage, small greenhouses, and heating and cooking food.

Operating rules

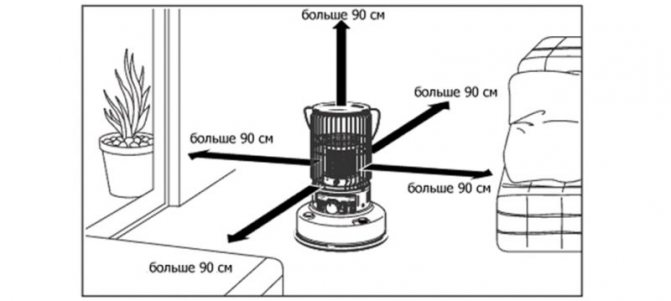

- For fire safety purposes, liquid fuel heaters must be located on a stable base, strictly horizontally and at a safe distance from the interior elements of the room.

Safe placement of an oil heater in a room - Refueling of the fuel tank is carried out only with the heater turned off or in another room - away from sources of fire. At the end of refueling, the tank lid must be tightly closed.

- Fuel storage should be carried out only in specially designated places that meet fire safety requirements.

- When switching from one type of liquid fuel to another, it is necessary to drain the remaining fuel from the tank, which is planned to be abandoned.

- A specific smell when the heater is first ignited is not a sign of a malfunction of the device - it is the preservative compounds burning out.

- It is prohibited to use liquid fuel heaters in children's rooms, cabins and interiors of motor vehicles, vans and trailers while driving, boats, poorly ventilated areas and basements.

- It is not allowed to independently change the design of the heater.

Heating with drippers

If a drip stove is used for heating, it needs a power of at least 15-16 kW. This cannot be achieved only by increasing the drop frequency: due to the increased heat generation, the drops will evaporate while still in the supply tube. The stove (now a homemade liquid fuel boiler) will start burning with pops and then go out. Therefore, in a heating boiler using diesel fuel and exhaust, the dropper tube is connected to a flame bowl in a jacket, cooled by an air flow.

But that is not all. Due to the same greater heat release, the evaporation of fuel and combustion of vapors will be more intense. Some of the fuel vapor will be immediately thrown aside, will not burn and will begin to accumulate in the volume of the boiler, which can lead to an explosion. Therefore, a swirler is installed at the outlet of the fuel line, and the design of the deflector will be different than in a drip stove.

Diagram of a heating system with a diesel-powered drip boiler

Air supply at power up to approx. 12 kW thermoconvection energy-independent: the intake air is first heated in the air jacket of the chimney, and then cools somewhat in the aluminum corrugated hose, which provides the necessary “suction”. At higher power, a boost from the fan is required of approx. 60 W, for example, blowing the radiator of a VAZ-2109.

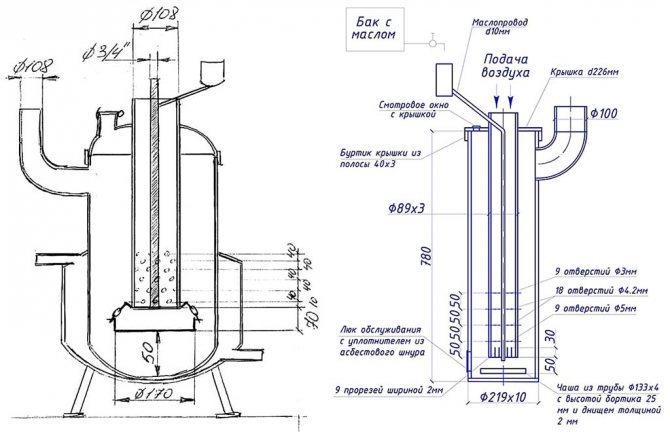

Note: drawings of a drip heating boiler made from a gas cylinder with a power of up to 12 kW and an air heating furnace made of pipes for 10 kW with a cooled drip are given on the following. rice.:

Drawings of diesel fuel drip boilers for water and air heating

A significant drawback of the described system is that in order to avoid burner extinguishing and the accumulation of explosive vapors in it, the water in the boiler jacket must flow countercurrent to natural thermosiphon circulation, i.e. top down. Therefore, the system requires a circulation pump with a non-volatile (thermomechanical) automatic emergency shutdown of the boiler in the event of a power failure. All this makes this system very complex and at the same time unreliable.

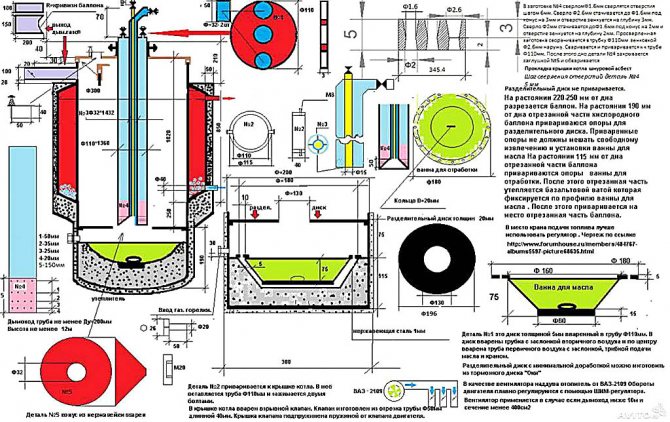

It is possible to build a drip boiler for a water heating system with natural thermosiphon circulation, but in this case its design becomes more complicated and it becomes necessary to force air into the cooling jacket of the fuel line. If you definitely want to heat yourself with diesel fuel or simply nothing else, then see the following for drawings of a drip heating boiler with natural circulation of coolant in the water jacket. rice.

Drawings of a diesel fuel drip boiler for a water heating system with thermosiphon circulation

Also an option

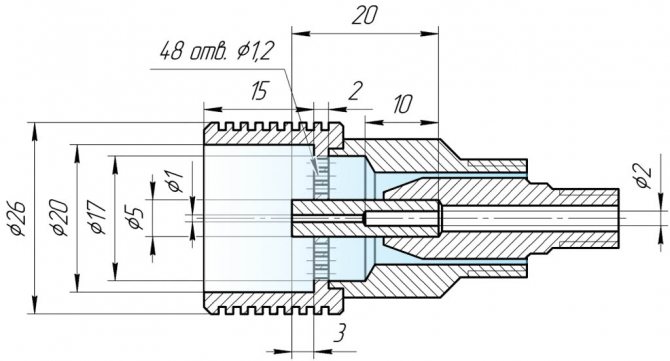

There is another way to start a wood-coal stove using kerosene and diesel fuel: stick an ejection burner into its firebox. It is possible if there is a source of compressed air - the boost required is 1.5-2 ati. Provided that the fuel tank is located below the burner (this is absolutely necessary!), this method is as safe as possible: there is no pressurization - the burner goes out. An assembly drawing of the spray head of an ejection burner for gasoline, kerosene and diesel fuel is shown in Fig. Air is supplied to the annular gap (highlighted in color); the missing dimensions can be taken proportionally, because drawing to scale.

Drawing of the spray head of an ejection burner for liquid fuel