This topic will cover:

- electrical diagrams of boilers;

- possible causes of boiler breakdowns and ways to eliminate them,

options for connecting electric boilers will also be considered for:

- two-wire single-phase network;

- four-wire three-phase network with a neutral wire.

For the two connection methods, you need to know that when connecting any electrical equipment, and we are talking about electric boilers that are equated to this category, the connection is made with grounding.

In this topic, the casings of electric boilers are subject to grounding.

Why does this need to be taken into account? - Then, in the event of a breakdown of the conductor phase insulation on the metal parts of the body and a person accidentally touches the body of the electric boiler, the current potential in the human body decreases.

Replacing the heating element

Replacing the heating element and other elements, as well as diagnostics to determine the cause of the malfunction, is carried out in a passive way when the electrical equipment is disconnected from the external alternating voltage source.

This issue cannot be resolved on your own if you are not an electrician and such work is carried out accordingly if you have knowledge of the regulatory documents of the electrical safety approval group.

So what is the need for these details? — You may ask, if in this or that case there is a malfunction, you can call the electrician directly.

Well, let's put it this way - knowledge of electrical and electrical engineering will not be superfluous for you.

Connecting an electric boiler

Let's consider connecting the EVAN S1-30 electric boiler to a four-wire, three-phase network with a neutral wire.

The fifth PE conductor in the diagram in Fig. 1 is grounding and is connected to the body of the EVAN S1-30 electric boiler. Reading the connection diagram:

The electric boiler is equipped with so-called buses; a network cable with a plug is connected to buses N, A, B, C. From the buses, three phases A, B, C have branching. One branch of phases A, B, C is connected to the first contacts of the heating elements of two blocks.

The second branch from the same four buses is connected through a starter to the second contacts of the heating elements of two blocks.

Here it should be taken into account that for each individual block with heating elements, each individual heating element is connected to phase wires as follows:

Phase A and neutral wire N from the busbars are connected to the control panel. In its combination, the control panel is connected to a voltage of 220 V, the conductors from the control panel are connected:

- with pump;

- with air temperature sensor;

- with thermostat sensor;

- with self-resetting thermal switch.

The control panel consists of electronic elements that are not indicated in the diagram.

For electronic elements, diagnostics are outlined in this blog.

After carrying out repairs to replace one or another electrical part:

- block with heating elements;

- self-resetting thermal switch

and other parts included in the electrical circuit, it is necessary, before connecting the electric boiler to an external source of alternating voltage, to check the electrical circuit of the boiler for resistance. Diagnostics of the resistance in the electrical circuit of this circuit is carried out either with an ohmmeter or a multimeter with the appropriate function.

If, as a result of measuring resistance, the device indicates a zero value, in this example you should reconsider the connections you have made. A zero resistance number indicates a short circuit in the electrical circuit.

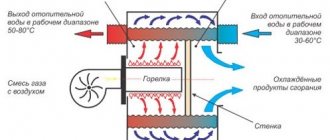

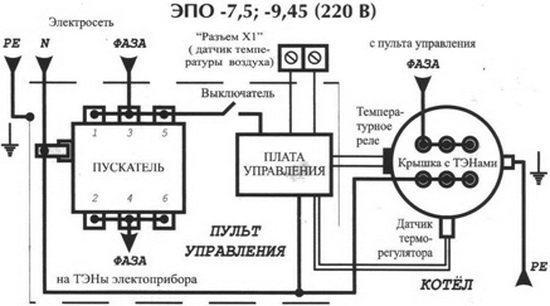

Consider the following electrical circuit for two types of boilers EPO-7.5 and EPO-9.45. The electrical circuit shown in Fig. 2 is identical and the difference here is only in the power of electric boilers. Let's follow the connection diagram:

These types of electric boilers are connected to a two-wire, single-phase network. The PE grounding wire is connected to the heating element block and to the body of the electric boiler. The phase wire from the phase bus in this circuit has a branching, one wire with phase potential goes to the control panel and is connected from the control panel to the first contacts of the heating elements,

Technical features of boilers

The product range of boilers is represented by the following series:

The “Standard” series is represented by the “Economy” and “Standard” models. All boilers of the standard category are characterized by the ability to smoothly adjust the coolant temperature and are equipped with an input for connecting a circulation pump. The design of these boilers is extremely simple and consists of a metal cylinder, in the lower part of which there is a heating element, and in the upper part there is a temperature regulator sensor.

The line of this series is rich in models of varying power - from 2.5 kW to 30 kW. For heating large areas, the additional installation of a circulation pump and an expansion tank is required. Typically used as electric boilers for home and small offices.

Devices in this category differ in their equipment - for example, depending on the power, the models contain a certain number of heating elements and connectors for connecting room temperature sensors.

Among private property owners, devices of this series are most in demand.

Electric boilers "Evan" have different technical characteristics in this series, depending on the presence or absence of a three-stage switch, a built-in circulation pump, and an electronic control unit. Accordingly, more expensive models have all three mechanisms, while economical models only have a three-stage power switch. The boiler power range is from 3.5 kW to 30 kW. They are used as electric boilers for homes, offices, and warehouses.

Boilers of this series have very high power characteristics - thus, the model range is represented by units with heating output from 36 kW to 480 kW. The boilers have (not in all models) four-stage power regulation, protection against short circuits, inappropriate pressure, overheating and overload.

The most popular models of electric boilers Evan

In this section we will give examples of models that are in greatest demand and have many positive user reviews.

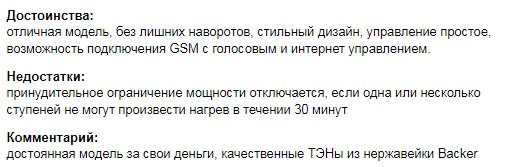

The most frequently purchased model is the Evan Epo 4 electric boiler. This device includes a heating element with a power of 4 kW. The maximum size of the room that such a device can heat is 40 m², the coolant temperature ranges from +30 to +85°C. The device is supplied with an external control panel and is connected to a single-phase 220 V network.

Electric boilers Evan Epo 6, 8, 9, 15 are also widely popular. The Evan 15 boiler is used for operation in three-phase electrical networks.

Electric boilers Evan Warmos IV-5 are equipped with heating elements whose power reaches 5 kW. Such devices can heat rooms with an area of 50 m². The unit is controlled via a built-in remote control or using a connected remote control unit. With the help of such boilers you can regulate the temperature with high precision, down to 1°C.

Review of the electric boiler Evan Warmos IV-5

They can also regulate power automatically and are equipped with built-in automation systems. If necessary, a circulation pump can be connected to them.

Electric boilers Evan Warmos QX-15 are designed for heating rooms up to 150 m². They are produced in wall-mounted versions and are equipped with self-diagnosis systems, air vents, safety valves and room thermostats. Also on board there is a built-in circulation pump and a 12-liter expansion tank. Such boilers combine functionality and an affordable price - they are well suited for ensuring a comfortable temperature in any building.

How to wire an electric boiler?

Evan boilers: pros and cons

Among the disadvantages of electric heating boilers for the Evan home are the dependence on electricity and its high consumption. However, the listed disadvantages are more or less characteristic of most electric heaters. Regarding Evan boilers specifically, many owners complain about the noisy operation of the devices, unreliable heating elements, frequent relay breakdowns and failure of the boiler automation.

Therefore, when choosing a boiler, it is better to consult with a company specialist, because the causes of breakdowns are often caused by operating conditions, instability of the supplied electricity, incorrectly executed connection diagram of the electric heating boiler and other reasons not related to manufacturing defects.

Speaking about the advantages of these Russian boilers, they usually highlight their low cost, ease of installation, a huge selection of models and ease of operation. In addition, the devices have all the advantages of electric boilers as such.

In this series, they note the absence of the need to prepare fuel and install a chimney (as is required in the case of gas and solid fuel boilers), high efficiency (99%) and a level of safety (subject to high-quality electrics).

Features of connecting electric boilers

Even for a non-specialist, the connection diagram for an electric heating boiler is clear, so installing the device will not be difficult. To understand how to install, you should know what devices you will be working with and what their purpose is.

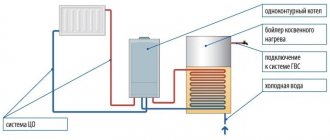

So, during installation you will have to mount the boiler itself, various regulators, and an expansion tank on the wall (or on the floor). Depending on the purpose, one or more main circuits are connected to the boiler. Also, depending on the model, installation of a circulation pump and boiler unit may be required.

Before proceeding with installation, you should familiarize yourself with a document such as the connection diagram for an electric heating boiler, which the manufacturer encloses with the package of documents for the unit. In accordance with this document, the device is connected to other devices in the heating network.

It should be borne in mind that if the boiler power does not exceed 3.5 kW, it can be plugged into an outlet. Otherwise, electrical installation is carried out directly from the junction box.

Moreover, if the power of the device exceeds 7 kW, the use of a three-phase network of 380 V will be required. The boiler must be protected by an RCD and a circuit breaker.

We should not forget about grounding the wiring.

More on this topic on our website:

- Gas boilers Proterm Bear 30 KLOM - technical characteristics and features Heating boilers “Bear” from the Slovak manufacturer Protherm are completely independent of electricity; the source of thermal energy is gas fuel. Proterm Bear 30 KLOM.

Electric boiler EVAN EPO ECONOMY - review and reviews from owners These electric boilers of the ECONOMY series, produced by , which has now ceased to be independent, and were bought by the large NIBE holding, are completely.

Solid fuel boiler KChM 5 - technical characteristics and reviews KChM 5 boilers are produced by the Kirov plant, founded in the 18th century. Over the years of operation, the boiler has proven itself to be very reliable.

Heating gas boiler Danko - technical characteristics and reviews is Ukrainian. In addition to gas boilers, the company produces a number of other heating devices - solid fuel and.

Models of electric boilers Evan

All products manufactured by Evan are divided into series, depending on their functionality, performance and cost.

Standard-Economy

This model range is represented by inexpensive wall-mounted electric boilers with a wide power range. The units with the lowest power produce only 2.5 kW and provide heating of one room from a 220 V network.

Externally, the devices look very simple; the package includes a control module that allows you to control and adjust the temperature in the range from +30 to + 85°C. To heat a large private house you will need a three-phase electric boiler Evan.

Today the most popular heating boilers are Evan EPO-18 kW 380 Standard-Economy. Productivity - 18 kW allows the use of such devices to supply heat to houses and apartments up to 180 m² in size. The boilers heat water up to +30-85°C, and even in such an inexpensive series there are controllers for turning on/off the heating element in case of changes in the characteristics of the coolant. The control panel is separate, because EPO models do not have a body as such.

Standard

This series is also budget-friendly; electric boilers are equipped with the necessary automation. Compared to EPO devices, here the control panel is built into the boiler body. The power range of the devices here is smaller than that of the previous series.

All models up to 7.6 kW can be connected to a single-phase network. You can adjust the temperature settings using the rotary knob. However, such changes will not affect energy consumption in operating mode.

Based on the specified heating, the relay will simply turn off the boiler at the moment when the coolant reaches the desired level. If the temperature of the liquid in the heating system exceeds +92°C, then the heating element will be automatically de-energized.

Electric boiler Evan Standard C1.5 - 7.5 is available in two variations: with the ability to connect to a dedicated single-phase line and a three-phase network (380 W).

At the same time, the technical characteristics of Evan Standard electric boilers and their cost remain exactly the same. Externally, the model is neat and small in size.

Electric boilers Evan S1 are mainly used to supply heat to residential and administrative buildings that do not have a connection to gas mains. Their main advantages are a very reasonable price and a fairly attractive appearance.

Comfort

This series is very economical, the boilers regulate the consumption of electrical energy according to the temperature difference: actual outside and indoors, according to the requirements. These devices have all kinds of automation systems, flame modulation, remote control, automatic temperature control and many other important and necessary options.

The Evan Universal boiler is equipped with weather-compensating automation and multi-stage power control; external control panels are connected to them. The electric boiler Evan Warmos iv 5 is equipped with reliable heating elements, automatic temperature control, and a special power limiter. Also, such units can operate at low supply voltage.

They have two auxiliary operating modes: “anti-freeze”, “warm floors”. The most advanced modifications include the electric boiler Evan Varmos-RX and Warmos-M; they are equipped with auxiliary safety systems and built-in circulation pumps.

The power of Comfort series units varies from 3.74 to 120 kW. Thanks to this, such devices can heat rooms up to 1200 m²

Electric boiler EVAN Warmos M 7.5

Lux

Electric boilers for private homes in this series operate in accordance with the specified settings. Apart from setting the required parameters, owners do not need to do anything else; the devices will independently coordinate the operation of all heating systems and ensure safety.

The Lux series includes Expert boilers, which are available in several power options - from 7.5 to 27 kW. The electric boiler Evan Expert 12 and the boiler Evan Expert 9 have found the widest demand among users.

Such devices have the following characteristics:

- An intelligent system that optimizes the operating mode based on the analysis of street and indoor sensors, as well as programs that the owners set independently.

- Full set of electronic security system.

- Built-in automatic air separator.

Technical characteristics Evan Expert for heating a standard private house, the area of which is 150 m² - you need average ones. The set of electric heating boilers of this series contains all the necessary sensors and control systems. In order to be able to heat water, it is possible to aggregate it with an indirect heating boiler.

Please note that you will still have to purchase a storage tank separately. An electric boiler will be responsible for its operation, which will respond to temperature changes and hot water supply.

VIP

This series includes multifunctional electric boilers, which can be used not only to supply heat to premises, but also to organize water supply in buildings of any type.

Assembly of electric boilers Evan VIP - Finnish!

These units are recognized as one of the most powerful, with thermal characteristics reaching up to 1.6 mW. Heating devices are equipped with various automation systems, durable fillings, remote controls, powerful heating elements - in some models their power reaches 105 kW.