Advantages of film heated floors

The advantages of installing a film floor include:

- low energy costs due to high-quality heat transfer, efficient heating of the room and low power consumption;

- no need to create a concrete screed for the finishing coating;

- safety for the health of children, pets and all residents of the house. The thermal wavelength is up to 20 microns, this value does not harm the inhabitants of the apartment;

- you can install the film heated floor yourself, you don’t need to involve craftsmen or purchase expensive equipment, just follow the instructions;

- if you connect the heated floor correctly, it can last up to 30-40 years;

- when changing place of residence, it is possible to remove the film and reuse it in a new apartment or private house. This sets it apart from other types of heating systems. The main condition is to use laminate, parquet, linoleum or carpet as flooring (these types of covering are easily dismantled and do not damage the infrared floor);

- the film provides heating of the room due to infrared radiation. Unlike other types of heating, it does not reduce air humidity. This contributes to the well-being of residents.

Separately, we note that electric film heated floors can become not the only heating system. A similar design can also be used by installing the film under the finishing materials of the ceiling or walls due to its small thickness.

Rod systems

Infrared film flooring is easy to install. You just need to connect all the parts correctly. Installing the rod circuit is also not difficult. Rod flooring is produced in rolls: width from 70 cm to 1.5 m; roll length 25 m.

The graphite or carbon mixture is enclosed in individual rods. They are insulated with a protective sheath made of polypropylene. The rods are located in increments of 10 cm from each other. At the edges they are connected by copper wire, which is protected by insulation. If one rod breaks, the system continues to operate. Heating stops only in a certain area.

We recommend: What are the advantages of Heat plus underfloor heating?

If the side wire breaks, the system shuts down completely. Installation of rod heating is carried out under tile adhesive or under a screed. With additional heating, energy costs will be minimal.

Operating principle of underfloor heating

Film heated floors operate based on the principle of infrared radiation. This technology is quite common today; it is used as a heating element under laminate, linoleum, carpet, parquet and even ceramic tiles. Under certain conditions, heating a wooden floor using a similar method is allowed. The film can also be placed in wooden or plasterboard suspended ceilings.

Heating by infrared rays from the floor is perceived by people as solar heat due to the same nature of the source. The design consists of several sheets of film, which are laid in a special way on the floor surface. In addition to the main material, the kit includes the necessary cables and rods. After installation, the floor is connected to the electrical network used in everyday life, and the floor covering is placed.

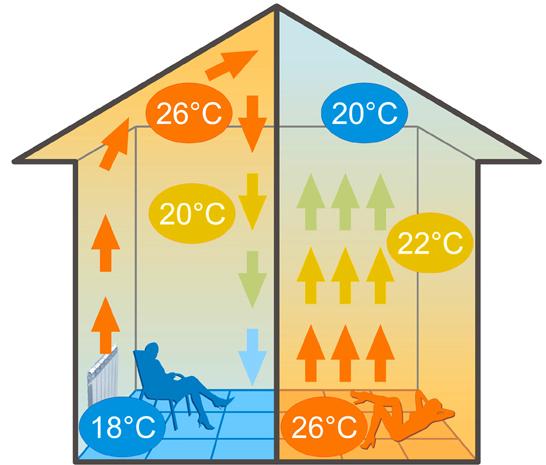

The operating principle is somewhat different from standard convection heating technologies. In fact, infrared radiation does not lead to heating of the air and, therefore, electricity is not wasted on heating furniture and other objects that are located outside the heating zone.

Connection and performance check

When connecting, you must follow the requirements set out in the instructions for use. As a rule, it shows a circuit diagram for connecting the heater to the electricity supply network and shows how to properly connect a film heated floor.

After the connection has been made, it is necessary to test the correct functioning of the floor.

In practice, two methods are used. For the first, a multimeter (tester) is used, the second, the so-called folk or old-fashioned one.

When using the first method, you will need to configure the device to measure resistance. If during the measurement process a zero appears on the indicator panel, this means that a short circuit has occurred in the heating system.

If the instrument panel shows a value tending to infinity, this means that a break has occurred, most often it occurs at the point of connection of wires or panels.

When the measurement results are comparable to the passport data, this may mean that the floor is in good condition and ready for use.

When using the traditional method, there is no need to use measuring instruments. To do this, the film is connected to the network directly, past the thermostat. You will have to do the following manipulations:

- Turn off the power.

- Connect the film.

- Turn on the heated floor and if after 30 - 40 minutes it becomes warm, then everything is in order, if not, then you need to look for a break.

Before you start testing, you need to understand how to connect the heated film floor to each other.

Attention! If, when connecting a heated floor, the protection device is directly triggered, then it is quite possible that there is a short circuit or another problem.

Technical characteristics of heating film

Before purchasing a film floor, it is recommended to carefully study the models offered on the market in order to choose the best option in terms of quality and cost. To do this, you need to understand the differences and technical parameters of the different options.

When purchasing thermal film, it is advisable to pay attention to the following characteristics:

- power - always indicated per linear meter. Generally, 44-68 W is a suitable value;

- melting temperature - 130 degrees is indicated, but during operation it should not rise above 55 degrees Celsius;

- percentage of IR radiation in the total frequency spectrum – a value above 95% is recommended;

- material thickness – the most common thickness is 0.4 mm;

- the length and width of the film sheet is in most cases 8 x 0.5 m. Determined based on the area of the room.

Calculation of materials and preparation of tools

Tools required for installation:

- single-sided and double-sided construction tape for fixing the base and film;

- perforator;

- grinder and the presence of a cutting disc for cutting stone;

- scissors;

- spatula with teeth;

- pliers;

- building level;

- brush with a wide base;

- mixer for construction purposes;

- container for mixing solutions.

To install a heated floor, you will need to prepare the following materials:

- thermal insulation substrate, which is placed under a warm film base;

- film made from polyester and heating components. The components used are carbon paste with connections using copper jumpers;

- temperature sensor and thermostat, which provide the ability to automatically change the temperature of the film heated floor. These elements also provide a change in temperature based on environmental factors;

- bitumen insulator to protect electrical connections;

- terminals that connect the contacts of electrical wires and underfloor heating cables.

It is also necessary to prepare finishing materials used as flooring. If the size of the film strips is not suitable for installation in the room, they can be cut.

However, this procedure must be carried out as carefully as possible, after making sure that the manufacturer of a particular model allows this.

It should be noted: to connect the cable contacts, it is important to use only the terminals that come with the kit. It is prohibited to use a tin connection or solder any section to the strip structure of a heated floor.

When soldering, the busbar that conducts electricity heats up significantly, resulting in an increased risk of damage to the contact point of the wire. This can in many cases cause a breakdown of the entire communication. Installation and connection should be made using crimp connection elements.

System health check

After installation is completed, it is necessary to check the film heated floor. The price of the issue is the efficiency and safe operation of the heating system. Experts recommend checking all contacts in the chain using a voltage indicator. Make sure that all contacts are securely insulated. After the heating elements are covered with film, it is necessary to perform a test switch-on.

If everything works fine, a clean floor covering is laid: laminate, parquet board or linoleum. As a result, you will get a heated film floor, reviews of which can be read on the Internet.

In conclusion - how to choose a film heated floor (video):

Installation of infrared heated floor

Installing an IR system under a particular coating has its own characteristics. So, if you plan to use soft materials such as linoleum or carpet as a finishing coating, you should lay sheets of fiberboard or plywood as a layer between the heating strips and it.

The hard layer will protect the film from “injury” due to the coating being pressed through by the legs of heavy furniture or women’s heels.

In any case, the installation of an infrared heated floor system is carried out in several stages.

Purchasing materials and tools

In addition to the IR film itself, it is also necessary to purchase a roll of thermal insulation material, as well as metallized or single-sided construction tape to fix it. The film itself is attached to the base using double-sided tape.

To carry out the work you will need a set of tools:

- grinder equipped with a disc for stone;

- perforator;

- knife or scissors;

- pliers or pliers;

- construction mixer;

- notched spatula;

- wide brush;

- container for mixing the solution.

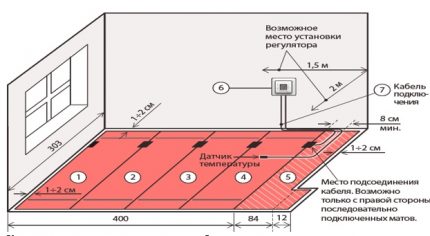

If you have not yet drawn up a layout diagram at the stage of choosing the material, you need to do this now, taking into account not only the size of the room, but also the width of the strips used.

The compiled plan of the room should reflect the placement of furniture and areas with fragments of heating elements

The location of the films can be either longitudinal or transverse. The best option should be chosen based on material savings. But still, experts recommend placing stripes in length. This allows you to minimize the number of connection points.

Preparing the base base

When preparing the base for laying the IR system, it is not at all necessary to dismantle the old coating. Dismantling will be required only if the base base is severely damaged and the surface is “strewn” with deep cracks and potholes.

According to the standards, the permissible height difference of the base base under the film system is only 0.2-0.3 cm per linear meter, regardless of the direction of the control rod or building level applied to the surface.

When preparing the base, it is necessary to clean the surface from any remaining debris and dust, and, if necessary, fill cracks and eliminate other minor defects.

The technology for laying an IR system involves installing a heat-insulating layer, the main task of which is to prevent heat leakage through the floor slabs, thereby increasing the efficiency of the system.

The best insulation material is:

- Izolon or Penofol are roll insulation made of foamed polyethylene. They have excellent waterproofing qualities, because... during the foaming process, closed cells that do not allow water to pass through are formed;

- Cork backing is compressed particles of cork wood mixed with a binder called suberin.

When installing heated floors, priority is given to substrates with a lavsan metallized or foil shell. It enhances heat transfer due to its own reflective effect.

The structure of the listed materials will prevent the absorption of moisture, performing the function of a waterproofer, and the reflective surface will direct the generated heat directly into the room, and not to the underlying floor.

The rolled material is laid on the cleaned surface with the foil side up, placing the strips end to end.

The substrate is spread over the entire area of the room close to the walls. The joints of the strips laid on the floor are fastened together with masking or aluminum tape. If the thickness of the material is small, the strips laid with a slight overlap can be secured with construction staples.

Laying the film system

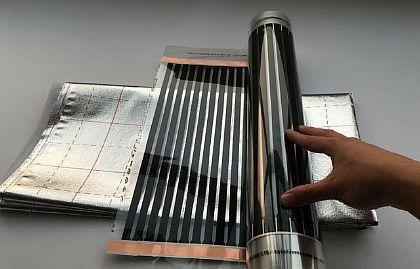

In accordance with the markings, the film is cut into separate fragments, taking into account that the maximum length of a solid panel should not exceed eight meters. Cutting can be done with scissors or a knife. The cut strip fragments are sequentially laid out on the substrate according to the drawn up diagram.

The divided strips, in accordance with the diagram, are laid out on the surface, directing the contacts to the wall where it is planned to install the thermostat

The film pieces are laid face up or down in accordance with the manufacturer's instructions. The IR system strips are placed strictly according to the instructions. For example, strips of Caleo film flooring are laid with a side overlap so that there is a gap of 1 cm between adjacent copper bars.

If there are brands whose manufacturers recommend laying strips without overlap and with a more impressive distance between the tires. When laying, it is not allowed to bend the carbon strips at an angle of 90°, as this may damage a fragment of the system.

If necessary, the strips are trimmed along the perimeter of the room, making cuts in the places strictly marked with a dotted line on the film. Approximate dotted stripes for the incision are usually located every 18 cm.

To fix the film to the surface, use double-sided tape. This solution allows you to prevent the elements from shifting relative to the markings and each other. In the process of laying strips of infrared heated floors, it is important to prevent damage to the material, which often happens when tools used during installation accidentally fall on them.

Floor covering

Thermal film or rods can be laid under any covering. When using tiles, a layer of glue must be applied to the heating circuit, but the thickness of the layer should not exceed 2 cm. Otherwise, heating will be ineffective. It will take a lot of energy to achieve the required temperature in the room.

We recommend: How to calculate the length of a heated floor?

For porcelain stoneware, a heating system with increased power is used. Before applying the glue, it is recommended to cover the film or rods with waterproofing material.

If linoleum or laminate was chosen as the cladding, then the thermal film is covered with a backing. In a room with a heavy load, the film is covered with sheets of plywood. In this case, stationary furniture can be installed on it. For a system of rods, it is recommended to make a screed from a concrete mixture.

Infrared heating is used for heating in country houses, but one must always remember that heating will depend on electricity. If there are frequent interruptions in the network, it is recommended to consider an alternative heating system. In city apartments, thermal film and rod systems with infrared radiation are often used as additional heating for cold areas.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- How to design a heated floor?

- How to lay a heated floor on the ground?

- How to install an electric heated floor?

- What are the advantages of a heated metal-plastic floor?

- How to connect a warm floor?

- How to lay heated floors on planks?

Thermoreg TI 200 thermostat

| Manufacturer: | Thermo |

| Model: | TI 200 |

| View: | electronic thermostat |

| Power: | 3600 W |

| Installation type: | recessed |

to compare old price RUR 3,528 RUR 2,990

Photo Name Price per piece. Quantity Cost

| Thermoreg TI 200 thermostat | 2,990 rub. | <1> | RUB 2,9902,990 |

There are 0 items in the cart worth 0 rub.

← Continue shopping

Thermostat Caleo UTH-130

| Manufacturer: | Caleo |

| View: | mechanical thermostat |

| Power: | 4000 W |

| Installation type: | overhead |

to compare RUB 3,173

Photo Name Price per piece. Quantity Cost

| Thermostat Caleo UTH-130 | RUB 3,173 | <1> | RUB 3,1733,173 |

There are 0 items in the cart worth 0 rub.

← Continue shopping

Thermostat Devireg Touch White (white)

| Manufacturer: | Devi |

| View: | electronic thermostat |

| Setting method: | programmable |

| Keyboard type: | sensory |

| Power: | 3680 W |

| Installation type: | recessed |

| Case color: | white, Pure white |

compare old price RUR 12,180 RUR 6,630

Photo Name Price per piece. Quantity Cost

| Thermostat Devireg Touch White (white) | 6,630 rub. | <1> | RUB 6,6306,630 |

Disadvantages of film heated floors

The disadvantages of such space heating systems include:

- Difficulty in repairing thermal elements if they fail. Repair is especially complicated if it is laid under ceramic tiles.

- The possibility of rearranging furniture and household appliances when changing the interior of the premises is significantly reduced.

Thus, infrared film can be called one of the most successful design options for heated floors. Having a relatively low power, it combines high efficiency, reliability, as well as ease of installation and operation.

No. 2. Pros and cons of warm film floors

The design features of film heated floors allow us to talk about a lot of its advantages :

- simplicity and high speed of installation , no need to install a cement screed, which allows you to install a heated floor in the shortest possible time even after all repair work has been completed;

- manufacturers say that dismantling the film is as easy as installing it, so you can literally take it with you when you move;

- the minimum thickness of the film and the absence of screed allows you to maintain the height of the room;

- the floor heats up almost instantly;

- uniform heating of the floor and room surfaces;

- possibility of using any decorative floor covering, incl. linoleum and laminate. Difficulties arise only when laying tiles, but more on that later;

- versatility _ The film can be mounted not only on the floor, but also on walls and ceilings. Moreover, the features of the material allow it to be used in rooms with heavy loads on the floor covering, incl. in gyms, shopping centers, offices. The film can be used to heat garages, greenhouses, sheds, and can also be used to prevent porch icing;

- complete harmlessness (and even usefulness) for the health of all inhabitants of the house.

disadvantages :

- this is still a fairly expensive system;

- susceptible to mechanical damage, so you should be especially careful during installation;

- Improper installation and operation may result in the film catching fire.

Heating elements should not be placed in places where large furniture will be permanently placed. This recommendation applies to absolutely all underfloor heating systems, but in the case of infrared film we can deal with the failure of an entire fragment as a result of overheating due to insufficient heat transfer.

The film is heated to a temperature of 330C, which allows it to be used together with such a “delicate” coating as linoleum, but this imposes restrictions on use as the main source of heat : in this case, the film must cover at least 70% of the floor area. Comfortable temperatures can only be achieved in regions with mild winters - otherwise, such a warm floor can be used as an auxiliary heat source , providing comfortable movement barefoot on the floor and allowing you to warm up the room in the autumn-spring period, when central heating is or is not yet working .

Infrared heated floor power consumption

The required cable power is determined by multiplying the power required to obtain the desired degree of heating by the free area. For example, a kitchen requires a power of at least 160 W. The kitchen area is 10 square meters. 4 of them are under furniture. Therefore, it turns out that 160 needs to be multiplied by 6 square meters. meters of free space, that is, the result will be the number 960. And the thermal cable is selected with the closest power rating of 1020 W.

Table for calculating the energy consumption of IR flooring for a house of 166 square meters:

The self-regulating IR rod mat is protected from system locking and overheating. Therefore, the heating area is equal to the area of the room. And the power is regulated by the presence of a thermostat with manual control or the necessary settings depending on the heat needs. This way you can save up to 35 percent on electricity bills.

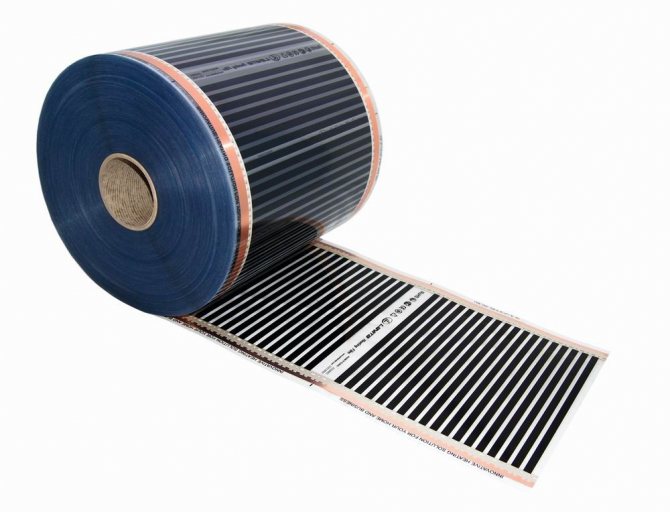

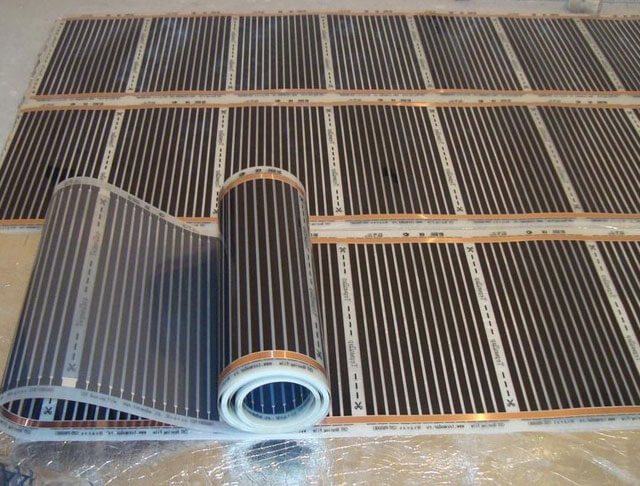

Characteristics of thermal film

To make thermal film, thin polypropylene or polyethylene is used. The film is two-layer. Between the layers there is a graphite or carbon mixture. It is applied to the surface in stripes. The top layer reliably protects the heating element from moisture.

Film thickness 0.33 mm. When installing infrared heated floors, the strips are left in their original form. The film can be cut only according to special markings that are applied to its surface.

The current reaches the strips along the heating busbars. They are made of copper and silver and are located at the edges of the film. To organize high-quality heating, manufacturers suggest using film flooring of various capacities.

- Infrared flooring under laminate is used with the ability to heat up to 27 0C.

- An infrared floor under tiles can heat up to 50 0C. Thermal film is used for heating loggias and utility rooms.

- There is also a universal material. It can withstand low and high temperature. Such systems include a coating with continuous application of a heating substance.

The carbon layer can be applied to the film not in separate strips, but in a continuous layer. This gives great opportunities to set up heating in rooms with any geometry. The fabric can be cut in any area. The advantage of this material is its resistance to external influences.

We recommend: How to set up a heated floor?

You can install stationary furniture on infrared heated floors. Soft and hard materials are used as cladding.

- Depending on the type of room, thermal film of varying strengths is chosen. Systems with a low power of 130 W/m2 are used as additional heating. They are installed in rooms with little load on the floor: bathroom, toilet.

- In the kitchen, in the hallway, for rooms with tiled cladding, infrared heated floors of medium power, up to 170 W, are chosen.

- In garages, workshops, and bathhouses, it is recommended to use thermal film with high output, more than 220 W.

The heating system is regulated automatically by the control unit. The mode is set initially. The heating turns on or off as the floor warms up. This mode allows you to reduce energy consumption. The system operates from 220 V.

The thermal film warms up quickly, in 2 minutes; begins to transfer heat to the floor covering. An infrared heated floor in a residential area with normal temperature consumes 50-70 W/m2 of energy per day; with additional heating 20 W/m2..

Electricity consumption is quite high, so in cold regions the systems are used only as additional heating. When creating a normal microclimate in the room, the film should occupy up to 70% of the surface of the floor base

In Moscow, they use infrared heated floors under linoleum and under wooden coverings of the “heat pro” brand, made in Malaysia. The company produces both thermal film and a system with a continuous heating layer. The “warm floor” heating system “stem energy”, manufactured in Korea, has proven itself well.

Finish coating

When you need to lay laminate or parquet, it is enough to put a waterproofing material (polyethylene film) on top of the film. For carpet or linoleum you will need fiberboard or plywood. A hard coating is needed to protect the infrared film from possible mechanical damage during operation.

Advice. Before purchasing linoleum for laying over a heated floor, you need to make sure the quality of the product to prevent it from deforming when heated.

The big advantage of such simple installation is that heated floors can be easily dismantled at any time: for example, when moving or during a major renovation of a room.

Effect of IR heat source on the body

Not many people know about such an advantage as a beneficial effect on the body. The secret is that human heat is emitted in the same range as infrared. This means that an infrared heated floor is perceived by a person as a natural source of heat and therefore more pleasant. For example, if with water heating a person needs 22-25 degrees of heat for comfort in a room, then when using IR heating the same feeling will be already at 18 degrees.

IR radiation ionizes the air, destroys harmful bacteria and viruses, and removes unpleasant odors.

IR rays treat many diseases. Under their influence, nervous tension goes away. In our age of constant stress, this is a great opportunity to strengthen the nervous system without leaving home.

Many people find it difficult to tolerate dry air in their apartments, which is caused by central heating radiators. You have to use humidifiers. IR heated floors do not dry out the air, so it is easy to breathe in such a room.

IR radiation does not heat the air itself, but objects. Therefore, walking on such a floor is a pleasure and a state close to relaxation arises.