Checking the operation of the chimney

The chimney works correctly if the gases are removed from the room to the street. Backdraft, when smoke enters the room from the chimney and stove, is an extremely undesirable phenomenon.

Signs of poor traction are easy to spot:

- when the stove operates, smoke enters the room;

- gusts of wind outside affect the movement of gases in the pipe, creating a reverse direction. Popping noises are heard in the stove and ash pan;

- fuel is difficult to ignite;

- even dry firewood burns slowly;

- opening the window or doors sharply reduces traction.

It is more difficult to find out about a bad hood of a water heater or gas boiler. Carbon monoxide can enter a room, but it is difficult to smell or see.

Breathing such gas is deadly.

To accurately determine the operating characteristics of the chimney, you can use an anemometer. It is used to measure the speed of movement of furnace gases

It is a common belief that the quality of a hood’s operation can be determined by the burning of a match or piece of paper. This method leads to an error and cannot be used. When burning, a match emits hundreds of times less smoke than wood in a fireplace, for example. The smoke from the match will go away, but this does not mean that the gases from the operating devices will be completely removed.

The exact parameters of the chimney are determined using special equipment. If you do not take into account the roughness and length of the walls, the speed of gas movement depends on the geometry of the channel and the pressure difference in the room and in the upper part of the pipe.

The gas flow must correspond to the power of the furnace equipment, gas water heater and other devices. Most often, the device readings range from 12 to 20 Pa.

Experts can determine smoke removal parameters using an anemometer. The device is compact and easy to use. They measure the speed of gas movement. But you need to know the geometry of the passages and the cross-sectional area of the pipe.

Before measurements, you need to warm up the chimney and stove. In winter, it is enough to heat a fireplace or use a gas water heater for an hour

The data obtained is checked against the requirements recorded in the passport of the gas or stove equipment. If the volume of gas removal in one hour is insufficient, operation of the equipment is prohibited.

Design and manufacture of smoke exhauster

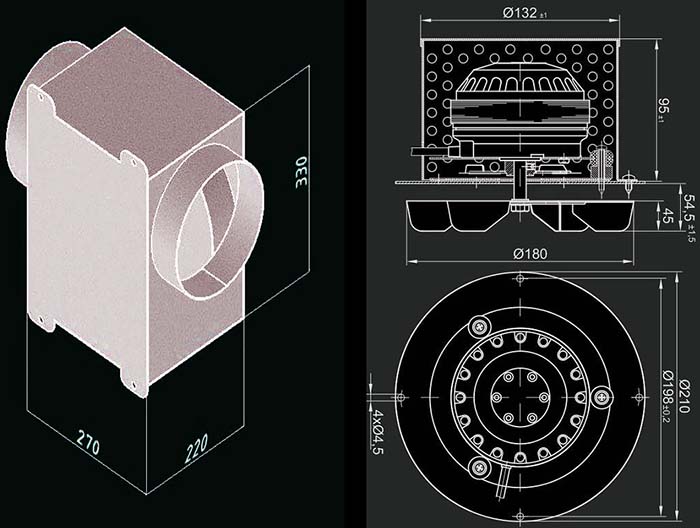

The smoke exhauster will require a self-made housing . To do this, you can use a piece of steel pipe with an internal diameter of 21 cm with a fan diameter of 18 cm. Wall thickness is within 3-5mm. A suction pipe with a wall thickness of 3-5mm, which must have an internal diameter corresponding to the inner edges of the fan blades, must be connected to the housing.

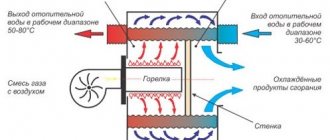

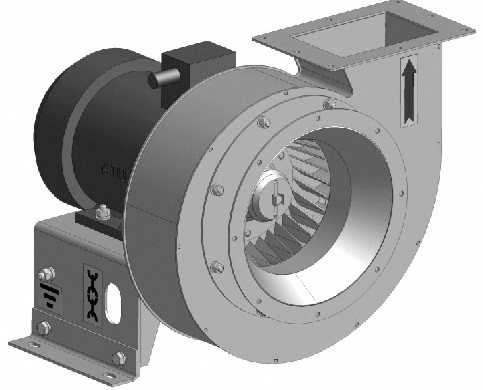

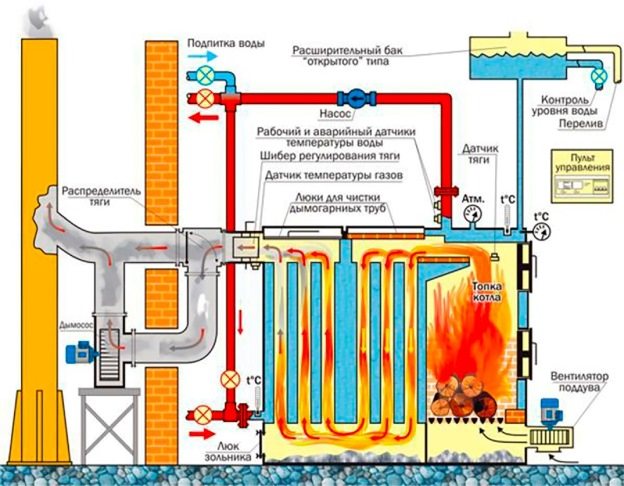

Smoke exhausters use centrifugal fans . They allow you to create the necessary vacuum and protect the electric motor from hot combustion products. The incoming flow entering the fan blades through the suction pipe and the outgoing flow are perpendicular. To make the smoke exhauster as simple as possible, it is best to install it on the roof on the chimney.

Inlet valve for increased draft

Without air entering the room or directly into the stove, the chimney will not work. Vents or cracks in old windows are not the best method for air flow.

The disadvantages are obvious:

- Cold air enters the room through the cracks even when the stove or fireplace is not working.

- In winter, air from the street constantly changes the indoor environment. At the same time, the relative humidity of the air drops sharply, which has a harmful effect on health. A person's mucous membranes dry out, creating conditions for colds.

- The window must be opened and closed manually.

It is much more effective to provide air flow using a valve. It closes automatically when furnace equipment or gas heaters are not operating.

This is what a wall supply valve looks like, which is installed in rooms with stove heating or gas equipment to improve air flow

Heaters require a boiler room valve to operate. The device has different characteristics than similar operating principles for room ventilation.

The supply valve is placed diagonally or above the heated surface so that the cold air rises to the ceiling. But it is best if oxygen is supplied directly to the firebox. At the same time, the humidity and temperature conditions in the room are not disturbed.

Design and principle of operation of a smoke exhauster.

Smoke exhausters of the DPE-7 model range consist of:

- aerodynamic part assembly;

- electric motor assembly;

- frame (with or without wheels, depending on the model of the exhaust fan);

- suction piping and pressure hose (equipment depends on the supplied equipment).

To move/carry the smoke exhauster, use a handle attached to the frame.

The smoke exhauster DPE-7 (1R) consists of a fan assembly.

The fan consists of a housing, an impeller, an electric motor, and a rigid air duct.

To carry the smoke exhauster, the power elements of the housing are used.

The smoke exhauster DPE-7 (1R) has the ability to reverse the air flow. To activate the “reverse” mode, a rotary valve is used. In this mode, the intake air is blown out through a parallel air duct with a high-pressure jet.

When turned on, the smoke exhauster creates a suction vacuum. Due to the resulting vacuum, smoke, toxic gases, fire extinguishing gas, powder or aerosol are sucked into the smoke exhauster and pumped into the pressure hose, along which they move to the point of release.

Security measures.

Using the smoke exhauster for its intended purpose. Using the smoke exhauster for purposes other than its intended purpose is a violation of the requirements of the Operation Manual.

TD Artikon LLC is not responsible for damage resulting from improper operation of the smoke exhauster. In this case, all responsibility rests with the user.

Basic safety rules.

Before operation, carefully read the operation manual of the smoke exhauster.

When working with a smoke exhauster, beware of possible injuries to the head, arms, and legs.

When working with a smoke exhauster, use gloves, long trousers, and personal eye and respiratory protection.

A smoke exhauster with an electric motor is allowed to be put into operation by persons who know its design and instructions for use, as well as those who know the safety rules when working with electrical installations under voltage of 220/380 V.

Before connecting the smoke exhauster to the power source, you must make sure that there is a neutral wire in the loaded socket.

Do not overload the engine during operation.

Turn off the engine of the DPE-7(1R) smoke exhauster when moving from one treated area to another and during breaks in work.

Turn off the engine and disconnect the power cable from the power outlet before servicing and cleaning the smoke exhauster, as well as if the power cable is damaged.

If increased vibration occurs, immediately turn off the exhaust fan and check it for damage.

The hoses are made of gas-tight synthetic fabric and can be used to transport gases with temperatures up to 100 °C.

Attention:

— in order to avoid reducing the performance of the smoke exhauster, the pressure hose should not be bent more than 90 degrees;

— if during operation the engine speed decreases, you should immediately turn off the smoke exhauster and disconnect the plug from the power socket;

— when working with the DPE-7(1R) smoke exhauster, hold it by the control handles with both hands;

— when using the smoke exhauster for the first time, a slight odor may appear, which goes away after some time;

— DPE-7* smoke exhausters create a large suction vacuum during operation! The suction hose placed on the smoke exhauster must be as stretched and straight as possible to avoid folding.

Moisture must not get on the electric motor and other contact surfaces of electrical wires.

Prohibited:

- plug the smoke exhauster into an outlet that does not have a neutral wire;

— plug the smoke exhauster into the outlet if the electrical cable or extension cord is faulty;

- turn on the smoke exhauster through an extension cord whose wire cross-section is not designed for a current of 11 A;

— continuous operation of smoke exhausters exceeding the specified requirements;

- use a smoke exhauster with a faulty starting switch;

- use the smoke exhauster indoors in the presence of flammable liquids or gases.

— use of a smoke exhauster to remove the gas-smoke-air environment during welding work.

What benefits does the introduction of a traction fan give?

In reality, these technical solutions are far from new. Traction and blowing machines have long been used in industrial thermal power plants. Indeed, with large volumes of fuel burned, the efficiency of this process plays a huge role. We can say that smoke exhausters for household solid fuel boilers migrated there from industrial equipment relatively recently, this is due to a massive increase in demand for this type of heaters. The use of a draft fan in solid fuel boilers provides the following advantages:

- Increasing the efficiency of the unit as a whole thanks to controlled fuel combustion.

- More precise regulation of coolant temperature by regulating combustion intensity.

- Possibility of stable operation of the heating installation in conditions where there is poor chimney draft.

- Preventing smoke from entering the furnace room when opening any firebox door.

Unlike blowing machines, smoke exhausters for domestic boilers are located not at the beginning of the gas-air duct, but at its end, immediately in front of the chimney pipe. They are a fan, the working part of which is protected from high temperatures (up to 250ºС) and small volatile inclusions contained in combustion products.

Smoke exhaust device

- Send a request

print version

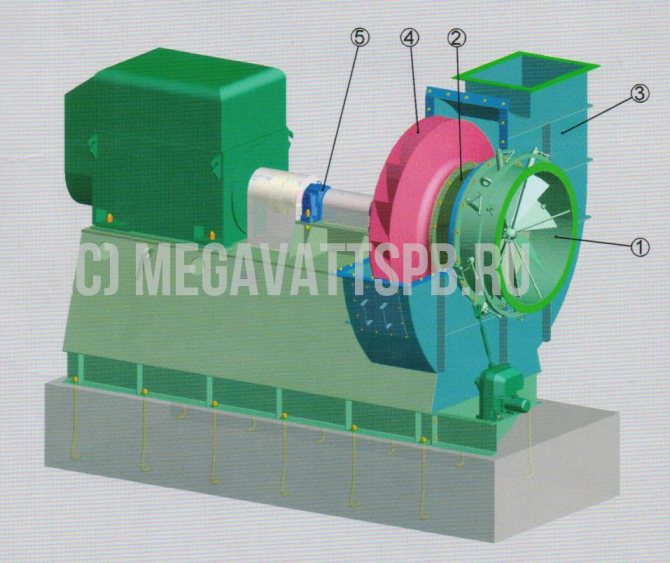

1- guide vane 2- suction funnel 3- spiral casing 4- impeller 5- running gear (Click on the picture to enlarge) The design of the blowing machine, depending on the assembly diagram, is somewhat different, but smoke exhausters DN of the cantilever design consist of the main assembly units: working wheels, chassis, volute, inlet pipe, axial guide vane, frame for the chassis and fasteners.

The impellers of fan exhaust fans are welded structures. The hubs are made of cast steel, the blades and cover discs are made of sheet steel. During manufacturing, the impeller of the smoke exhaust fan DN and VDN are subjected to balancing.

The running gear of VDN blower fans and DN smoke exhausters consists of a housing, covers, a shaft and a pin-type coupling. The shaft of the smoke exhauster DN or the blower fan VDN is supported on the coupling side by a double angular contact ball bearing and on the impeller side by two radial roller bearings.

The exhaust exhaust device of the chassis allows for dismantling the bearings without removing the impeller. The running gear of the VDN blower fan and the DN smoke exhauster is bolted to the welded frame.

The volutes and inlet pipes of blowing machines are welded and made of sheet steel. For the durability of smoke exhausters Dn and blower fans VDN, the wall thickness of the volutes has been increased.

The smoke exhaust device allows it to be attached to the foundation with welded supports. To remove the rotor, there are removable diaphragms on the rear wall of the volutes of smoke exhausters Dn and draft fans VDN, and in the air duct the smoke exhaust device provides a section that ensures free exit of the rotor.

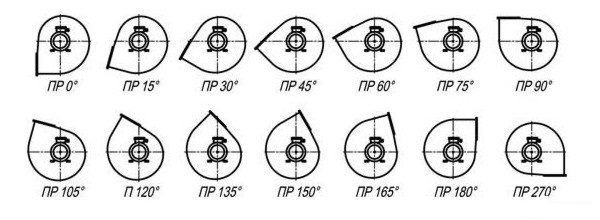

Single-suction blower fans VDN and smoke exhausters DN are supplied with a volute whose rotation angles are 0,90,180,270 degrees.

The sections of the inlet pipes of the smoke exhausters Dn and VDN of the fans, forming a sealing unit with the covering disks of the impeller, and the connecting surfaces of the flanges are subjected to mechanical processing.

Smoke exhaust devices are equipped with standardized axial guide vanes for adjustment to the required operating mode.

To monitor the oil level in the oil bath, an oil level indicator is installed on the chassis housing in the smoke exhaust device. The temperature of the chassis housing of smoke exhausters Dn and blower fans VDN in the places where bearings are installed is checked with mercury thermometers, the frames for which are supplied.

Cooling of the oil and chassis housing of smoke exhausters Dn and blower fans VDN is carried out by a coil built into the oil bath of the chassis housing, and through which water is passed at a temperature of no higher than 20 degrees.

You can buy a complete smoke exhauster, or you can buy only a part of a smoke exhauster DN or a draft fan VDN.

see also

:

- Additional reference information on smoke exhausters and forced-air fans

- Smoke exhauster impeller

- How to buy a smoke exhauster

- Smoke exhauster guide vane

- How to choose a smoke exhauster

- How to choose a blower fan

- Blower fan

- Smoke exhausters for boilers

- VDN fan and VD fan

- Productivity of the draft machine

We work only with legal entities of the Russian Federation

When is it necessary to increase the performance of a chimney?

Poor draft is not always the only reason for chimney work. It may be necessary to increase the rate of carbon monoxide removal if additional equipment is connected to the hood from the stove.

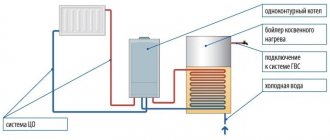

It is allowed to use a chimney to connect a column if the equipment is located on the same floor. And if the chimney has a sufficient smoke removal volume for operating the gas heater.

Another reason to increase the draft in the chimney is to install a more powerful heater. The required parameters of the chimney are indicated in the product data sheet.

It is also worth paying attention to how quickly you can light a fire in the stove. For example, if the draft is weak, damp wood will not burn

If the volumes of gases removed do not match the capabilities of the existing system, then the chimney needs to be modernized.

Purpose of the smoke exhauster

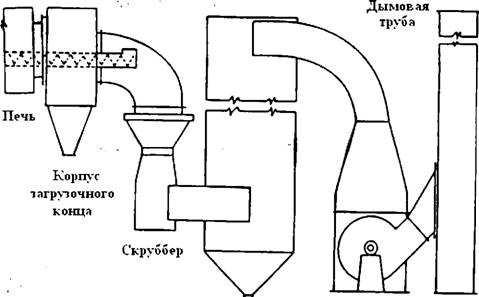

One-way suction type devices are used in cases where it is necessary to pump out flue gases from boiler houses that are equipped with special systems for ash collection or for the purpose of removing gases from oil-gas boiler houses.

Steam and hot water boilers are equipped with such devices. As an alternative replacement, certain types of fans can serve as such gas and smoke removal fans. The configuration of such devices is designed for long-term continuous operation. They can be used for work both indoors and outdoors.

The design of smoke exhausters can be of two types (used in thermal power engineering)

The impeller sits on the motor shaft. In this case, the device itself will be small in size

Types of smoke exhausters

If a chimney shaft has been built in your house, the draft of which is not enough for the operation of a new heating unit, then a simple smoke exhauster for the boiler will help solve this problem. It is not at all necessary to immediately purchase electromechanical devices; sometimes it is enough to install a special deflector at the end of the pipe, which creates additional natural traction. But when all such options have been tried, you can purchase and install one of the proposed devices:

- fan – natural draft amplifier;

- flow exhauster;

- centrifugal traction machine.

A draft amplifier is a device equipped with an axial fan; it is placed at the end of an exhaust shaft or pipe. The performance of the device can be adjusted manually using a thyristor control unit.

Flow-through smoke exhausters for boilers are installed immediately at the outlet pipe of the unit and also serve to increase the draft force. The design of the apparatus is such that inside the smoke channel there is only an impeller that does not block its cross section. The electric motor and other elements are located outside, which allows the device to be turned on when necessary, and the rest of the time the shaft can successfully remove smoke using natural draft. You can control the switching on and performance of the device either manually or automatically by connecting it to the automation of the boiler installation.

In reality, this type of smoke exhauster cannot always serve as a full-fledged traction unit, but only as an exhaust amplifier. The reason is the insufficiently high pressure developed by the impeller of the device due to its design. To get a good result, it is better to install a centrifugal type smoke exhauster on a solid fuel boiler. In this case, the control of all functions of the device should be linked to the electronic unit of the heat generator, then the operation of all elements of the system will be consistent. In addition, centrifugal fans are capable of not only creating a vacuum in the combustion chamber, but also developing high pressure, which will force any chimney to operate.

High-power heating units use a forced draft circuit with two fans; this is an ideal option. But the implementation of such a scheme is associated with certain difficulties, since for balanced operation of the system it is necessary to calculate the smoke exhauster and blower, the amount of air for combustion and the resistance of the entire gas-air path, including the exhaust duct.

Features of installing a smoke exhauster

All blower fans, depending on the rotation of the engine, are divided into right-hand and left-hand. It is important to correctly determine the type of smoke exhauster, since if connected incorrectly, the fan will not suck in air, but blow it out. To determine the direction of rotation of the impeller, you need to approach the device from the electric motor side and look in which direction the blades rotate. If clockwise, then it is a right-handed fan. If it’s against it, then it’s left-sided. In case of incorrect connection, it is enough to swap the phases.

For inspection and maintenance, special hatches are installed in the volute. To remove condensate, drain holes are provided in the housing. Large blower fans become very hot during operation, so they are equipped with cooling coils.

Technical characteristics and calculation of parameters

The design of any smoke exhauster for household solid fuel boilers looks something like this:

- Housing or casing for the impeller , made of heat-resistant steel with a thickness of at least 1.5-2 mm;

- motor is usually located outside the housing. This placement guarantees its stable operation, while motors installed in the chimney itself fail faster;

- Shaft connecting the impeller to the engine. Mounted on bearings and can be sealed to prevent smoke leakage;

- Inlet and discharge pipes and outlet valves;

- A special bunker in which ash and large unburnt fuel particles will settle;

- The impeller or impeller is the main element of the circulation pump, made of alloy steel. Withstands temperatures of 250-3000C and the aggressive environment of hot exhaust gases. Must be well balanced and have high performance. There are blade and centrifugal impellers.

The smoke exhauster for a solid fuel boiler has the following parameters:

- electric motor power,

- productivity (cubic meters per hour),

- created pressure.

Preparing for the manufacture of a smoke exhauster

You can make a smoke exhauster yourself. The main thing in a smoke exhauster is an electric motor and a fan . For a home smoke exhauster, a fan with a diameter of 15-18 cm . When choosing an electric motor and fan, you must ensure that they are aligned correctly. It is important to check a used motor and fan. When an electric motor operates with a misaligned fan, vibration will appear, which will create a hum or hum.

To assess the quality of engine alignment , it must be attached to a sheet of plywood. The thickness of the plywood must be selected in accordance with the weight of the engine. The edge of a sheet of plywood with the engine installed must be clamped in a vice, rigidly fixed to a table or workbench. Then you need to turn on the electric motor and, holding the plywood sheet with your hand, evaluate the vibration by touch. If the vibration is weak, you need to attach the fan to the motor shaft and turn on the motor again. If the vibration of a motor with a fan is acceptable, then they can be used for a smoke exhauster.

Making a smoke exhauster with your own hands

If you wish, you can assemble such a device yourself from scrap materials. We only need an electric motor. Everything else can be made independently, although it is better to purchase a factory-made impeller, even if it is used.

Tool you may need:

- Bulgarian;

- Welding machine or inverter;

- Drill, plumbing tool, hammer;

- Ruler, caliper.

The easiest way to manufacture is an exhaust fan, which will be installed inside the pipe. To do this, you will need a small electric motor with a power of up to 1 kW and a suitable impeller with blades. It is mounted on the motor shaft, and its housing is equipped with fasteners for placement in the pipe. When connecting the wiring and starting up for the first time, pay attention to where the air flow will go.

A self-made smoke exhauster for a solid fuel boiler can be seen in the following video.

A design with a volute and a centrifugal fan will be more complicated. The procedure for its manufacture is as follows:

- For a ready-made turbine, we select a piece of pipe with a diameter 2-3 centimeters larger. Cut it to the size of the fan plus 3-5 mm;

- We cut a hole on the side for the outlet pipe, and weld a lid to one of the ends with a hole in the center for the chimney from the boiler. The incoming flow will be perpendicular to the outgoing one; with this scheme, the electric motor is located horizontally;

- The most critical stage is installing the shaft and fan . For accuracy, you can use bushings for centering and pressing the bearing. When the engine is turned on, beating and vibration are unacceptable.

- We weld or screw the back cover and install the engine on the stand. We connect air ducts and electrical wiring.

How to make a long-burning solid fuel boiler with your own hands: instructions, drawing, diagram.

We install a sandwich chimney with our own hands: assembly rules, installation and operation.

How to properly install a smoke exhauster on a fuel boiler

Here are some tips:

- If there is a separate room for the boiler, then the hood is mounted in it for ease of maintenance;

- It is advisable to place powerful chimneys outside the house due to the loud noise during operation;

- The electric motor is protected by a separate circuit breaker, and its control is conveniently transferred to the general heating system control panel;

- There must be free access to the smoke exhauster for cleaning.

Cost of installation of a smoke exhauster

For homemade products, the price is determined by the cost of the electric motor and impeller. The cost of a three-phase electric motor with a power of 0.18 kW starts from 1950 rubles , the simplest blade impellers - from 350 rubles. Add to this the purchase of wires and small accessories. There will be benefits if you can get a used engine.

A ready-made smoke exhauster costs a little more. So, for a device with a capacity of 2000 m3 per hour you will have to pay from 14,000 rubles for an unknown manufacturer to 23,500 for a smoke exhauster from the company Wirbel . Simple blade units cost inexpensively 6-8 thousand rubles. If the installation of a smoke exhauster on a solid fuel boiler is carried out by a specialist, then for the work and turnkey connection you will have to pay up to the cost of the pump itself, depending on the complexity.

Main components of the smoke exhauster

Today, the smoke exhauster is a centrifugal fan, which consists of a limited number of parts and assemblies. They all have their own purpose. So, such a fan consists of:

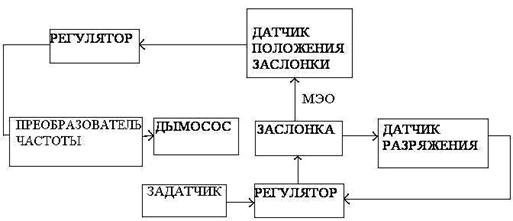

Block diagram for a smoke exhauster.

- Snails. This is a kind of casing, which really resembles this simple insect in its structure. The snail is created in a special way from metal. It is in it that vortex air flows will circulate. This housing allows the unit to operate as efficiently as possible.

- Impeller. It is sometimes called squirrel. Indeed, its design resembles where this animal runs. This wheel consists of two plates. The first one is mounted on the shaft. A bushing is provided here for these purposes. The second plate is used to fasten the blades, that is, metal plates. They have a certain bend angle, which is done specifically to ensure that the air flow works as efficiently as possible.

- Electric motor. This element is the main one for any fan. This also applies to the smoke exhaust device. Today, a wide variety of engine types are used in industry. As for the smoke exhauster or fan, it is best to use asynchronous models. They are capable of operating for a long time on a three-phase power supply. In addition, such units are not that expensive.

Today it is not difficult to purchase them. They are distributed by many specialty stores. Of course, it is best to use smoke exhausters that have the ability to adjust engine rotation. For these purposes, an asynchronous three-phase motor can be equipped with special devices that can have both linear and nonlinear characteristics. Everything depends directly on the specific case.

Right-hand rotation smoke exhausters.

Of course, when installing a fan or smoke exhauster that has high power ratings, additional protection must be connected. In this case, the use of an automation system is implied. It is best if a separate circuit breaker is connected to the panel, which will turn off the motor in the event of an unforeseen situation.

The electric motor is thus protected from many unfavorable factors. Automatic machines are selected depending on engine power. In this case, their current strength should exceed the original smoke exhauster by several percent. Today, such protection devices are used everywhere. They allow you to save the unit if a short circuit or breakage of one of the working phases occurs.

Calculation of ventilation. The principle of computer fan control. How do smoke exhausters work? More details>>

How to make an exhaust unit

The main difficulty in assembling a smoke exhauster with your own hands is making a balanced impeller; the remaining parts are not difficult for a home craftsman who knows how to weld. If the impeller blades vary in weight, normal fan noise will turn into rumble due to vibration.

In addition to the blades, you will need the following elements:

- electric motor with a power of up to 150 W, maximum shaft speed – 1400 rpm;

- snail or homemade box shown in the drawing;

- a shaft with ventilation holes or an additional cooling impeller;

- studs with M8 nuts and other fasteners;

- power cable.

The design of all smoke exhausters is the same

They consist of:

- casing (snail);

- impeller;

- engine.

The impeller blades are made of metal plates bent at a certain angle. The wheel is attached to the shaft using a bushing. Blower fans are equipped with three-phase asynchronous motors. All smoke exhausters are equipped with automatic control and protection equipment. To turn off the unit in emergency situations, it is necessary to install automatic devices depending on the engine power.

Sometimes a metal frame is used to attach the blower fan to the base. It is not mandatory and is made to order, taking into account the smoke exhauster diagram. Frames are used mainly for non-standard installation. There are a total of 6 standard execution schemes, which are selected from the project conditions. In accordance with these schemes, additional equipment is selected.

WPA boost fan and exhaust fan

– these are units with which you can significantly improve the process of operation of equipment that produces thermal energy. Currently, the main heating device for private homes is a solid fuel boiler. Technical progress keeps pace with the times, making it possible to regulate the boiler operating modes automatically using a WPA fan or a smoke exhauster.

The main advantages of using a boost fan for a boiler Recently, WPA boost fans for solid fuel boilers have become very popular. Let's figure out what this is connected with and whether purchasing this electromechanical device is actually advisable.

In order to correctly answer the question posed above, you need to familiarize yourself with the operating principle of a solid fuel boiler. It releases thermal energy due to the fact that fuel burns inside it. In real environmental conditions, it is difficult for a heating device to produce the required amount of heat. There is too little fresh air, as a result of which the draft parameter does not even reach the norm.

What happens when using a blower fan for a WPA solid fuel boiler or a smoke exhauster? First of all, the supercharging unit will have a beneficial effect on the air supply to the combustion chamber, increasing its flow. This leads to an increase in combustion intensity and, as a consequence, an increase in heat transfer.

Smoke exhausters for boiler installations

Steam and hot water boilers are equipped with smoke exhausters. Separate types of fans are sometimes used as smoke exhausters. Temperature of the transported medium up to 400 °C. Smoke exhausters are designed for continuous operation with a long service life. Can be installed indoors or outdoors.

Smoke exhausters of right rotation and left rotation are manufactured[n 1].

Smoke exhausters come in two designs:

- the impeller is mounted on the motor shaft. The unit is smaller in size.

- the impeller is mounted on the shaft of the drive chassis. The unit is reliable and durable, but requires more drive power.

The main characteristics of the smoke exhauster are performance and pressure (pressure).

The performance and pressure of the smoke exhauster are regulated by an axial guide vane or a suction pocket with a damper. The suction pocket delivers gases more smoothly to the blades of the impeller and eliminates swirling of the flow, therefore, the efficiency of the smoke exhauster increases.

The smoke exhaust body (scroll) can be rotated when installed at angles of 0…270°.[n 2]

Main advantages of WPA fan

It is worth noting that the modern market of heating devices and accessories offers several models of electromechanical devices. Perhaps the most popular is the WPA fan from MplusM, which has its main representative office in Poland. This organization is engaged in the production of turbines designed for solid fuel boilers.

Why should you buy a WPA fan? It's all about the quality of his execution. The Polish company MplusM uses materials with a high degree of strength in the production process, which indicates the reliability and long service life of the WPA unit. Among other things, this WPA model is perfect for all types of solid fuel boilers. The Polish WPA fan can be used both in everyday life and in industry.

Take into account the fact that it is not difficult to buy a WPA fan in Moscow, but the most important thing is not to run into a fake. offers a wide range of original units from the Polish organization MplusM. WPA fans are in stock and available for immediate order.

Smoke exhausters DN

Smoke exhauster (fan) DN price from the manufacturer

DN brand draft machines are used in technological ventilation systems to remove combustion products from the combustion chambers of hot water and steam gas-oil boilers, and can also be used to supply air to furnaces and in other industrial ventilation systems (for example, for ventilation of grain elevators).

Design Features

Smoke exhausters DN belong to the ventilation equipment of one-way suction, structurally they have the form of a snail with an electric motor. The following can be identified as the main design elements.

Frame.

The frame of the draft machines has a welded structure made of standardized rolled steel of ordinary quality and is attached to the building floor using anchors.

Frame.

The housing of DN smoke exhausters has a spiral configuration (“Snail”). The inlet and outlet pipes are round and rectangular in shape, respectively.

To connect the unit to the ventilation ducts, the nozzles are provided with flanges with holes for installing bolts. To give the body additional rigidity, additional stiffening ribs are located on its outer sides.

The housing part has the ability to rotate angularly relative to the support frame - when installing the equipment, the housing can be set at the required angle to the exhaust air duct.

Working wheel.

An impeller (impeller) of radial type with 16 blades is installed inside the volute of the smoke exhauster DN. Torque from the engine is transmitted directly (the wheel hub is rigidly fixed directly to the rotor). Based on the direction of rotation of the impeller relative to the electric drive, DN smoke exhausters are divided into “Left” and “Right”.

Manufacturing options:

DN draft fans are manufactured in 11 standard sizes, differing in aerodynamic characteristics (total pressure, performance, etc.). The choice of blowing machine model is carried out based on specific operating conditions and purpose. Smoke exhausters DN can be manufactured according to 2 design schemes: scheme 1 and scheme 3. If you wish, you can give us the initial data, and we will choose the optimal version of the draft unit.

terms of Use

DN fans are designed for operation in the third and second categories of placement (in closed, unheated rooms or under a canopy, respectively).

The operating temperature range of the equipment is from -30°С to +40°С.

Features of the smoke exhauster

An exhaust fan or smoke exhauster for a solid fuel boiler is an indispensable unit for every country house. Its main task is to ensure the safe use of the heating device and maintain its overall operation. The smoke exhauster does an excellent job of removing smoke and other particles that contribute to air pollution. But the functions of the smoke exhauster do not end there.

In any large region of Russia you can buy smoke exhausters. Moscow has a particularly wide range. How not to make a mistake when choosing an exhaust fan and will its purchase be justified?

The main advantages of using a smoke exhauster In cases where the chimney does not have sufficient ventilation, purchasing an exhaust fan is mandatory. But in other cases, it is advisable to buy an exhaust fan because of its advantages. The smoke exhauster helps reduce fuel consumption in the boiler. The smoke exhauster protects the chimney from tar and soot. The amount of generated thermal energy increases when using a smoke exhauster. The smoke exhauster prevents the spread of burnt smell and smoke throughout the house. The smoke exhauster directly affects the functionality of the boiler. The smoke exhauster eliminates the odor that often arises during boiler operation.

Returning to the issue of choosing a unit, it is worth considering that powerful models operate smoothly even in bad weather. Neither strong wind nor precipitation will prevent the smoke exhauster from getting rid of the generated smoke.

It is important to remember that a solid fuel boiler will serve you for a long time only if it operates correctly. In order to obtain a high-quality result and high heat transfer, it is necessary to provide conditions in which combustion products are removed as completely as possible. For this you need a smoke exhauster, which is an important and integral part of the heating device.

Why should you start working with? A large selection of different models of boost fans, including WPA and smoke exhausters for domestic solid fuel boilers. You can buy them at a competitive price. Cooperation only with reliable and trusted manufacturers, including the Polish company MplusM, whose models of WPA units are in demand on the market. All presented products of WPA boost fans and smoke exhausters are made of high-strength materials, which guarantees a long service life. Loyal working conditions for our clients. Possibility to quickly place and receive an order. WPA fans and smoke exhausters are available. There are several options for delivering goods to any city in Russia.

The principle of calculating the power of the smoke exhauster

If there is insufficient traction, experts will advise making appropriate calculations to understand how the situation can be corrected. When choosing a solution in favor of a special device, you will also have to organize a calculation of the power of the smoke exhauster for the boiler. This will not be difficult to do, especially since all the formulas have long been derived and tested in practice. Then all that remains is to select a device that matches the obtained parameters.

Forced ventilation for the heating system will make the following improvements:

- — increase the efficiency of the boiler;

- — fuel consumption required to generate a kilowatt of energy will be reduced;

- — draft will improve and combustion products will not enter living quarters;

- - you don’t have to redo the chimney or modernize it.

These improvements apply to any heating system, regardless of its type.

Designation of the smoke exhauster

The designation is set by the manufacturer. But the established notation system is generally accepted.

Smoke exhausters in thermal power engineering

The designation consists of the brand, number of the smoke exhauster and rotation speed in revolutions per minute. Smoke exhaust brands:

- D - with forward-curved impeller blades.

- DN - with backward-curved impeller blades.

- DRG - Gas recirculation exhaust fan

- DOD - Axial two-stage smoke exhauster

- DC – Cement smoke exhauster

- YES - Smoke exhauster (for the aluminum industry and sinter plants)

- GD - Hot blast exhaust fan

VDN brand fans can be used as smoke exhausters.

Fire smoke exhausters

Firefighter portable smoke exhausters are designated by drive type:

- DPE is a portable electric motor (centrifugal, centrifugal mobile, axial turbocharged, axial turbocharged mobile).

- DPM is a portable motor-driven smoke exhauster (centrifugal fire engine, axial turbocharged fire engine).

- DP - trailed smoke exhauster.

The number of the smoke exhauster is the nominal diameter of the impeller in decimeters, measured along the outer edges of the blades, for example, DPE-7.

Limitation of use

The content of dust and other solid impurities in flue gases should not exceed the value established by the manufacturer. This value is higher than for fans. To protect against the abrasive effect of ash, hard alloys are fused to the blades of the smoke exhaust fan during manufacturing.

The temperature of the gases must not exceed the value established by the manufacturer. It can be:

- up to 200…250 °C, if the impeller is made of carbon steel

- up to 400 °C, if the impeller is made of low-alloy steel 09G2S

Blower fan

This mechanism consists of: a running gear, a casing-volute with two pipes - inlet (suction) and outlet (discharge), - an impeller and a guide vane.

- The chassis is formed by a shaft mounted on a pair of bearings (ball or roller). It is entirely in an oil bath with a lid and pan. The oil in the bath is spindle or turbine. Control devices for checking the condition of the oil are a thermometer and a level indicator. The oil is cooled by water supplied through a pipe designed for this purpose.

- The impeller is a disk with blades with ends connected to each other by a ring. The blades are welded or riveted. The disk is attached to the shaft by means of a sleeve (hub) welded to it. Rotating, the fan impeller creates a vacuum in the area adjacent to its center. The air sucked through the air duct to the center of the wheel is thrown away from the center to the peripheral zone by the centrifugal force created by the wheel blades. Under the influence of this force, it is forced into the air duct and enters further into the fuel combustion zone.

- The guide vane is used to regulate the speed of air supply to the firebox. Its location is the suction pipe located in front of the fan. The device is a metal pipe with mounting flanges. There are rotating blades inside it. These blades rotate to the same angle simultaneously using a common rotating mechanism. The profile of the blades is such that they direct the flow of incoming air directly in the direction of rotation of the fan rotor. This helps reduce air resistance and, accordingly, eliminate unnecessary energy costs and increase the performance of the mechanism.

Of the blower fans, the most popular are the products of the VD series with modifications from 6 to 20. Here, the numerical value also reflects the diameter of the impeller in decimeters.

Since the performance of fan devices is displayed in cubic meters per unit of time, blowing mechanisms are selected based on lower values of this parameter than smoke exhausters. This is due to a strong increase in air volume when its temperature rises by hundreds of degrees.