Home / Plumbing / Equipment / What is the service life of metal-plastic pipes for water supply and heating

Metal-plastic pipes are used in those areas of human activity where strength and durability are required.

Metal-plastic pipes (MPP) are intended for installation of water supply, heating systems, and heated floors.

MPTs have found application in many areas; the main advantage of such tubular products is their operating time, subject to installation rules and operating conditions. pipes last from 35 to 50 years.

Composition and production

For domestic use, products are manufactured in accordance with GOST R 53630-2009.

The standard is intended for the manufacture of pressure multilayer pipes with a round cross-section, which are intended for transporting water, including drinking water, and for installing water supply and heat supply.

MPTs consist of several layers of plastic, metal and special glue:

- layer - internal, in constant contact with liquid, plastic;

- adhesive layer;

- barrier layer, thin-rolled aluminum or fiberglass;

- adhesive layer;

- layer - outer, exposed to environmental influences, plastic.

The adhesive composition consists of composites based on thermoplastic polymers with adhesion to layers and a melting point of 120 degrees. Plastic components for the inner layer are produced based on the following polymers:

- cross-linked polyethylene, with a strength of 8 MPa (what tools you will need to buy for pipe installation);

- polyethylene with increased heat resistance and strength from 8 MPa;

- polypropylene with a strength of 8 MPa;

- polybutene with a strength of 12.5 MPa.

Do you know the installation height of the heated towel rail? Instructions on how to equip a bathroom with year-round coolant are posted in a useful article.

About polypropylene or cross-linked polyethylene for heating is written on this page.

The metal layer is made of thin aluminum or fiberglass tape. The outer layer is made of polymers with low oxygen permeability.

The production of MPT is a complex high-tech process.

Molten polymers are uniformly fed into molding mechanisms, where the layers are glued together. At the same time, pipes are formed along the outer and inner diameters.

At the exit, the product enters cooling tanks, after which it is cut or wound into coils.

The use of polymers and metal made it possible to use the advantages of each material, achieving a combination of useful characteristics from pipes.

Polymer layers protect the reinforcing aluminum layer from corrosive processes. Metal makes products flexible, increasing fracture toughness.

Thanks to this combination, the pipes can withstand the temperature of hot water without changing their technical characteristics (read this article about the use of cold welding for pipes under pressure).

Modifications and markings

To extend the service life of polypropylene pipes, it is necessary to take into account the markings. Below are the most common modifications:

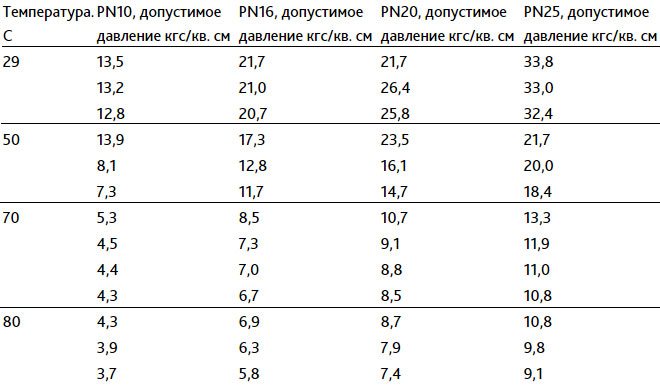

- Type PN-10 is designed exclusively for systems with a carrier pressure of no more than ten atmospheres. This includes pipelines with cold technical or drinking water. The permissible heating temperature of the liquid is no more than 45 degrees Celsius. These products are among the cheapest options.

- The PN-16 index indicates that the pipes are suitable for installation in systems with a maximum pressure of no more than 16 atmospheres. The media temperature is allowed up to +60 °C.

- The N-20 series is well resistant to the use of centralized heating systems, operating pressure is up to 20 Atm, the maximum coolant temperature is +95 °C.

- The PN-25 marking indicates that the pipes are reinforced with reinforcing aluminum foil, which gives the product additional strength. Most hot water supply and heating structures are equipped with just such elements; they can withstand 25 atmospheres and a working fluid temperature of 95 °C.

It is necessary to select polypropylene pipes taking into account their use in a hot or cold circuit, because their service life depends on technical indicators.

Characteristics and technical description

Pipe products have not only technical characteristics, but also operational ones.

When purchasing metal-plastic products , you make a choice according to all characteristics.

Some technical details can tell a plumber a lot about pipes, but are incomprehensible to the average person.

When choosing an MPT, we are guided by the following technical parameters:

- external diameter , products are produced with an indicator from 16 to 63 millimeters;

- wall thickness , pipes with a thickness of 2 and 3 millimeters are produced;

- the thickness of the reinforcing layer , depending on the purpose, is 0.19-0.3 millimeters;

- the weight depends on the length and diameter (find out about the weight of steel, galvanized pipes on this page);

- operating pressure – up to 10 bar for hot water, up to 25 bar for cold water;

- short-term temperature exposure up to 110 degrees.

You can select an MPT for a water supply system based on operational data.

They do not give numerical characteristics, but reflect the reaction of the material and product to certain influences.

The main performance qualities are:

- no harmful impact on the environment;

- rust, scale, and mineral deposits do not form on the pipes;

- products regain their shape after bending;

- plasticity will allow you to bypass the elements of the premises and save on stainless steel fittings (described here);

- installation is carried out without the use of special tools (compression fittings);

- no waste after assembly is completed;

- smooth inner surface facilitates water flow;

- MPTs are compatible with pipes made of other materials;

- resistant to condensation and freezing;

- the composition of the water remains unchanged;

- used for re-installation;

- do not require external paint coating.

What do you know about cross-linked polyethylene pipe fittings? In this useful article, read about ways to install innovative products.

What diameters can ceramic pipes have is written here.

On the page: it says what the cable for cleaning the sewer is called.

The positive qualities of MPT are due to the design features and materials used.

The combination of the strength of metal and the flexibility of plastic makes the pipe plastic, with the ability to restore its original shape.

Durability options

Industrial production offers consumers polypropylene pipes of various diameters and wall thicknesses. These characteristics determine the scope of application of plastic products.

Each category of products has its own markings and corresponding technical characteristics. For polypropylene products, the letter marking PN and digital marking are used, indicating the maximum permissible pressure.

Categories of polypropylene pipes:

- PN 10. Polypropylene pipes with a diameter of 20 to 250 mm are produced under this marking. They are designed for transporting and supplying cold and warm liquids and gases under pressure. The maximum permitted temperature is 45°C, the optimum for the stated service life is 25°C. Pressure is indicated by the number 10 and means 1 MPa (1 MegaPascal, which is about 10 atmospheres).

- PN 16. The purpose of the products is similar to the first. Permitted temperature - 60°C, pressure 16 atmospheres.

- PN 20. This category of products allows their use for hot and cold water supply, water heating, and drainage. Maximum temperature 75°C, permissible pressure 2 MPa.

- PN 25. Products in this category are made with reinforced walls with aluminum foil or fiberglass. They have a more rigid structure and are less susceptible to thermal expansion and deformation. Used for installation of heating (water) and hot water supply systems. Withstands pressure of 24 atmospheres.

We recommend that you read: What are reinforced polypropylene pipes?

When choosing products, you should pay attention only to the labeling. The color of the pipes does not convey information, with the exception of black ones. Black polypropylene pipes are more resistant to ultraviolet radiation.

Disadvantages of MAT

The correct choice takes into account both the negative aspects of operation and installation of pipe metal-plastic products.

There are a few of them:

- hidden installation does not allow the use of dismountable connections;

- the polymers contained in the pipes are destroyed by prolonged exposure to ultraviolet radiation;

- When exposed to cold water for a long time at low temperatures, the pipes burst. It is necessary to use heat-insulating materials.

Pipes are supplied in coils . The length of the bay is 50-200 meters. When selling, products are cut to size.

Areas of use

The spread of metal-plastic pipe products is explained by a number of technical features:

- internal cold and hot water supply;

- heating of premises (how to remove air from the system in a private house);

- floor heating structures, sports grounds, swimming pools;

- movement of liquids and gases, including chemically active ones, in enterprises and agriculture;

- compressed air supply;

- air conditioning system pipelines;

- protective frame for electrics;

- production of ships and wagons;

- water supply for watering , irrigation activities, drainage of water from water pumps.

Such a pipe replaces products made of plastic and alloys . The reason is the long service life.

Operating rules

During installation and operation, the technical and operational characteristics of metal-plastic pipes are taken into account.

This made it possible to reduce the harmful effects on the products and to use the pipeline for the prescribed period.

- Where pipelines are laid There should be no mechanical or high temperature impacts on the pipes.

Avoid direct exposure to ultraviolet rays.The pipes are mounted on holders that are located at a distance of 50 centimeters from each other.

The holes in the walls are equipped with sleeves through which pipes are mounted.

- Heating installation determines the service life of the MPT. In a private house they use a two-pipe system with a collector.

The use of "Leningradka" is undesirable.For a small number of bends, a tee is used.

- Operating pressureexceeding 10 bar destroys the pipeline structure.

In your home, where the pressure does not exceed 7-8 bar, the pipes are operated normally.In apartment buildings, at the time of pressure testing, the pressure rises to 25 bar.

In such systems a pressure reducer is installed.

- Polymers and metal have different coefficients of expansion when exposed to heat.

Pipes that are used to supply cold water cannot transport hot water.In this case, the product begins to delaminate and leaks appear.

During installation, connecting elements made of appropriate materials are used.

Hot and cold pipelines passing nearby are not located closer than 30 centimeters.

- Installation of MPT structures is carried out at an ambient temperature of not lower than plus ten degrees.

IMPORTANT! Do not use metal-plastic pipes for installing heated floors in cold rooms.

The use of MPT outdoors and outbuildings is recommended only in warm weather. In winter, water is drained from such pipelines.

A service life of half a century and the price-quality ratio allow metal-plastic pipes to successfully replace products made from other materials.

What condition are metal-plastic pipes in after 7 years of operation, see in the proposed video.

Subscribe to updates by E-Mail:

Disadvantages of polypropylene pipes.

When installing home heating

A reasonable question arises about the required plumbing materials and the types of pipes used for the work. The best choice is to purchase polypropylene pipes of various sizes for any category of room.

Selection of polypropylene pipes.

Disadvantages of polypropylene pipes

Today, the market offers a huge variety of pipes with PVC wrapping, internal and external reinforcement with fiberglass or aluminum. The installed pipeline is resistant to corrosion, without the formation of condensation, and will last for quite a long time without repair work or its complete replacement if installed correctly and with high quality in compliance with all technological rules and nuances. All the operational characteristics of the pipes indicate their obvious advantage over metal-plastic or cast iron when installing heating distribution in various rooms. Disadvantages of polypropylene pipes

are associated with the wrong choice of size, type of product or improper assembly.

Simple polypropylene pipes can undergo significant deformation when heated, losing their aesthetic appearance and creating preconditions for damage to the shell and surrounding objects. The most resistant reinforced types of pipes. With internal reinforcement, it is possible to change shape when overheated, but at the same time they are most optimal for installation in heating systems of houses and cottages due to their small overall dimensions and quick installation work. With external reinforcement, some defects in the top layer occur, which can lead to swelling during operation, so the choice of the required type of pipes should be made only from reliable manufacturers who have proven themselves to be the best in this niche. Handicraft products can be attractive with a low price, but the period of use may differ significantly from a high-quality product, and all the shortcomings of polypropylene pipes

will be revealed in the very near future.

Installation of polypropylene pipes.

When installing home heating

For reinforced polypropylene pipes, it is recommended to pre-treat the ends with a special trimmer or file, especially with a reinforcing layer of aluminum. This guarantees the reliability of the connection of the pipe ends without delamination and destruction of the reinforcing composition. With a reinforcing layer of fiberglass, trimming work can be omitted, because melting when welding the ends is carried out evenly. The sized pipes are heated and connected using a fitting. And now part of the pipeline is already ready. All other sections are connected in the same way. The listed works are carried out by competent, qualified specialists of the company, taking into account all the nuances of the location of heating devices and wiring throughout the house or cottage. This helps to save significant money on reworking incorrectly installed systems, avoid various emergency situations and allow all family members and guests to enjoy comfort and warmth in every home.

Similar services:

- BAXI boiler Small dimensions and undoubtedly high performance allow us to classify BAXI boilers as innovative and modern equipment. They are quite often used when designing heating systems from scratch,......

- A quality house starts with a pebble When the time comes to build global buildings, it is worth thinking about the quality of their foundation and the composition of materials. The level of...... depends on the properties of those products that are used in construction.

- Block house and floorboard: reasons for popularity Block house and floorboard: reasons for popularity In modern Russia, individual housing construction is developed in almost all cities. Despite the difficult times, people continue...

- Industrial boilers are a constant supplier of heat. Modern manufacturers of machinery and equipment produce a huge number of units of devices that are firmly entrenched in the everyday life of every person and entire industries. So today there are a large number of......

- Homemade boiler room Homemade boiler room.1 Homemade boiler room.2 Performing boiler room installation services.3 Heating in a country house.4 Installation of a boiler room from the company Design Prestige.4.1 House heating4.2 Cottage heating4.3 House water supply4.4……

- What are the advantages of professional apartment design in Reutov? Are you planning a renovation? In this case, it would be a good idea to pre-order an interior design project so that subsequent work is carried out strictly according to the approved sketches. It makes sense to invite a professional designer even......

- Installing a gas boiler on the wall Installing a gas boiler on the wall.1 Installing a gas boiler on the wall.2 What equipment is installed on the wall? 3 Installation of a gas boiler on the wall4 Installation of a wall-mounted boiler from the Design company......

- Cooperation with Steelrex: profitable and convenient I have a small store of building materials, I opened it next to a complex of new buildings, assuming that the owners of new housing would definitely need various materials and tools. Basically, no......

- Advantages of Copper Pipes for Heating Copper pipes were used in ancient times to supply water when steel and cast iron were not produced. Today, copper pipes for various pipelines are the best, let......

- How to correctly determine the material for thermal insulation of a home? Today, there is a special need to reduce energy costs, which means the question arises: “How to insulate walls?” It is worth noting that by insulating the walls, you......

- Are sliding doors difficult to install? As it becomes obvious, installing sliding doors is quite simple. You will see this if you purchase a ready-made kit. To separate part of a room or to hide......

- Frozen water supply Winter, as a rule, comes unexpectedly and brings many surprises. Unfortunately, they are not always pleasant. Owners of private homes often encounter frozen water pipes. Solve this......

- Repair without much hassle No matter how strange it may sound, repairs can be done without much hassle, refuting the generally accepted opinion that equates it to a natural disaster. If such a decision is made, you should......

- How to decorate a house in the Art Nouveau style In culture, the Art Nouveau style appeared at the end of the nineteenth century. Its main feature at that time was that it was completely original and did not incorporate…

- Reconstruction of buildings and industrial premises Reconstruction includes many different actions performed on the building. Reconstruction is the complete remaking of something old into something new or different. This may include......

- A new solution for repairing and replacing an old pipeline Undoubtedly, installing heating with plastic pipes is much cheaper than copper, therefore, most people install plastic pipelines without thinking that they will need to replace the pipes very soon. How……

- Insulation for walls in Moscow Insulation of housing is one of the main stages of construction. Not only comfortable living in the rooms, but also the service life of the house depends on the quality of this work.

- Our hosting The site is maintained by the company hostsity.ru…

- Wood heating is a good alternative Wood heating is a good alternative.1 Wood heating is a good alternative.2 Speaking about the advantages of wood heating in general, we should first of all note the following: Wood heating is the oldest......

- How to choose heating pipes My home is my castle. Everyone has heard this proverb at least once in their life. Folk wisdom, as you know, is never wrong. Indeed, everyone is in a hurry with pleasure......