Among the wide variety of shut-off equipment, ball valves are especially popular due to their reliability and convenience. This type of tap was invented more than a century ago, but gained popularity relatively recently, with the advent of polymer materials. They are used in everyday life and in industrial enterprises. Let's take a closer look at the design of a ball valve for water and figure out how to choose a truly reliable and durable option.

The ball valve is used as a shut-off (shut-off) valve on water supply pipelines, including hot water, as well as in heating systems. The simple operating principle ensures long service life and ease of use.

Increasingly, ball valves are being used instead of conventional valves, since the latter are more reliable, require less repair and are very easy to use. But like any device, it can break. Without knowing its structure, you should not undertake repairs. So first you need to understand how it works.

Classification

Ball valves can be divided into two types:

- plumbing;

- mixer.

Taps can be installed between water supply elements and also serve as an end point. In the first case, they will be shut-off; in the second, they serve as water collection points; they are also installed in residential buildings and apartments - in kitchens and bathrooms. The second option is most often represented by mixers.

A mixer is a mechanism that is used to mix two streams of water - cold and hot. Thus, the mixer is used to regulate not only the water supply pressure, but also to regulate the flow temperature. Shut-off ball valves are divided into:

- walkthroughs installed on straight sections of the pipeline;

- angular, mounted at a pipeline turn at an angle of 90 degrees;

- three-way, used to divide the flow into two parts. The separated flows are sent to different branches of the pipeline.

Classification of ball valves

The throughput diameter of the crane determines its permeability. Based on this parameter, full bore and part bore products are distinguished:

- A full bore valve has an opening the same diameter as the diameter of the pipe. The fittings ensure that the flow pressure is maintained with a low level of hydraulic resistance.

- A partial bore valve has a diameter of the hole in the ball that is smaller than the diameter of the pipe into which the fittings are mounted. Of the two types of water ball valves, partial bore products are usually chosen because they are cheaper.

The advantages of partial bore valves are low price, light weight and compactness. However, these advantages are achieved at the expense of service life and convenience. If even a small loss of media is unacceptable, it is better to choose a full bore valve.

The type of connection of the valve to the pipeline is of particular importance. The method and characteristics of the connection affect further repairs, the tightness of the joints and the operating characteristics of the system as a whole. Possible options:

- Welded valves are made of steel in accordance with GOST standards. To install a faucet, you don’t need to think about the thread; just weld the product onto the prepared section of pipe. Welded fittings are used for aggressive environments where protection against system depressurization is important. The downside is that if the product fails, you need to cut off the entire valve along with a piece of pipe and weld a new product.

- Flange valves have a large diameter and are used for liquid and gaseous media that do not require perfect sealing. By design, flanged products are two-piece and three-piece. The three-part design greatly facilitates repair and operation, since it allows you to change gaskets without dismantling the fittings.

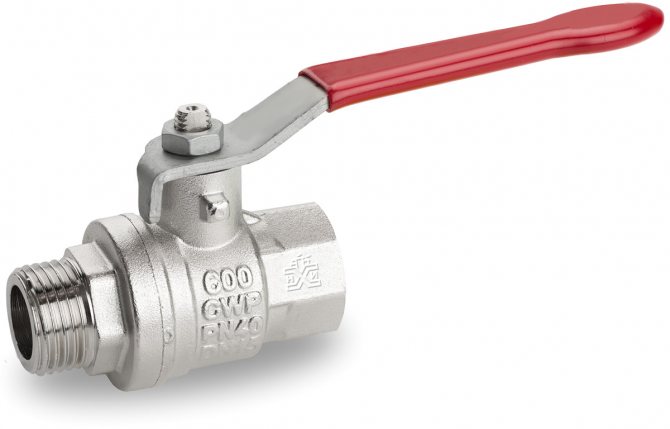

- Coupling taps - are connected via a thread, allowing repairs without complete dismantling. This is the most common type of ball valves for water supply in housing and communal services.

- Combined fittings - there may be a flange at one end of the pipe, and a welded part of the tap at the other. This type of product is extremely versatile and ensures that the functionality of the valves is adjusted to the operating conditions in a particular pipeline.

Taps can change the direction of flow or have no effect on it. This type of fittings is also used to combine and separate flows. Taking into account the specified functionality, there is the following classification:

- Pass-through products do not change the direction of the working medium.

- Angle products are designed for installation at bend points and in hard-to-reach areas of the pipeline.

- Three-way valves - equipped with two inlet pipes and one outlet pipe. The simplest example is a mixer for cold and hot water.

- Multi-way valves are used for separation and mixing of flows.

Design features

Like any water tap, the product has a body with a spout and a movable element. The body can have different shapes, depending on the design of the product and its purpose. The moving element is the same for all models.

This is a ball, hollow inside and cut off on two opposite sides. The ball is secured in sealing rings. Water passes through the hole in the ball, while in household taps the size of the hole corresponds to the size of the pipe, which is why they are called full bore.

When the tap is fully opened, there is no hydraulic resistance to the movement of water. If the ball is rotated 90 degrees, the water passage will be completely blocked.

Advantages

Ball valves have gained wide popularity due to their design features. Among the main advantages:

- Long service life;

- High degree of tightness;

- Aesthetics;

- Ease of use and ease of installation.

In addition, ball valves rarely require repairs; as a rule, the trouble-free service life of these devices is several decades. However, collapsible models can be repaired if problems arise. You can do the repairs yourself, since their design is simple.

Advice! Ball valves are recommended to be installed on pipelines through which liquid that does not contain a large amount of impurities is transported. Otherwise, the fluoroplastic gaskets may be damaged and the faucet will require repair.

Operating principles and scope of application of ball valves

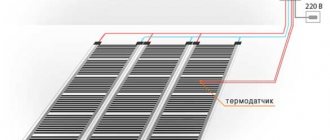

The trouble-free operating mechanism of the ball valve is ensured by its simple and functional design. The bolt, which is a ball with a through hole, is located inside the seat (metal or plastic body). The hole parameters must match the stroke and outlet dimensions of the ball valve. The ball valve is connected to the handle and rotates with it. The rotation of the ball occurs relative to its own axis, which is located arbitrarily relative to the flow. The opening and closing process looks like this:

- When the ball valve orifice is in the open flow position, water flows freely without pressure drops or other obstructions.

- When the ball valve is turned 90 degrees (this happens when the tap is closed), the flow of media collides with a blank wall and the movement stops.

Ball valves are versatile and are used in pipelines intended for transporting various media: gases, liquids, media containing solid particles. This type of fittings is also suitable for pumping aggressive media such as bitumen, oil, alkalis, acids, rubber, ethylene, hydrogen peroxide.

The ball valve has several important advantages:

- Light weight and compact.

- Convenience and durability.

- The design works in any orientation in space.

- Avoiding stagnation of water flow.

- Low level of media loss during operation.

- A high degree of tightness of the connection with the pipeline is maintained.

- The balance between cost and quality is in favor of the consumer.

This type of fittings has its disadvantages. For example, without prolonged use, the product may turn sour, so it is recommended to open and close the tap weekly. If the media contains a large amount of foreign matter, the hole may become clogged. For example, tap water with rust particles quickly damages taps.

It should also be taken into account that ball valves in water supply pipelines operate properly only at above-zero ambient temperatures. If the temperature drops below zero, the water inside the pipes will turn to ice, which will cause the ball mechanism to rupture from the expansion of the media. All of the listed disadvantages can be avoided by choosing the product wisely, taking into account the type of pipeline, type of media and operating conditions.

Faucet materials

Today, the industry produces ball valves from various materials. Most often used:

- Different grades of steel (carbon, stainless, with modifying additives, etc.).

- Brass and other copper alloys.

- Polymer materials.

Plastic

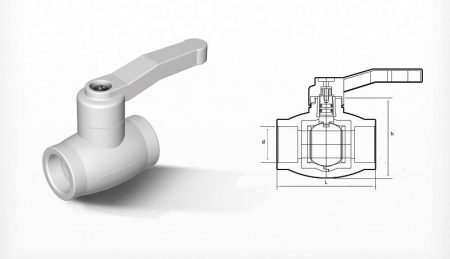

Plastic taps are a relatively new type of shut-off valve. Polypropylene and polyethylene are used to manufacture products. Their main advantage is resistance to corrosion, including when transporting aggressive agents.

However, they are not suitable for installation on pipelines that transport hot liquids. When exposed to high temperatures, deformation of individual elements and, as a result, loss of tightness is possible.

Steel

Cranes with steel elements are used, as a rule, in production and for equipment of main pipelines. This type of product can be used when it is necessary to transport hot liquids, as well as liquids under pressure.

Made of brass

Brass taps are the most common type; they are widely used both in everyday life and in production. They are made using two technologies - using casting or forging. As a rule, forged products are a more reliable option, since during the casting process, areas with a non-uniform metal structure may form.

Since the alloy contains lead and zinc - materials that are highly susceptible to corrosion, a layer of protective coating is applied to the products by galvanic means.

Advice! It is recommended to use where the ambient temperature does not exceed 150 degrees. Otherwise, the metal is “washed out” and the material becomes porous.

Characteristics and dimensions

As mentioned above, before purchasing, it is recommended that you familiarize yourself with the dimensions of the locking devices. For example, the classification of ball valves for water is based on the diameter of the passage inside the product. In addition, the devices differ in the type of thread coating and operating pressure.

Once you know the size of the internal passage of the ball valve, you can determine the purpose and frequency of use of the locking mechanism. Thus, mechanisms with sizes of 1, 1.25 or 1.5 inches indicate infrequent use and are not designed for constant loads. Otherwise, the device will fail.

In everyday life, products with a diameter of 0.5 (about 12.5 mm) or 0.75 inches are used. The first option is excellent for water supply, and the second is for heating systems with a circular pump. If the circulation is based on a natural working environment, pipes with a diameter of 40-50 mm will be required. Otherwise, you can get by with narrower products.

Of course, there are other models with an even larger diameter, but they are installed purely in production or at special facilities. In everyday life, products with a diameter of 0.5 to 1.5 inches are quite sufficient.

How to choose a quality faucet?

When purchasing, you need to carefully consider your choice so as not to accidentally purchase a fake. It must be said that ball valves are in great demand, so products from well-known companies are often counterfeited at home. Naturally, fake faucets will not last long, so you need to carefully inspect the product before purchasing. Useful tips:

- First, you should look at information about taps and mixers on the Internet. Having chosen the appropriate model, you should remember the size and weight of the product, as well as the marking features.

- When you arrive at the store, you will need to carefully examine the model and check that the markings match the original. All information must be presented clearly, without distortion in the inscriptions.

- Next, you will need to inspect the body of the product to identify cracks, irregularities, sagging and other defects. The thickness of the walls of the housing must be the same.

- Now you need to use a small magnet to check what the body is made of - steel or brass. Since steel taps are not produced for domestic use, the presence of magnetic properties in the metal body should be alarming.

- Of course, to determine “by eye” the quality of the material from which the body is made, this will require at least cutting the faucet, but sellers naturally will not allow this to be done. Therefore, when choosing, you will have to focus on price. An excessively low price should alert the buyer, since a high-quality mixer cannot be cheap.

So, ball valves are a fairly popular model of shut-off valves. This type of product is used both in everyday life when equipping an apartment or house, and in industry, for example, in the construction of main pipelines.