Producing biodiesel at home

Technological scheme for biodiesel production.

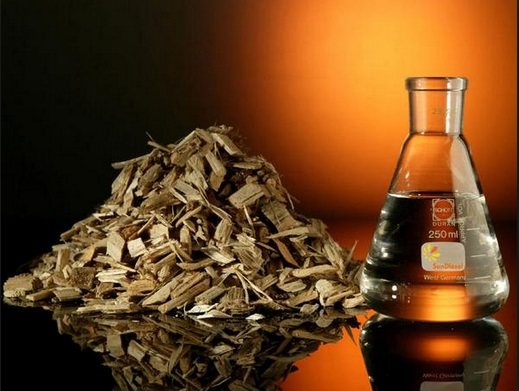

Making biodiesel with your own hands is quite simple. Let us immediately note that in order for production to be profitable, you need to have your own vegetable oil. Any will do: sunflower, rapeseed, hemp, etc. You will also need the purest possible methanol. You can take undiluted alcohol. In addition, you will need a catalyst; in artisanal conditions, soda is suitable for this purpose.

Please note that it is difficult to obtain high-quality biodiesel at home; the production of such fuel is technologically more difficult. Biofuel is passed through several different filters, the last one retains fractions with a diameter of 1/5 of a human hair. It is unlikely that it will be possible to assemble such installations in the backyard, so we will limit ourselves to a low degree of cleaning, which is quite sufficient for the normal operation of heating equipment.

The better the purity of biodiesel, the less it clogs burner nozzles.

The easiest way is to buy equipment for the production of biodiesel, and the price is not too high - about 9 thousand rubles. Such installations can be assembled independently, but without understanding the production principle this is impossible. To make biodiesel at home you need:

- take vegetable oil and heat it - the temperature should not exceed 60 degrees, optimally 55-58 degrees;

- dissolve soda in alcohol and add the mixture to the heated oil;

- maintain temperature and stir for 40 minutes;

- let it sit - the glycerin will settle and can be drained.

The use of equipment for the production of biodiesel is also convenient because the components are mixed in the correct proportions. When making it yourself, 0.98 kg of oil requires 0.125 kg of alcohol, in which 0.024 kg of soda is dissolved. The output will be 1 kg of biofuel and 0.12 kg of glycerin. Decide for yourself how to use glycerin; its scope is very wide.

If a leak appears, then local repair of copper pipes is ineffective; part of the damaged circuit must be replaced.

A detailed diagram of the greenhouse heating system is on this page.

DIY methods

There are many options for producing biofuel at home. We will consider these options.

Biofuel from manure

Biofuels from manure are produced by fermenting organic waste. The mixture is placed in a special sealed bunker for a long time. As a result of the evaporation of the liquid, gas is released, which can be used for heating residential premises or for cooking and liquid fertilizer, which is the basis of organic farming.

Products grown using such fertilizers are environmentally friendly and their sales value increases compared to products grown using pesticides and other chemical fertilizers.

Biogas production

The second product that we obtain as a result of manure fermentation is gas.

To obtain gas from this raw material, the following is used:

- manure;

- bird droppings;

- toilet drains;

- food waste;

- plant matter;

All raw materials must be crushed, otherwise the pipes intended for the removal of waste raw materials may become clogged.

You can also obtain gas at home. To do this, you need to purchase a gas-tight container. This container must be sealed, since air should not come into contact with the resulting gas.

Then you need to place the raw material (manure) inside this container, heat it a little and wait 5 days. Then, collect the resulting gas in a container and use it at your discretion. You can assemble a device for producing biogas yourself, or you can purchase it from a company that specializes in selling this equipment.

Coal for creating biogas

To create biofuel, charcoal can also be useful, the same coal that we cannot do without in nature when frying vegetables and barbecue. You can buy it at the store, or you can make it yourself.

Coal can be made at home in 2 ways:

Let's consider each method separately. And after that you will be able to make coal yourself.

To make charcoal in a barrel, you will need, strictly speaking, a 200 liter barrel. At the bottom of the barrel we make a fitting for pumping oxygen. Then we build a fire in a barrel, gradually adding logs.

When the barrel is half filled with firewood, we begin to pump in oxygen. To do this, you can use a vacuum cleaner. After this, the amount of smoke will decrease and the fire will burn better. When the logs burn out a little, you need to close the barrel with a lid and cover the existing cracks with wet clay or earth. We wait until the barrel has cooled completely and the charcoal is ready.

To make coal in a pit, we need to dig a hole, the diameter of which will be 0.8 m with sloping walls, and light a fire in it. But before you light a fire, take a sufficient amount of logs, dried wood, and tree branches from which you will get coal.

Rapeseed biofuel

Oil and meal are obtained from rapeseed seeds received at the oil mill. Next, this oil enters a special installation, where, as a result of various chemical reactions, methyl ether - biodiesel - is obtained from rapeseed oil.

Before use, it must be filtered. This type of diesel fuel has better flammability compared to conventional diesel fuel.

Biodiesel heating equipment

Various equipment options for the production of biofuel from vegetable oil.

Boilers, heat guns, and furnaces use liquid fuel. But each of the devices must have a burner. It can be with or without inflation. If you buy a burner in a store, make sure that the instructions indicate the possibility of working with biofuel. The nozzles in some models are too small; particles in homemade biodiesel easily clog them.

The most popular liquid fuel boiler on the Russian market is Kiturami, which is manufactured in South Korea. It is not very expensive, about 32 thousand rubles, works quietly, small, modern design. Characteristics:

- closed combustion chamber;

- the presence of two circuits;

- Efficiency 91.5%;

- volatile, requires connection to a 220 W network;

- separate heat exchanger made of stainless steel;

- maximum pressure in the circuit is 3 atmospheres.

In one of the articles we talked about how to make a stove for working off. So, it can quite work on biodiesel.

What is biofuel?

The energy hidden in plant matter is practically inexhaustible, because its source is our sun. Plants know how to use the energy of the sun, processing it for their growth. In turn, animals and birds receive energy by eating biomass, while producing waste products. By definition, biofuel is a fuel obtained from raw materials of plant or animal origin, as well as waste products and various industries associated with the processing of biomass.

Modern technologies make it possible to obtain biofuel in three forms: solid, liquid and gaseous. We encounter solid fuel in life most often in the form of pellets and various briquettes obtained by pressing. Liquid fuel - biodiesel - is still rare in the countries of the post-Soviet space, this is due to the presence of a large amount of fossil hydrocarbons at an affordable price. While obtaining liquid biofuel from vegetable oil is quite expensive and technologically difficult.

The production of combustible biogas is much simpler and cheaper, as a result of which it is gaining increasing popularity. Owners of livestock and poultry farms are increasingly thinking about purchasing a biogas plant, because they have at their disposal a huge amount of litter and manure, which is perfectly suitable for this purpose.

It makes no sense to list here all types of plant raw materials for processing into fuel, their sources and production technology. We are only interested in those types of biofuels that can be successfully produced at home without investing large amounts of money. Here they are:

- biogas extracted from waste products of domestic animals and poultry;

- briquettes from various plant wastes;

- charcoal.

Of course, if you try really hard, you can make pellets, eco-diesel, and even eco-gasoline yourself. People do such things as a hobby, spending years of their lives and often considerable money on it. Such complex technologies are inaccessible to a wide range of users, and therefore we will not consider them.

Advantages of biodiesel over petroleum diesel

Biodiesel does not pollute the planet.

If we are talking about buying ready-made fuel, then from an economic point of view, ordinary diesel fuel, which is made from oil, will be more profitable, since it is cheaper. If you make biodiesel at home from purchased oil, it is also expensive. The only option when it is profitable to produce biofuel is to have your own oil. If this is not the case, buy regular diesel fuel and heat it with it.

Strengths of using biofuels to heat your home:

- it is much safer to store energy reserves - the ignition temperature is 100 degrees, while ordinary diesel fuel ignites at 60 degrees;

- biodiesel does not pollute nature, minimal sulfur content;

- Biodiesel emits little carbon dioxide.

The fact that it is safer to store biofuels is good, but not everything is ideal here either. After three months, biodiesel begins to break down into its component parts, and this imposes some restrictions.

It is not always when the radiator stops heating that heating radiators need to be repaired. Sometimes flushing the system is enough.

If the heating pump is noisy, this is a clear sign of its malfunction. Read how to fix it here.

Usage

Biofuel" for fireplaces

Installing traditional fireplaces requires chimneys. Often, this cannot be done in ordinary apartments. And here biofireplaces with special biofuel for them come to the rescue. Biofuel for fireplaces consists of a mixture of ethanol with impurities. Before ignition, it is poured into a special metal block and lit with a special long match.

When burned, it releases carbon dioxide in a safe amount and water, which helps humidify the air in the room and is not dangerous to humans. However, certain safety precautions must be observed to ensure that the use of biofireplaces and biofuel is safe.

Namely:

- Do not add biofuel to the flame , this will lead to a fire. It should only be added to a cooled burner.

- light a fireplace only with a special lighter or a long match.

- To store biofuel, use the manufacturer's packaging and do not transfer it to another container.

- If bio-fireplace liquid is spilled, you must thoroughly wipe the floor and ventilate the room, and only then start lighting the fireplace.

While burning biofuel for fireplaces, you can enjoy the sight of beautiful and even flames that look no different from the flames of burning wood.

Results

It is possible to make biodiesel at home, but the fuel will be of low quality. If you are considering switching to biofuel heating, it only makes sense if you make it yourself from your own oil. Otherwise, it’s easier to buy diesel fuel from oil and not fool yourself.

Yes, biodiesel does not pollute the environment. This is certainly important, but as you understand, such a factor cannot be decisive when it comes to money. Be that as it may, self-interest always comes first, and only then all other benefits.

We also want to warn you that low-purity biodiesel clogs heating equipment more strongly. There are burners for which it doesn’t matter what they burn, but there are also those for which the quality of the liquid fuel matters. Pay attention to this.

Why is it better to use biofuel?

Biofuels are an alternative, renewable source of energy on earth.

Its main advantages are as follows:

- Affordability allows the use of this type of fuel in all spheres of human life.

- Renewability. One of the important advantages over gasoline is the ability of biofuels to renew.

- Biofuels help slow global change. Its use reduces the greenhouse effect (up to 65%)

- Biofuel producing countries are decreasing their dependence on imports of this product.

- Excellent refueling for your car.

A huge amount of biomass grows on the marine and continental expanses of our planet. At the same time, humanity uses a very small share of the energy contained in this plant mass, preferring to burn hydrocarbons. But times are changing and previously unnecessary waste is becoming raw material for the production of various types of biofuels. Various European firewood, pellets and briquettes made from such waste have appeared on sale. However, if there are suitable conditions at home, then why not make biofuel with your own hands? This material will tell you what and how you can make fuel at home.