From the history of the company

Many online sources write that the birthplace of the Valtek brand is Italy, but this is far from the case. The idea of developing and releasing this brand belongs equally to both Russian and Italian specialists.

Initially, the company supplied to the market only shut-off and control valves, water supply and heating systems that best suited Russian operating conditions.

Currently, Valtek equipment and almost all components for water underfloor heating systems supplied to the market are manufactured in China. The company’s specialists closely monitor the quality of the equipment produced, checking it for compliance with domestic and European norms and quality standards.

Pros of the Valtec system

The brand's products are different:

- High reliability. High-quality materials and fasteners, the complete set of the system with branded blocks and modules reduce to zero the likelihood of errors when performing calculations and design, which can already indicate stability and efficiency of operation without the risk of leaks.

- The manufacturer's product range includes everything required for installing a heating system, including accompanying materials, for combining it with the future final coating, and adjusting thermal and waterproofing. That is, everything that makes it possible to ensure the greatest energy efficiency of the heated floor used.

- Valtek focuses its production on uniform standards that ensure full compatibility of various equipment components, as well as materials.

Operating principle of underfloor heating

The Valtec heating system consists of two sections. The first looks like pipes laid in a special way on the floor, produced using a unique technology. These pipes are heated by the second section, which consists of a pumping and mixing unit.

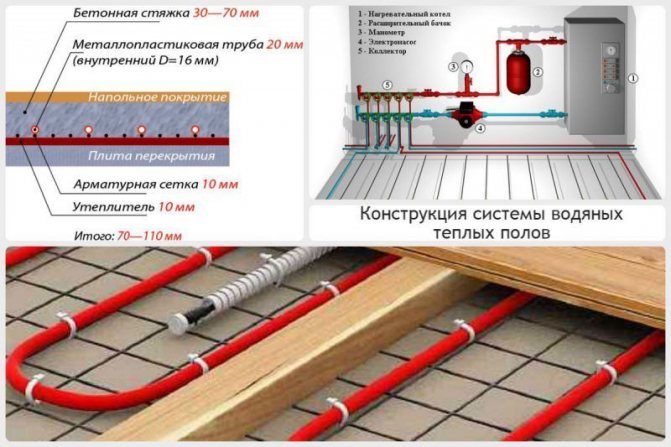

In the figure you can see a diagram of the universal connection of a Valtek water heated floor through a boiler.

Connection diagram for Valtek heated floor through a boiler

The pipes offered by the manufacturer are represented by basic models:

- Metal-plastic pipe. It is designed specifically for organizing drinking water, ceiling and radiator heating. The diameter of the pipe is 16-40 mm. It can be easily bent, and the top layer of protection will not be damaged. Fastening is done using clamps.

- Red pipe made of cross-linked polyethylene. Produced for organizing underfloor heating and heating the room. The surface is smooth from the inside, which eliminates the risk of dirt plugs forming. Pipes are not afraid of temperature changes, they are not subject to corrosion, mechanical stress, and cannot be crushed or flattened. The outer shell provides excellent protection against cement exposure. It will serve properly for more than half a century.

To connect the pipes, press fittings are used - also a unique development by Valtec. Pipes are laid either in a spiral or in a circle. The pumping and mixing unit includes a pumping and manifold block, control and shut-off valves, as well as special wall mounts and sockets for installing auxiliary equipment. The coolant is prepared from water and glycol antifreeze.

How to choose a boiler for a warm water floor?

Description of the elements of the collector group

produces heating equipment for heating systems, radiator and floor. For water heating, a pipe and perforated insulation with fastening elements for the liquid line are purchased.

The pipes are connected to a comb, which consists of supply and return manifolds. What does a Valtec fluid distribution block provide?

- Supply manifold; a line with hot coolant is connected to it.

- The unit is equipped with flow meters that monitor the filling of the floor water circuit.

- An end tube with a float device is used to remove air.

- On the return circuit there are outputs for installing a thermal head. If the head is faulty, it is removed for repair. At the same time, the “warm floor” heating system operates in normal mode, without draining the coolant. The thermal head can be replaced with a servo drive or other control device.

- Flow meter valves; they are not permanently mounted on the hot water bar. A threaded connection is provided for them. If necessary, they can be removed.

- The system is equipped with a float device for air removal. A shut-off valve is connected to it, which allows you to remove the float if necessary.

- A drain valve is designed to remove coolant from the heating system. It has a hinged design.

- To ensure that the installation of the collector block for underfloor heating “Valtec” does not cause difficulties, the equipment kit includes adapter nipples and fittings. They are equipped with heat-resistant rubber gaskets.

- The operating temperature of the comb is 90 0C.

- Optimal pressure 8 bar.

- The filling level of the main line is 2.5 m3/h.

We recommend: What types of mats are there for warm water floors?

Systems that do not include flow meters are cheaper, but if, along with large rooms, the mains of a bathroom or bathroom that are small in size are connected to the comb, then a device for filling the water circuit is necessary.

Along with a thermal head or servos, it regulates the filling of the water circuit and the room temperature. The flow meter is a valve. It closes, preventing hot water from entering a certain circuit. The device is triggered if the coolant flow exceeds the permissible limit.

The Valtek manifold for heated floors is made of stainless steel or nickel-plated brass. Fittings are made from hot-stamped brass. The air vent float is made of polypropylene.

- The size of the collector group depends on the number of outputs. If the block provides 3 outputs, then the length of the tube is 230 mm. With 7 outlets, the comb has a length of 430 mm.

- The pitch between the outlets is 60 mm.

- Outlet size 1”.

The comb is mounted on the wall using brackets. They have a figured design. The edge that fits tightly to the wall surface is provided for the cold circuit. A tube with hot coolant is fixed on the protruding surface.

Flow meters are located on the supply manifold. The equipment is configured when the circulation pump is turned on. Set the filling level of the highway to 2.5. The temperature parameters on the thermal head should be set before putting the heating system into operation.

Equipment

The Valtek warm water floor is supplied with:

- pipes: it is possible to use metal-polymer products or channels made of cross-linked high-pressure polyethylene;

- elements for installation: these include heat-distributing plates, mats with clamps and insulating substrates;

- The system is controlled using thermostats and mixing units. All elements are mounted on the collector block, which is the main control unit;

- automatic: needed to regulate the temperature at a distance, taking into account the data of the floor heating of the air in the room.

All of the above components are present in the company’s product range.

Calculator for calculating the footage of a heated water floor pipe.

Installation instructions for heated floors

All work on laying heated floors must be carried out by specialists. Only in this case is guaranteed high-quality and correct assembly, and, consequently, a positive result.

The Valtec water heated floor is installed according to the following scheme:

- The manifold cabinet is being installed.

- A pumping and mixing unit and a collector block are mounted in it.

- The floor surface in the room is leveled.

Design of a water heated floor system - A damper tape is laid out along the edges of the room.

- Hydro- and vapor barrier is done.

- Insulation is being laid.

- Pipes are laid using one of the options.

- The pipes are connected to the manifold. Hydraulic tests are being carried out.

- All automation is connected.

- The floor is poured with concrete screed.

A properly installed heated floor will provide the necessary comfort in the home.

Installation of Valtek underfloor heating

It’s worth saying right away that all work on installing such a water floor must be carried out by qualified craftsmen. Only in this case is there a guarantee of high-quality and correct assembly and, as a result, successful completion of installation.

Installation instructions for Valtek heated water floors:

- First, the manifold cabinet is installed.

- A pumping and mixing unit and a manifold block are installed in it.

- Level the floor surface in the room.

- Lay out the damper tape along the edges of the room.

- They do vapor and waterproofing.

- Lay insulation.

- Lay pipes using any of the options.

- Connect the pipes to the collector. Conduct hydraulic tests.

- All automation is connected.

- After all, the floor is filled with concrete screed.

It must be said that Valtec water heated floor is universal, i.e. You can lay both finishing tiles and parquet on it. The only important condition is the top layer of screed, at least 2 cm thick, which ensures uniform thermal distribution over the floor surface.

How to assemble a collector?

The Valtec distribution block is manufactured assembled. Flow meters are already installed on the hot tube. There are thermal heads on the cold line, but the product may only have outputs for attaching temperature control devices. They are protected by plastic caps. The manufacturer gives you the opportunity to choose which automation to install: thermal head, servo drive.

Some small elements need to be connected to the collector group:

- On the right, shut-off valves are connected to the tubes. There are 2 of them in the set.

- A float device is connected to the valves to remove air.

- Opposite the air vents, drain valves are connected to the underside of the tubes.

- The ends of the comb are closed with plugs.

We recommend: How to turn on underfloor heating?

A circulation pump and a three-way or two-way valve are separately connected to the comb. These devices must be purchased separately. They are connected on the left to the tube into which the cold coolant flows. Use brass threaded fittings.

The cold and hot circuits are removed from metal pipes that are connected to the boiler or furnace. They are connected via a bypass at the outlet of the collector group. A circulation pump with a temperature sensor is installed between the circuits.

The rotameter is adjusted when testing the heating system. The protective sleeve must be removed from the device. Using the red ring, the upper bushing, set the rotameter to zero.

Next, using the same bushing, install the valve on the o for large rooms, on the o for small rooms. To fix the rotameter parameters, turn the lower ring to the right until it stops.

Return the protective cap to its original place. The rotameter may not have a locking ring. In this case, the pipeline fill indicator is set without fixing. Valve operation must be checked regularly.

Valtek collectors for heated floors are installed with a liquid heating system. The coolant can be water, antifreeze, glycol fillers that do not freeze at low temperatures. If the heating system is not used, then the coolant does not need to be drained.

The number of circuits on the distribution block is 3-12 pcs. If necessary, additional equipment can be connected to them to increase the flow capacity of the coolant to all rooms in the house.

The comb is mounted on the wall or placed in a manifold cabinet. The manufacturer provides a 10-year warranty on the equipment. Service centers are located in St. Petersburg and Moscow. The block will last more than 50 years.

If necessary, the rotameter or thermal head can be replaced without turning off the heating system. When using a programmable thermostat, the operation of the heated floor control unit can be carried out through electronic gadgets.

We recommend: How to install Devi heated floors?

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- Features of Legrand heated floors

- How to make a warm water floor in a private house with your own hands?

- What characteristics does Shtein underfloor heating have?

- How to lay heated floors on planks?

- How to install heated floors in a country house?

- Is it possible to lay warm floors under linoleum?