How to check the oil in a compressor

When the compressor is running, oil circulates through the system; after the air conditioner is turned off, some oil remains in it. We check the oil level in the compressor as follows:

- let the air conditioner run in cooling mode for about twenty minutes;

- we check the oil level in the compressor through the inspection window - it should be at a level above the lowest point, but above 1/8 of the height of the inspection window;

- However, the oil should not foam, and if this happens, there is likely a freon leak that should be repaired. If the oil is higher than normal, excess oil must be removed from the system; if the level is low, oil must be added.

Diagnostics and refueling

Ford Focus Hatchback ,, blue ,, Logbook antibacterial treatment of the air conditioner

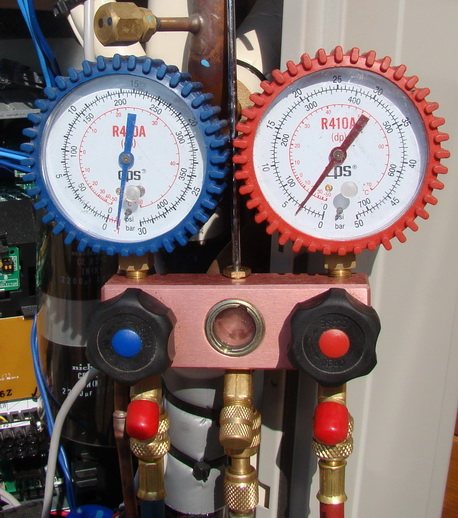

A specialist can determine leaks and how much freon is left in the air conditioner using special equipment. The main indicator of the amount of gas in the system is its pressure. Check the pressure using a pressure gauge station.

As a rule, such a check is carried out in the warm season on the suction side, i.e. using a blue pressure gauge. The hose from the device is connected to the service valve located on the suction side, and the air conditioner is started. After 10-15 minutes the pressure gauge will show correct readings.

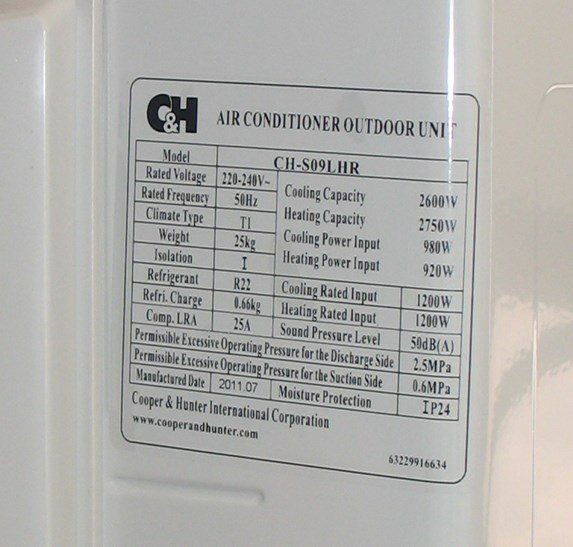

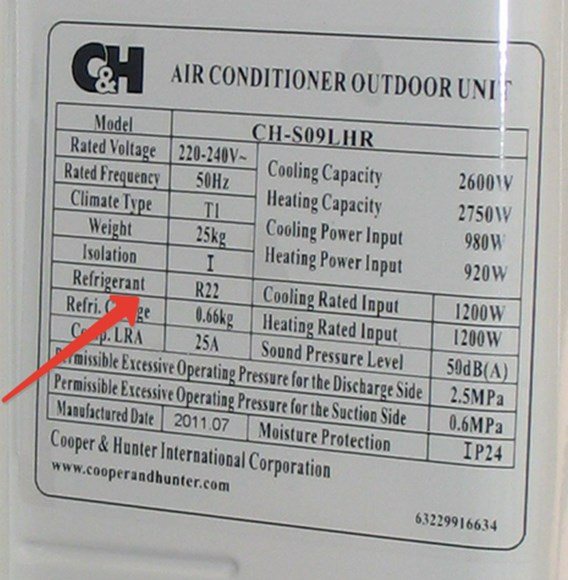

A table of freon pressures in an air conditioner for a specific brand of device is located on the external unit of the air conditioning equipment.

- Discharge side is the operating pressure on the discharge side.

- Suction side is an indicator of the operating pressure on the suction side.

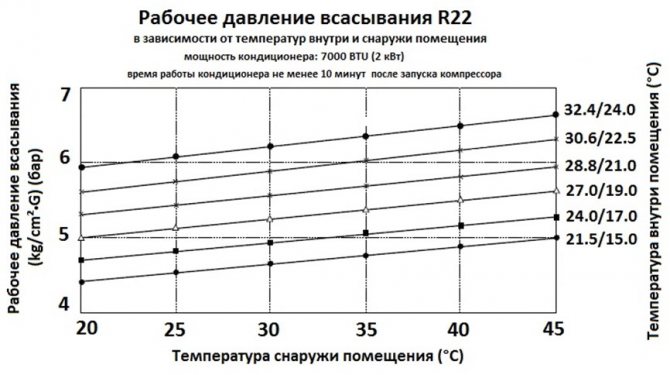

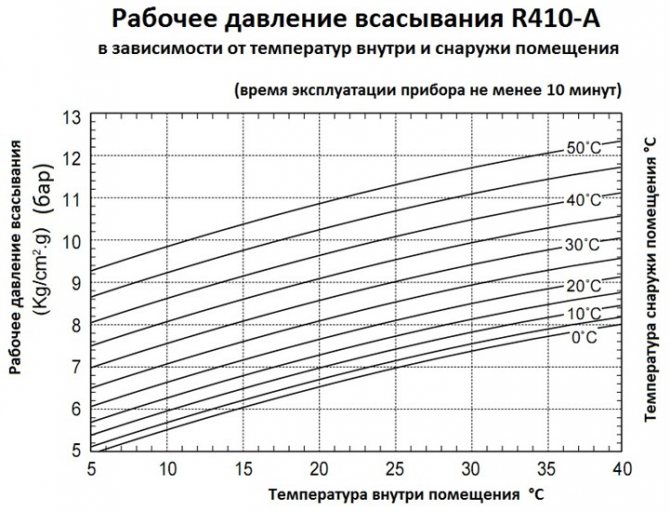

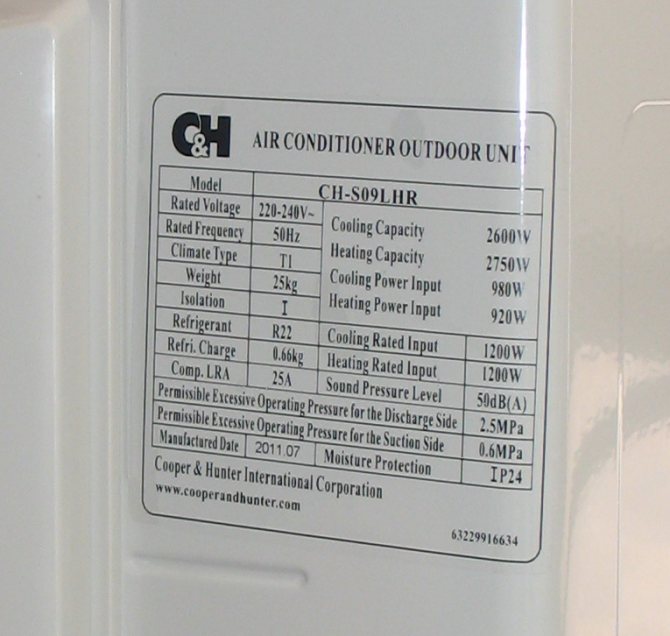

Please note that pressure readings vary depending on the ambient temperature and room temperature. Below are tables of the dependence of pressure on air temperature for the gases most in demand in climate control technology.

Many owners of climate control equipment ask the question, how to determine what kind of freon is in the air conditioner, when and how much it needs to be refilled?

In order to find out the type of gas used, you should carefully look at the factory markings, which are located on the external unit of the device.

The line labeled Refrigerant contains the brand of refrigerant used in a specific model of climate control equipment. In our case it is R22.

Refueling should be carried out when the following symptoms occur:

- Cooled air does not flow from the indoor unit when the unit is running.

- Ice appears on the pipes.

Refueling the split system will also be required when reinstalling air conditioning equipment and after repairing the compressor unit.

There are no specific standards for refueling household split systems. The specialist is guided by the readings of the pressure gauge station, scales and on the basis of his own experience. That is why it is necessary to invite only qualified specialists to refuel air conditioning equipment, who provide a guarantee for their work.

Many people ask: how much does it cost to refill an air conditioner with freon? The cost of refilling an air conditioner is rarely fixed. The price includes the cost of labor plus the cost of refrigerant. In addition to these factors, competition and the good name of the company also play a role in pricing.

Average cost of refilling an air conditioner in Moscow:

- R22 refill – 1500 rub. work + gas cost, based on 300 rubles per 100 grams of gas.

- R410A refill – 1500 rub. work + gas cost, based on 500 rubles. 100 grams of refrigerant.

There is nothing complicated or scary about refilling a split system with refrigerant yourself. All you need is equipment and some knowledge. But you should understand that as a result of improper refueling, the split system may fail. The cost of services with a quality guarantee is significantly lower than the price of a new air conditioner, so it is best to entrust the work of refueling (refilling) the air conditioner to professionals.

Freon R410a pressure parameters on the suction side

Washing the outdoor unit of the air conditioner using a KARCHER mini washer

Refilling the air conditioner, refilling the air conditioner, checking the pressure.

To operate, the air conditioner requires a refrigerant - freon . In household systems, as a rule, two types of refrigerant are used: R22 freon or R410a freon . The letter R stands for Refrigerant - cooler, refrigerant. It is possible to buy freon yourself and refill the air conditioner, but it is better to invite a specialist!

You can check the freon pressure in the air conditioner using a pressure gauge station.

| Pressure station for R22

| Pressure gauge station for R410a

|

When the air conditioner is operating in cooling mode, the blue pressure gauge ( low pressure ) measures the pressure at the inlet of the main circuit to the outdoor unit - the refrigerant suction side (in front of the condensing unit), the red pressure gauge ( high pressure ) measures the pressure at the outlet of the main circuit from the outdoor unit - discharge side (after the compressor-condensing unit).

The maximum low and high pressure values for each air conditioner, for any type of freon, are usually indicated on the external unit housing on the factory markings:

Discharge side - the discharge side, that is, high pressure, the refrigerant (freon) is in a liquid state, after the compression process by the compressor in the outdoor unit;

Suction side - suction side, that is, low pressure, the refrigerant (freon) is in a gaseous state after the evaporation process in the indoor unit of the air conditioner.

In household split systems, when operating in cooling mode in the warm season, as a rule, the low pressure on the suction side of the refrigerant is measured, that is, using a blue pressure gauge. To measure, the pressure gauge is connected (screwed) using a special hose to the service valve, which is located at the point where the thicker tube is connected to the outdoor unit. Next, let the air conditioner run (with the compressor running) in cooling mode for 10-15 minutes, and look at the pressure gauge. It is important to remember that the compressor is switched off periodically, measurements are taken only when it is running.

Below are tables with pressure parameters for various types of freons and popular air conditioner capacities. For the pressure measurement process, it is desirable to know (measure) the air temperature inside and outside the room. It is also important to understand that the parameters given below (in the tables) may differ slightly from those measured under these specific conditions.

Freon R410a pressure parameters on the suction side

Let's normalize the indicators

Electronic circuit of the air conditioner on a car. Everything about the design, operating principle and maintenance of a car air conditioner

Monitoring the operation of the air conditioner is extremely important. As practice shows, a car that has been driven for more than three years inevitably needs freon pumping. This is necessary both to ensure normal operation of the air conditioning unit and to cool the air more efficiently and quickly.

It is not difficult to replenish the amount of freon yourself. In addition to the pressure gauge, it is worth having a compressed gas cylinder that can be connected to the pressure gauge using adapters to ensure uninterrupted monitoring of the required readings.

Having connected the pressure gauge with the cylinder to the air conditioning pipe, you need to start the engine and check the pressure again. Then you need to turn on the cooling device at full power, setting the minimum temperature in the cabin and switching the dampers to recirculation mode.

By turning off the cylinder tap, you can pump up freon in the required quantity. As soon as the pressure gauge gives the expected readings, turn off the tap and disconnect the cylinder, then closing the lid on the pipe.

How to refill the air conditioner with 410 freon? Basic methods for refilling air conditioning systems

How to refill the air conditioner with 410 freon? What are the main methods used to charge air conditioning systems? Refilling the air conditioner with liquid freon type 410.

How to refill the air conditioner with 410 freon ? There are times when the air conditioning system needs additional charging with refrigerant, for example, in the event of any breakdowns or emergency leaks of the substance. It should be said that refilling the air conditioner with freon type 410 should be carried out by an experienced technician. You need to know that you can both top up and refill freons. Refilling with refrigerant is carried out only with one-component freons. This type of freon includes the r22, which is so popular today. In addition, it is possible to carry out the process of refueling and isotropic mixtures. The most commonly used in air conditioning systems today is an isotropic mixture called freon r410. Before the refueling process, cooling systems are diagnosed in order to determine the main reason for the decrease in their efficiency.

There may be several such reasons. Most often, a failure in the operation of such a system occurs due to overheating of freon vapors, as well as their entry into the condenser of the climate control equipment from the compressor. In addition, a possible reason for the climate system to require refilling may be a decrease in the freon temperature directly to the condensation point due to the effects of air flow. In addition, the temperature throughout the entire zone of the main line can be the same, including also the zone where condensation itself occurs. Additionally, the air flow can lower the temperature, which results in condensation to a temperature that only helps to cool the freon, which is directly in a liquid state. Freon, which is located on the inner walls of the condenser, is kept under equal pressure. By measuring this pressure, as well as looking at the manufacturers’ specially designed tables, you can find out the temperature at which the active freon condenses under the created conditions.

Subcooling temperature standards are typically reported by the manufacturer. This value is calculated using the difference in condensation temperature, which is measured at the outlet of the cooled freon. If the measured subcooling value is lower than the figures specified by the system manufacturer, then the freon must be topped up. Such indicators also indicate that the capacity of the condenser to cool the freon is not enough, and this can negatively affect the increase in the load of the system itself, as well as a decrease in its service life. Standard refilling of air conditioning systems along with subcooling always begins with connecting a cylinder with refrigerant to the climate system, as well as a pressure manifold. Next, a temperature sensor is installed along the high pressure line, after which the system starts up. During operation of the system, the pressure is carefully monitored using a pressure gauge, and the temperature itself is calculated, as a result of which freon condenses.

The temperature of the freon leaving the condenser is also measured using a thermometer. It should be within the value obtained by summing the given subcooling and condensation temperatures. If the temperature of freon exceeds the permissible norm, it is, accordingly, not enough for the normal operation of the climate system. Therefore, the substance is added to the air conditioner until the required temperature is reached. If freon 410 is added to the system in excess, then its excess is gradually released to the most optimal and temperature-appropriate indicators. With the SH-36N, the process of refilling the climate system is much simpler. When the device is set to zero, it switches to the required charging mode, and it also indicates the type of refrigerant used - freon. Afterwards, you should connect the cylinder with freon to the air conditioner, as well as the pressure manifold. The sensors of the device, as a rule, are set to the line of the desired pressure. All data related to refilling the air conditioner is usually shown on the screen. In principle, R410 freon is a replacement for R22, and is also intended for refilling newer high-pressure climate control systems. R410 retains all its performance properties much longer than other types of freon. R410 is environmentally friendly and completely safe for the environment. Therefore, it is very often used to refill new generation air conditioners.

Relationship between working pressure and temperature conditions

Car air conditioner malfunctions. 7 main car air conditioning problems

Thus, if external temperature conditions are slightly increased, then the operating pressure will increase proportionally. So, for example, if we consider refrigerant 410, then in this case, under conditions of an increase in the temperature within the room or outside it by five degrees, the operating pressure of freon in the air conditioning system will also increase. The value will be increased by 0.5 bar. Another dependence is observed for such a type of freon as R22, but here it differs depending on the street temperature, or this indicator within the room. In order to obtain updated figures, you should refer to specialized tables, everything should be indicated there.

Freon

As the dictionary states, freons– halogenalkanes, derivatives of saturated hydrocarbons containing fluorine. The most commonly used hydrocarbons are methane and ethane. Freons are used as refrigerants for refrigeration machines, which are what they are, including air conditioning systems. To put it a little more simply, a refrigerant is a working substance that, during the process of boiling or isometric expansion, takes heat from the object being cooled and then, after compression, releases it to the environment in the form of condensate. The refrigerant is thus a kind of coolant. As mentioned above, freons contain fluorine atoms; chlorine and bromine are also found in its composition. Freons are produced on an industrial scale, and there are about 40 different types.

It can be argued that freon

for an air conditioner it is the same as gasoline for a car. Special oils are used together with freon to lubricate the compressor parts rubbing against each other. Those who have climate control equipment should remember Ra forever - only certain oils are suitable for each group of freons.

Let's look at those freons that are and have been used previously in the field of climate control technology. The most widely used freon was R-22. All over the world today it is classified as a prohibited refrigerant for refrigeration machines, in view of the fact proven by the Montreal Substances Protocol that R-22 destroys the ozone layer. The UN program provides for a gradual reduction in the production and use of this type of freon. Along with R-22, R-12 freon is recognized as the most harmful enemy of the ozone layer among refrigerants, so it should leave the climate market altogether. Which is exactly what is happening.

At the moment, despite the fact that most manufacturers are moving away from creating air conditioning systems using R-22 freon in Europe, a number of Russian companies selling climate control equipment are still actively offering R-22 to their customers as a refrigerant for air conditioners.

R-407C and R-410A are freons that replaced prohibited refrigerants, which were considered traditional. New developments do not relate to substances of a homogeneous type - they are mixtures of different types of freons. Such a qualitative composition imposes a number of difficulties on the use of these freons. Refrigerant R-407C, which has become an alternative to R-22, consists of the following freons in their percentage ratio:

- R-32 (23%);

- R-125 (25%);

- R-134a (52%).

Each of the components of the R-407C freon mixture is responsible for providing certain properties. Thus, R-32 allows you to increase the performance of equipment, R-125 eliminates the situation of fire inside the air conditioner, and R-134a organizes a certain operating pressure in the refrigerant circulation circuit.

The main disadvantage preventing the widespread distribution of these groups of freons (R-407C and R-410A) is the high cost and the creation of higher pressure when compared with the work of R-22 freon. That is, for example, at a temperature of +43C, the pressure in the air conditioning system with R-22 freon is 16 atmospheres, and in the case of using R-410A this value is already equal to 26 atmospheres. In addition to the above, it should be noted that new types of refrigerants require more skilled handling: they need proper storage, transportation, as well as charging and refueling. Also, with the use of new freons, it is necessary to use new synthetic oils, not those that were used previously (mineral oils).

In case of any leaks of freon R-407C, which are inevitable (the so-called normalized leak), it implies an uneven release of fractions from the refrigerant circuit in the air conditioner, that is, the optimal composition of the working substance in the system changes. Consequently, in this case, it is not enough to refill the air conditioning system - the percentage of freons in the R-407C mixture will already change. In this case, you should drain all the refrigerant from the system and fill the circuit with a new portion of freon. This was the key obstacle to the spread of R-407C. The point here is that collecting old freon is a labor-intensive process that requires not so much skill as high qualifications.

R-410A refrigerant consists of two freons: R-32 (50%), R-125 (50%). It is conditionally isotropic, in other words, any slightest leak of refrigerant will not lead to a change in the qualitative (percentage) composition of the mixture. This means that the air conditioning system with R-410A refrigerant requires refilling. But nothing is perfect. The disadvantage is that each part of the compressor is lubricated with special oil, which, as mentioned above, comes with freon. If you incorrectly combine the brand of oil and the type of freon, you can easily ruin the heart of the air conditioner - the compressor. So, when using new types of refrigerants, you should select the brand of oil with particular precision. Synthetic polyester oils are suitable for R-407C and R-410A.

The outdoor unit of the air conditioner consists of the following components

- Compressor - compresses freon and maintains its movement along the refrigeration circuit. More information about compressors for air conditioners can be found in the Compressors section.

- Four-way valve - installed in reversible (heat - cold) air conditioners. In heating mode, this valve changes the direction of movement of freon. In this case, the indoor and outdoor units seem to change places: the indoor unit works for heating, and the outdoor unit for cooling.

- Control board - as a rule, is installed only on inverter, multi-split systems and cassette or duct type air conditioners. In conventional split systems, all electronics are placed only in the indoor unit.

- Fan - creates a flow of air blowing across the condenser. In low-power models it has only one rotation speed. Such an air conditioner can operate stably in a small range of outdoor temperatures. In models of a higher class and power, designed for a wide temperature range, as well as in all semi-industrial air conditioners, the fan has 2 - 3 fixed rotation speeds or smooth adjustment.

- Condenser is a radiator in which freon is cooled and condensed. The air blown through the condenser is correspondingly heated.

- Freon system filter - installed in front of the compressor inlet and protects it from copper chips and other small particles that may enter the system when installing the air conditioner. Of course, if the installation was carried out in violation of the technology and a large amount of debris got into the system, then the filter will not help.

- Union connections - copper pipes connecting the outdoor and indoor units are connected to them.

- Protective quick-release cover - covers the fitting connections and terminal connector used to connect electrical cables. In some models, the protective cover covers only the terminal connector, and the male connections remain outside.

How often should the system be charged with refrigerant?

Preventive refilling of freon is carried out 1-2 times a year, since absolute tightness does not exist. In accordance with regulatory documents, refrigerant losses of 5-8% during the year are allowed.

The second reason is a decrease in operating efficiency when the freon pressure in the air conditioner drops due to leakage through leaks in roller and other connections. If there is a malfunction, you can hear a continuous hum from the compressor. In this case, a full cycle of measures is carried out to eliminate the leak and fill it with refrigerant.

Before refueling the air conditioner at home, you should make sure that you have all the necessary equipment listed in the list:

- a refrigerant bottle of the exact brand your cooler requires;

- dry nitrogen cylinder;

- set of hoses with threaded connections;

- manifold;

- electronic balance;

- vacuum pump for air conditioner.

Car air conditioner malfunctions

The causes of breakdowns can be divided into three groups:

- technological (poor quality materials, assembly, engineering errors);

- operational (violation of operating and maintenance rules, natural wear and tear);

- external (aggressive environment and external influences).

The first reason is relatively clear, and the motorist simply cannot influence it. Marriage is marriage, no matter what the reasons are. This is the manufacturer's fault. Modern production policy must also be taken into account.

Now “disposable” materials and components are used, and the declared service life of devices rarely exceeds 5-7 years. Cause? Money! It is profitable for manufacturers that if something breaks, the consumer will buy a new one. This boosts production and generates profits. You can no longer find refrigerators or vacuum cleaners that work without repair for 30-40 years - nothing has been done “forever” for a long time.

Well, we are not able to influence production, but we will talk about the last two causes of breakdowns in detail. In order to better understand the causes of the malfunction, you need to know how the air conditioner works. Read the article: “The principle of operation of a car air conditioner.”

Types of freon for air conditioning systems

For about half a century, the main refrigerant in household air conditioning systems was freon 22. Approximately from the mid-80s of the last century, serious persecution began against its use, since allegedly chlorine, which is a component of this gas, affects the ozone layer that protects our planet from hard ultraviolet radiation. Although this stuffing was not 100% proven, this information led to the development of new and safer refrigerants: R410 and R407 freons.

New types have not been able to completely displace R22 from the climate control market due to the ease of maintenance and some physical properties of this gas. Today in household split systems the following are most often used: R22; R410 and R407.

Freon R22 can most often be found in air conditioning systems used in everyday life, production and transportation of perishable goods. Since almost all refrigeration equipment produced until the end of the last century operated on this type of refrigerant, refilling air conditioners with this gas is most in demand.

Freon R410 is a colorless gas that is a complete replacement for its predecessor. Now it is used in new climate control equipment, regardless of its purpose. One of the features of this refill is that if it leaks from the air conditioner, more than 35% requires a complete refill of the equipment.

Freon R407 is nothing more than a mixture of several gases, each of which is responsible for certain physical properties of the refrigerant. Most often used in multi-zone or semi-industrial split systems. This type of gas cannot be refilled with climate control equipment: in case of leaks, it must be completely drained and only after that the refilling procedure must be carried out.

WHAT IS THE FREON GROUP OF A MODERN AIR CONDITIONER?

TYPES OF REFRIGERANTS FOR AIR CONDITIONERS

Air conditioners, including inverter split systems, use several types of freons as refrigerants. Modern equipment uses freons R22, R407C and R410A. As a rule, air conditioners with R22 and R407C freon are cheaper than split systems that use R410A freon, which is relatively new to the air conditioning equipment market in Russia. What is the difference between these refrigerants? Is it worth overpaying for air conditioners with environmentally friendly freon?

R22

Freon R22 is a hydrochlorofluorocarbon aerosol propellant. This refrigerant is a colorless gas with a faint chloroform odor and is thermally and chemically stable. Due to the low operating pressure, R22 has virtually no effect on the elements of the refrigeration circuit, and its isotropic properties make it possible to refuel air conditioning equipment in the event of a leak.

However, R22 has a negative impact on the ozone layer, and therefore, since 2010, this refrigerant has been banned for use in the USA and Europe. Russia also does not import equipment that uses R22. Therefore, companies producing floor-mounted, wall-mounted split systems, etc., industrial-grade air conditioners and other air recirculation equipment for the European market are switching to the use of other types of freons.

R407C

R407C is a mixture of refrigerants R32, R125 and R134A. Unlike R22, freon is non-isotropic and in the event of a leak changes its composition, so it is not possible to refill the circuit. In this case, it is necessary to remove the remaining freon and refill the air conditioner. R407C has a high operating pressure, which creates a load on the elements of the refrigeration system, and therefore high-quality and expensive parts are used for the production of air conditioning equipment, including wall-mounted split systems and other air recirculation systems.

The main advantage of R407C is that it can be used in equipment designed for R22 without significant changes to the refrigeration systems. In this regard, today R407C freon is considered as an alternative to R22 in terms of performance and saturated vapor pressure.

R410A

It is a mixture of difluoromethane R32 and pentafluoroethane R125. A distinctive feature of R410A is the absence of chlorine, which makes the use of this refrigerant completely safe for the ozone layer. Like R407C, this freon is non-toxic and non-flammable. R410A is conditionally isotropic, since in the event of a leak the mixture does not change its composition, and the possibility of refueling the refrigeration circuit is also preserved. All climate control equipment produced by MHI, from the simplest units to inverter split systems and multi-zone equipment, uses R410A as a refrigeration element. This is due to the main principle of the corporation – concern for environmental protection.

How does an air conditioner work?

All car air conditioners operate on the same principle - freon flows through the lines of the device, which is compressed during operation of the compressor. Under enormous pressure, freon confiscates heat from the environment and heats up; later, the heated gas passes through the tubes, where it produces heat. Just when the pressure drops, the freon cools down, and then cool air is supplied to the interior of your car.

As it gets warmer outside, we advise you to check the serviceability of your car air conditioner and carry out all preventive measures. In this case, you can be sure that at the peak of the summer heat you will not be left without a chill in the cabin. It is recommended to diagnose the device at least once a season. You can do it at any special car service or yourself at home. In the second case, you will need to have certain tools and devices.

The device that keeps the pressure in the car air conditioner lines under control is a pressure sensor. It is located on one of the highways. With all this, it can be either a high or low pressure line. It is this sensor that determines how much freon is needed to operate the compressor and controls its switching on and off. A breakdown of the pressure sensor can have serious consequences. The compressor may not turn on or turn on when the pressure is low or completely absent, or may not turn off when there is too much freon in the system.

All these consequences can lead to complete failure of the compressor - the device may simply jam. The pressure sensor may fail due to mechanical damage or oxidation of the contacts at its terminals. For each brand of car, manufacturers come up with a special type of sensor. Devices may have different types of threads, the presence of two or more contacts, and differ in different types of connectors. The more representative the car model, the more difficult it is to find a suitable sensor model!

Freon types

Manufacturers of climate control equipment charge their air conditioners with different types of freon. They differ in both formulas and physical qualities.

The most common types of freons for air conditioners:

- R-22;

- R-410A;

- R-32.

Freons like R-22 are harmful to the environment: they violate the integrity of the ozone layer.

Equipment using 22 freon does not work correctly when the temperature drops below -5 degrees and rises above +43. Many countries, including Russia, have banned the import of equipment operating on this type of refrigerant.

R-410A air conditioners not only do not burn or explode, but are also completely safe for the environment. The physical properties of this refrigerant are maintained down to -15 degrees. Therefore, the best manufacturers have already switched to freon for R-410A type air conditioners. This led to an increase in the cost of equipment by 10 percent. The fact is that the thickness of expensive copper pipes for the cold line depends on what kind of freon is used in air conditioners. The pressure of R-410A is much higher, and therefore the cost of valuable non-ferrous metal increases. Changing the refrigerant does not in any way affect the ability to cool or warm the air.

As for the R-32 refrigerant, this is the latest development of chemists. It is cheaper than R-410A, more efficient, and completely safe. Its energy efficiency is 5% higher than that of R-410A. DAIKIN Corporation has already released the first heat pump using this type of refrigerant. By 2015, all Chinese-made air conditioners will be produced with R-32, and by 2020 it is planned to completely replace the existing refrigerants with it.