During the normal functioning of the market, manufacturers' offers are demand satellites, and this is not only about the quantity of goods. New consumer demands force us to constantly introduce modern technologies, look for rational solutions, and release new product models.

The unprecedented popularity of fireplaces has led to the fact that leading manufacturers have tried to do everything so that everyone can enjoy a fireplace in the room, and this fireplace is designed according to personal taste and performs the specified functions.

Buyers' requirements concern both the method of installing fireplaces and the type of fuel on which the fireplaces operate. In a word, the fireplace market is saturated to such an extent that it is impossible to give an example where the customer’s imagination remains just a fantasy.

Bright home

Modern models of fireplaces, in their various classifications, are presented in the form of modular units. This approach was made, rather, to attract customers, because it is beneficial only to the buyer. So, if the fireplace insert fails, you can purchase a new one and replace it. It is possible to order a firebox from one manufacturer, and a portal from another, and there are many such examples.

Varieties

All fireplaces in their structure necessarily have a main element - a firebox. If we consider the entire model range, we can try to classify fireplace inserts. Distributing these units into groups will help determine the limits of applicability of fireplaces and highlight the main advantages and disadvantages. The classification approach is to select a specific parameter and list its acceptable values. So, let's start distribution.

According to the method of arranging the firebox in the fireplace, all models are divided into built-in and made with a single design:

- Built-in options are presented as a ready-made cassette and must be framed by a portal, a body, or there are walls or furniture built into a niche.

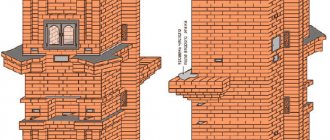

- The second category of this classification is found in brick wood-burning fireplaces, when the firebox is formed during the row laying of the device.

Classic cassette version of the fireplace

Based on access to the hearth, open and closed types are distinguished:

The open firebox is externally designed in the form of a niche in which fuel combustion occurs. A characteristic feature of the operation of a fireplace with an open firebox is direct observation of the process. You can hear the characteristic cracking of logs and smell a slight smell of smoke.

Good to know: Adhesive for stoves and fireplaces: heat-resistant, heat-resistant, fireproof

Closed types include a fireplace insert with glass. Glass allows you to see the flame, but already isolates residents from direct contact with it.

Classification by material divides units into brick and metal (steel, cast iron) models:

- A fireplace insert made with fireclay bricks is found in the classic versions of a fireplace built on a separate foundation and with a brick chimney.

- Metal fireboxes are found in various variations. Due to their light weight, they do not require a solid foundation and are used in single buildings, country houses, city or suburban apartments.

Cast iron version

You cannot ignore the classification according to the type of fuel used. There are fireboxes for wood-burning, gas, coal and electric fireplaces. In electric models, the hearth for the fireplace is represented by a system that simulates fuel combustion, so this firebox is somewhat isolated in this distribution.

Now, after all the many devices have been sorted out, we can make an overview of each type.

Fireplace inserts - description and types

It is difficult to say which element performs the determining function in ensuring the viability of a heating device - a stove or fireplace, because a complete organism cannot “live” if any organ is missing. So, if there is no chimney, then the fireplace stops breathing, since the combustion products are disposed of outside through the pipe; if there is no portal, then the eye does not linger on the unit, which provokes a decrease in purchasing interest; if the stove design does not have a firebox, then the heating device can only be used in as a book stand or table, but certainly not as a device for heating a person’s home.

Currently, there is a huge variety of types of fireplaces and stoves. They are focused on performing both utilitarian (practical) and aesthetic functions. The fireplace industry produces models for people with different incomes, needs, tastes, living space, etc. Thus, anyone who wants to bask in a real flame will be able to fulfill their dream.

Choosing fireboxes when purchasing

It’s not for nothing that the firebox is called the “heart” of the fireplace. The direct process of fuel combustion occurs in it, that is, it is objectively considered its most functional part. However, it is not enough to buy a fireplace insert; you must first choose the right one. The choice of firebox depends on many factors - the model of the heating device, the location of the fireplace or stove in the room, the size of the heating structure, customer requests, etc.

The effective functioning of the heating device, that is, the accumulation and subsequent distribution of heat into the room, depends on the correct choice of firebox. The thermal conductivity of the firebox is also affected by the material from which it is made. Traditionally, steel and cast iron are used. Fireproof glass is used as an innovative material, and the cheapest products include cement mixture and fireclay. Absolutely all of the materials listed are capable of withstanding large temperature changes, have high thermal conductivity, resistance, durability, etc. However, they will differ in price, which is set according to their performance characteristics.

Types of fireplace inserts

Here you need to understand that ready-made built-in fireboxes are called inset fireboxes (inset; from the English inset - insert). This type includes all fireboxes that are designed to be mounted inside the fireplace, i.e. all the fireboxes mentioned in this article, since in the classical sense the firebox is an ordinary combustion chamber, which can simply be made of the same material as the fireplace itself, i.e. brick, stone.

Built-in fireboxes can be used to reconstruct old fireplaces, or they can also be built into the frame of a newly built, but not equipped heating device. Such fireboxes are considered the most economical, since large resource costs (labor, financial and material) are not required for the fireplace to start providing heat. The main problem is drying the solution with which the firebox is attached to the frame of the heating device.

In addition, inset fireboxes can be equipped with various specific systems - for effective ash collection, protection of panoramic glass from burning and soot (dirty, sooty glass is a consequence of the use of resinous tree species), turbines and thermostats. Another advantage is that you can buy an inset fireplace insert without any problems in any specialized store and get free advice on its installation and maintenance.

Let's consider the classification of built-in fireboxes.

Classification by type of construction: Fireplace inserts are divided into two main types - open and closed. Also available are guillotine and inset fireboxes, which are used much less frequently.

Open fireboxes are a traditional classic. They have been known since the era of ancient civilizations; they work on the principle of radiant energy, that is, they heat while the fire burns in them. However, as soon as the combustion process is over, heat stops flowing into the room.

Open fireboxes have their advantages. Firstly, in our country, a fireplace is rarely used as the only heating system, but is used as a decorative decoration. The contemplative function of an open fireplace has been known for a long time and is used for relaxation and recreational purposes. It cools quickly, so you don't have to wait long for the last coal to burn out. In addition, prices for open-type fireplace inserts are usually lower than for closed-type fireplace inserts.

Closed fireboxes are more functional, have high thermal conductivity due to their high efficiency. Efficiency can reach up to 85% due to the convective operating principle of the design. The principle of convection is that warm air rises, cools and slowly sinks to the floor; near the floor it warms up again and rises. Thus, there is constant air circulation, which can continue throughout the day.

Closed fireboxes are also absolutely safe for humans. They are equipped with durable fireproof panoramic glass, through which you can observe the process of burning wood. Closed fireboxes can be supplemented with specific systems - secondary combustion, automatic control of wood combustion, etc. In addition, the door can open not only to the sides, but also upwards, which significantly saves space and gives the stove an aesthetic appeal.

The guillotine firebox is a multifunctional device that can easily turn from an open firebox to a closed one and vice versa. This can be achieved with a simple touch of your hand - raise or lower the front window. Such fireboxes can be used both as decoration, since they have a unique appearance, and as a heating system, since by closing the glass, they can work on the principle of convection and bring heat into the house for a long time. The guillotine firebox is usually equipped with panoramic glass that opens vertically and horizontally.

Classification by firebox material:

A cast iron firebox is the most common option in the production of modern fireboxes or stoves. Cast iron is a material that is characterized by durability, resistance to high temperature changes (sometimes the temperature in the firebox can reach up to 1500 degrees Celsius), and durability. However, cast iron can expand greatly during strong heating, which can cause deformation of the firebox.

Sooner or later, the life cycle of the firebox ends. It may occur too early due to the fact that, due to high temperatures, the sealant that fills the seams between the firebox elements begins to deteriorate. There can be no talk of repairs, since they are too costly and time-consuming.

The steel firebox is a modern version of new technologies.

Considering the shortcomings of cast iron structures, manufacturing companies have developed steel fireboxes with a double casing that can operate for a long time without collapsing under the influence of high temperature changes. As they say, “and the casket just opened” - two cases of different sizes are manufactured simultaneously (one is larger than the other). The large body is made of steel, and the small one is made of fireclay or brick. Both housings perform, first of all, a safety function, since if the internal one fails, it will not be difficult to replace it. According to research and manufacturers' statements, such a firebox can last at least 60 years, in addition, the price of a steel fireplace insert will please the consumer with its affordability.

Advantages and disadvantages of open and closed options

As already mentioned, free access to the flame is implemented in many models, and not only in brick fireplaces. The desire to relax to the sound of burning wood overshadows all the disadvantages of open fireplaces, and, unfortunately, these disadvantages abound.

Any combustion consumes oxygen; a fireplace requires a constant flow of air to operate. Due to the difference in pressure in the room and outside, warm air rises through the chimney and leaves the room along with combustion products. This leads to a huge amount of energy being wasted. The efficiency of such a device does not break records, but barely reaches 20%.

Fireplace in English style

An open flame, even with all safety precautions, is dangerous. It lies in the fact that flying sparks can land on the floor, furniture, paper and cause a fire, and children present in the room only increase the likelihood of this event. By the way, the floor in front of a fireplace with an open firebox is always finished with non-combustible materials in order to somehow protect yourself from fire.

Closed fireboxes limit the flow of air, regulating its quantity. This achieves a slow burning effect. In this process, an equal amount of heat is released, according to the basic physical law, as in the open model, only the energy has time to be transferred to the air in the room due to heat exchange. As a result, the efficiency of the fireplace increases to 80%

The firebox opening, closed with a glass door, protects against embers flying out and makes the fireplace safe to operate. Immediately after kindling, the door can be closed and the air flow can be regulated with a special damper. After the firewood burns, the oxygen supply is reduced, due to which the time until the next lining increases several times.

Good to know: Fireplace protective screen, ready-made solutions and self-production

Firebox as a fireplace design element

This is the most important part of the hearth, on which the efficiency of the fireplace, service life, and appearance of the structure depend. You can make a fireplace insert with your own hands, purchase a ready-made industrial one, or order it from a craftsman. The firebox is mounted in a housing, which is most often made of brick or stone.

The perception of the living room interior as a whole depends on the design and design of the firebox.

During installation, the direction of the flow of thermal energy is of fundamental importance. A gap is left between the firebox and the lining, and the wall behind it is thermally insulated. The air is heated and enters the room through the vents.

Layout of a heating system with a fireplace

Features of the operation of metal models

A modern solution, used by leading fireplace manufacturers, is the production of metal fireboxes. The main practical task when heating a room is to ensure efficient heat removal. Due to the fact that the heat capacity is lower than that of a brick, it has time to heat up and give off energy to the surrounding air before the heat goes up the chimney.

Original decoration of the fireplace portal

Structures made of steel and cast iron are in constant competition with each other.

- Steel is most susceptible to destruction at high temperatures. Corrosion may form on the surface, since one of the combustion products is water. The low heat capacity contributes to a high rate of energy transfer. But when the fireplace is stopped, the heat immediately stops flowing and the firebox cools down. But the steel structure has less weight, which means that it will be easier to install.

- All cast iron fireplace inserts have radically opposite qualities. However, it is still not possible to give preference to one material or another. Cast iron is more resistant to temperature changes. Its fragility is compensated by the fact that the firebox is static during operation. Compared to steel, the heat capacity of cast iron is higher. It is inert in the field of energy transfer, but after the fuel burns, the cast iron firebox itself is a source of heat for a certain time. The disadvantage is the large mass. Fireplaces with this device must be installed on a special concrete platform. It should be noted that the devices used use pellets, firewood, coal, natural or bottled gas as fuel. It immediately becomes clear in which direction the manufacturers prefer.

How does an electric fireplace firebox work?

In an electric fireplace, the combustion chamber is not intended for combustion. All heat comes from electric heating elements. The combustion process is simulated in the hearth. Based on the design principle, fireboxes are divided into several types:

3D hearth for home use

- Optical devices. They illuminate the fake firewood with orange light. For lateral vision, it creates the feeling of the presence of a fire, but when viewed from the front, the quality is noticeably low.

- Optical-mechanical systems. The role of the flame is played by fluttering strips of red matter. Air is blown onto them from a fan, and the back wall is illuminated by LED lamps.

- Liquid crystal systems. An image of the flame is formed on the monitor in the form of a video clip, which is played periodically. It is not difficult to imagine this picture, and there is no point in revealing the advantages and disadvantages.

- System with ultrasonic steam generator. Today it provides the highest quality visualization. The work is based on the formation of cold steam by an element vibrating in water. The smallest particles are illuminated, creating a three-dimensional image of flames and smoke.

Good to know: How to protect the floor in front of the fireplace, what materials can be used

Classification of finished closed fireboxes for wood-burning fireplaces

- by firebox material:

cast iron, steel; - according to the door opening method:

with side opening, with vertical lift (guillotine), with a combined opening method; - according to the vertical lifting mechanism (guillotine):

chain and cable door lifting mechanisms are common; - ' by the number and shape of facades:

with one facade, with two facades (through fireboxes, English double face); - according to the shape of the facade:

rectangular (vertical or horizontal), square, arched; - by the width of the facade:

the most common are horizontal rectangular facades with a width of 60, 70 and 80 cm, however, almost any size from 40 cm to more than 1.5 m is acceptable; - according to the shape of the glass:

with flat glass, with oval or semicircular glass, with prismatic (bay window) glass, L-shaped, or corner (one edge can be longer than the other, in this case the firebox is positioned as left-handed or right-handed, or the edges can be the same lengths), U-shaped (the front part can be longer or narrower than the sides); - according to the size of the hole for connecting to the chimney:

most often it is 150, 180, 200, 250 mm; - by thermal power:

as a rule, these are values from 4 to 25 kW, they depend on the size of the firebox, on the material from which it is made, on the lining of the combustion chamber, on the presence of a secondary combustion system for flue gases, on the presence of a water circuit. The actual power of the firebox installed in the fireplace will also depend on the design of the air ducts. - according to the design of the ash drawer:

retractable (like a table drawer, it is pulled out from the front) or removed from the inside; - according to the material of the internal lining of the combustion chamber:

without lining, with fireclay, with vermiculite, with other refractory materials. - by the presence of additional structural elements:

water circuit, external air supply, secondary combustion system, etc.

Preferences of leading manufacturers

Despite the fact that any branded company wants to satisfy all the needs of the buyer by producing various types of fireplace inserts, it is still possible to trace a certain direction of their specialization. Thus, French models of the Laudel brand, Polish NordFlam and Russian Meta focus on cast iron options.

The Czech group ABX, the Italian EdilKamin and the Serbian MBS are famous for the fact that the basis of their designs is a fireplace insert with a water circuit. It works on the same principle as a heating boiler, but does not lose the functions of a classic fireplace.

The Polish company Kratki has launched the production of biofuel fireplaces. The virtual absence of significant competitors did not cause the company to regress. The developers research the state of the market, design ideas, fashion and offer new models, stylized for various types of interior.

When choosing electric fireplaces, pay attention to the Irish Dimplex and the Polish Eurokom. All of the listed data is taken from the top sales for some versions and does not mean an objective advantage over other manufacturers' brands.